Rules for using the foam gun

Considering that such material, after opening the cylinder, begins to intensively go beyond the container, you need to study the instructions for using the tool. If applicable polyurethane foam without pistol, its consumption increases.

How to charge?

First you need to prepare the instrument and the balloon. To prevent foam from getting into the barrel ahead of time, before using the gun, you need to turn the valve clockwise until it stops. Such a measure creates an obstacle for the material to exit from the container. Shake the container with foam before use. To do this, it is necessary to perform reciprocating movements, holding the balloon with the lid up. The actions are repeated for 15-30 seconds.

Remove the cap from the balloon. To install the container, you need to lift the gun ring. The next step is to dock the balloon and the fastener. At the last stage, the ring is lowered. When the control valve is turned 1/2 (direction of movement - counterclockwise), foam will enter the barrel. Using a gun for spraying polyurethane foam, regulate the intensity of its release from the cylinder. In this case, the valve turns in the desired direction.

How to work?

At the stage of connection to the gun, the cylinder is placed from below. However, when using the foam, the container should be at the top of the tool. Another condition is that the balloon is located strictly vertically. This ensures an intensive squeezing out of the material under gas pressure. If the container is located at the bottom of the barrel, the gaseous substance will come out when the trigger mechanism is used. The material will remain inside.

How to remove?

After completing the work, you must first turn the valve clockwise. This will shut off the foam. It is not recommended to disconnect the container. You can keep the cylinder connected to the tool until the material is used up. However, sometimes it is necessary to remove the container. This is done after the valve is turned all the way. In this case, it is recommended to immediately clean the tool barrel. Flushing after the material has solidified becomes much more difficult.

Application rules

If it becomes necessary to use the composition at a low temperature, it must be pre-warmed, optimally up to + 5-10 degrees. There is a special foam that can be used in a variety of climates. The gun should also be warmed up to 20 degrees. The temperature of the surface to be processed can range from -5 to +30 degrees.

Polyurethane foam is toxic, therefore, if work is planned to be carried out inside the building, it is recommended to carry out ventilation. Gloves and face shield should be used to avoid allergic reactions.

Before work, the foam canister must be secured in the gun adapter and shaken well. When the trigger is pulled, the composition begins to flow. You should wait for its consistency to return to normal.

The foam itself must be applied from top to bottom or from left to right. The material should flow evenly. After that, it must be dried. When the foam hardens, the thickness of its layer should not exceed 3 centimeters.

Tools of this brand are characterized by durability and resistance to mechanical stress. They can have a Teflon layer and a lightweight body and are completely sealed. It is possible to adjust the foam consumption using a lock.

The elements of the all-metal movement are made of stainless steel. The gun does not cause problems during assembly, maintenance and repair, it is simple and convenient to use. Also an undoubted advantage is the affordable price of the models of this manufacturer.

In addition to polyurethane foam guns, pistols for sealants are produced under the Zubr brand. With their help, work is carried out with silicone. The design is a frame, handle and trigger.

Among other models, attention should be paid to the Zubr multifunctional pistols, which are designed to work with both sealant and polyurethane foam. For a comparison of polyurethane foam guns, see the following video

For a comparison of polyurethane foam guns, see the following video.

Varieties of pistols

By design, various models practically do not differ: they contain the same elements, the principle of operation is the same in each of the cases. However, when choosing a gun, one should take into account the type of material from which the main components are made. Available options:

- plastic tool;

- metal;

- combined.

The products of the first group are simple, such devices can be purchased at an affordable price. This type of tool has a disadvantage - low strength. The material cannot withstand the constant exposure to intense pressure, which leads to breakage. In addition, the plastic tool cannot be disassembled. Some manufacturers include removable barrels with such devices. Even if the polyurethane foam dries up inside the pistol, they continue to use it, since only the feeding part changes.

Metal tools are much more expensive. They are durable. The inner surface is smooth for easy cleaning. This feature makes the gun suitable for multiple use. In order to be able to clean and repair the instrument, collapsible models should be considered.

Views

Pistols of this brand can be used both in professional and in household activities. Depending on this, they are subdivided into types.

In professional works such models of instruments as "Professional", "Expert", "Standard" and "Drummer" are used. These types of pistols are completely sealed, they are connected to the cylinders through which the composition is supplied.

Model "Professional" is made of metal, has a one-piece construction and Teflon coating. The barrel is made of stainless steel. The clamp allows you to accurately calculate the amount of the supplied composition.

In everyday life such models of pistols as "Master", "Assembler" and "Buran" are used. They have a plastic nozzle, but they do not provide a material feed lock. This is not very convenient, since it is not possible to dose the material receipt, as is the case with professional counterparts. In addition, with the use of a plastic nozzle, the foam sets much faster and is not completely consumed.

