Advantages and disadvantages

Tile adhesive of the trade mark has a wide range of advantages. For example, it can be used with different types of blades. It is suitable for cladding concrete, cement, brick, stone and other bases (gypsum board, gypsum plasterboard, PGP, SML, TsSP). Cladding with this glue can also be carried out on cement plaster. In addition, the composition is easy to prepare: if you follow the instructions on the packaging of the product, it will not be difficult to prepare it.

This composition is plastic, which allows it to be used for finishing the base with a height difference of up to 2 mm per 1 m2. The diluted mass is comfortable, does not flow and does not slide from vertical planes, therefore it does not increase the degree of the angle of inclination of each top stacked row. The mortar has a long life cycle, so there is no need to dilute it in small portions.

The company's glue is resistant to high dynamic loads. It can be used for laying not only ceramic tiles and porcelain stoneware, but also for tiles, mosaics in the form of separate fragments and on a grid, natural and artificial facing stone. This is a modern adhesive that allows you to perform surface cladding at a professional level. Convenience for buyers is the availability of modifications, due to which it is possible to choose a special type of glue for a specific material.

In this case, there is no need to pre-soak the tiles. Due to its high plasticity, the solution not only fits well on the base, but also allows you to correct its minor irregularities. It will cover small pits and remove microcracks from the rough base. It is a material with a long service life. Subject to the technology of breeding and laying, the facing of surfaces with glue of the trademark will last for more than a decade, without needing to be repaired.

Due to its high resistance to moisture, the mixture can be used for finishing rooms with a high humidity coefficient. The adhesive is a waterproofing of hygroscopic and mineral floors. An additional advantage is the fact that this composition is suitable for laying on previously installed tiles. In addition, the price of the material pleases every buyer.

However, with a lot of advantages, the glue also has disadvantages. For example, it will not hold the cladding well if the base is not properly prepared. In addition, if you do not withstand the temperature regime during operation, this can affect the quality and durability of the coating. If the air in the room is too dry, the life cycle of the finished solution will be shortened.

