Possible problems and solutions

Various difficulties can arise when using powder pigments. Technologists believe that the main reason for problems with powders is insufficient grounding of the surface prepared for painting. To avoid difficulties with grounding, it is recommended to check it in advance. The resistance indicator should not exceed 4 ohms.

Poor-quality grounding leads to the following consequences:

- Deterioration of sludge quality, decrease in productivity of painting works.

- Non-painting of zones, provoking marriage.

- Increase in powder losses leading to overruns.

- Deterioration of the quality of the formed layer, obtaining a "crust" effect, which implies the transmission of metal, a tendency to develop cracks.

- Hand dyeing can cause electric shocks to a person.

Many users note that they have problems with the material intended for the job. Raw powder paint can clump, clog nozzles, and misfeed. This leads to the creation of an uneven layer, the suspension of work or the creation of a rejected zone.

The raw powder crumbles if the storage rules are violated or conditions are created for poor-quality air compression at the start of work. To remedy the situation, it is necessary to change the air compression ratio. The change in pressure will stop the deterioration of the material.

> Failure to paint the inner corners of complex configuration parts - a problem resulting from the incorrect position of the torch. Too close approach of the gun barrel to the processed corner leads to powder blowing off, the formation of unpainted areas, and the appearance of gaps.

How to paint metal?

The right product is the key to success, which is why this is the most important factor when working with metal substrates.

Versatile materials

Painting can be carried out with the following common types of products:

- Epoxy. For the manufacture of such compositions, silicone resins are used, which are supplemented with a hardener. Due to their high toxicity, they are used only for outdoor work. Differ in the complexity of application.

- Oil. Traditional version based on organic matter. Before processing with such a composition, the metal is pre-coated with soil. Due to the toxicity and pungent odor, it will be possible to paint the parts only with good ventilation.

- Alkyd. They have a steady demand in cases when it is necessary to process a metal product. Suitable for indoor and outdoor events. If the base is well prepared and has no problems, then the composition can be applied without prior priming.

- Acrylic. Modern version based on polymers. Non-toxicity and ease of application ensure the popularity of the material. The composition is suitable for painting metal surfaces, subject to careful preparation.

- Rubber. Suitable for outdoor use, great for roofs or areas exposed to atmospheric precipitation.

Rubber paint for metal is often used for finishing galvanized roofs

Rubber paint for metal is often used for finishing galvanized roofs

These solutions are considered classic and are used everywhere. Powder painting method is worth a separate price. It is complex in that it requires the use of special equipment and tools.

Specialized options

To ensure reliability and durability, in some cases, special materials are required:

- Compounds used in the presence of rust. They are an epoxy variety with special additives. They create a reliable film, preventing further deterioration.They are applied directly to rusted areas without pretreatment of the substrate.

- To prevent corrosion. Such materials give the surface additional protection from moisture and oxygen, that is, they do not allow parts to rust.

- Hammer compounds. They form an interesting decorative coating reminiscent of the traces of multiple hammer blows. They have good stability. Various base options are used for production: epoxy, acrylic, alkyd.

- Primer-enamel. A versatile product that combines primer, corrosion protection and paint.

- Blacksmith mixtures. Polymer compounds are involved in their manufacture, which gives the coatings excellent wear resistance. Demonstrates good adhesion.

- Nitro paint. Sold in spray cans. Possesses high toxicity.

There are other types of dye mixtures - varnish and enamel, which are used in the processing of ovens and other similar products. They are heat-resistant materials.

Powder paint consumption per 1m2

Painting consists in applying a powder coloring agent to the object to be painted. The material dissolves under the influence of polymerization, due to which it is able to evenly cover the painted object.

Powder colorant is only applied once, as its layer is the same thickness as 3 coats of any other colorant.

Its great advantage is its durability - the painted object receives maximum protection from external influences such as temperature changes, chemicals, corrosion and mechanical damage.

A wide range of powder paint mixtures can be found, including polyester epoxy and polyester paints. When choosing, it is worth consulting with a specialist who can select the quantity and composition in relation to the needs.

