The importance of elimination

Modern material is not afraid of water, acids of various origins, alkali and solutions of chemical salts. For the production of products, such resistance to external influences is only on hand, but it can threaten a catastrophe in the environment.

Waste from polyethylene is very dangerous. The substance is subject to thermal aging and slow decomposition under the influence of heat, sun and air. During this period, the material begins to emit corrosive substances that pollute wastewater and soil.

Every year the number of organizations whose activities are related to the processing of hazardous waste is growing. This is due not only to the deterioration of the atmosphere. Recycling hazardous substances into secondary raw materials is considered a lucrative business.

Used film and polyethylene can be used to create raw materials for:

- Garbage bins.

- Panels.

- Household and industrial containers.

Despite the emergence of new recycling technologies, the production of goods from such raw materials has limitations.

Despite the emergence of new recycling technologies, the production of goods from such raw materials has limitations.

The recycling of polyethylene waste itself is not difficult. The materials used in everyday life remain unchanged, since their use does not last long, and the service life for industrial use is much longer.

The impact on polyethylene under such conditions is large. The sun's rays and constant temperature fluctuations have a strong effect on the material. Dust generated during operation cannot be removed. The processed raw materials are not famous for their high quality, therefore they are not suitable for production in any area.

Window treatments

In order to make a high-quality window during the production process, a metal-plastic profile is required. It can be obtained from PVC waste. When the bindings are made, scrap is formed. The profile is adjusted in size, in the area of the joints it is done at an acute angle, which contributes to an increase in the percentage of residues.

In order to make a high-quality window during the production process, a metal-plastic profile is required. It can be obtained from PVC waste. When the bindings are made, scrap is formed. The profile is adjusted in size, in the area of the joints it is done at an acute angle, which contributes to an increase in the percentage of residues.

The properties of the recycled plastic are no different from those of the original product. According to experts, processing is allowed up to 5 times. The most valuable are the wastes of the window profile, not contaminated with foreign inclusions.

For a number of reasons, PVC is rarely recycled in the Russian Federation. Most often it is taken to special landfills and landfills. But recyclable materials are a cost effective option. Any costs for this process will pay off quickly enough.

Film recycling

Film made from PVC is often used in the production of packaging material. Of all the plastic products existing today, about 40% falls on its share. PVC film is safe and comfortable to use. It is formed in large quantities when repair and construction work is carried out. It is irreplaceable when installing a stretch ceiling.

Film made from PVC is often used in the production of packaging material. Of all the plastic products existing today, about 40% falls on its share. PVC film is safe and comfortable to use. It is formed in large quantities when repair and construction work is carried out. It is irreplaceable when installing a stretch ceiling.

In modern conditions, PVC film waste is usually simply taken to the landfill, but it will be much more economical to recycle it. This material can be used to make packaging materials, containers. Compared to other types of disposal, this option is less expensive. In our country, there are laws that allow the use of products obtained after the processing of primary material. We must not forget that such an approach to business reduces the negative impact on the natural environment.

Waste handling

To recycle PVC, technological operations are followed in a certain sequence. The first step is crushing them.After that, the material is washed and followed in a further cycle. Mechanical processing is practiced.

To recycle PVC, technological operations are followed in a certain sequence. The first step is crushing them.After that, the material is washed and followed in a further cycle. Mechanical processing is practiced.

There is also a chemical method. The first option consists in grinding the raw material to the state of granules or powder. From them, new products are created in the future. In comparison with other types of polymers, secondary polyvinyl chloride retains all its basic properties. At the same time, the mechanical method does not allow the removal of toxic compounds. Here you cannot do without the use of special additives.

The chemical method is used as an adjunct to the mechanical one. This processing is sensitive to any kind of dirt and is only applicable to quality material. At the same time, this method has the main advantage of the ability to remove toxins that contribute to the formation of harmful fumes. Heat treatment can be distinguished into a separate branch. It is divided into several subtypes, including pyrolysis, hydrogenation and gasification.

Domestic and foreign experience in PVC processing

Unfortunately, Russia does not yet have an effective system for the collection and processing of PVC waste. And although specialized collection points have already appeared in many large cities where you can hand over such garbage, enterprises that process it are still deprived of proper government support. Another obstacle to recycling PVC waste is the lack of mandatory labeling on products and materials containing PVC.

Abroad, recycling of many types of waste is widespread and has strong government support. In most developed countries, municipal authorities are responsible for the disposal of municipal waste (including not only household waste, but also industrial waste).