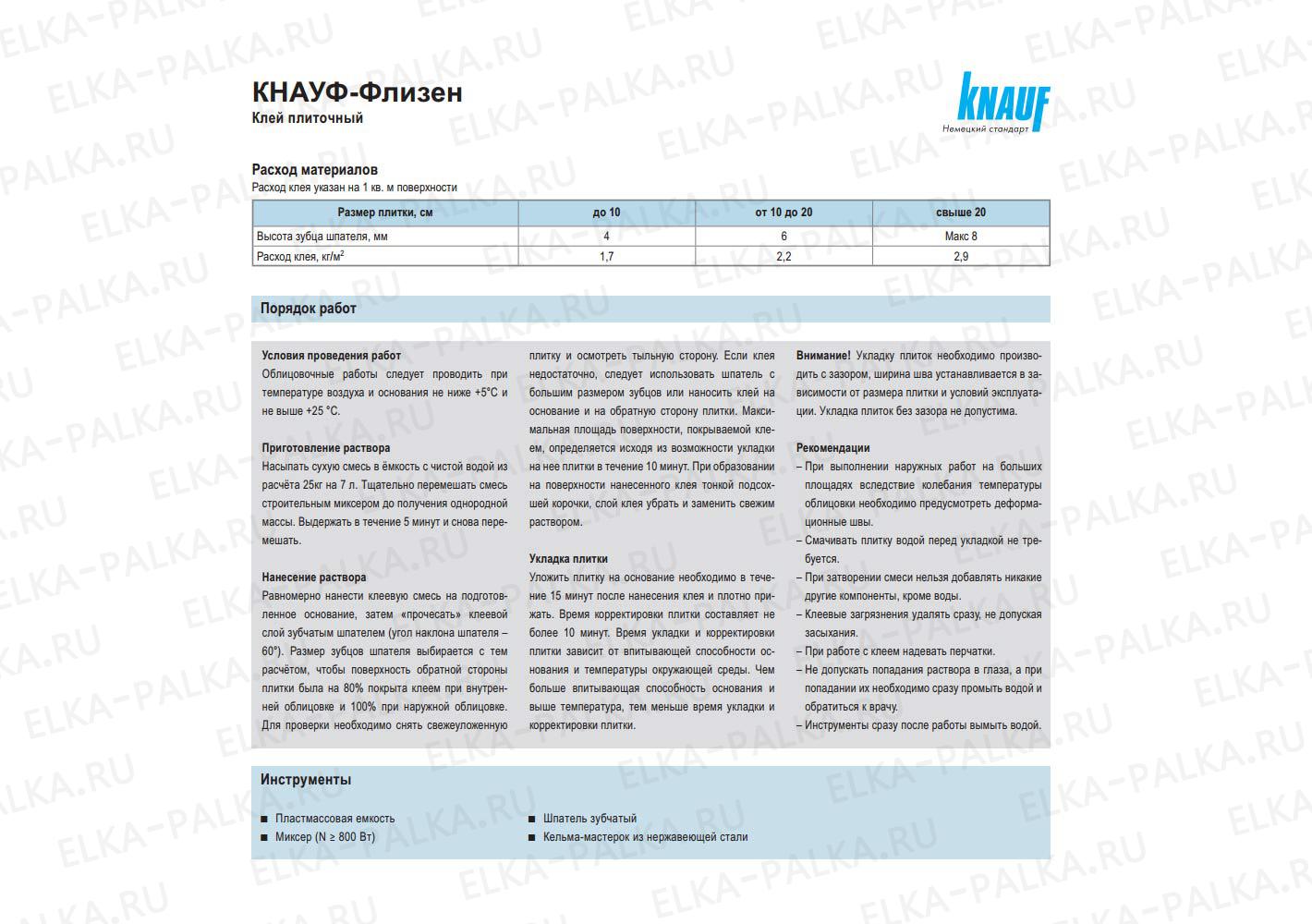

Specifications

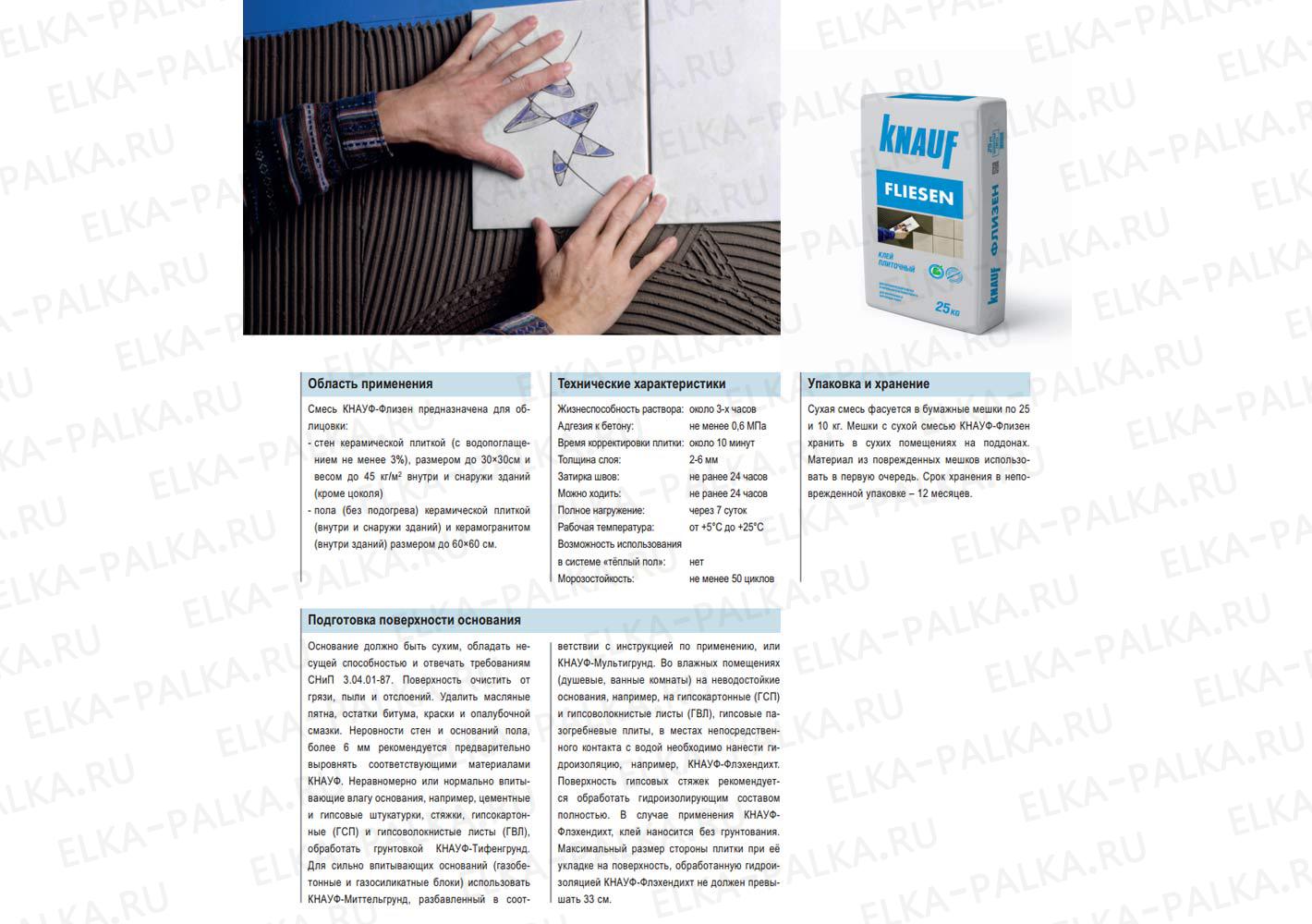

Before buying a dry composition, you need to pay attention not only to its cost, but also to technical indicators. Knauf Fliesen composition has the following technical parameters:

Knauf Fliesen composition has the following technical parameters:

- high adhesion to concrete bases (more than 0.5 MPa);

- exposure to sharp fluctuations in ambient temperatures (from -45 to +80 degrees);

- fast setting and hardening time of the finished solution (dries within 2 days under optimal conditions);

- economical mass consumption (from 2 to 2.5 kg per 1 m2, depending on the quality of base preparation);

- low coefficient of moisture absorption (does not exceed 3%).