It is worth choosing a powder coating because it surpasses traditional paints in its properties. Powder coating is suitable for painting small metal objects such as:

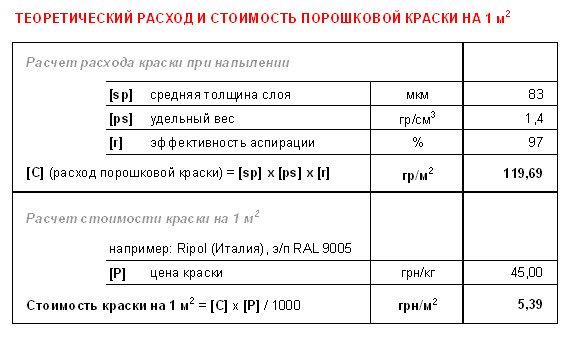

Powder paint consumption information.

- Gates;

- ladder;

- railings;

- accessories and auto parts;

- alloy wheels;

- bumpers for off-road vehicles;

- bicycle frames;

- car parts and car bodies;

- Appliances;

- electrical equipment housings;

- racks;

- radiators;

- lamps;

- facade elements;

- gutters;

- window sills;

- metal garden furniture.

Average consumption varies within 140 grams per square meter. But it can differ significantly from the original under the influence of various factors, including the size and shape of the surface, its evenness, the method of application and the type of dye.

- The size. First of all, it is necessary to calculate the area of the painted surface. If the surface is curved, the flow rate may increase.

- Smoothness is an important factor when calculating material consumption. The smoother the surface, the less paint will be required. Therefore, before painting the product, it must be sanded to a shine.

- Application method. Experts advise applying paint with a spray gun. This method of application makes it possible to reduce the amount of material used by almost 2 times.

- Variety. Consumption depends on the type of paint. Manufacturers indicate the consumption and weight of the coloring composition on the container in which the paint is located. If you adhere to all the rules when painting objects, the consumption will differ little from that indicated on the packaging by the manufacturer.

4 How to paint a galvanized sheet - applied technologies

Now you can paint galvanized by the following methods:

- pneumatic painting;

- combined;

- electrostatic;

- airless.

The pneumatic method involves the use of a special pneumatic spray gun that uses compressed air for its work.If you choose the correct speed of paint supply, the shape of the spray torch, the ratio of the air speed and the flow of the coloring composition, you can achieve an ideal surface. But not always even an experienced professional can correctly take into account all these factors. In addition, the pneumatic method is considered low-cost and not environmentally friendly, since a dense paint-and-varnish mist is formed when the paint is sprayed.

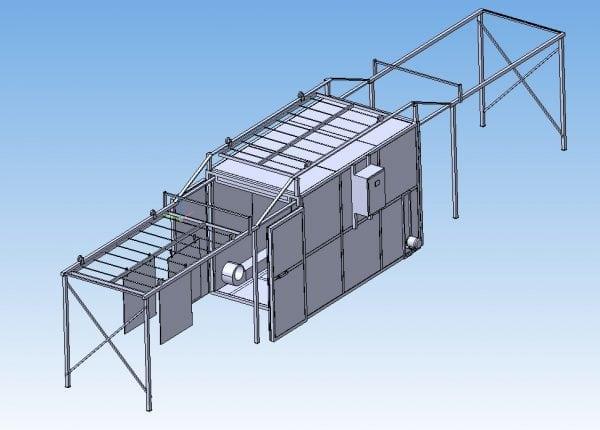

When working with powder paint

After passing through the equipment for powder coating, the products receive excellent decorative and anti-corrosion properties. The material saving is almost 100% here (paint that has not settled on the surface can be used again). Modern lines of equipment for powder coating and decorative finishing of metal are fully automated.

Among the advantages of the powder over enamels, the greater strength of the coatings to mechanical stress is noted (for impact - 100 kg / m, for bending - 4-6 mm). It is also worth mentioning the increased adhesion (adhesion of the powder to the surface - 500 kg / nm). The coating improves the anti-corrosion performance of the product. It can withstand solutions of alkalis, acids and organic solvents.

