Instructions for use of the foam gun

Instructions for use are included with each tool. It contains several sections:

- Introduction. It is suggested to tighten all threaded connections, as they may loosen during transport.

- Connecting the foam bottle. Shake it for 1-2 minutes before winding it up.

- Replacing the cylinder. When replacing, hold the gun with the cylinder down.

- Storing a pistol with a cylinder. It is necessary to store the bottle down.

- Storing the gun without a can. Be sure to keep it clean and washed after use. Never store gun uncleaned.

Features of the work

Before starting work, places for foaming must be cleaned of dirt and dust. Be sure to moisten them with water. It is advisable to carry out work not in hot weather, in which moisture evaporates more slowly. The optimum temperature for foam is + 20 degrees. When working with the foam gun, always hold it with the cylinder facing up.

In the case of lowering the cylinder down, only gas can escape from the barrel. Therefore, first, the upper seams are foamed until the cylinder is full, and then the foam is distributed from top to bottom. Lastly, the foam is applied to the bottom seams.

If at the beginning of work the cylinder is not full, you should start foaming from the middle, for example, a door frame, and move down. After production of foam and replacement with a full bottle, foam the upper part. When working under ceilings and in deep joints, a flexible extension can be used.

Gun care

After the work on foaming has been carried out, it is necessary to determine the approximate amount of the remaining foam in the cylinder. If its amount is more than half, then it is necessary to remove the remaining foam from the spout with a cloth moistened with acetone. After that, put the gun with the cylinder on the rack. In this form, the foam can be stored for up to 5 months, necessarily with the balloon down. And if necessary, you can immediately do foaming by shaking the bottle several times.

If the foam in the cylinder runs out, then it is removed and the internal parts are rinsed by attaching the cylinder with the rinsing liquid. The outside of the pistol is wiped with a rag moistened with acetone.

How to use?

In order for the work carried out to be of high quality and durability, it is necessary to use the foam gun correctly

Close attention in this process must be paid to the preparatory stage, the essence of which is to shake the can of foam at least 20 times within a minute. Only then will it be possible to remove the cap and turn the adjusting screw on the gun itself

As a result, the valve closes, after which it will be possible to connect the container so that it is under the gun. The adjusting screws are used to control the release rate of the foam. The trigger should be pulled as smoothly as possible, since this is what allows you to control the speed of the foam protrusion.

Sometimes it happens that the muzzle of the pistol is too thick and because of this it is not possible to penetrate into a hard-to-reach place. In this case, it is necessary to use special tubes that come with the construction tool.

In the process of carrying out the work, it is necessary to be as careful as possible, since if the foam hardens, and the work was carried out poorly, then the process of their elimination will be quite difficult and lengthy. After using the gun, the nozzles should also be rinsed immediately, since after the substance has hardened, it is extremely difficult to cope with this matter.

Maintenance of the foam canister after work

Of course, if the work was carried out without a gun, the foam can is thrown away, since the sealant hardens after use in the tube and valve. Reapplication is not possible. But I have one popular secret in my bins, which tells about how to keep the valve mechanism operational in combat readiness.

The secret is quite simple: in order for the polyurethane foam to be reapplied, you just need to shut off the air access to the valve mechanism. How to do it? I'll tell you now.

It is required to insert a foreign object-plug into the tube filled with foam, which will prevent air from entering it. After sealing, the container must be placed in a dark and cool place.

If there is a need for foam, it is enough to cut off a part of the tube in the place where the installed plug is located. For example, I never wash a pistol, and it is always ready and loaded for the fifth year already. Thus, even household foam can be reused.

In addition, the container should be kept clean. If foam gets on it, you need to wipe the container using a solvent, not allowing the plastic elements to get wet. By the way, it is not necessary to carry out work on sealing and insulation in the rain and snow - it is fraught with poor performance.

Budget models

Foam gun

If a gun for polyurethane foam is required only for the duration of the repair or for one-time work with long interruptions, it makes no sense to overpay for a professional tool. The market offers a wide range of budget models with decent functionality.

back to menu

Stayer Master EconoMax

Stayer Master EconoMax

Stayer Master EconoMax

This is an inexpensive model of a popular German brand with a lightweight design. The cylinder body and threaded retainer are made of silumin, the feed tube is made of stainless steel, and the handle is made of plastic. The product cannot be disassembled and needs to be rinsed after use.

