Types of ceiling tiles

According to the manufacturing method, extruded, extruded and injection options are distinguished. The latter two are distinguished by their high cost and a wide range of different qualities. Pressed slabs are made from blocks using compression. Their performance characteristics include many restrictions, so the material is used with an emphasis on pricing. There are also design restrictions for use in various interiors. Extruded versions are obtained by pressing the strips. The advantages of raw materials are expressed in durability, structure perfection. Extruded tiles are also used to imitate natural materials: their colors and textures. Injection moldings are manufactured at high temperatures, which provides additional processing options. The surface layer is clear thanks to the special manufacturing shapes.

Pressed

It is obtained by stamping (pressing), which is why it got its name. Pressed tiles are made from a base in the form of expanded polystyrene blocks. The press compresses the raw material to a thickness of 6-8 mm. The quality of the products is not the highest, but manufacturers compensate for this with a low price. This is the most affordable option among the main ones offered by the market. The surface has a porous loose texture, which is bad for performance. Contamination must be wiped off immediately, but washing is generally not recommended. In this case, staining with water-based solutions will not interfere. When choosing, they must be guided by a margin of safety, because the plates are relatively fragile and often break. An unpleasant feature is also in the structure of the edges: when cutting, they sometimes crumble. Before facing the ceiling, the slabs are kept in a dry room for 3 days - in order to avoid shrinkage and the appearance of cracks on the finishing layer.

Extruded

The product is made from a polystyrene strip obtained by pressing. The workpiece is painted or laminated. The surface of the material is perfectly flat and without grainy texture. The coating has good density, water and dust repellent properties. Thanks to these features, as well as the lamination, the boards can be washed. The finished material turns out to be more expensive than pressed (stamped), but at the same time it is stronger, and gives greater reliability and hygiene. The shape of the tile has a "memory": the material quickly recovers after deformation. The products are produced in the form of squares, most often with parameters 50 × 50 cm. The edges of the slabs get a perfectly even shape, and the canvas itself is conveniently cut. There is a small cavity on the reverse side - because the ends are slightly bent downward. The feature allows you to hide small defects in the ceiling.

Injection

In production, sintering of polystyrene foam components is used. During the manufacturing process, the correctness of the shape is controlled, and after processing, a clear and deep pattern remains on the finished coating. The method gives a thickness in the range of 9-14 mm, and among all the options for ceiling slabs, injection is the thickest. Ceiling surfaces are ultimately formed without visible seams. Injection finish has sound insulation properties. Moreover, in addition to noisy rooms, it is also suitable for humid ones, since the increased indicators will not spoil the structure. The plates are highly durable and do not burn. They are environmentally friendly. The products are sold in white - this design will be optimal for ceilings, but it will not hurt to add creaminess to the shade.The problem with injection products is their high price: stamped versions, for example, are 3-4 times cheaper.

No. 2. Advantages and disadvantages

Styrofoam ceiling tiles are among the most popular finishing materials. Customers appreciate it for its many benefits:

- affordable price. In this regard, tiles can become a competitor even to conventional painting. The most expensive samples with an exquisite design, which do not allow at first glance to determine what the ceiling is made of, will cost much less than, for example, a system of stretch or suspended ceilings;

- ease of installation. You can cope with gluing ceiling tiles on your own, without any special skills. Given the low price of the material, it can be called an ideal choice if the repair budget is limited;

- big variety. On sale you can find both the simplest white tile with an uncomplicated pattern, and a material that very accurately repeats the structure of a tree or stone, therefore, using ceiling tiles, you can equip any interior. White tiles can be painted in any desired shade;

- additional heat and sound insulation of the room;

- resistance to temperature extremes and high humidity, so the tiles can be used even in the bathroom;

- tiles do not steal height, unlike stretch and false ceilings. Additionally, it hides small irregularities and cracks that would have to be removed during painting;

- expanded polystyrene - although an unnatural material, it does not carry any particular danger. It does not emit harmful substances under normal operating conditions, if, of course, it is made with high quality and has all the safety certificates. The tile becomes dangerous at high temperatures, i.e. during a fire;

- it is easy to take care of the material, it can be cleaned with a vacuum cleaner or a damp sponge;

- high maintainability. If part of the ceiling is damaged, it is easy to replace some of the old elements with new ones, so always take tiles with a margin.

Now about the disadvantages:

low durability and the ability to turn yellow over time, and the process is accelerated if direct sunlight constantly falls on the surface;

the tile is easily damaged by tobacco smoke, grease and soot, therefore, it is not recommended to use it in the kitchen;

constant temperature drops can lead to the falling off of some elements, but this is only if a low-quality glue was chosen for installation;

expanded polystyrene is a rather delicate material, so you should be careful when transporting and installing it;

Styrofoam tiles are not very resistant to fire, and even when impregnated with fire retardants, they can ignite, emitting toxic substances. To play it safe, it is best not to place the lamp very close to the ceiling.

Such precautions, moreover, will prevent yellow spots from the lamp from appearing on the material;

when cleaning the surface, you should be extremely careful - a sponge that is too wet or the use of a coarse brush can cause the tiles to peel off.

Experts are convinced that a truly high-quality ceiling tile, thanks to the additives used, does not turn yellow for a long time and almost does not support combustion. Conscientious manufacturers declare that all the myths that exist among the people are caused by the abundance of low-quality products on the counter, and they advise you to always ask for a certificate of conformity. Sometimes we ourselves are to blame for the fact that the experience of using expanded polystyrene turns out to be negative. It’s not only the choice of low-quality tiles, but also the wrong choice of glue, on which a lot also depends.

