Advantages

Are there any characteristics that are specific to a plastic coating? Which, moreover, will become the advantage of the fence?

- The size of the cell, the color of the coating, the configuration, and so on may differ at the request of the client.

- Even so, where the soil is uneven, hedges are easy to install, and all thanks to its plasticity and lightness.

- A plastic fence tolerates alkaline compounds, exposure to UV rays, temperature changes well.

- The fence is very easy to transport as it rolls up and, in fact, weighs very little.

- Due to the fact that the fence allows air and sun to pass through well, light-loving flowers can be grown next to it.

- The fence does not need to be poured into the foundation.

- Due to the fact that the grid is flexible, even the most daring ideas are realized with its help.

Production technology

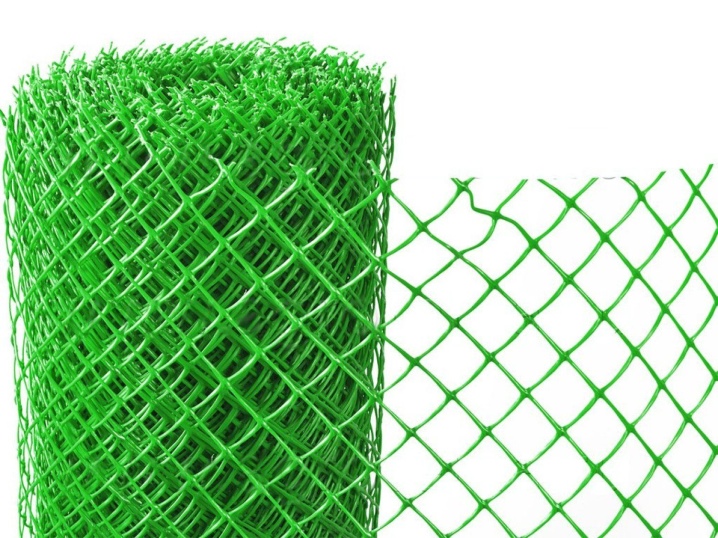

The plastic chain-link is distinguished by the fact that, thanks to the polymer composition, the fence is painted in almost any shade, which makes it easier when decorating a summer cottage. For example, a green polymer chain-link is used, a red one, and so on. In addition, the coating does not need to be repainted, which saves money.

The netting is woven, the chain-link with a polymer coating is woven not by hand, but with the help of special machines that can work with both one and several threads. Today's machines are usually designed for small volumes, and therefore do not require too large a room. When weaving, flat spirals are connected, and then the ends are bent.

The PVC chain-link is usually covered with a protective layer in two ways:

- Galvanizing method. Usually, the hot method of zinc deposition is used, but recently the electric method is becoming more common, which saves material several times.

- Plasticization method. If the finished fence is covered with a polymer compound, it will prevent moisture from entering the metal. You can apply the composition not only to an untreated mesh, but also to. In the latter case, the wire will be protected, even if the top layer is damaged.

What will you choose?

GalvanizedPlasticization

2 Do-it-yourself fence from a plastic chain-link

Making a fence from a polymer chain-link does not require special construction skills. Adhering to the technology below, anyone can install such a fence without any problems.

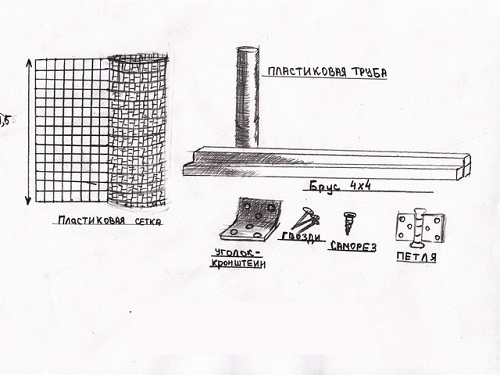

So, for the manufacture of the fence, we need the following materials:

- metal pipes with a diameter of 50 mm, a height of 2.4 meters;

- steel triangular profile 2 × 4 cm;

- plasticized mesh netting 150 cm high;

- screws, bolts;

- knitting wire or plastic clamps.