PROS:

- affordable price

- metal case

- light weight and comfortable grip

- valve reliability

- good foam regulator

MINUSES:

- the mount is not suitable for some types of cylinders

- the structure is not collapsible

back to menu

P.I.T. PROFI R7000004

P.I.T. PROFI R7000004

P.I.T. PROFI R7000004

A well-known Chinese manufacturer offers several models of polyurethane foam guns, including Teflon coated ones. But for home repairs, a tool that is almost entirely made of plastic is enough. The exception is the stainless steel barrel and valve. The kit includes a barrel extension for filling hard-to-reach areas with foam.

PROS:

- the most affordable price

- light weight and ease of use

- the regulator allows you to fine-tune the foam flow

MINUSES:

- the thread of the plastic retainer is gradually erased, the tool is enough for one or two repairs

- non-separable design makes cleaning difficult

back to menu

FIT 14272

FIT 14272

FIT 14272

A budget representative of a Canadian brand, made in China. The body of the gun is made of zinc alloy, which ensures its reliability. Due to the plastic handle, the weight of the tool is reduced. The design is non-separable, which complicates the cleaning of the feed tube. The trigger is positioned to avoid pinching your fingers.

PROS:

- low price

- robust housing with metal cylinder retainer

- light weight

MINUSES:

- the plastic handle may break if dropped

- the trigger is far away, which is inconvenient for a small hand

back to menu

SibrTech 88671

SibrTech 88671

SibrTech 88671

The tool is manufactured in China under a Russian brand. The reinforced pistol body is made of solid aluminum. In this case, the mount for the cylinder is plastic.The tool pleases with well-thought-out ergonomics - a comfortable grip, a large adjustment knob with a plastic tip. The gun is non-separable, but the smooth feed tube and valve are easy to clean.

PROS:

- affordable price

- the convenience of use

- durable housing

MINUSES:

- the plastic cylinder retainer from impact when dropped may break

- the gun does not understand

back to menu

Blast Extra Lite

Blast Extra Lite

An ultralight model of a gun for working with polyurethane foam is being produced under a Russian brand in China. Due to the use of plastic, the weight of the tool is only 150 g. The volumetric grooved handle fits comfortably in the palm of your hand. A special lever is used to adjust the foam output. The delivery tube is made of stainless steel. Non-separable design.

PROS:

- low price

- extremely light weight

- thoughtful ergonomics

- reliable valve

MINUSES:

- the plastic balloon retainer is short-lived

- non-separable design makes cleaning difficult

- the gun may break if dropped

- a primitive mechanism for adjusting the foam output - fine tuning is not possible

back to menu

2. BARTEX Standart CY-087

The model with a non-slip handle guarantees a secure grip even with wet hands in extreme conditions. The price is budgetary, while the model is distinguished by the quality of performance.

The barrel, cylinder retainer and trigger are made of durable, non-corrosive stainless steel alloy. In high humidity conditions, the product will retain its performance characteristics.

There are no problems with cleaning all the elements after work. The exact dosage of the foam output will be ensured by the adjusting screw.

pros

- budget price;

- high-quality assembly;

- ease of use;

- does not require special maintenance;

- high tightness.

Minuses

part of the body is made of plastic

Criterias of choice

Since the construction of a gun for supplying polyurethane foam is quite simple, its quality depends on the version of only a few details:

- Balloon retainer (adapter). The thread of the retainer, made of plastic or silumin of low quality, is erased with prolonged use.

- Service valve. Durable valves are available in stainless steel or bronze. If the strength of the metal is insufficient, the element deforms - an increase in the contact patch between the seat and the needle increases the risk of leakage.

- Check valve. If the reliability of this part is insufficient, when the cylinder is removed, the foam from the gun comes out and must be removed immediately. At the same time, air enters the tube through the valve, which leads to rapid polymerization of the remaining foam inside the instrument.

- Tube fixing. If the part is pressed into the body, the gun is more difficult to clean after use. Threaded connection is more practical. To pick up the handset, a spanner or open-end wrench is used.

The structure of the pistol

Body material

The durability of the product depends on the material of manufacture of the case. Manufacturers use different types of alloys, plastic, a combination of plastic with metal. The more plastic, the lighter and cheaper the tool. Such models are suitable for use during home renovations. The exception is a professional tool made of impact-resistant plastic and stainless steel.

A metal gun for working with polyurethane foam is noticeably heavier than a plastic one. For the manufacture of the tool body, aluminum, brass can be used, but most often this is one of the alloys:

- Zinc-aluminum-copper spav (TsAM). Comparable in strength to low carbon steel. Models made of this material have the greatest weight and are designed for a long service life.

- Silumin. Alloy of aluminum with silicon is significantly inferior to TsAM in strength. The reliability of the silumin case depends on the conscientiousness of a particular manufacturer. Such a tool is noticeably lighter than models from TsAM

When choosing a tool, pay attention to the ease of cleaning.Expensive models often have a Teflon coating.

