Cleaning the main valve

It is produced without dismantling the entire mechanism. If the foam had time to set and blocked the lever:

- Do not apply too much pressure on it. This could damage the base frame;

- Cut the sealant from the tip of the barrel with a blade, try to make a depression;

- Drop a remover inside;

- Lower the gun barrel down and drop the solvent into the barrel so that the liquid flows towards the barrel;

- Wait 20-30 minutes;

- Press the hook with translational movements until it is free and begins to move freely;

- After flushing the lever, try screwing on a tube of cleaner and blowing out the mechanism.

If the trigger is still locked, a complete flush of all parts is required.

Full flush

Recommended for significant contamination, or if you plan to store the device for a long time without use:

- Disassemble the equipment: unscrew the valve crown at the place where the containers with solutions are attached.

- Pour the solvent inside onto the distribution ball, spray on the outside of the parts.

- Pull out the spring, piston, gasket and also treat with a cleaner.

- Wait 20-30 minutes.

- Wipe all parts with a hard cloth soaked in solvent.

- Check the movement of the ball. If it moves, treat the elements with machine oil, reassemble the tool in the reverse order.

- If dirt remains, repeat the procedure.

Which foam gun to choose and how to use it

The assembly gun is a simple tool that will help to accurately seal the seams and spend less consumables than using only one foam cylinder. The seam made with a pistol is thinner, the foam does not bulge out in large bubbles. Some home craftsmen, even with complex work (for example, on the ceiling), do without it - they attach a plastic or rubber tube to the cylinder. Of course, the advantages and disadvantages of this method can be fully appreciated only by trying it, but the fact that the pistol is "grippier" than the cylinder and it is more convenient for them to manipulate even a beginner is a fact.

In order not to regret the money and time spent on the purchase, it is better to know in advance which tool to choose and how to use it.

Popular models and prices for them

Among professionals, the following products are popular, which are included in the rating of the highest quality:

Hilti. This manufacturer offers models for home use and for professional builders. Prices range from 650 to 1200 rubles.

Hilti CF DS1.

Hilti CF DS1.

Bison. Under this brand, all-metal pneumatic guns are produced, including those with a Teflon coating. The cost is from 400 to 1350 rubles.

Bison Turbo 4-06877.

Bison Turbo 4-06877.

Blast. Convenient and lightweight aluminum pistols with a plastic handle, easy to use, additionally equipped with replaceable nozzles. The cost is within 700 rubles.

Blast Extra Lite.

Blast Extra Lite.

Kraftool. Pneumatic guns of this brand allow you to work with high accuracy, as they clearly regulate the spraying. Prices from 500 to 1150 rubles.

Kraftool Celnometal.

Kraftool Celnometal.

- Soudal. This manufacturer is engaged in the production of models for professional builders. The cost is from 1200 to 1600 rubles.

- Workman. Metal pistols that can be used for domestic needs and for installation on a construction site. The cost is from 350 to 1750 rubles.

This overview will help you find the best foam gun. Which one is better can be solved exclusively empirically, but the listed models are among the most common and reliable.

How to care for a foam gun?

Proper handling of the tool will allow even an inexpensive gun to “cope” with a large number of polyurethane foam cylinders.This simple device, with flawless operation, will not require either complete disassembly or external intervention. In order to guarantee the long life of the equipment, certain rules must be followed.

- The foam cylinder is removed from the gun only in one case: if the container needs to be replaced. A container that is "successfully" emptied at the end of the work does not need to be removed.

- After blowing out the joints, only the shut-off valve and nozzle are cleaned from the sealant.

- Flushing the adapter when changing the container is mandatory. The foam is removed with a solvent.

- If the hardened sealant interferes with disassembly, then acetone or inexpensive solvent 646 can be used to soften and remove it.

A pistol that refuses to work due to unexplained problems is not yet a reason to send it to the landfill. The tool is simple, so in most cases you can find the cause of the breakdown and then fix it. The broken part is replaced with a new one, the parts are lubricated. These simple steps will extend the useful life of your equipment.

The principle of the construction of the gun for polyurethane foam

The purpose of the gun is the controlled supply of raw polyurethane foam to the area to be treated. If the tool is used correctly, it can usually save material and solve the problem without flaws.

The device is quite simple:

- Threaded adapter into which the cylinder is screwed.

- Ball valve that opens under pressure.

- The tube-trunk through which the raw mass moves.

- A nozzle at the end of the barrel that acts as a working valve.

- A metal rod inside the tube connecting the trigger to the nozzle.

- Trigger handle.

More expensive models of the tool are equipped with an adjusting screw that limits the opening of the working valve. The main elements - tube, valve and rod - are usually made of metal. Brand samples worth under 5 thousand rubles. often contain Teflon-coated parts.

Polyurethane foam, gun.

