Operating procedure

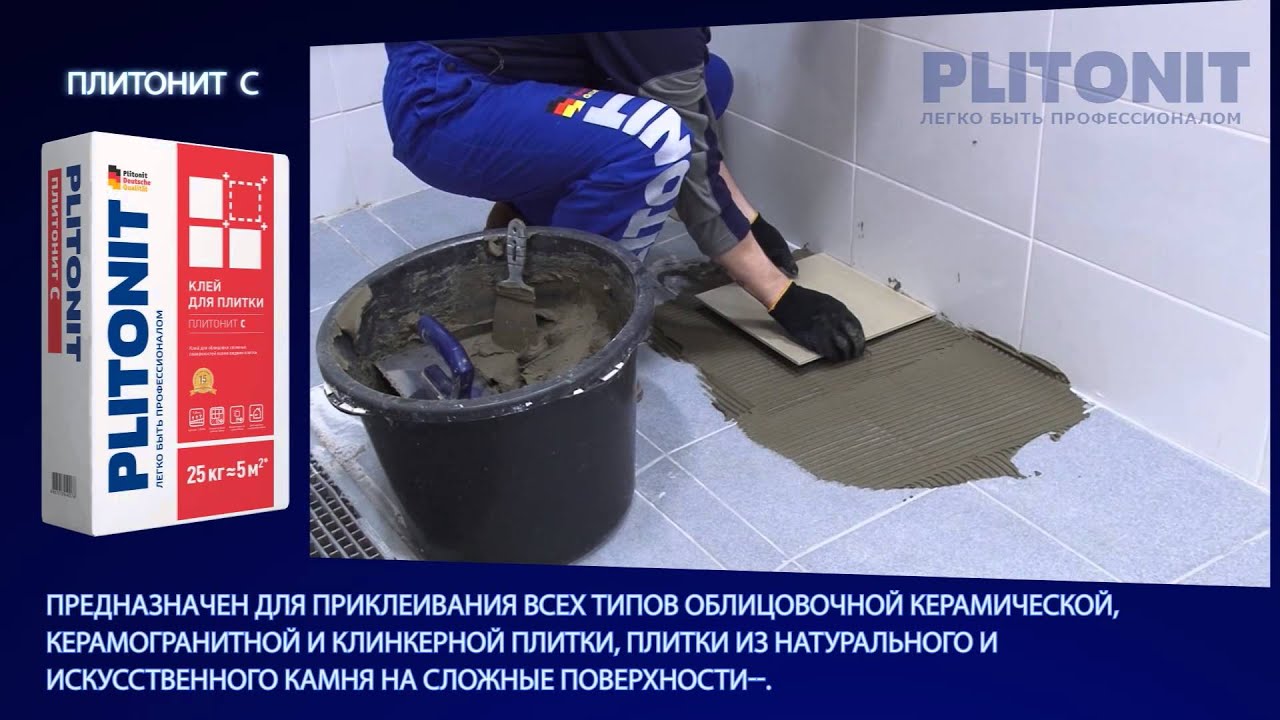

Apply the prepared mortar mixture evenly to the substrate using a smooth trowel and give a comb-like structure to the notched teeth (the size of the trowel's teeth depends on the size and type of tile). The mortar should be applied to an area that can be tiled within 10 minutes (open time). If a dried crust has formed on the surface of the applied glue, the mortar mixture must be removed from the surface and replaced with a new one. Place the tiles on the glue mortar and press them into it with small turning movements. The position of the tiles can be adjusted within the next 10 minutes. Drafts, high temperatures as well as strong surface absorbency will reduce the open time and correction times. The tiles are laid with open joints and aligned with appropriate devices (for example, PLITONIT crosses). When facing tiles with a relief height of the back side of more than 2 mm or more than 30x30 cm, in order to avoid voids under the tile and to increase the adhesion strength, it is necessary to apply glue in a combined way (both on the base and on the back side of the tile). Apply glue to the base as described above. On the back of the tile, the glue is first applied with a notched trowel, and then evenly smoothed over the entire area of the tile with a smooth trowel. The material consumption for the combined method increases by 1.4 kg / m² at a layer thickness of 1 mm.

Trainings and seminars

Our priorities lie in the field of increasing the efficiency of construction and finishing, through the advanced training of master finishers, conducting technical seminars and master classes. We organize training seminars in various formats, incl. on the basis of the customer and the leading retail operators of the market. Qualified technical specialists introduce the students to the most modern PLITONIT technologies and materials, and also allow them to practice the acquired skills in practice.

Nearest event

November 25, 2020 Moscow

Finishing as a business: reducing financial risks, solving typical problems

Mortar preparation

For mixing the dry mixture, it is necessary to use water from the drinking water supply. Mixing ratio: 0.17-0.21 liters of water is required per 1 kg of dry adhesive mixture (4.25-5.25 liters per 25 kg). Pour the dry mixture into a predetermined amount of water at room temperature and stir for 2-3 minutes using an electric mixer or an electric drill with a nozzle, with a rotation frequency of no more than 600 rpm, until a homogeneous consistency is obtained. Let the mortar mixture stand for 5 minutes and mix again. While stirring again, add water up to the maximum value of the above ratio. The time of using the ready-made mortar mixture is no more than 4 hours (drafts and high temperatures reduce this time).

Types and features of Plitonit adhesives for porcelain stoneware

There are several types of adhesives:

- Dry glue for porcelain stoneware for outdoor use - withstands sudden temperature changes. Has a high adhesive power. Fixes tiles well on floors and walls.

- Finishing adhesive for porcelain stoneware tiles for interior use in dry and wet conditions.

- Universal elastic adhesive for porcelain stoneware for walls and floors. Resistant to cracking, suitable for cladding surfaces subject to high deformation loads (steps, terraces, balconies).

According to specific characteristics, there are:

- Adhesive for porcelain stoneware waterproof. Used in damp areas (swimming pools, bathrooms, saunas).

- Frost resistant adhesive for porcelain stoneware.Contains polymer additives and other components that improve temperature resistance. Provides optimal adhesion of heavy porcelain stoneware to the substrate. Withstands at least 75 freeze / thaw cycles (with full preservation of strength indicators).

Multifunctional adhesive for laying porcelain stoneware outdoors is not subject to shrinkage, has high plasticity, and has an increased degree of adhesion to porcelain stoneware. Due to the presence of cellulose fibers in the composition of the glue for porcelain stoneware, it is distinguished by the minimum indicators of tile sliding from the vertical plane (no more than 0.5 mm). Special adhesive for porcelain stoneware 600x600 is designed for gluing large-format tiles on vertical and horizontal surfaces. Adhesive with enhanced strength characteristics for large-format porcelain stoneware can be used to attach the facing material to gypsum-containing substrates with a high degree of absorbency (gypsum fiber board, gypsum plasterboard, etc.) outside and inside the premises.

The floor adhesive for porcelain stoneware has high thermal conductivity, compressive strength, holding capacity and elasticity. Also, glue for porcelain stoneware on a warm floor is suitable for facing fireplaces and stoves, fixing heavy stone and ceramic plates. High-strength adhesive for laying porcelain stoneware on the floor is used in places with a large pedestrian flow, high traffic.