The remains of polyurethane foam can be easily removed from it, even if it has time to harden. But Teflon is easy to damage, so you need to be careful when cleaning - in places where the coating is peeled off, the foam polyurethane will stick tightly.

The polished stainless steel tube is also easy to clean due to its smooth surface. If the feed tube is made of plastic, the gun must be rinsed immediately after work, since later it will not be possible to fully clean the channel. For cleaning it is necessary to use special means.

The best hacksaw: choosing saws for wood and metal for household and professional work | TOP-10: Rating + Reviews

Criteria for choosing a gun for polyurethane foam

Polyurethane foam has excellent adhesion, which becomes a negative factor when cleaning the gun. It is easier to disassemble the tool to gently remove the dried insulator from the tubing and isolation valves. When buying a non-separable model, you need to stock up on a special bottle of solvent and after each use of the gun, immediately rinse it from the inside with a cleaner

When choosing a gun, you should pay attention to what material such critical parts as a tube, valves, threaded fastener and body are made of. The most reliable products will be made of stainless steel or copper alloys (brass, bronze)

Parts coated with nickel or Teflon have the greatest durability.

Since the polyurethane foam is under pressure in the cylinder, the threaded holder becomes an important connecting element of the gun. Maximum reliability is ensured by a metal alloy; with careful operation, impact-resistant plastic can also serve for a long time.

Users have a variety of requirements for a pistol. A high-quality regulator of the mixture supply allows to satisfy the needs of buyers. With its help, it is possible to economically consume polyurethane foam.

Professionals, who often hold a pistol in their hand, have to pay attention to the ergonomics of the handle and the lightness of the tool. These parameters directly affect the degree of employee fatigue.

Only the best pistols have been selected for our review. When selecting applicants, the following criteria were taken into account:

- the purpose of the tool;

- technical specifications;

- price;

- expert opinion;

- consumer reviews.

The main criteria for making the right choice:

- What material are the main elements made of.

- Is the device disassembled?

- Ergonomics of the instrument.

- Tube length.

- Coating type of gun parts.

- Foam regulator type.

Materials used for the production of foam guns:

- Plastic is a material used for the production of inexpensive, mostly disposable instrument models. Working with such a device is fraught with difficulties during work. Due to the frequent clogging of the nozzle, during operation, you have to disassemble and rinse the device. The foam supply valve does not work stably, as it cannot provide the required material pressure.

- Metal is the best option in terms of price and quality. With proper handling of the instrument and the obligatory flushing after each use, it will serve without failure for a long time.

Instructions for use

The following are tips and tricks for using the foam gun to help you operate the appliance more accurately and safely:

Workplace. A sufficiently illuminated place is required for good visibility while working with the tool and the required surface. The foam contains various chemicals, including harmful ones, so the room must be constantly ventilated.

If the pistol has already been used before. It is recommended to trim off dried foam from the tip every time before using the device.

Foam bottle before starting work.Shake it vigorously at least 10 or 15 times for a more uniform foam consistency.

Remember that if the cylinder is already attached to the gun, then you need to shake the entire tool without unscrewing the container with foam. It is necessary to connect the cylinder with the mounting fluid to the inverted device to avoid the release of internal pressure.

Working with a nailer - pros and cons

Before using the assembly gun, it is necessary to assess the adequacy of its use.

The most powerful hammer drill, when "driving" a concrete wall, will require intense force for several minutes. If you drill a ceiling or a horizontal beam, then these efforts will be coupled with a stream of concrete dust directly into the eyes of the driller. Then a plastic or wooden chopik will have to be hammered into the punched hole, then a screw or a bracket will have to be tightened ...

The construction pistol does this job in a few seconds, if you choose the right cartridges, accurately and strongly direct the "barrel" to the selected target. It does not depend on external power sources, it can be used in the most inaccessible places. Dampness and moisture on the wall, rain and wind are not an obstacle to installation "with shooting". The fastening speed depends on the speed of reloading and the movement of the scaffold.

The disadvantages of assembly guns include their significant cost - and this is relevant both for the tool itself and for consumable parts. Cartridges for the construction and assembly gun should be bought branded and must be checked before use for their integrity, the absence of rust, bruises, etc. Repairing an assembly gun is quite expensive and requires serious professional knowledge - an independent attempt to fix a malfunction can lead to serious injury to the worker himself and the people around him.

To work with a construction gun, you must have an appropriate approval certificate. Now this requirement is often ignored. However, disregard for the laws does not exempt from liability for their violation, including in the construction and repair business.

Classification

In order not to feel like a "blonde" while "shopping", you should study the varieties of the substance.