Items painted with powder paint are capable of operating in the range of -60 ° C ... + 150 ° C. The coating thickness can be from 0.05 to 0.3 mm. Produced paints of this type are presented in all colors according to the RAL card. By the type of film formation, they are divided into several main groups:

- epoxy;

- polyester;

- epoxy polyester;

- polyamide.

With their help, glossy and matte surfaces can be formed.

Powder handling is more environmentally friendly as it does not emit liquid solvent vapors. Equipment for powder coating does not require preliminary priming of products. To apply the coating, it is enough to pass the product through the painting line once.

This method provides production with a 20-40% reduction in total energy consumption. The staining process becomes faster and less labor intensive. It is almost completely safe for personnel and does not require spacious rooms. The conclusion is obvious: in many ways it is more profitable to use powder paints than liquid paints.

Required materials and equipment

So, let's give a detailed description of the technology of powder coating of metal. To create a durable spray layer on it, you will need:

- oven (chamber) for polymerization: it can be made by yourself or purchased in a specialized store;

- spray gun: since such a device costs a lot, it can also be assembled from a converter often used in gas stove lighters, a power supply and an ordinary plastic bottle;

- naturally, the paint itself.

The drying ovens will need to be connected to a voltage source of 25 kW. In operation, it will produce 6 kW, while warming up a little more - 12 kW. For its manufacture, you will need thick sheet metal for the case, heating elements, a tangential-type fan in which air masses will move in one direction, as well as any non-combustible heat insulator for the casing.

Heating elements are arranged parallel to each other on opposite walls of the furnace. The main part of the fan is mounted outside the chamber. It is welded in such a way that the exit is narrow and the entrance is wide enough. It is also necessary to make a separate spraying chamber in the drying oven. For processing large parts, it is better to provide rail-type trolleys.

Powder Coating Techniques

Although the powder painting method has been known for quite some time, its technical development began relatively recently. During this time, several ways of carrying out the process have appeared.

- The most popular and widespread is electrostatic spraying. The principle is that the powder particles acquire an electrical charge as they pass through the spray gun.In this case, the treated coating remains electrically neutral. It is this difference that creates an electric field, due to which the powder is attracted to the surface and firmly held. This is the first stage of painting. Further, the processed part is placed in a special oven, where it is heated at a temperature of about 200 degrees. Short-term exposure melts the top layer, and it is reliably absorbed into the base. The electric charge gradually disappears.

- A more complicated method is considered a method that involves preheating. That is, the painted metal product is heated to a certain temperature (the indicator is selected individually). Using a spray gun, particles of powder paint are applied to the substrate and melted. Further steps do not always involve reheating and depend on the type of coating applied.

- For the third option, thermoplastic powder is used predominantly. In the work, a special spray tool is used, which is supplied with a chamber with burning propane. The preheated particles hit the surface to form a durable protective layer. Although this technology can be used to paint a variety of materials, its spread is relatively small.

The demand for the first painting method is explained by the fact that this option has a greater technological development. With other methods, everything is more complicated: the second method requires careful selection of temperature, and the third appeared relatively recently.

Home painting - powder paint technology

Preparation stages:

Cleaning. Any method required for a specific case is suitable:

- mechanical - with a grinder, brush, rags ...;

- chemical agents (solvent, acid, alkali);

- to remove rust, you can do abrasive cleaning (in a sandblaster) or treat the surface with a special compound (metal cleaner).

Priming with inorganic paints. A conversion layer is applied - protection from moisture, air, pollution under the film.

Passivation. The product is treated with a sodium compound, chromium 3 nitrate or phosphated, which prevents secondary oxidation of the metal.

The last step in preparing for painting is the part is rinsed, dried and cooled. The product has been prepared. You can start painting.

In a special chamber for spraying on the processed object, which must be grounded, a powder-dye is applied, for which an electrostatic gun (spray gun) is used. The part must be positioned so that it can be accessed from all sides. Due to the difference in electrical charges, dry paint particles "stick" to the surface of the workpiece.