Prepare all the necessary tools in advance, such as:

- garden drill - to create holes for posts;

- buckets, or a wheelbarrow for the export of earth;

- grinder, for cutting pipes into pieces of the desired size;

- nippers for cutting knitting wire;

- welding, or a drill with a drill for metal, for fixing the veins.

The stages of making a fence from a plastic mesh do-it-yourself chain-link are given below.

2.2 Preparation of substrates

For bases under the mesh, metal pipes with diameters up to 50 millimeters are perfect, since the mesh itself is light, then using bases with a large diameter is unjustified - they will not bring any additional benefit, but will only increase the cost of arranging the fence.

Cut the pipes into pieces of the desired size (240 cm) and paint the part that will be located on the surface with paint that matches the overall range of the fence. It makes sense to treat the part of the posts located in the ground with bitumen mastic to prevent corrosion.

Painting of metal stems

You can also purchase special polymer posts, but their cost is comparable to the price of normal metal pipes, and the strength, as you understand, is much lower.

While the paint dries, mark the area where the fence will be located. Install pegs along the perimeter of the fence that will determine the installation locations of the bases. The optimal pitch of the peg is 2.5-3 meters.

2.3 Setting the posts

Use a garden auger to make holes 90 centimeters deep at the base locations. For pipes with a diameter of 50 millimeters, a drill with a 13 cm auger is suitable. Then insert the posts into the hole, and fill it halfway with fine gravel.

Tamp the crushed stone well, for this you can use ordinary scrap, and cover it with earth. If you succeed in all of the above, then you do not need to concrete the bases, their stability to hold the fence made of polymer mesh will be more than enough.

Installation of metal foundations of the fence

If you don't have a drill at hand, and you have to dig holes with a shovel, then make a hole one and a half or two bayonets of a shovel deep - it still won't work deeper, since the earth will crumble, and submerge the posts to the remaining depth with blows of a sledgehammer. If the soil does not allow you to do this, then it makes sense to concreted the bases.

To track the uniformity of the height of the columns, you can use the water level, or first of all, set the extreme bases between which to stretch the vein, and adjust the height of the remaining columns along it.

It is recommended to make a gate with a width of at least one meter, so it will not interfere with any household work. To create a wicket, it is necessary to install additional bases, which are recommended to be concreted in order to prevent them from swaying during operation. The gate itself can be made from the same plastic mesh used for the main part of the fence, or from wood.

2.4 Setting the veins

It is best to use a triangular profile as a vein; of course, you can simply pull on a metal wire, but in this case, the structure of the fence will lose its strength.

An example of fixing veins on metal substrates

Everything is simple here, cut the profile into pieces corresponding to the distance between the posts, paint with the same paint, and weld to the top and bottom of the bases. It can also be fixed by means of screws, having previously drilled a hole of a suitable diameter on the supports and the profile.

Ready-made fence made of chain-link mesh

The last step in the construction of the fence is to secure the mesh to the post. It can be fixed using knitting wire or plastic clamps. The spacing of the bindings should be about 20 centimeters.

2 We equip the fence with our own hands

In this section of the article, we will consider the technology of making a decorative fence from wooden frames, which is both a reliable and aesthetically pleasing fence for the inner part of the yard.

Decorative fencing based on a wooden frame requires the following materials:

- garden plastic mesh for a fence with a height of one and a half meters (choose the length of the mesh based on the planned height of the fence);

- a wooden beam measuring 4 × 4 cm and 210 centimeters long. For one cage of the fence, 210 cm long, we need 2 beams of 142 cm, and 2 beams of 210 cm;

- bracket-corner for joining timber, at the rate of 4 pieces per one cage;

- plastic pipes for the base of the fence with a height of 200 cm - since the fence is light, pipes with diameters of 10-15 centimeters are suitable;

- wood screws;

- hinges for wicket mounting;

- varnish for wooden coatings;

- nails 3-5 cm.