How to choose?

First you need to consider that tools made of metal are more reliable and durable than their plastic counterparts. Therefore, first of all, you need to decide how important these characteristics are. Whether the gun is really metal can be checked with a conventional magnet. Teflon coating will become an indisputable advantage of the product.

You also need to pay attention to the convenience of the model and its warranty period. Pistols can be tested and disassembled before purchasing

The important points are the weight of the product, how smoothly the trigger moves, what the needle is made of, and whether the inner surface of the barrel is properly processed. Naturally, the product should not be damaged or defective.

You also need to decide whether you need a solid or collapsible pistol model. Collapsible tools have their advantages. They are easier to maintain and repair, if necessary, and it becomes much more convenient to clean the remains of the product.

Cleaning is done with a special cleaning liquid.

Cleaning is carried out as follows. The cleaning agent is attached to the adapter, after which the barrel is completely filled with the composition. The liquid is left inside for 2-3 days, after which it is removed.

Rating of the top 8 best pistols

Before buying, take into account not only the type of material, the ability of the product to withstand pressure, but also the brand. Some models are more popular due to their reliability and ease of use.

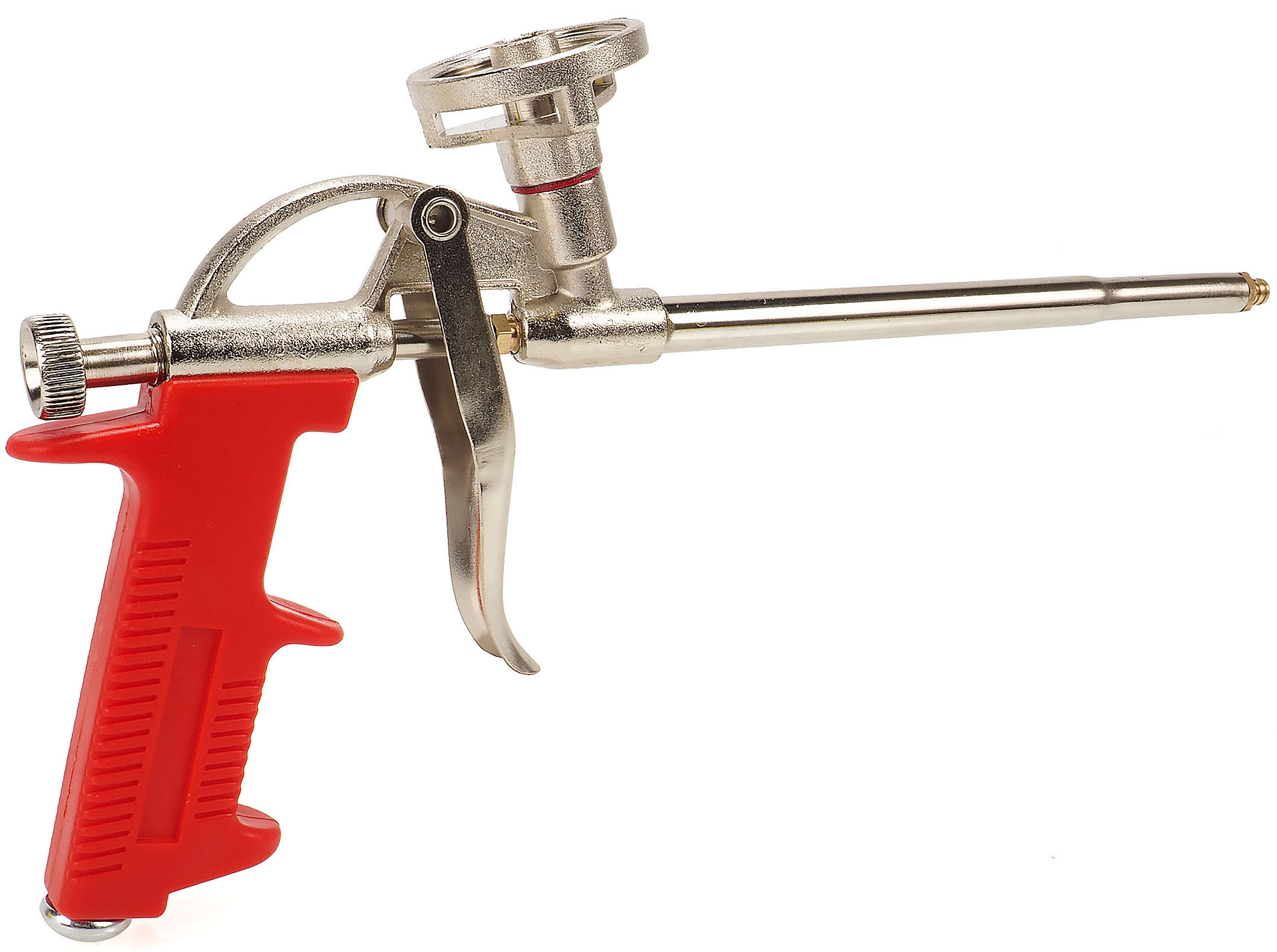

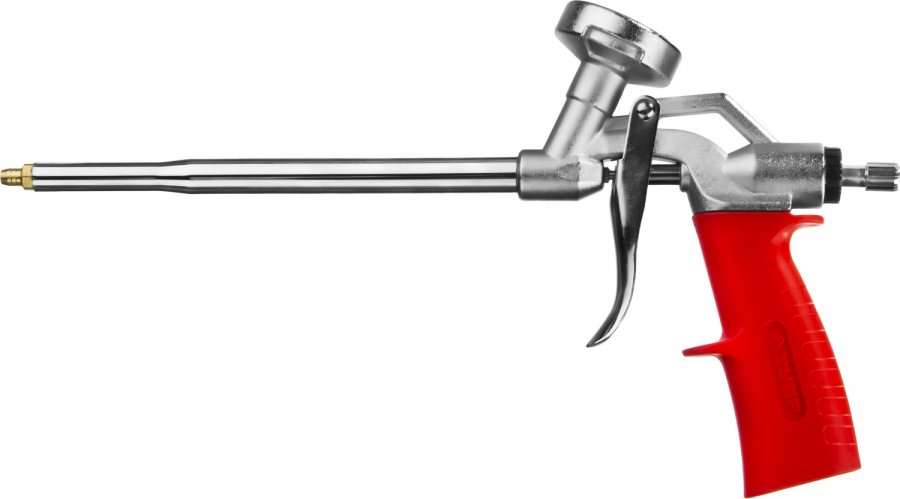

1: Kraftool

The product range includes different models:

- With a Teflon coating, in this case, a needle valve is provided, the main advantage of such devices is easier and faster cleaning. Products can be purchased at different prices, depending on the design features, but they all belong to a combined tool (they consist of metal and plastic parts).

- The all-metal version is durable, withstands significant pressure, is not damaged when dropped, and is more expensive than analogues.

- With brass body and Teflon coating, this model belongs to the high price category.

2: Matrix 88669

The body of the device is made of metal. As a result, the tool can be used for a long period, provided it is properly maintained. The advantage is the presence of a two-layer Teflon coating. This makes it easier to remove foam from surfaces. The protective coating lasts longer due to the fact that 2 layers are applied. It is possible to adjust the foam flow.

3: Hilti CF DS1