That is why, for our country, one of the primary tasks is to create a full-fledged waste management system, which is based on the selective disposal of various types of plastics in cost-effective and safe ways. This will help reduce the amount of environmentally harmful waste at landfills and return a significant portion of recyclable PVC into circulation.

Where can I take the film?

Such a great popularity of plastic wrap has led to the fact that quite a lot of objects made of this material are collected in garbage cans every day.

Polyethylene foam is collected everywhere. These are not only film products, but also household and industrial containers.

Canisters, bottles, vials - all of this is widely used by humans in everyday life. LDPE, PVC and HDPE products are thrown into waste containers every day. Of the total volume of garbage produced by humans, the share of such waste is 10%.

Among the waste is also a manufacturing defect, and its about 10% of manufactured products.

Why has polyethylene become so popular? First of all, it is inexpensive. In addition, such packaging is very convenient, easy to use, and suitable for storing substances of various types.

But, the polyethylene film has one significant drawback - a long disintegration period. According to scientists, such a product completely decomposes in the natural environment only within 100, or even 200 years. This suggests that if you do not recycle such garbage, then humanity may soon drown in the mountains of plastic.

Most of the film ends up in our trash cans, then into the collection containers. As a result, it does not end up in specially prepared processing plants. As a result, environmental pollution

It is very important to separate the plastic from such a pile of debris, and then clean it

The best option is considered to be preliminary sorting even at the moment when the waste tank is just filling. That is, a person is offered to immediately throw paper, glass and plastic into separate containers.This solution greatly simplifies the process of subsequent waste disposal.

If the penalty system worked for incorrect sorting of garbage, then the residents would not be lazy - and sort the garbage as it should be. And so, in containers, where there should be a polyethylene film, and other plastic. More often other, unsuitable waste is found.

You can hand over PET to enterprises that are specifically engaged in the processing of such waste.

And also on the territory of the country there are points where recyclable materials are collected. They accept not only plastic, but also metal and paper. Of course, you can't make a lot of money on this, but you can make your own contribution to protecting the environment, thereby saving not only nature, but also birds and animals, which also suffer from human waste.

Waste types

What is polyethylene? It is a product that is obtained from the polymerization of ethylene.

It is worth saying that this substance does not occur in nature, it is created artificially by man.

For polymerization, it is necessary to break one of the bonds in the molecule and connect the monomer into a non-cyclic chain. The substance is influenced by pressure, temperature and catalyst. I am synthesizing several types of polyethylene.

LDPE

We are talking about high pressure polyethylene. It is a completely transparent material with good elasticity but low tensile strength.

If you look at a molecule, you will find that it has many branches. For this reason, it is impossible to create a crystalline structure, and the substance passes into a liquid state at a temperature of 103 ° C.

These are the so-called packaging materials in the form of films, bags.

HDPE

This is low pressure polyethylene. If you compare it with the previous version, then it is stronger, noticeably tougher. The threads have a structure, and there are not many branches.

Even at room temperature, the material is in a crystalline state. Melts at 125 ° C.

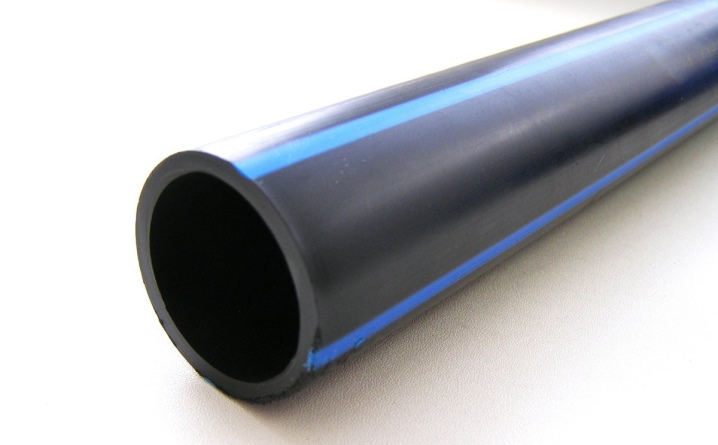

This polyethylene is used to make garbage bags, containers for solvents and oils, and pipes.

PSD

Medium pressure substance has the same benefits as HDPE. Bags, containers with thick walls and even a film are made from it.

LPVD

It stands for "linear high pressure polyethylene".

Quite soft material with good elasticity. One of the advantages is tear resistance. Can be painted.