Scheme of the necessary materials for creating a fence

From the tools we need a drill, or a screwdriver, a hammer, a file, a screwdriver, a shovel and scissors.

2.2 Preparation and marking of the territory

First, prepare the area where the fence will be installed. Then mark its contour: for this, in every 210 centimeters (the distance corresponding to the length of one fence cell), drive in small pegs, and stretch a vein from a fishing line or twine.

The pegs will determine where the base pipes are to be buried. You can build a broken-shaped fence - diamond-shaped, or with a pocket for a car.

2.3 Working with a bar

We prepare and mark the timber - we need to cut it into pieces of 210 and 142 centimeters. Calculate the number of pieces based on the total length of the fence. After the timber has been cut into strips of the desired size, you can start assembling the frame for the fence. The frame is connected from the inside by means of fastening brackets, into which self-tapping screws are screwed.

2.4 Tensioning the mesh

Next, we proceed to varnishing the frame. To do this, you can use regular wood varnish. In order for the fence to have a beautiful appearance, you will need to apply two layers of varnish. In addition to the visual component, the varnish will give the tree an additional layer of protection against weathering, which will significantly increase the life of the fence. After the varnish has hardened, you can start pulling the mesh onto the wooden frames.

This is what the frame for the plastic mesh should look like.

It is necessary to fasten the plastic mesh for the fence from the inside of the frame. To do this, you can use ordinary nails - hammer them in every 5-10 centimeters so that the head of the nail presses the threads of the mesh against the bar.

By the way, in order to arrange a fence for small pets, it is better to use a fine mesh, a chain-link, with its large cells, is not suitable due to the fact that a small animal can get confused in them.

It is more preferable to use a fine mesh for purely decorative fences for flower beds, or a garden plot - such a mesh is visually more attractive. For fencing enclosures, a polymer chain-link is better suited - it has greater strength.

2.5 Installation of posts

According to preliminary markings, every 210 centimeters, we dig holes about half a meter deep to install the pillars. We insert plastic pipes into them, and fill them with earth, not forgetting to carefully tamp them.

Most of the leading manufacturers produce special plastic posts for their nets, which have the same color and texture, however, you can use ordinary metal pipes of a suitable diameter, painted in the desired color.

2.6 We attach the frame to the posts

This part of the work is the most time consuming. You may need one extra helper to hold the opposite side of the frame. The easiest way is to fix the frames by first connecting two cells into one, using self-tapping screws.

Ready-made fencing made of polymer mesh

Such a garden structure at the junction is preliminarily fixed to the posts using ordinary knitting wire, after which it is attached to the pipe with ordinary self-tapping screws.

2.7 Installing the wicket

The gate can be made of any material. Since our fence has a minimum weight, it makes sense to make it from a wooden frame, similar to what we did from a bar for the main areas, only of a smaller size.

We fix the gate to the edge of the frame, located near the support post, using ordinary door hinges. To strengthen the structure, you need to make one additional post along the second edge of the wicket.

Reinforcement portal »Mesh» For fences »Which plastic mesh for fencing is better?

How to choose a chain-link

Therefore, such a hedge is valued so highly.

But it is important to choose the fence that will meet the gost requirements.

There are three indicators that the buyer relies on:

The coating is sold as smooth as possible

It is important that there are no bumps, drops, or, conversely, gaps.

If the mesh is made on a machine, and not by handicraft, then the cells will be of the same shape, and the edges will be even.

Pay due attention to damage and dents. If the fence is deformed, then after the construction of the fence it will become noticeable

And it is impossible to fix this in the finished version .. Sometimes the grid is placed in frames

This gives the fence an aesthetically pleasing look.

Sometimes the mesh is placed in frames. This gives the fence an aesthetically pleasing look.

How to fix the mesh?

Plastic fence installation requires compliance with certain rules during installation. Special slats, corners, strips help to fix the structure. In this case, the pillars are also often chosen from polymeric materials, since the load on the surface is not too high. The procedure includes a number of steps.