After laying the material on the mortar, the position of the tiles can be adjusted within 10 minutes. The glue has excellent physical and mechanical properties: it does not "slip" and reliably holds heavy finishing materials, even such as stone.

Adhesive selection

| Glue | Life span | Adjustment | Grouting | Full load | Consumption | Frost resistance | Adhesion to concrete | t operation |

|---|---|---|---|---|---|---|---|---|

| Fliesen | 3 h | 10 min | 2 days | 7 days | 2.2-2.9 kg / m2 | > 25 cycles | 0.5 MPa | Up to +80 |

| Flizen Plus | 3 h | 10 min | 2 days | 7 days | 1.7-3.7 kg / m2 | > 25 cycles | 0.5 MPa | Up to +80 |

| Flex | 3 h | 10 min | 2 days | 7 days | 2.2-2.9 kg / m2 | > 25 cycles | 1 MPa | Up to +80 |

| Marble | 45 minutes | 10 min | 2 days | 7 days | 2.3-2.9 kg / m2 | > 25 cycles | 1 MPa | Up to +80 |

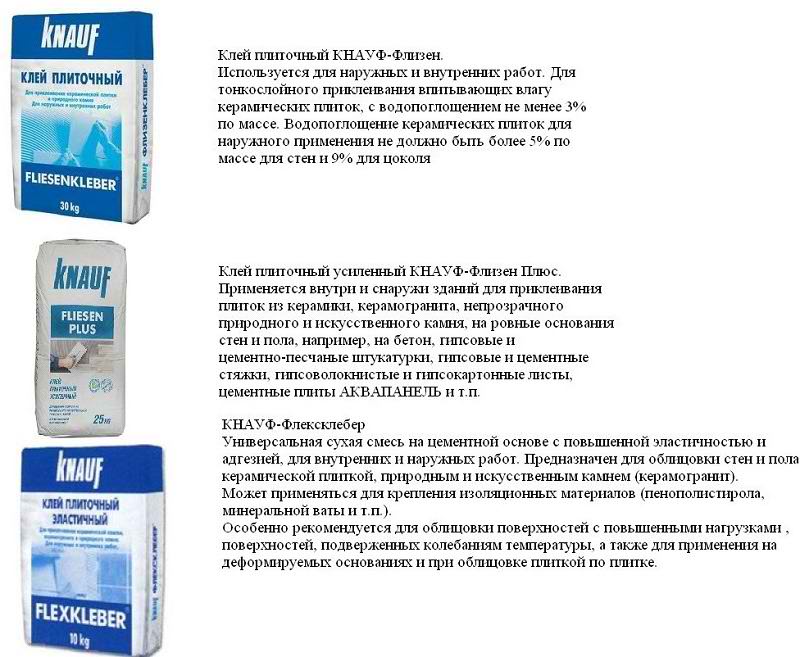

Fliesen

It is used for indoor and outdoor use. Packaged in 25 kg bags. The composition can be applied only in a thin layer - it is a universal composition that is not designed for specialized use. It is recommended to work with porous ceramics that can absorb moisture. Porcelain stoneware slabs have a low-porous structure with a water absorption coefficient of less than 0.05%, therefore they are not suitable for working with the Flizen composition.

Interior cladding requires ceramic tiles with a water absorption of less than 3% by weight. For outdoor installation, tiles are used that, according to the same indicator, have at least 5% for the walls and 9% for the basement.

Scope of application in terms of bases: concrete, cement-sand screed and plaster, drywall, cement-particle boards. The temperature of the air and the base during installation is from +5 to +25 degrees.

Consumption:

| Tile size | ||

|---|---|---|

| 10-20 cm | More than 20 cm | |

| Spatula teeth height, mm | 6 | 8 |

| Glue consumption, kg | 2,2 | 2,9 |

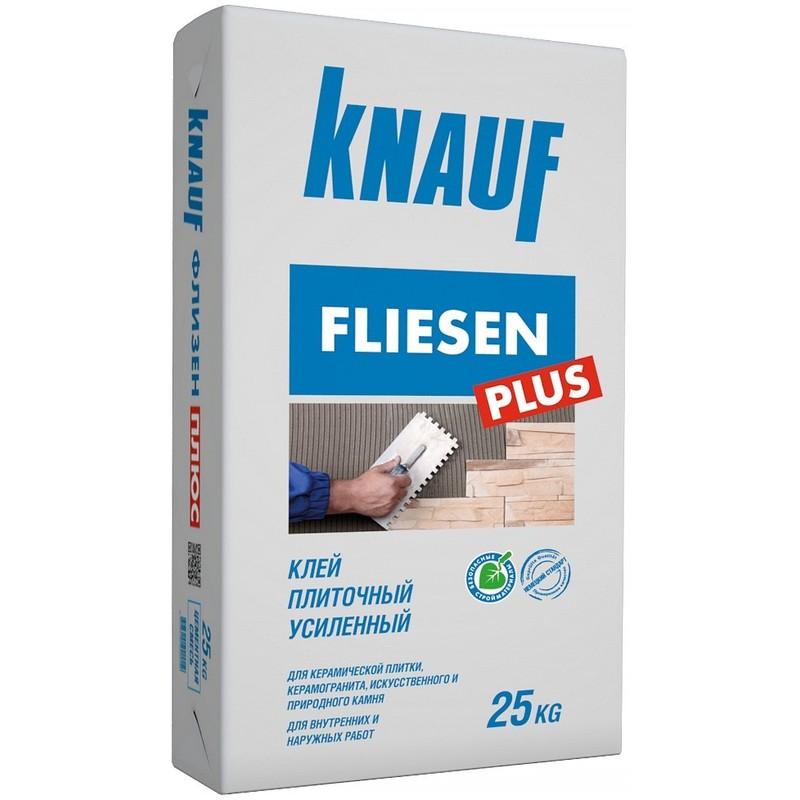

Flizen Plus

Reinforced frost-resistant glue, used for cladding outside and inside with ceramic and porcelain stoneware tiles, natural stone. Slip resistant. NOT suitable for underfloor heating.

Substrate suitable for laying on Knauf Flisen Plus: concrete, gypsum plasterboard and gypsum fiber sheets, cement-sand plaster and screed, cement slabs of the Knauf Aquapanel type. The surface before laying must be flat and clean, strong and dry, with a temperature of at least +5 degrees.

| Tile size, cm | To 10 | 10—20 | More than 20 |

|---|---|---|---|

| Spatula teeth height, mm | 4 | 6 | 8 |

| Glue consumption, kg / m2 | 1,7 | 2,2 | 2,9 |

Compared to the Flisen mixture, Knauf Flisen Plus has an advantage in a wider range of facing materials. With the same adhesion to concrete with the composition of Flisen (not less than 0.5 MPa), it allows you to work with low-porous slabs - porcelain stoneware. The consumption of the mixture is reduced due to its elasticity, laying on a thin layer is possible.

Flex

Composition with increased adhesion and elasticity. Designed for facing with porous tiles and non-absorbent slabs - porcelain stoneware and natural stone. It is used for the installation of insulating materials (mineral wool, expanded polystyrene, etc.).

Laying on a non-standard base - waterproofing.

Flex withstands high thermal and dynamic loads thanks to additives; some of them contribute to elasticity, which is responsible for the ability to resist deformation.

Consumption:

| Tile size, cm | 10—20 | 20—30 | Over 30 |

|---|---|---|---|

| Spatula teeth height, mm | 6 | 8 | 10 |

| Glue consumption, kg / m2 | 2,2 | 2,9 | 3,7 |

Marble

Tile adhesive Knauf Marble is a fast-hardening white mixture, which, in addition to cement, includes polymer additives and mineral filler. It is used for cladding on a thin layer of marble, granite and other stone slabs. The white shade allows you to work with translucent ceramics, glass tiles and glass mosaics. The color of the glue protects porous tiles and natural stone from discoloration.

Laying the mosaic on white glue.

The mixture sets quickly, therefore the adjustment time for the laid tiles is reduced and amounts to a maximum of 10 minutes.

The composition is used for laying tiles on floors with heavy loads. But in this case, it is recommended to glue both the facing material and the base. When laying a large area outside, it is recommended to use expansion joints due to thermal vibrations.

Consumption:

| Tile size | ||

|---|---|---|

| 10-20 cm | More than 20 cm | |

| Spatula teeth height, mm | 6 | 8 |

| Glue consumption, kg | 2,3 | 2,9 |

To get a quality cladding, do not neglect the study of glue nuances. Laying tiles on the wrong composition will lead to unnecessary financial costs if you use expensive strong glue under standard conditions, or to the destruction of the cladding, if you do not take into account the specifics of the surface and materials.

comments powered by HyperComments

Application features

Carrying out installation requires adherence to the temperature range. The solution will be applied with a trowel and a notched trowel. Glue Flizen is distinguished by an easy way of working, so repairs can be carried out independently, saving money on the services of specialists.

The solution will be applied with a trowel and a notched trowel.

Preparatory work

You can work only at certain temperatures, if the weather is hot, then you should postpone the repair. Also, you can not work at indicators below +5 degrees. Surface preparation consists of the following steps:

- Cleans the wall from dirt and dust;

- The form-release agent is removed from the concrete surface;

- Degreasing is carried out with the available means;

- Eliminate the old finish;

- If there is a painted surface, the non-waterproof type of paint is removed, if a moisture-resistant coloring agent was used, then it is allowed to leave it and sand it;

- The wall must be completely dry;

- If the work is carried out with a warm floor, then it is turned off in advance a day in advance.

The plaster screed and part of the area where contact with water is implied is covered with waterproofing materials. The plaster layer should not exceed a centimeter; application in one layer is used. If the installation will be carried out on surfaces characterized by good moisture absorption, then priming is required. It is better to choose a primer from the same manufacturer, the combination of materials will give the best result, Knauf has two types of suitable primer solutions, which are selected for the type of base.