They make a laminate, stretch film from it.

PEX

The material has recently appeared on the market. It is a product of additional processing of HDPE. It stands for cross-linked polyethylene.

To obtain, reagents and ionizing radiation are used. As a result, hydrogen atoms are split off from the polymer chain.

This is how a three-dimensional network is formed, which has a well-defined structure.

Insulation for cables, pipes are made of PEX-polyethylene.

Methods for processing polyethylene waste in Russia

Waste films retain their original technological conditions, therefore they are valuable as a raw material for reuse.

What is being recycled

On the Russian market of secondary raw materials, industrial and consumer waste LDPE and HDPE are considered suitable for processing.

Most of the production waste is clean, homogeneous, and the least hassle with them.

Raw materials are processed in two ways:

- from shops, businesses, other commercial sources;

- from consumer waste.

Waste stretch film is collected separately.

Processing problems

A headache for recyclers is consumer waste. They always get dirty when they come into contact with the "filling" (usually food). In addition, such waste often has printed or colored LDPE films.

Household waste films

Household waste films

Pollution is classified as internal and surface. For example, HDPE waste in the form of packaging of halva, butter, meat, and other products. Crumbs, grains, traces of fat remain on the surface.Part is absorbed by the packaging. Even if the material has gone through all the washing steps, an odor may remain after processing. And stubborn residues can change the properties of the new film.

Surface contamination is removed at the sink. Here the material is scrupulously processed with water under pressure (friction washers). A dry cleaning method is used, but even advanced equipment is ineffective against sticky contaminants.

Waste film recycling technology

The most widespread method of recycling polyethylene waste in Russia and the world is mechanical recycling.

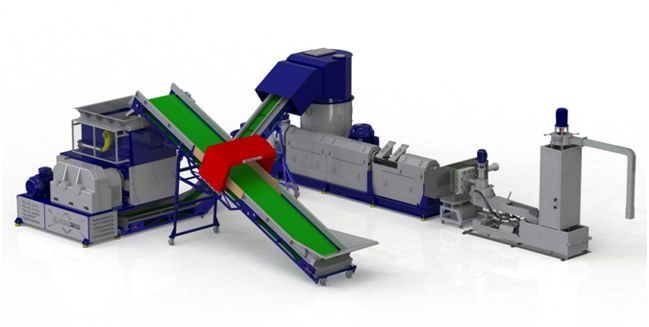

Household waste processing equipment

Household waste processing equipment

It consists of the following steps:

- Coarse sorting of waste. There is a division (usually manually) by type, color, shape, size of plastic.

- Pre-wash. Raw materials are washed from external dirt, foreign components are removed.

- Shredding. Its degree depends on the characteristics of future products. Knife crushers transform the raw material into an amorphous mass with particles of 0.25-0.95 cm. The cryogenic method is considered to be an innovative one. As a result of freezing, a crumb of 0.06 - 0.19 cm is obtained.

- Separation of the mixture. Vibrating screens are used, other methods are used, the most popular is flotation. The polymer mixture is poured with water with the addition of caustic soda, due to which heavy impurities are separated.

- Final wash. The crushed film is fed into the continuous washing apparatus, where it is finally freed from dust and dirt.

- Drying. The primary drying of raw materials takes place in a centrifuge, the final (up to 0.25%) - in a drying unit.

- Agglomeration (granulation). The prepared raw material is sent to the granulator. Here it is melted, compacted, mixed with additives or impurities. Homogenization takes place, creating conditions for obtaining a regranulate of a given recipe.

- Final product. Granules suitable for the production of new products or materials according to the specified parameters. They are obtained by feeding the molten homogenized mixture to a screw extruder.

The combination of processes depends on the condition of the feedstock and the type of equipment. So, grinding can include one or two stages, relatively clean raw materials (not from garbage) go through one wash.

Waste PET film is sorted, crushed into flakes (flex), washed. The paper stickers are removed in a centrifuge. Wash, dry, pack again. Sometimes granulation is used.

Disposal

Recycling of polymers includes various methods that differ not only in the technological process, but also in the degree of environmental safety and profitability. Let's list the main methods.

Burial. Until now, this method of waste disposal is the most popular. Assumes the use of large land areas. Plastic waste does not lend itself to biodegradation, because of this, more and more areas allocated for burial are required. The implementation of this method has an extremely negative effect on the state of the environment.