- Territory marking. It is necessary to determine the perimeter of the future fence, mark the location of the pillars. It is worth considering the length of the roll. If it is 15-18 m, the supports are placed every 3 m.In other cases, every 2-2.5 m.

- Installation of pillars. For a capital structure, it is better to take metal ones with a diameter of 50-100 mm, holes for them are dug 80 cm deep.First, corner posts are mounted, leveled from the ground, then control marks are pulled along them and the remaining points are marked with a plumb line. The installed supports are backed up with stone or broken brick, concreted.

- Hanging the net. It is pulled from the corner, secured with polymer clamps. Having hung the extreme section, you can move on to the next support, trying to stretch the canvas as much as possible. You can cut out the material, trim its edge with an ordinary pruner or scissors. If several rolls are used, at the junction for 1 post 2 parts of the canvas will be held at once.

When it is planned to make a sectional fence, in the process of work it will be necessary to make a frame from a bar. Installation is carried out from the inside, on brackets. The mesh is also fixed from the seamy side with small nails or special strips in the corners. Special fasteners are made under the sections on the pillars, depending on the mass, they are hung on self-tapping screws or bolts. The frame can be quite light as the loads from the mesh are low.

Given these recommendations, you can easily cope with self-installation of a fence made of a plastic mesh-chain-link. With a minimum of tools and a small investment of time, the created fencing will successfully maintain an attractive appearance for many years.

You can see what kind of plastic mesh-netting to choose as a fence for your site in the next video.

How to make a plastic mesh fence with your own hands

It is worth starting with the preparation of materials and tools. We will need:

- bayonet shovel;

- wooden pegs, cord (for marking);

- screwdriver;

- hammer;

- screwdriver;

- gardening scissors;

- saw;

- plastic mesh (the exact footage depends on the length of the fence);

- nails ranging in size from 3 to 5 cm;

- wicket hinges;

- plastic pipes 2 m high, with a diameter of 10 to 15 cm (for poles).

There are two ways to mount the mesh:

- pulling the canvas between the supports;

- by sections.

As a fastener, you will have to buy 4 angle brackets for 1 frame, wood screws. To protect the wood from moisture and give it aesthetics, prepare a varnish.

Users are also looking for:

- Installation of a fence from a gitter mesh

- Installation of a fence made of gabions

- DIY fence made of construction mesh

Marking, installation of pillars

The first step is to determine the location of the fence. Then clear the site for construction, make the markings by driving in the pegs at the points of installation of the supports and pulling the cord between them.

Since the mesh fabric weighs little, it is not necessary to deeply deepen and concrete the pillars. In addition to plastic pipes, it is allowed to use metal pipes of the same diameter.

Fastening the mesh

The sequence of work with the tensioning method of installation:

The edge of the roll with the help of plastic clamps, we attach the wire to the corner support.

We gradually unwind the roll and fix it with a slight interference to each subsequent pillar.

It is important to calculate that the joints of the canvas fall on the racks. The transition will become unnoticed and the fence will have a solid appearance

For example, it is better to install poles in a roll 15 m long every 3 m.

The construction of a sectional structure will have to spend a little more effort, time:

- From the prepared pieces of timber, 2.1 and 1.42 m long, we assemble the frame. We fix the elements on the inside with brackets and screw the self-tapping screws into them.

- We varnish the finished frame in 2 layers. This will extend the life of the frame and protect the tree from high humidity. Let it dry.

- Cut out pieces of the mesh corresponding to the parameters of the frame.

- We fix the prepared canvas from the inside of the frame with nails every 5-10 cm. In this case, the nail head should press the plastic threads tightly against the frame.

- We mount the finished sections to the posts with wire, and then reinforce them with self-tapping screws.

Polymeric canvas is a good option for outlining the boundaries of a summer cottage and a decorative fence for climbing plants. If you want the fence to perform a protective function, then you should choose more reliable materials.