If the installation will be carried out on surfaces characterized by good moisture absorption, then priming is required.

If the installation will be carried out on surfaces characterized by good moisture absorption, then priming is required.

Dilution and application of glue

The composition must be diluted strictly according to the instructions in the instructions from the manufacturer. For a kilogram of mixture from the bag, you will need to use 250-300 milliliters of water. Cold water is poured into the prepared container in the required amount, then the mixture is poured, and the components are mixed. For this purpose, use a construction mixer, or a drill with a nozzle. You need to get a homogeneous mass, without lumps. After the solution is left in a closed container for five minutes, after this time, the composition is mixed again and begins to work.

You need to get a homogeneous mass, without lumps.

You need to get a homogeneous mass, without lumps.

The glue is taken with a trowel, transferred to a spatula, applied to the material, then leveled with a notched trowel. It is necessary that 80% of the area is covered with glue, to check the freshly applied tile is removed, and they look how much glue is left on it. If the amount is insufficient, you can use a larger trowel size, or apply the composition to the base too.

Ten minutes are given to correct the position of the tiles, they should be pressed firmly to the surface. When a crust appears on the glue, it is removed manually. If the composition gets on the front side of the tile material, then you need to wipe it immediately, use a damp cloth.

Ten minutes are given to correct the position of the tiles, they should be pressed firmly to the surface.

Ten minutes are given to correct the position of the tiles, they should be pressed firmly to the surface.

Application and consumption

Knauf Fliesen tile adhesive is versatile. It can be used both indoors and outdoors. The composition is able to withstand the harsh climatic conditions typical for Russia.

With the help of a solution, the following materials are fixed:

- porcelain stoneware;

- ceramic tile;

- various types of opaque stones, tongue-and-groove slabs and other materials.

A dry mix will work for almost every base. It can be made of concrete, cement, limestone, drywall and other materials. Also, the solution is allowed to be laid on previously installed matte tiles. Due to the fact that the glue is able to withstand temperature fluctuations, it can be used for arranging floors with a heating system.

With the maximum allowable layer thickness of the mixture of 5 mm, the consumption per 1 m2 will be approximately as follows:

- for tiles with dimensions of 10x10 cm, no more than 1.8 kg of material will be used (when using a spatula with a tooth length of 4 mm);

- for facing 20x20 cm, at least 2.3 kg of mortar will be required (spatula with 6 mm teeth);

- for tiles of 30x30 cm, up to 3 kg of the finished mass can go.

Breeding

Prepare a dry mixture before use. To do this, you need to take 1.4 liters of water and 5 kg of material (to dilute 1 bag, you will need about 7 liters of water). To prepare the solution, you need to pour the mixture into the prepared container with a measured amount of liquid. After that, the components should be mixed using a construction mixer or a drill with a special attachment. You need to knead the composition for 2 minutes. The finished mass is characterized by plasticity and uniformity.

After mixing, it is necessary to let the mass stand for 10 minutes, and then mix again. The finished solution must be used within 3 hours (then it will begin to lose its elasticity). Working time with material can be shortened due to too high air temperature or in the presence of drafts. If the mixture has thickened, you need to re-mix it with a mixer without adding liquid. Additional water will degrade the performance of the solution.

Preparatory work

Knauf Fliesen mortar must not be applied to unprepared substrates. Before starting finishing work, it is necessary to clean the base from various dirt, grease stains, old peeling layers. You also need to rinse off the water-based paint. After all the manipulations, the base should dry well. It is not allowed to apply the composition to wet structures.

When working with a solution, it is important to ensure that the room temperature is within the range from +5 to +15 degrees. If the composition is planned to be used for arranging underfloor heating, the heating system must be turned off a day

If you intend to apply the material on low-absorbent substrates (for example, concrete), they must be pre-treated with a primer. The primer is applied to the cleaned surface with a brush, roller or spray gun. If the base is characterized by increased moisture absorption (cellular concrete, porous brick), it must be primed at least twice.

Application of the solution

The ready-made adhesive composition must be distributed evenly over the surface of the base, using the smooth side of the trowel. Then you should "comb" the applied solution with the serrated side. Only the area that can be treated within 20 minutes should be covered with the solution. When working outdoors and installing tiles with a corrugated texture, the solution is applied both to the base and to the finishing material.

After laying the first tile, you need to lightly press it down to the base. Within 10 minutes, it is possible to correct its position, since after this time the cladding reliably adheres to the material.

Ceramic tiles are installed using the "open seam" method. In this case, the plane must be leveled using special construction equipment (level, level). If a dried crust forms on the surface of the laid solution, the layer must be removed and the composition must be reapplied. If glue accidentally gets on the cladding, it must be immediately removed with a damp sponge or rag until it hardens.

It is important not to forget that the composition contains cement, which is why you need to follow some safety rules: you should work in protective gloves and do not let the solution get into your eyes. After the installation is completed, immediately rinse all the tools used with water.