The next stage is baking and polymerizing the paint. The dyed product is placed in the oven. The main process will take place there - reflow and formation of the film layer. The processing time and temperature depend on the composition of the dye. They are necessarily indicated on the packaging. The material of the product to be painted is also taken into account, in what conditions it will be used.

The last moment - the product must completely cool down.

How to paint with powder paint

After all the equipment is assembled, purchased and installed, you can paint the metal parts yourself.

Choice of paint

Powder paints fall into two categories:

- Thermoplastic. The principle of obtaining a coating is that the powder is applied to the part that is baked. Only temperature affects the created layer. This group includes compositions based on polyvinyl butyral, polymers, polyamide, polyelifin.

- Thermosetting. The essence of the process is that fusion is accompanied by a certain chemical reaction. This allows you to get a surface that is resistant to any impact.Options for such mixtures: epoxy, polyester, epoxy-polyester, polyurethane.

It should be borne in mind that the color of the selected paint is not tinted.

Both thermoplastic and thermosetting compounds are available in a wide range of colors

Both thermoplastic and thermosetting compounds are available in a wide range of colors

Dyeing technology

Household work requires the creation of certain conditions. All processes are divided into sections to exclude a violation of the painting technology due to dust and dirt.

Procedure:

Metal processing is in progress. The surface is thoroughly cleaned from the old layer. If there are traces of blackening or bluing, then the coating must be completely removed.

The cleaned parts are degreased and thoroughly dried. If required, phosphating is carried out. Areas that should not be painted are closed.

The processed product is placed in a spray booth and grounded. For this, it is hung on suspensions. Hooks should not interfere with the uniform distribution of the composition.

Using a gun, the powder is sprayed onto the surface of the part

Care must be taken, because when touched, the composition is easily erased. If this happens, then a new layer will need to be applied.

For this, a mobile attachment is the best solution.

After processing, the product is placed in an oven. The required temperature mode is selected, the heating process lasts from 10 to 30 minutes. To paint the product correctly, you need to observe the temperature for each layer: if a primer is applied, then it is about 150-160 ° C, for the base coat - 170-180 degrees, and for the main one - more than 190 ° C. Naturally, the indicators depend on the material and size of the part.

After baking, the product is removed from the oven. For full adhesion of the paint, it is recommended to wait a day.

Naturally, to obtain an optimal result, it will take some time to properly set up all equipment and develop a clear sequence of the technological process. But if all the conditions are met, the result will exceed all expectations.

Required equipment

In order for the process of self-painting to practically not differ from the factory one, it is necessary to choose a suitable place where the work will be carried out.

When the premises are found, you need to assemble and prepare the necessary equipment:

- oven for polymerization (drying);

- constant voltage source (about 25 kV);

- powder paint sprayer (gun);

- LMB.

In the work, accuracy and a little experience will not interfere. But if it is not there, it doesn’t matter, following the instructions, you can avoid most mistakes and get quite a decent result.

Furnace making

Polymerization is an important step in the curing of powder paint. If this point of work is omitted, the paintwork will not adhere to metal surfaces. Therefore, such equipment as a furnace - it is also called a polymerization chamber - is necessary first of all. This thing is expensive, so you can make it yourself, from scrap materials. We will need (the polymerization chamber will have dimensions of 2x1x1 m):

- profile pipe;

- non-combustible thermal insulation (basalt slab);

- sheet metal (can be ordered by size);

- tangential fan;

- Heating elements.

The oven assembly instructions consist of the following steps:

- Weld the frame from the profile.

- Put insulation in it.

- Sew up the walls with sheet metal. Finish the outside with gypsum fiber.

- For convection in the chamber, install a tangential fan, weld on a narrow outlet and a wide inlet.

- Insert the fan into the chamber. It will take air from the top, drive it through the heating elements, expel it at the bottom, and then distribute it throughout the chamber.

- Install the heating elements along the parallel walls and connect them according to the distribution into phases.