Release:

professional (for a gun);

household (with a tube nozzle).

Composition:

- two-component;

- one-component.

Flammability:

- В1 - does not burn;

- B2 - burns, but fades out;

- B3 is on.

Season:

- winter - used at outdoor temperatures –20 / + 35 ° С;

- summer - used at + 5–35 ° С;

- winter-spring-summer-autumn - used at -10 / + 35 ° С.

Usage:

- reusable - reused;

- one-time - applied once (the remainder is thrown away).

So, we figured out the views of the main character of the article.

Which one is better? Well, to each his own. For example, specialists in large volumes use professional two-component polyurethane foam, which is multi-season, non-combustible and reusable. Who cares - here is an article on sprayed thermal insulation. But for us, as non-professionals, you can use the household option with the B1 flammability class, intended for single use.

Features of the device

Today, a wide range of tools is presented on the shelves, among which attention is drawn to a gun for working with polyurethane foam. It allows you to easily dispense the required amount of polyurethane sealant to the right places.

Polyurethane foam is used to fill seams when installing door frames, windows and window sills, slopes and sills, as well as various cracks and holes. A sealant gun should be at hand for every craftsman.

There are quite a few advantages of a pistol, in comparison with a conventional sealant cylinder.

- Economical consumption. The tool is designed in such a way as to independently dose the outgoing material.This allows you to almost three times reduce the consumption of foam. An even distribution of the product has a positive effect on the quality of the seam.

- Practicality and convenience. The pistol works by pulling the trigger. The mechanism is practical, since the foam comes out in small quantities, filling only the voids. If you only use a can of sealant, it is difficult to handle the high flow of foam. It not only fills in the seams, but also hits objects and walls.

- Ease of work in hard-to-reach places. The narrow tool barrel allows foam to be poured even into hard to reach areas. This is especially true for filling gaps in the ceiling.

- Reuse of the foam canister. The gun is characterized by the presence of special valves that are responsible for tightness. If the work has already been done, and the sealant remains in the cylinder, then the gun prevents it from hardening, and in the future it can be used again. If you work only with a foam cylinder, then you can throw it away, since the foam quickly solidifies in an open cylinder.

The assembly gun will last a long time if you know its characteristics and how it works. Subject to the basic rules of use, the tool will last much longer. Do not forget that the sealant is unsafe, as it is highly flammable and can cause severe irritation if it comes into contact with open areas of the body or in the eyes.

Before using the gun, you should study how it works:

- First, shake the sealant bottle well, place it vertically on a flat surface and carefully screw the gun onto it, with the tool at the top. When the cylinder is firmly fixed to the gun, it is necessary to turn the structure over. The gun should be at the bottom, this is its working position. It must be firmly held by the handle.

- First you need to clean the surface on which the sealant will be sprayed. For better adhesion, it can be slightly moistened. It is advisable to work with the sealant at room temperature.

- To increase the intensity of the foam from the gun, you do not need to push the trigger with more force, it is enough to slightly tighten the control screw. The pressure contributes to the rapid release of the material, therefore, you should first prepare the entire space where it is necessary to pour the foam. This will allow you to perform the work efficiently and correctly organize the consumption of the sealant.

- When working with the tool, it is advisable to wear special gloves, overalls and goggles. If you need to remove excess sealant from the surface, then it is strictly forbidden to do it with your hands. For this purpose, you need to have a spatula or at least an ordinary rag on hand.

- To foam a vertical seam, start at the bottom and work your way up. It is this order that will allow you to control the uniform filling of voids with material. When the gun nozzle rises higher, you can immediately see the result of the joint filling. This will allow you to analyze and determine the need for pressure regulation.

- After finishing work, the gun needs to be cleaned. To get rid of caked foam, you should use a solvent. Cleaning the tool after completing the work supplied will extend its service life.

- When working with the gun is stopped even for a few minutes, the cylinder should always be in an upright position. It is worth excluding direct sunlight from hitting it, and also working with it away from open fire.

- If, after completing all the tasks, foam remains in the cylinder, then the gun does not need to be disconnected, since it will keep the foam in a liquid state. To reapply sealant, you will first need to clean the gun nozzle or the tool may break.

No. 7 - Kraftool PROKRAFT 0685_z03

Price: 1 200 rubles

Our top moves on. Kraftool PROKRAFT 0685_z03 - an almost perfect ergonomic pistol. Its trigger does not require a strong push from the owner, which positively affects the ease of use. The gun has an innovative design with two o-rings and a precision machined needle valve to ensure a reliable seal.