Types and forms of release

The line of Knauf tile adhesive masses is presented in various types. The mass is produced in dry form in packages of 5, 25 kilograms. The bag is made of durable material that protects the contents from moisture and solar radiation.

Glue Flizen

Glue Knauf Flizen is a high-quality, consumer-grade mixture on the market. It does not require special skills in preparing a solution, it is enough to study the instructions and follow the proportions and directions. Designed for gluing various types of tiles.

Advantages:

- Flexibility.It is used for leveling planes with a difference of up to 2 mm per square meter.

- Durability, reliability is provided by special synthetic-based components. They significantly increase the adhesion of materials, which withstands maximum loads.

- Availability. Along with similar compositions, flizen of low cost, with economical consumption.

Flizen Plus

This adhesive composition is analogous to the previous one. But an additional quality is the ability to work with a stone.

Application requires preliminary cleaning and leveling of the working plane. It is also worth following strictly according to the instructions.

Knauf Marble

Adhesive mixture for tiles Marble - white shade composition. The composition includes polymers, additional components. A mixture is used for finishing with marble, granite, etc. Since the white consistency does not change the color of materials, it is applicable for translucent products: ceramic tiles, glass mosaics.

When covering floor tiles, the mixture must be applied to both surfaces to be bonded.

Advantages:

- Fast hardening.

- Suitable for indoor and outdoor use.

- Thermal stability. Used with underfloor heating system.

- Low consumption.

Of the shortcomings, the need for careful preparation of the working plane is highlighted. The principle of working with this composition:

- Remove dirt, dust, grease stains, loose materials.

- Prime and allow to dry completely.

- The diluted mixture is infused for 10 minutes, then mixed, applied with a notched trowel to 80% of the surface.

Knauf Perlfix

Perlfix glue is a gypsum mixture containing polymer components. It is used for interior decoration of hygroscopic surfaces (brick, concrete, etc.).

When preparing the solution, lumps are not formed, fast adhesion, adhesion strength. Complete drying occurs after half a day. The period depends on the room temperature and humidity. The shades of the mass may differ, which depends on the observance of the ratios of additives in different batches. Knauf Perlfix is produced in packages of 15, 30 kilograms.

Clay Knauf Flex

Knauf Flex is a tile material used for indoor and outdoor application of ceramics, stones of all kinds, and porcelain stoneware. Materials are glued to horizontal (floor) and vertical (walls) planes. Applicable for underfloor heating system.

Advantages:

- Waterproof.

- For fastening heavy materials that are under constant mechanical and physical stress.

- Basis: concrete, brick, stone, old tiles.

The negative side is a long drying period. To achieve maximum performance, you must wait at least a week. Before application, it is required to level the plane and ensure its strength.

Varieties

Knauf is available in several types, each of which has its own technical characteristics that distinguish it from the rest. To obtain a high-quality cladding, before choosing a composition, it is necessary to study the features of each adhesive variety.

Flizen universal

Recommended for work inside and outside the building. The shelf life after preparation is about 3 hours. For 1m2, you need from 2.2 to 2.9 kg of Flisen. Apply in a thin layer. Adhesion - 0.5 MPa. Recommended for porous ceramics that absorb moisture. Not suitable for porcelain stoneware slabs, since they have low water absorption and have a low-porous structure.

Flizen Plus with a reinforced formula

This composition has increased frost resistance. Indispensable for interior and exterior decoration using porcelain stoneware, ceramic tiles, natural stone. Not applicable for underfloor heating. For 1 sq.m. consumed from 1.7 to 2.2 kg (reduced consumption), depending on the type of surface, which must be leveled, dried and cleaned before laying.It differs from the universal Flizen by a large range of facing materials, since it allows you to work with low-porosity.

Flizen Flex

It differs from the universal Flisen in increased adhesion to concrete (1MPa) and elasticity, since it contains certain additives. Used for natural stone, porcelain stoneware, suitable for porous tiles. It is used for fixing expanded polystyrene, mineral wool, and other insulating materials.

Flisen Flex is recommended for surfaces with severe stress or temperature fluctuations. Suitable for industrial enterprises, as well as balconies, terraces, heated floors. It has proven itself well when used on wood and chipboard. Thanks to the increased adhesion, it is possible to lay the tiles on top of other tiles.

Flizen Marble

Fast-hardening adhesive containing cement, mineral filler, polymer additives. The life of the prepared mixture is 45 minutes. It has a white tint, which allows it to be used for glass tiles, translucent ceramics, glass mosaics. The color of the glue protects the facing material from discoloration. Also suitable for cladding granite, marble and other stone slabs.

Flisen Marble is suitable for both exterior and interior decoration of all standard flat substrates. It is used for balconies, terraces, underfloor heating and other surfaces subject to temperature fluctuations. It is used for laying tiles on floors with a high load, in this case it is applied to the tiles as well.

Fliesen max

A thick-layer mortar used in cases where increased masonry strength is important. It is applied in a layer up to 3 cm, allows, in parallel with the cladding, to achieve the effect of leveling the floor and walls. Not suitable for warm floors.