Colleagues, I install doors, of course I use a pistol. As I finish frothing, I release the trigger, and foam comes out of the barrel in such a thin, thin stream. started again. Who faced, tell me how to treat. The advice "buy a new one" is not accepted, I want to understand the problem!

the ball in the pistol can jam this happens very often

Disassemble it like a toy and analyze the purpose of the giblets. Buy only professional tools. Yes, expensive, but reliable.

the foam has nothing to do with it. It is necessary to rub the needle to the outlet valve.

How? This is not a valve!

Most likely, there is a leak between the stem and the foam seat due to wear on the seat or stem, or foam has hardened at the end of the stem. It is necessary to completely disassemble the gun and make an audit with cleaning. If there is no result, then buy a new one. Another option, the stem does not reach the saddle due to the fact that in the area of the trigger in the sleeve there is coking, which does not allow it to move freely and (or) the spring has weakened or does not have enough power to cope with the resistance to movement due to contamination in the sleeve. In general, you need to completely disassemble, watch and clean. The sleeve can be lubricated.

Thanks for the advice, I'll try.

clean well with a foam cleaner or adjust.

The whole reason, not only as a gun, but also in the contamination in the sleeve, clean and try, if there is no result, then replace the tool

And the gun itself. means “the pin does not block the nozzle.

good day! I have a question, how do you clean the gun?

I never cleaned any pistols. Always at work. Amateur lasted for a year. Now professional two years. Maybe already a term?

I completely agree with the opinion of Andrey Surkov.another recommendation, if you have not washed the gun after use and there is foam left on the tip of the gun, do not clean it off with a knife, otherwise the copper ball will grind off, the consequences are foam incontinence in the barrel)

The simplest problem, in some types of foam, the composition reacts very sharply to air and a thin layer of foam is deposited on the needle, after which, accordingly, the gun starts to pass, so it is best, after each use, to rinse it))) good luck with your difficult task and try to find a normal foam. Makroflex has never let me down, try it.

Andrey, just after the macroflex, the opposite problem is: the foam barely comes out and yes, here you have to constantly rinse. With my work schedule, it is simply not realistic to constantly rinse. There are up to three objects a day!

The problem is that gradually the remaining foam dries up and the stem does not sit tightly in place. In household pistols, you need to tighten the valve every time. Ideally, after work, if there is not too much foam left in the cylinder, throw it away, rinse the pistol and immediately screw on a new cylinder. comes out from the side of the trigger.

Sergei, at current prices for foam, throwing out a third of the bottle, you will be left without pants! Unless, of course, the foam is hollow.

Flush more often and when finished foaming shut off completely that's all.

just do not need to clean the nose with a knife from the foam. you need to rinse the nose. and you will be happy

are you kidding? normal and generally use something like foam gun cleaner

the ball in the pistol can jam this happens very often

The foam froze inside the barrel of the pistol. After use, it is required to tighten the gun to the end. From practice, pistols, live, 6-18 months with this use.

The whole reason, not only as a gun, but also in the contamination in the sleeve, clean and try, if there is no result, then replace the tool

And if the spring is more powerful to put.

Thank you all for the advice. With the installation of a new cylinder, everything began to work fine. The considerations are: either there was too much pressure in the cylinder, or there was something horrible between the ball and the end of the tube. I change the 5th cylinder, everything is fine!