- Close the heating elements, leaving the fan open, the main part of which should be located outside the chamber (so as not to melt the winding).

- Install the electrical panel.True, it is better to entrust this work to a specialist.

The resulting equipment - a polymerization chamber - will have a power of 12 kW for heating and 6 kW for operation.

Important! The energy carrier in such ovens for drying powder paint can be not only electricity, but also natural gas and diesel fuel.

Painting tool - pistol

To apply powder paint to a product, a special device is required. This is an electrostatic spray gun or a tribostatic powder spray gun. But buying expensive equipment for the sake of rare use is not advisable. Since in our case everything is made by hand at home, such a device can be made in 10 minutes. Such a gun is easy to use, cheap and practical. The transition from one paint to another takes a few seconds.

Design and equipment of a powder coating gun

Design and equipment of a powder coating gun

How to make a powder paint gun:

- Take a regular plastic 1.5 liter bottle. The main thing is that it is dry and clean.

- Fill it 1/3 full with powder paint, tighten with a metal plug.

- Punch small holes in the cork. The more holes there are, the better the application will be. Strip the outside of the cork from any burrs left after piercing.

- Connect the positive wire from the high-voltage source to the plug.

For this purpose, a converter is needed that can supply 25,000 volts DC. These are used in stun guns, gas stove lighters, boilers and water heaters. They can operate on batteries or accumulators, converting 3-6 volts to the required 25 kV.

Be careful when working with high voltages. It is better to entrust the assembly of the inverter to a qualified electrician.

After all the manipulations, you get a pretty decent pistol.

Little things you can't do without

Before starting painting, care must be taken to ensure that all operations take place under ideal conditions:

- Great lighting needed. Use fluorescent lamps. Powder paint adheres well to a regular lamp.

- Need good ventilation with two motors (inlet and outlet). Additionally, you will have to wear a gauze bandage, or better, a professional respirator.

- We'll have to invent a way to collect the remains of the powder paint. In the initial stages, use an old powerful vacuum cleaner.

When everything is carefully prepared, you can start painting the necessary parts with your own hands.

Choosing paint

After we have prepared the equipment, the most crucial moment comes - the choice of paint. Today there are a huge number of types, brands and colors of powder dyes. It is necessary to figure out what kind of material we need. When painting discs with your own hands, the following types of paints are used:

- epoxy;

- polyester;

- polyurethane;

- silicone.

Epoxy paints are resistant to alkali and acids. Polyester is considered to be anti-corrosion. Polyurethane - resistant to abrasive substances and solvents. Silicone - withstand even the highest temperatures.

The most famous paint manufacturers: Pulverit, Infralit, P-EP 45, Bichon, TFK, Beckers, Radar, Inver, Flycoat. With the help of the products of these companies, you can create a completely unique design of discs with your own hands. It is possible not only to choose a color, but also to change the texture of the discs: from matte to glossy.

With the help of some types of paints, it is possible to change the structure of the coating with your own hands. Shagreen, moire, antique and other types of textured paints are commercially available. The range of colors is determined by the RAL standard.

Powder painting of discs at home requires special clothing.

Consumption

The attractiveness of powder paint is beyond doubt. However, you need to accurately determine the need for it, find out how much the coloring composition goes for each m2.The minimum layer thickness to be created is 100 µm, in order to reduce the use of dye, it is advisable to spray it. The aerosol method of application allows you to spend from 0.12 to 0.14 kg of material per 1 square meter. But all these calculations are only approximate, and allow you to determine the order of the numbers.

An accurate estimate can be made by knowing the properties of the particular paint type and the characteristics of the substrate to which it will be applied. Remember that the norm indicated on labels and packaging, which is shown on advertising posters, implies a painting of a surface that is absolutely free of pores. Plastic or metal has only a slight porosity, and therefore, even when painting them, you will need to use a little more dye than prescribed by the manufacturer. When other materials need to be processed, costs will increase significantly. So do not be indignant if you find “inflated” figures in the bills for powder painting services.