Main advantages

Clay Knauf has several undeniable advantages.

Plastic

Due to its plasticity, the composition can be used on surfaces with small defects, since it will evenly fill problem areas. In this case, it is not required to pre-soak the tiles in water. Knauf's elastic structure allows it not to collapse for a long time.

Frost resistance

High frost resistance allows Knauf to be used for outdoor work. When changing temperatures, the seam retains its characteristics, remains intact.

Strength

The glue does not slip from the surface, makes it possible to hold even heavy facing materials

At the same time, it is important during work and further operation to observe the temperature specified in the characteristics of the mixture.

Good adhesion of the mortar

Knauf glue has good adhesion to substrates. However, since Knauf hardens quickly, it cannot be applied at a time to large areas, since when laying facing materials on a glue that begins to dry out, the quality of the bond will be reduced.

Ease of use

Working with Knauf glue does not require special training. It is enough just to strictly follow the instructions written on the packaging. Thanks to the fluidity of the composition, its inherent self-leveling effect, gluing tiles to walls and floors is not difficult.

Views

Knauf is one of the most popular among consumers. Currently, it produces several types of adhesive mixtures at once. Each of them differs in its characteristics and properties. Common features for all samples are high frost resistance, moisture resistance, strength and low consumption.

Knauf fliesen

This adhesive can be used for a wide variety of construction work. It is often used for interior and exterior decoration of premises. It is worth noting that such a solution is able to glue together even heavy, massive structures made of ceramics or porcelain stoneware.

Knauf Fliesen glue is an excellent base for fixing various insulating materials:

- polyurethane;

- polystyrene;

- foam;

- glass wool;

- mineral insulation;

- decorative items made of polystyrene.

Apply this adhesive in a thin layer using a notched trowel. Experts refer to this adhesive solution as a universal type. After all, it can be used on almost any type of surface.

Most often, this glue sample is used for the following types of substrates:

- silicate;

- brick;

- cement;

- gypsum and plasterboard;

- limestone;

- concrete.

Knauf flex

This adhesive mixture is also very popular with consumers. It is distinguished by its special hermetic properties and high elasticity, boasting special moisture resistance and frost resistance. Such a composition is ideal for bonding porous surfaces, stone, moisture-absorbing porcelain stoneware.

Such glue, as a rule, is used for gluing large, heavy boards and for installing insulating materials (expanded polystyrene, mineral wool). It is often used in the design of balconies, verandas, terraces. During the manufacture of this solution, special substances are added, which determine the high strength and reliability of the mixture.

Knauf fliesen plus

Such an adhesive mixture has the same enhanced frost resistance, moisture resistance, and hermetic properties as the Knauf Fliesen sample. But at the same time, this solution can boast that its consumption is much lower compared to other samples of this brand (1.7-2.9 kg / m2).

The time for adjusting the tile structure with such glue is only 10-15 minutes. The solution hardens within a few hours. This mixture is one of the most durable and reliable. It is often used for heavy and large porcelain stoneware and ceramic tiles.

Most often, such an adhesive mixture is used for finishing the following materials:

- fake diamond;

- marble;

- mosaic and glass tiles;

- ceramics;

- porcelain stoneware;

- decorative brick;

- granite.

Knauf mramor

This sample of Knauf assembly glue is the fastest hardening among analogues. Therefore, plates and other parts should be fixed within the first few minutes. The mixture includes not only the usual cement mass, but also various mineral fillers, polymer additives. Such an adhesive solution is used, as a rule, for cladding a tile covering made of granite, marble.

Such an adhesive is suitable for both external and internal decoration. It can be applied to almost any type of surface: concrete, gypsum and plasterboard structures, screed, cement-sand plaster, cement-particle products. He can glue different types of materials.

Such a sample, as already mentioned, is seized very quickly, the time for adjusting the tile is no more than 10 minutes. The composition is perfect for structures that are exposed to heavy loads. At the same time, most experts recommend glueing both the base and the facing material with glue.

Varieties of Knauf brand glue for tiles, technical characteristics

Knauf's tile adhesives have four varieties, they differ somewhat in their properties and working rules. Mixes are produced in paper bags, in which protective layers are made to prevent the ingress of moisture and other substances inside. Packing is carried out in 10 and 25 kilograms. Storage should preferably be carried out on wooden pallets in dry conditions.

Mixes are produced in paper bags, in which protective layers are made to prevent the ingress of moisture and other substances inside.

Mixes are produced in paper bags, in which protective layers are made to prevent the ingress of moisture and other substances inside.

Fliesen

Knauf Fliesen is a universal composition suitable for tile material that will be installed indoors with a moisture absorption level of up to 3%. When working outside, the level should be up to 5%. It shows the best quality when glued to plasterboard, concrete, cement-sand base, also to plaster. It is unacceptable to use for the purpose of connecting low-porosity tiles to walls, their moisture absorption rate is low.

A universal composition suitable for tile material that will be installed indoors with a moisture absorption level of up to 3%.

A universal composition suitable for tile material that will be installed indoors with a moisture absorption level of up to 3%.