Selection Tips

The variety of plastic nets on the market makes it somewhat difficult to choose the right option. To facilitate decision-making, it is worthwhile to determine the basic requirements for the fence from the very beginning. Will it be solid or partial, decorative or functional, only the owner himself decides. In addition, the budget for the purchase is of great importance: prices vary from 60-70 rubles. / m2 up to 140 rubles. / m2, foreign-made products are more expensive.

Here are the basic guidelines for choosing.

- Appointment. If there are animals on the site that are capable of escape, small children who can lean on the fence with all their weight, it is better to immediately choose the emergency option. It will withstand maximum loads without deformation. For installation between the sites of neighbors, an ordinary chain-link is suitable; for the facade, it is better to choose a lattice that easily turns into a hedge.

- Cell size. It is also directly related to the purpose of the fence. To protect the territory from any unauthorized intrusion, a fine-mesh mesh is suitable. For decorative fencing, options with parameters 10x10 or 20x20 mm are more suitable for each weave. This parameter also affects the light transmission - the smaller the cell, the more shadows will be.

- Appearance. Meshes with an original design are well suited for creating façade fencing. Here, the unusual shape of the cells or their variable cross-section looks original and catchy. To cut off the territory from the neighboring site, you can choose a simple chain-link or an emergency option. If you want to combine the mesh with a hedge, it is better to make a sectional fence that can withstand such loads.

- Material. One-piece plastic mesh has significantly lower bearing capacity than metal mesh with polymer braiding. If you have a choice, you should give preference to environmentally friendly and durable PVC.

These are the main selection criteria

In addition, it is worth paying attention to characteristics such as the height and thickness of the mesh. Today fences of 2-2.5 m with rather strong and thick cells are popular.

To make the fence difficult to cut or tear, you can choose the metal-reinforced option.

Specifications

The material is classified according to:

- shape, size of cells;

- the thickness of the plastic;

- stiffness indicator;

- colors.

Popular cell shapes:

- square;

- honeycomb;

- rhombus;

- rectangle;

- circle.

The following colors are in demand:

-

green;

- khaki;

- Gray;

- yellow;

- Red;

- Brown;

- blue.

By purpose, it is divided into 3 types:

- Garden.It is considered universal, since it is excellent both for lathing climbing plants and as a canvas for small fences, animal enclosures. The mesh size ranges from 10 * 10 to 20 * 20 mm.

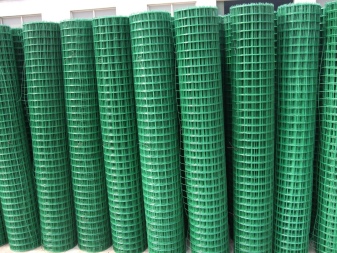

- Rabitz. Such a polymer coating is much tougher and more reliable, since it is based on durable PVC. Weaving is similar to the metal type of chain-link. Copes well with loads. Popular mesh sizes: 55 mm, 50 mm, 40 mm, 35 mm, 32 mm, 18 mm.

-

Emergency. The main difference from other types is increased strength. They are painted in bright even acidic luminescent colors so that the mesh is visible from a distance. She is fenced off construction sites, places of emergency work, delimit the territory into zones during concerts, football matches.

To create a fence from a polymer mesh at a summer cottage, preference should be given to the first two types. The design will turn out to be practical and inexpensive.

Peculiarities

Plastic mesh-netting is a relatively new material in the construction market. It is used to organize a fence on an ongoing basis, as well as for zoning a site. A garden fence of this type compares favorably with analogs made of metal materials, wood. The use of plastic mesh for fences avoids their destruction under the influence of atmospheric factors.

Consider the main operational characteristics and features of the material.

- Light weight. A running meter of mesh has a weight of up to 200 g, the whole roll - up to 8 kg.

- Diverse cell shape. It can be diamond-shaped, rounded, in the form of honeycombs, squares, rectangles.

- Color spectrum. The most popular are green, white, blue, red, gray nets, as well as more complex camouflage colors.