Burning. It does not require sorting of raw materials and does not involve huge territories. However, during the combustion of polymers, toxic gases are released into the atmosphere, which make their significant "contribution" to the formation of the greenhouse effect and the formation of ozone holes. To minimize such phenomena, expensive types of equipment for the purification of combustion products can be introduced, but in this case, disposal by incineration is most likely to be unprofitable.

Pyrolysis. The process of decomposition of polymer compounds is carried out under conditions of high temperature and lack of oxygen. Pyrolysis of plastic results in gaseous, liquid and solid products. The former are used, for example, for heating. The resulting liquid components can be used to obtain heat transfer fluids, while solid components can be used at enterprises producing protective lubricants, emulsions, impregnating compounds, etc.

Cleavage of polymers to produce lower molecular weight products.The process of decomposition of polymer molecules is carried out at high temperatures and pressures, as well as in the presence of various compounds: water and catalysts (hydrolysis), glycols, methyl alcohol (methanolysis), etc.

Recycling of polymers. The most modern and rational method implemented in a number of developed countries. The technology and processing of polymer waste involves the use of different methods.

What products can be recycled?

Not every type of polymer waste can be recycled. Only those synthetic thermoplastic materials that change shape when exposed to high temperatures can be recycled.

It makes sense to collect and prepare the following types of waste for recycling:

- Used polymer products. This type includes household waste - plastic bottles, disposable dishes, worn-out window profiles, etc. The complexity of working with such materials is associated with their contamination. A lot of effort and resources is spent on sorting and cleaning them.

- Materials that remain after the manufacture of plastic products. Basically, this group includes line segments. From this group, 90% of the total volume of waste is subject to recycling. It is pure and high quality material.

Types of secondary raw materials

- Waste paper - paper, cardboard, newspapers, textiles, tetrapak

- Glass - glass containers, cullet

- Scrap metal - black, non-ferrous, precious

- Chemicals - acids, alkalis, organics

- Petroleum products - oils, bitumen, asphalt

- Electronics - products, boards, batteries, mercury lamps, wire

- Plastics - PET, PVC, LDPE, HDPE

- Rubber - tires, rubber

- Biological - food waste, fats, sewage

- Wood - twigs, shavings, leaves

- Construction - brick, concrete

- Wastewater

The most common recycling on one scale or another is for materials such as glass, paper, aluminum, asphalt, iron, textiles, and various types of plastics. There is a corresponding processing technology for each type of raw material. To separate waste into different materials, various types of separation are used, for example, for metal extraction - magnetic.

But then the same waste in some cases should act as a secondary raw material, in others - only in the form of an initial product or material for the production of secondary raw materials. For example, for some purposes, worn-out tires can be used without preliminary preparation - say, for use as heating oil in cement kilns, in others - they need to be crushed into crumb and obtained from it a regenerate, in particular, for use in the production of rubber products ... Pieces of textile fabrics can be used in some cases without preparation, in others they require their preliminary razvlechenie with subsequent production of new textile materials from them. Obsolete electronic equipment and products of the electrical industry undergo preliminary disassembly with the release of ferrous and non-ferrous metals, wood and polymer fragments.

Recycling polyethylene into granules

A highly efficient business is secondary processing of polyethylene into granules, since this task meets the interests of society associated with the disposal of a colossal amount of polyethylene waste, and at the same time satisfies the need of manufacturers in granular polyethylene.

This project provides for work only with transparent HDPE films, since narrow specialization significantly increases the efficiency of the enterprise.

The delivery will be transparent granules of the first grade, the production profitability of which is much higher, and the demand for them is greater than for the products of recycled colored polyethylene.

The technology used for the processing of polyethylene into pellets is very typical for the processing of plastics and many other materials.

The raw material is crushed, after which dirt and foreign elements are removed from it with the help of a washing machine. After removal of water in a centrifuge and complete drying, the raw mass passes through the compacting agglomerator and enters the granulation operation, which completes the technological process of recycling polyethylene into granules.

The scale of production envisaged by the project does not require gigantic multi-ton installations, for the placement of which specialized buildings and powerful foundations are required. There is no need for a branch line and access roads, power substations and provision of industrial sewage.

For the proposed production, an ordinary workshop with premises for storing raw materials and finished products is quite suitable.

The required volume of storage facilities can be estimated based on the fact that the productivity of the equipment planned for the purchase is 250 kilograms of pellets per hour, and the processing ratio of raw materials is close to 100 percent.

With two-shift work, the production capacity is about 75 tons of products per month.

To launch the project, an investment of 4.5 million rubles is required.