3 way

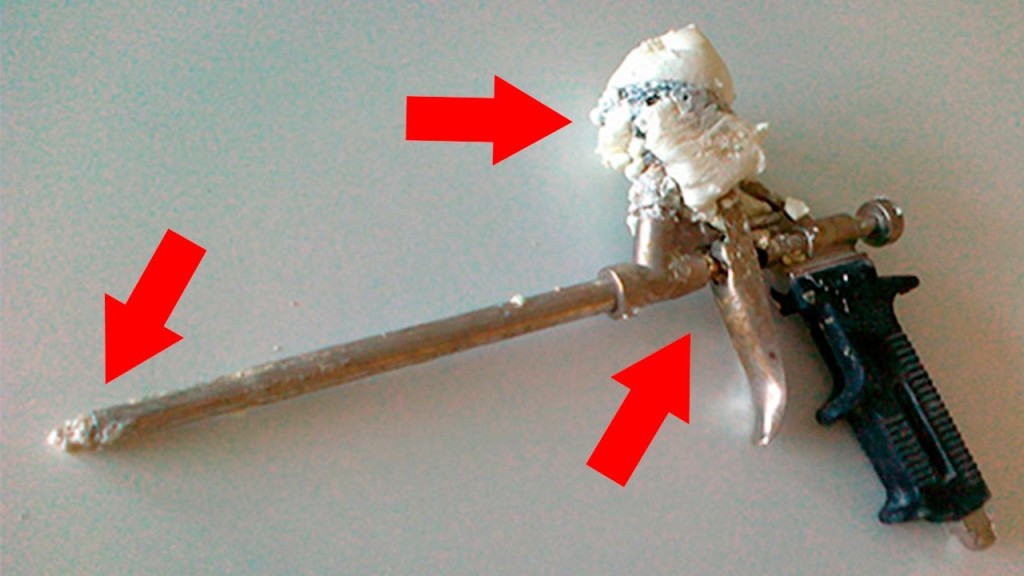

In the most severe case, the device can be disassembled. To do this, carefully untwist all the parts that can be dismantled, taking care not to damage the threads. They are cleaned with a solvent, rags, a clerical knife and a wire ramrod. Acetone, white spirit, gasoline, nail polish remover can be used as a cleaning agent. At construction forums, masters recommend Dimexidum as a softening agent for polyurethane foam. You can buy it at the pharmacy

Large flakes of foam are carefully removed with a knife so as not to scratch the coating. Small parts are soaked in a solvent, then wiped off with a wire

A homemade wire ramrod is used for the barrel. To begin with, a cleaner is buried in it. Then the hardened particles are removed by screwing the wire into the plug until it passes freely along the entire tube. After that, the apparatus is assembled and washed again with an aerosol, as in the first method.

The above method works, but it will not be possible to completely clean the barrel - small particles of polyurethane foam will still remain inside. Narrowing the diameter of the tube leads to a decrease in the head of the solution, but the situation will improve over time.

Instagram @ back_street83

When cleaning the instrument, it is best to keep the plastic parts away from solvent. During work, it is necessary to observe safety precautions.

Self-assembly of the unit

Foam concentrate drawing. (To enlarge, click) On the websites of manufacturers engaged in the manufacture of equipment for the production of penoizol, you can purchase installation drawings and find out the production technology.

By purchasing such a package of documents, you can assemble this device yourself, especially since spare parts are always available.

A budget option would be a self-assembled structure consisting of:

- gas-liquid installation;

- a set of cranes;

- supply hose;

- compressor for the production of compressed air;

- plastic drums up to 300 liters.

The process of obtaining insulation is based on the principle of foaming solutions with a catalyst and mixing it with urea resin. With the help of a pump, the components enter the installation, where they are foamed under the influence of compressed air.

Diagram of a foam-insulating plant. (Click to enlarge) One of the main components of the system in a gas-liquid installation is a pump, so it is better to purchase a high-quality pump.

We do not recommend pumps of type NSh 6 (gear pump) and NSh 10, as they can supply in dosages when feeding one of the components - resin.

These pumps also have problems with the electric motor. The declared capacity may not be enough when feeding the finished product to fill the voids.

Please note: when choosing pumps for installation, it is necessary to take into account dosing errors, errors in the instability of engine speed from voltage and load.

Keep in mind: when choosing a plunger or vortex pump, it is imperative to consult about the material from which the internal parts are made. It is desirable that it be a nickel plating, stainless steel, ceramic or plastic.

The most effective method today is double foaming. Penoizol at the exit appears as a dry mass, which makes it possible not to flow out of the cavity to be filled.

The compressor on the equipment must be installed with a certain capacity

Be sure to pay attention to the resin consumption, it should be no more than 25 kg in order to get a quality product

Ready-made penoizol

The final product should be white and, when pressed, restore to its original shape.

As an insulating material with low cost and high insulating properties, penoizol is beneficial for its own production. Having assembled equipment according to the drawings, you can open your own small business and start earning.

Watch the video, which shows in detail the stages of work on the equipment for penoizol, made by hand:

How to use a foam gun

Prepare the seam. Dampen the surface to be lathering with water. Shake the canister with the pistol mounted on it twenty times. You need to shake with force, vigorously and only then turn it over. Guide the tip into the seam

Press the trigger of the gun carefully. Understanding how to get the right foam flow will only come with practice.

If the foam does not come in the volume that is required, tighten the adjusting screw at the back. The more you tighten, the less foam will go, the thinner its layer will be.

Fill the seam from bottom to top with zigzag movements, try not to clog it completely - the foam expands, and it is better to fill the voids later than cut off considerable excess. The seam is very long and the foam is already of a different consistency - stop, shake the can again. Then, with a little more practice, you will understand for yourself how often you need to do this. For hard-to-reach seams such as ceilings or angled seams, use an extension adapter — a thin plastic tube. It is often sold complete with a pistol.

During pauses, clean the tip with a cloth soaked in solvent to prevent clogging of the nozzle. There are also special wet wipes for this. When finished, be sure to tighten the adjusting screw.

Unscrew the empty bottle from the pistol.Remember to direct the nozzle into a trash can or tight bag.

Precautionary measures

- After finishing work, always tighten the adjusting screw as far as it will go - shut off the foam flow.

- Do not clean the inside of the nozzle with metallic objects, this will damage its tightness.