This pistol belongs to the high price category. It is distinguished by its reliability, withstands significant loads, and does not clog with frequent replacement of cylinders. The advantages include a streamlined body that is comfortable to hold in your hand.

4: Matequs Super Teflon

These are professional products. The pistol belongs to the devices of a high price category. The advantage is the presence of a long tube of small diameter, a comfortable handle, as well as the ability to quickly dismantle the cylinder. The case is completely disassembled. The construction is covered with polyteflon. Due to the increased diameter of the barrel needle, material consumption is reduced.

5: Stayer Econom

The pistol is a low-price product. The body is made of plastic. The handle is rubberized for ease of use. This is a lightweight tool, making it easy to work with, the hand does not get tired. Given the simplicity and compact dimensions of the structure, it should not be used for regular filling of cracks with polyurethane foam.

6: Atoll G 116

This model is much cheaper than analogs. Despite the low cost, the device is positioned by the manufacturer as a professional one. The advantages include having a needle in the barrel. The body is made of metal. However, there is no protective coating, which makes it difficult to clean the structural elements.

7: Blast Extra Light

The products of this brand are inexpensive. The tool has an original design. Combined design: parts are made of plastic and metal. The advantages include the low weight of the product.

8: P I T

The gun is designed to work with professional polyurethane foam. It can be used to fill gaps of various thicknesses. For this, the kit includes a plastic nozzle. It further increases the length of the tool barrel. Products of this type belong to the low price category. The design of the tool is simple. Low weight is considered an advantage.

Scope of use

This tool can be used at various stages of construction, renovation and finishing work. It is an irreplaceable assistant in the installation of windows and doors, helps to insulate the roof, door and window openings. When installing plumbing, air conditioning and heating systems, it does an excellent job of sealing them. In addition, it does an excellent job of heat and sound insulation.

With the help of Zubr pistols, it is easier and more convenient to fill seams and cracks.It becomes possible to easily fix tiles of light weight on the surface. Also, these foam assembly guns are actively used in the repair of various structures.