The payback period of the project does not exceed 6 months. The expected monthly profit is 1.4 million rubles.

The investor is offered 50 percent of the profit received.

Currently, there is an agreement with large sorting companies, which are ready to supply up to 120 tons of film waste per month, which will be used as raw materials. At the same time, two enterprises near Moscow have already expressed their readiness to purchase the entire produced volume of pellets at an agreed price.

The production is planned to open on the territory of the Moscow region near the settlement of Podolsk, where a suitable production facility has already been selected, which has all the necessary communications and the required electrical power.

Domodedovskoe highway passes in the immediate vicinity of the production facility, which simplifies the logistics of raw materials and manufactured products.

The initiator of the project is the Russian businessman G.M. Golota.

Georgy Mikhailovich is a graduate of All Saints' College in the Australian state of Western Australia and has a diploma from the International Institute of Management MGIMO (U) of the Ministry of Foreign Affairs of the Russian Federation.

Georgy Mikhailovich Golota is an excellent organizer and has extensive experience in entrepreneurial activity. He developed a detailed business plan for this project, which includes a full detailing of all costs, a list of necessary equipment, contacts with potential suppliers of raw materials and buyers of manufactured products.

- We recommend reading:

- Highly profitable wood pellet production

- A patent has been issued for an engine that cannot be

- Successful businesswoman Marina Bogacheva, who started her business from scratch

Processing

Most plastic recycling plants operate on the same principle. Let's consider the stages of the process in more detail.

Note! Not all types of polymers are suitable for recycling. The enterprises process thermoplastic synthetic materials, among which the most common are polyethylene, PP, PVC, PS and ABS plastic

Processing technology

On the way of obtaining raw materials from polymer waste for different areas of production, they carry out:

- Waste pre-sorting. Polymers are roughly classified according to the type of plastic, its color, shape and size. Typically, this processing step is done manually. Foreign components are removed from the polymer mass.

- Shredding. An extremely important stage. The characteristics of the resulting product are determined by the degree of grinding. Knife crushers crush polymers into a loose mass with a particle size of 0.2-0.9 cm.The cryogenic grinding method is an innovative one, which ensures the production of polymer chips with a diameter of only 0.05 - 0.2 cm.

- Separation of a mixture of polymers. Various methods are used here, the most popular of which is flotation: surfactants are added to water with a plastic mixture, which provide a change in the hydrophilic properties of polymer materials.

- Washing and drying. The crushed mass is washed with special detergents in industrial washing machines. With the help of a centrifuge, primary drying of raw materials is carried out, bringing its moisture content to 10-15%. Final drying (up to 0.2% moisture) is carried out in a drying unit.

- Granulation. The prepared raw materials are compacted in the granulator, which facilitates the subsequent processing of the material and ensures the homogenization of its characteristics. The final product is granules suitable for the production of new products and materials.

Equipment

The complex of equipment for processing polymers (into granules) consists of:

- washing lines;

- crushers;

- extruders;

- belt conveyors;

- shredders;

- agglomerators and granulators;

- mixers and dispensers.

All of these types of equipment can be purchased separately. It is also possible to purchase a complete line for the processing of polymer waste into granules.

Where to hand over for processing

Acceptance of polymers is carried out at special points that are in all major cities. Also, to hand over plastic waste, you can directly contact specialized companies (their addresses can be easily found on the Internet). "Suppliers" of polymers can be both individuals and organizations, and it is possible to get a good amount of money for the delivery of recyclable materials. Among other things, in our country, separate waste collection is beginning to be practiced, which means that plastic products must be thrown into a special container with the appropriate marking.

How the process of obtaining granules from plastic waste is carried out at one of the enterprises, and the importance of processing polymer materials, are described in this video.

Processing of polymers is not a "hackneyed topic" in our country. This is a free business niche, the opening of which will not only have a positive effect on the state of the environment, but will also bring profit to the businessman. Recycling plastics is considered a cost-effective business, but government support is needed to successfully launch it.

Types of plastics that can be recycled?

Thirty years ago, a uniform labeling for plastic products was adopted. If you have a plastic container handy, look at the badges printed on the bottom of the container.

Thirty years ago, a uniform labeling for plastic products was adopted. If you have a plastic container handy, look at the badges printed on the bottom of the container.

First, there will be a triangle symbol. Under it there may be an alphabetic code of the type of plastic, and inside there is a marking of plastic for processing, a number indicating what type of plastic the container is made of:

- PET (PETE) or PET (PET) - polyethylene terephthalate. Bottles and most food containers are made from it. We recommend reading an interesting article about PET waste.