Fliesen plus

Knauf Fliesen Plus has better strength characteristics than the previous one. To obtain a similar quality, polymers and mineral fillers are added to the composition. They stand out for better adhesion to different surfaces. Can be used when laying tiles with low moisture absorption, stones. It has the property of frost resistance, therefore it is often used for facing work, also for facing plinths.

Can be used when laying tiles with low moisture absorption, stones.

Flex

"Flex", when compared with the universal tile adhesive Knauf Flizen, is more plastic and elastic. It can be used for porous and medium-porous tiles, porcelain stoneware. Application is possible for work with insulating products. Resistant to dynamic loads. Suitable for working with wood, chipboard, underfloor heating.

It can be used for porous and medium-porous tiles, porcelain stoneware.

Mramor

It has a white color, a white cement mixture, polymers and minerals are used in the composition. It stands out for its excellent indicators of reliability and adhesion, therefore it is used when working with different types of stones, both artificial and natural. Knauf is suitable for porcelain stoneware, also suitable for glass and ceramic tiles, mosaics. To enhance the bonding effect, it is advised to apply the solution to both the base and the tiles.

It stands out for its excellent indicators of reliability and adhesion, therefore it is used when working with different types of stones.

Usage

Before laying tiles or other facing material, it is necessary to properly prepare the base. This does not only involve removing the old crumbling coating. It is necessary to remove any dirt and oil stains, get rid of lime, if it is on the surfaces of the floors.

Next, a deep penetration primer is applied to the floor. It will strengthen the base, align its structure, bind the remaining dust particles and microcracks. After applying the primer, the surface is leveled with a rough cement-based plaster mixture, then trimmed and treated with a primer again. And only then can the cladding be performed.

The glue is diluted with clean water at room temperature according to the instructions on the labeling of the bag. In this case, a construction mixer is used so that the working solution has a uniform consistency. After the initial stirring, it is left for a few minutes, then mixed again and used. In the course of work, a conventional spatula is used to apply glue to the work surface, as well as a toothed tool for standardizing the amount of glue.

Glue is applied to a part of the surface, it is evenly distributed, then the excess is removed with a notched trowel. They take a die, spread glue on it, and then pass through the solution with a notched trowel in a direction perpendicular to that on the plane. So it will be possible to distribute the glue correctly, as well as to carry out the work as accurately as possible. After the element is pressed slightly against the base.

This is how all the dies are laid. For the identity of the gaps between the tiles, use plastic crosses or special clamps. The excess composition is removed with a rag. You can not scratch it off the tile or other material, as this will affect the aesthetics of the cladding.

In a day from the moment of laying, the crosses or clamps are removed, and the voids between the fragments are filled with a special grouting mass. After it dries and hardens, the remnants of the grout are removed with a dry sponge, passing it over the entire facing area. You can treat the surface with a special spray. Do not grout if the tile adhesive is still wet.

Types and forms of release

The Knauf company produces several varieties of glue: Flizen Universal, Flizen Plus with a reinforced formula, Flizen Flex, Flizen Marble.They have a lot in common, but there are also differences: in the thickness of the adhesive layer, the possibility of laying tiles of different sizes.

Also in stores there is Knauf Flisen Max glue - a thick-layer material that can be applied in a layer of up to 3 cm when increased strength of the masonry is required. In addition, "Flisen Max" makes it possible to level the floor, walls, while this glue is not suitable for underfloor heating systems.

Forms of release of all products - strong paper bags of 10 and 25 kg, with several levels of protection. Store the glue on wooden pallets in dry rooms.

Universal adhesive

This composition is a classic glue "Knauf Fliesen", which is used indoors for tiles with water absorption up to 3%. For outdoor work, this figure should be higher - from 5%. Best of all, the glue is in contact with concrete, drywall, cement-sand bases, plastered surfaces. It cannot be used for low porosity tiles, as their water absorption coefficient is too low.

Flizen Flex

This glue is more elastic, plastic compared to the previous version. It is also used for porous, medium porous tiles, stone blocks and porcelain stoneware. Flisen Flex is suitable for all substrates, including insulating materials. The adhesive is especially effective where significant dynamic loads are expected. It is also widely used for cladding wooden bases, chipboard surfaces, for installing underfloor heating.

Glue "Flizen Plus"

Knauf Fliesen Plus is another tile adhesive with improved strength characteristics. This is achieved through the addition of mineral fillers and special polymers. The product has the highest level of adhesion to concrete, cement screed, drywall. It is well suited even for tiles with low water absorption and various types of stone, is frost-resistant, and is used for finishing facades of buildings and plinths. The total load per 1 sq. m. of cladding made with "Flisen Flex" can be 50 kg.

Flizen Marble

This glue is white, because it is created on the basis of white cement and minerals, polymers. Due to its reliability and high level of adhesion, the product is suitable for cladding various substrates with natural and artificial stone, granite, porcelain stoneware, mosaics and ceramics, glass tiles. To enhance the adhesion of large-sized products, "Flizen Marble" is recommended to be applied to the base and to the tile itself.