- Lifetime. He reaches 40 years old.

- Lack of complicated care. It is enough to rinse the material with water from a hose to put it in order.

- Heat resistance. The plastic mesh can withstand operation at temperatures down to -50 degrees and heating up to +80. And also the material does not fade, retains its original temperature in the sun.

- Ease of installation. Thanks to the manufactured accessories, you can easily do the installation yourself.

By its design, the plastic mesh is divided into completely polymer and metal with a PVC coating - the so-called plasticized. In terms of its parameters, it is completely similar to galvanized steel, but it is better protected from the influence of atmospheric factors. The PVC braid can have different colors, it is mounted in the same way as the classic options, it looks presentable.

Completely plastic nets are also quite in demand by summer residents and owners of garden plots. They are made from extruded polymeric materials that are first stretched into fibers and then woven into the desired range of meshes. Coloring is done in bulk, which avoids color unevenness. The net is produced in rolls up to 100 m long, the width varies in the range of 1-2.5 m.

There are several varieties of polymer-based products at once.

Garden mesh. This is a universal option for zoning the territory of a garden plot. It is distinguished by an increased level of rigidity, has cells with a section of 20x20 or 10x10 mm. The material is used as a lattice for climbing and climbing plants, as a fence for lawns and flower beds.

Plastic mesh-netting have the widest application. They are used for fencing sports and construction sites, children's playgrounds. In the dacha sector or on a personal plot, they are installed as part of stationary and temporary fence structures.

Installation of plastic mesh

The process of installing a plastic mesh is very simple and similar to installing a chain-link. But there are also some differences.

Stages of installing a plastic mesh fence:

Installation of support pillars.At this stage, it is necessary to take into account some features: the plastic mesh is softer and more elastic than the mesh netting, and therefore the distance between the support posts must be less than when installing a metal structure;

plastic mesh is lighter than metal, and therefore does not require a strong deepening of the support pillars.

So, having decided on the size and shape of the fence, it is necessary to install support pillars around the perimeter of the fenced area at a distance of 2-2.5 m from each other. At the installation site of the support pillar, a hole is dug, a pillar is inserted into it, and then its base is poured with concrete.

Plumb lines need to control the clear vertical installation of the pole.

Fastening the garden mesh to the posts. The end of the net roll is attached to the outermost support post by means of clamps, knitting wire or synthetic thick thread. Then the roll is stretched to the next post, where the mesh is again attached, etc.

It is important to make a good stretch so that the garden mesh does not sag over time. In addition, a thick wire threaded into each mesh cell from below and from above will allow to give rigidity to the structure.

There are options when the plastic mesh is mounted without support pillars. These are the cases when a flowerbed with tall plants is fenced off or a support is created for climbing vines. In the first case, a mesh of small height (up to 50 cm) is used.

With the help of a rectangular canvas, you can create the arches of the gazebo, which will later be braided with green plants, or phytopan, which will become a stunning bright spot in the design of any country house or summer cottage.

The creation of a cylindrical structure involves two options for placing the plant relative to the grid: inside and outside.

Inside the mesh are plants that do not have the ability to attach to supports, but have a large height and a fragile stem. For example, the well-known "golden ball" (rudbeckia), which has a height of up to 2 - 2.5 m, very often tilts without additional support, which leads to damage to the stem and death of the plant.

Gardeners equip a cylindrical fence made of plastic mesh for this plant, which does not spoil the appearance of the flower bed and protects the plant from breakage and death.

With the help of a grid, a cylindrical support is created for these plants, twisting which the lianas create a phyto-column that organically fits into the design of the site.