- Clean the outside and inside of the gun after removing the cylinder. Do not leave the tool clogged with foam, otherwise it will quickly fail.

- Before putting on a new cylinder, pull the trigger of the pistol, bleed off excess gas. At the same time, direct the nozzle into a garbage bag or container - first, foam will fly out of the gun along with the liquid.

- Do not use a cold bottle (already at 15–20 degrees - not worth it). You can warm it up in warm (but not higher than 30–40 degrees) water. If you work outside in hot or cold weather, put a cover on the cylinder.

- When unscrewing an incompletely emptied cylinder, be careful - if the valve is faulty in it, the foam can go in a dense stream. It happened that there was not even enough bucket to hold everything.

- Take care of hand and eye protection, use gloves and construction goggles.

- Remember, flushing fluid is flammable.

Vasya, don't do that!

Forum visitors often share personal experiences, including negative ones. Such experience is very valuable - there is no need to test the warnings on your own skin.

Just now we ordered a flush to the facility. No, not because there was a need for it, just during the breaks I was a flamethrower. Flame jet up to 2 meters.

Maratto

Frost, 25 degrees. In the presence of 2 cylinders, those that are up to -10, both covered with frost and categorically do not want to give the contents. And it is necessary to shed it, otherwise the people will grow stiff. We put the foam under the heat gun, while back and forth, the bazaar-station, the cylinders start to grow strangely, swell and a terrorist attack turns out - everything is in foam, the owners have shock and grimaces of despair in the photographs.

They wiped it off, however, quickly, well, and had to go for new ones.

Strashila

Experienced craftsmen find ways to work with the same tool longer and more efficiently. A thin plastic tube - extension adapter - will help keep the barrel and nozzle of the gun clean. Put it on the barrel and do not take it off all the time you work. The foam solidifies in the tube itself, but remains liquid in the tip of the gun. The cured foam plug can be removed from the tube with a long self-tapping screw.

Sealant Gun Operating Instructions

First, a little advice. If at the right time the gun was suddenly not at hand, then in order to knock out the sealant from the cartridge, you can use any tool at hand. For example, a hammer.

And in order to use the pistol successfully, follow these steps, which we have illustrated with pictures.

Step 1. Take personal protection first - at least wear gloves.

Step 2. Next, prepare the surface to apply the sealant. In this case, we cannot advise anything specific, since everything depends on the instructions of the manufacturer of the cartridge. Everything should be written on the back of the latter. Use a sharp knife or triangular scraper to remove the previous coating. Remove the remaining crumbs with a brush or use a vacuum cleaner.

In addition, the work surface must be degreased without fail.

Step 3. Next, remove the delimiters. If we are talking about a half-body or skeletal pistol, then this procedure will happen quickly. First, make sure that there is no special limiter on the tube. And if it is still present, then delete it.

Step 4. Let's figure out how to use a sealant gun. Then pull out the stem in the device. To this end, press down on the lever and remove the part. In the place that was freed after the rod, place the cartridge and make several gentle pressure on the hook in order to finally strengthen the container.

Installing a cartridge in a skeletal sealant gun (photo)

Step 5.Next, make a hole in the container through which the sealant will be supplied to the cone, which, in fact, provides a uniform and even line.

Note! In most cases, these cones are sealed. And if you also have it sealed, then you will have to cut off the end of the cone in order to form the required seam diameter

In this case, it is important that the dimensions of the cut are smaller than required for work. But if you decide to use a tubular or syringe tool for work, then you should use it in a slightly different way.

But if you decide to use a tubular or syringe tool for work, then you should use it in a slightly different way.

Installing a cartridge in a tubular (syringe) sealant gun

Photo - diagram of a tubular pistol

Step 1. First, make a hole in the sealant tube. If you use pre-packaged material, or "sausage", then cut off one corner / end with the utmost care so that the mixture can easily come out of the bag.

Step 2. Next, put the prepared container with the material into the tool itself, but so that it is the cut end of the container that comes out to the tip, through which, in fact, the strip of material will be squeezed out.

Step 3. Of course, before that it is necessary to remove the stem - do this in the same way as with a skeletal device.

Step 4. Often, guns are equipped with several nozzles with such tips. Choose one of them and spin the cylinder with it. If you notice that there is no hole on it (tip), then take a clerical knife and cut the tip, but strictly at an angle of 45 degrees. Of course, in this case, you must also guess with the dimensions of the future hole in order to get a seam of the required diameter.

Be that as it may, if you have a sealant gun on hand, then there must be a manufacturer's instruction. Do not be too lazy to familiarize yourself with it, since manufacturers often complete tools with some improvements and developments that are not provided for in standard models.

You might be interested in this

Previously, we considered the characteristics of self-adhesive foam, which is very often used for warming rooms. We advise you to see this article