- PEHD (HDPE) or LDPE, LDPE - high density polyethylene. Used for more rigid containers. Safe for food storage. We also recommend reading about LDPE waste.

- PVC or PVC - polyvinyl chloride. Most containers are made of it that are not intended for contact with food, furniture and decorative elements, sewer pipes. Read more about the danger of PVC waste and its disposal here.

- LDPE (PELD) or HDPE - low density polyethylene. It is used to make bags, garbage bags, cling film, flexible containers. Contact with food is allowed. We also recommend reading about HDPE waste.

- PP or PP - polypropylene. Used in the manufacture of toys, auto parts, food packaging. Contact with food is allowed. Read more about polypropylene plastic waste here.

- PS or PS - polystyrene. Thermal insulation, disposable dishes, toys, stationery are made of it. Dangerous only when burned.

- O (OTHER) OTHER - This is how plastic products are labeled that do not fit into any of the groups above. Most often it is solid and transparent polycarbonate. It is used for the manufacture of CDs, lenses, goggles, light guide elements for construction. Or it is ABS plastic, which is massively used for the manufacture of plastic parts for cars.

Today all types of plastics can be recycled. Most large cities have collection points from where waste is sent to recycling plants.

Problems can arise when looking for PVC processing plants marked with the number "3" in the triangle and anything that falls into the OTHER category with the number "7". Such enterprises are located mainly in the central regions.

It is important that you cannot burn plastic! Some plastics release toxic substances when they burn.

Features and classification

Polyvinyl chloride can be categorized as a synthetic polymer. It is widely used for the production of household goods and packaging materials. Waste PVC can accumulate in metropolitan areas in large quantities. You can throw them in a garbage dump, but it's much safer and more profitable to send them for recycling. Before embarking on this process, experts must carry out sorting.

There are two key types of it:

- Plastic compound. Material with increased elasticity and softness. Waste PVC compounds are used in the production of linoleum, oilcloth film.

- Viniplast is a material characterized by transparency. It is quite hard, but it lends itself well to processing. It is used for the production of car components, pipes and fittings. It is also the basis for the manufacture of PVC profiles.

It takes more than one hundred years for polyvinyl chloride to decompose in vivo. Throughout this time, the release of toxic components from this material is observed. Substances that adversely affect the environment include:

- Toxic compounds formed from stabilizers and other inclusions used to normalize the physicochemical properties of PVC.

- Chlorine compounds. If this component gets into water and soil, they can pose a direct threat to human health. If you grow plants in such soil or drink water containing these substances, you can achieve a metabolic disorder, a malfunction of the immune system.

- Combustion products. During this process, dioxides are formed and released into the atmospheric air.

PVC structure

There are various sources from which PVC residues can be obtained. These are decorative items that decorate the interior, dishes, various technological raw materials. Quite often, these are window profiles, PVC cables, foil, pipe fragments.

There are various sources from which PVC residues can be obtained. These are decorative items that decorate the interior, dishes, various technological raw materials. Quite often, these are window profiles, PVC cables, foil, pipe fragments.

The greatest difficulty today is PVC household waste. It is not so easy to pass them successfully today. They can be difficult to recycle if they are mixed with other types of solid waste.

The structure of PVC may differ slightly depending on what it is used for. If this is a profile, then heat stabilizers are most often used. Lead compounds play their role. This is the classic version. Can also include compounds of zinc, calcium. They form non-toxic substances, although this technology is considered more expensive.

Disposal options

In Moscow, there are special firms that, when accepting PVC waste, indicate specifically what requirements are imposed on the raw materials being handed over. You can just send them to a landfill. Also, most cities have special polygons. The so-called pyrolysis is also possible. It is a technology that is used to generate heat energy. It is required to maintain production and household processes. You can send such raw materials to a waste recycling plant.

In Moscow, there are special firms that, when accepting PVC waste, indicate specifically what requirements are imposed on the raw materials being handed over. You can just send them to a landfill. Also, most cities have special polygons. The so-called pyrolysis is also possible. It is a technology that is used to generate heat energy. It is required to maintain production and household processes. You can send such raw materials to a waste recycling plant.

The most progressive option is considered to be recycling using polyvinyl chloride in the creation of new products. It is he who helps to reduce the volume of waste generated by PVC, and allows you to spend a minimum of money on the production process.