1 General information and application

Let's consider the main ways of using this product:

creation of a fence for a private plot;

The plasticized chain-link is an ideal material for creating fences around the inner perimeter of a summer cottage. In addition to creating classic fences, it is perfect for creating a hedge from plants: such products will be a reliable fence until climbing plants - vines or shrubs grow, after which they will become a good support for them, not standing out from the general color scheme.

in animal husbandry, and simply among farmers, the netting is very popular for creating a fence for animals;

This mesh has high elasticity, which allows you to create pens of any shape, without much additional effort. Most often, the chain-link is used to equip pens for birds and other small animals, since the plasticized mesh is quite soft, which excludes the possibility of injury to the bird on the fence.

In order to create corrals for cattle and horses, plastic mesh is used less often, due to its low strength characteristics.

An example of a garden fence made of a plastic mesh netting

- in agriculture, the netting chain-link is used to keep snow in the fields in the winter.For these purposes, it is necessary to use a large amount of material, which is not economically profitable in the case of metal meshes, while the cost of a plastic chain-link is an order of magnitude lower;

- arrangement of fences at sports and civil events - rallies, demonstrations, concerts, etc. The main advantage of the plastic mesh in this case is the possibility of its quick installation and dismantling;

- on construction sites, a plastic chain-link is used for the purpose of fencing the working area, and in order to protect workers, and passing under the high-rise construction of people;

- in the sports and recreation field, the polymer chain-link is widely used to create a fence around children's and sports grounds, tennis courts, mini-football fields, etc.

1.1 Overview of prices and major manufacturers

The world's leading manufacturers of polymer chain-link include such companies as "Conwed Plastics" (America), "Tensar" (America) and "Tenax" (Italy), their products are of high quality, but at the same time, the same high price, sometimes reaching the cost of a metal mesh of domestic production.

If you are not constrained in funds and are looking for a high-quality version of a polymer material for arranging a fence, then you should pay attention to the products of these companies. It is difficult to say that goods from domestic manufacturers are significantly inferior to foreign products in quality and reliability.

Rather, it is an ingrained stereotype in the minds of many people, stating that everything foreign is better than domestic, and expensive is better than cheap

It is difficult to say that products from domestic producers are significantly inferior to foreign products in quality and reliability. Rather, it is an ingrained stereotype in the minds of many people, stating that everything foreign is better than domestic, and expensive is better than cheap.

In practice, however, this is not entirely true. We can say that the polymer mesh from proven domestic brands, in terms of performance, is not inferior to imported goods, but at the same time, it has an order of magnitude lower cost.

Different versions of plastic mesh

The leading Russian companies producing plastic nets, the quality of the products of which is not in doubt, are STREN, Slavros (Proekt), and Lepse Mesh Factory.

The average cost of such grids is about 56 rubles per square meter of a grid with 24x25 mm cells, 72 rubles for a product with 40x40 mm cells, and about 90 rubles for 70x55 mm. For comparison, the price for the cheapest metal chain-link starts at 150 rubles.

Top manufacturers

A galvanized mesh-netting in a PVC sheath or a classic plastic lattice is an excellent solution for creating temporary and permanent fences. White, green, red - it is produced by dozens of manufacturers in Russia and abroad. It is worth finding out in more detail about which companies produce material with and without braiding in order to avoid possible mistakes.

Several brands can be distinguished among the leading companies in the plastic fence mesh market.

- "LEPSE". Russian company specializing in the production of chain-link of various types. In addition to metal options, the plant also has a line of polymer nets. The company also sells accessories for installation.

- Conwed Plastics. Sales leader among foreign companies. The brand manufactures products at its own factories in the USA and Belgium. The nets meet the requirements of European standardization systems, the polymer fabric is flexible, elastic, and can withstand significant loads. The brand's products are distinguished by their aesthetics.

- TPK Polistren LLC. The mesh has been produced under the Stren brand since 2006. The company is considered a recognized market leader, cooperates with many large construction companies and agricultural producers.

- Tenax. The Italian manufacturer produces biaxially oriented mesh made of high quality polymeric materials.All products comply with European standards, the line includes a wide range of sizes and many color options.

Other well-known companies include Tenser from the USA, Russian SpiderNet, Slavros, SlavPlast. The last three brands offer original decorative weaving options and products with non-standard designs.