The cylinders and nozzle are PTFE coated for easy maintenance. The two-component pistol grip is non-slip for comfortable handling. The barrel is polished from the inside to prevent foam from hardening inside the pistol. After analyzing the reviews of the owners, we did not find any significant flaws.

Kraftool PROKRAFT 0685_z03

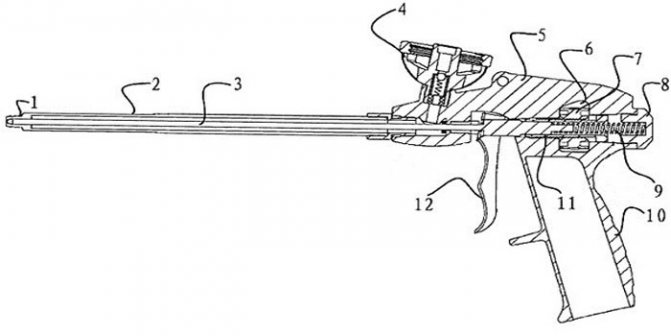

Detailed sectional diagram of gun parts

The pistol consists of a body part (5) to which the barrel (2) and the handle (10) are fastened with a threaded connection. At the end of the barrel there is a nozzle (1), an axially located needle bar (3) connected to the trigger handle (12) is crimped inside. The foam flow is regulated by a device located in the body and includes a pressure spring (9) clamped in a lock nut (8) and connected at one end with the body, and at the other end with a needle bar, a lining (7) placed in a through bore (6) and retaining sleeve (11). Rotation of the liner results in axial movement of the sleeve and restricts needle bar sliding, thereby controlling the flow of the polyurethane foam. The pistol body is also equipped with an adapter (4), which is interconnected with the barrel.

Depending on the type of model, assembly guns can also have additional functional parts, for example:

- gasket bolt - most often soldered into the gun body;

- replaceable nozzles - plastic or silicone tubes of various shapes, diameters or lengths. Their use makes it easier to work in hard-to-reach places.

Read also: The thickness of the foam rubber for the carriage coupler

Replacing the cylinder

The principle of replacing the cartridge does not differ much from the initial installation. But at the same time, you will need to follow some necessary rules:

- If foam remains on the outlet valve, dispose of it. To do this, you need to purchase a solvent in advance from a hardware store.

- To prevent foam from sticking to the nozzle tip, wipe it regularly with a clean cloth.

- To reduce costs, as well as save consumables, you can leave and save the leftover foam for the next time (no more than 2 weeks). You just need to tighten the valve on the device harder, get rid of dried materials on the entire body and leave the gun in this position until the next need to use it.

- When the cylinder is empty, after removal, the gun must be thoroughly cleaned in all contaminated areas.

No. 10 - Kraftool SUPER-KRAFT

Price: 2,000 rubles

Inexpensive, but good model, common in Russia. Users appreciate it for its infinitely variable needle-type valve travel. Thanks to it, you can achieve the required foam consumption, significantly saving on material. In addition, the valve is made of reliable materials - Teflon-coated brass, the body, in turn, is made of durable metal. This combination is rarely found in pistols at a similar cost.

Note also the fact that the release coating prevents foam from sticking to metal components such as the nozzle, valve and holder. Of the minuses - it is not as easy to disassemble for cleaning as we would like.

Kraftool SUPER-KRAFT

Household and professional polyurethane foam - what's the difference?

In most cases, it is enough for an average person to buy a tool that belongs to the category of "household" and is much cheaper than a professional one.For example, a household chainsaw - for homework once a month (if not less often) there is absolutely no need to buy an expensive professional version, which may never pay for itself. In this case, among household tools, you can find a very high-quality tool, which will be even more comfortable to work with than with a professional one, it just will have a smaller motor resource and need breaks from time to time.

But in the case of polyurethane foam, we are engaged in self-deception with the light hand of marketers. Dividing the prepolymer cylinders into household and professional ones, we are pushed to a completely rash act - buying low-quality foam. You are very much mistaken if you think that professional cylinders are intended only for professional builders, and every beginner can use household ones.

All you need to do is connect the tube to the valve, press it and get a stream of polymer. After the gap or hole in the wall is sealed, such a cylinder can only be thrown away, even if half of the contents remain in it. After standing for several hours, the foam inside the tube polymerizes, and it can no longer be cleaned.

A professional cylinder, according to everyone, differs in that to use it, you need a special assembly gun, which is screwed onto the valve. The cylinder for such a gun is reusable, since the gun and valve can be flushed with solvent after use. All these manipulations can be performed with equal success by both a master builder and a beginner. Moreover, experience proves that it is more difficult for a beginner to cope with household cylinders, and the master gets a completely different quality of work.