Styrofoam ceiling tiles can be used in almost any room. It is undesirable only to glue it in the kitchen, and you can still find other material for the nursery.

Manufacturers and sizes

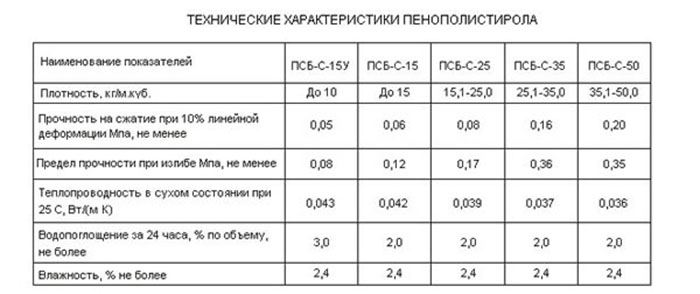

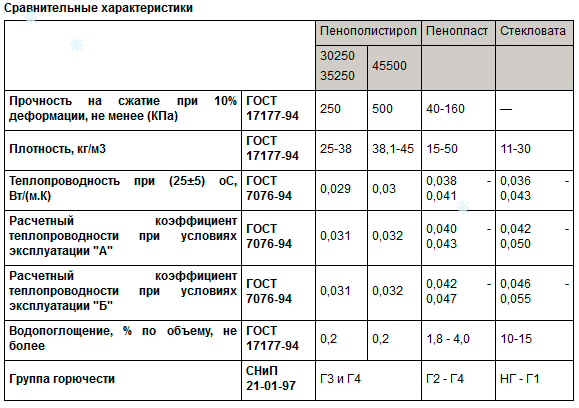

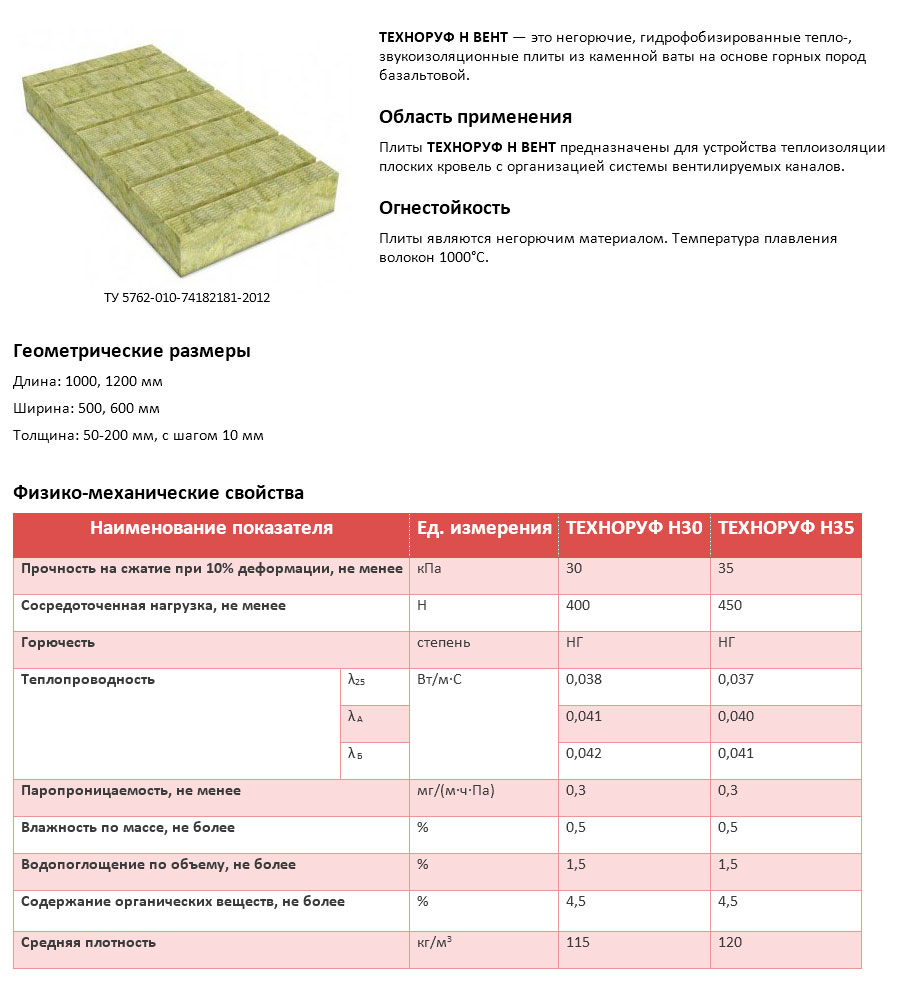

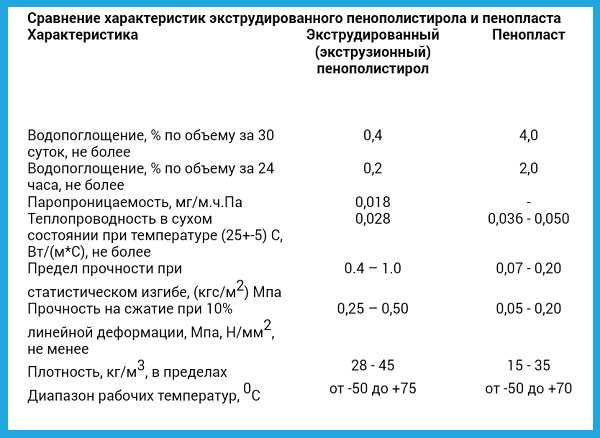

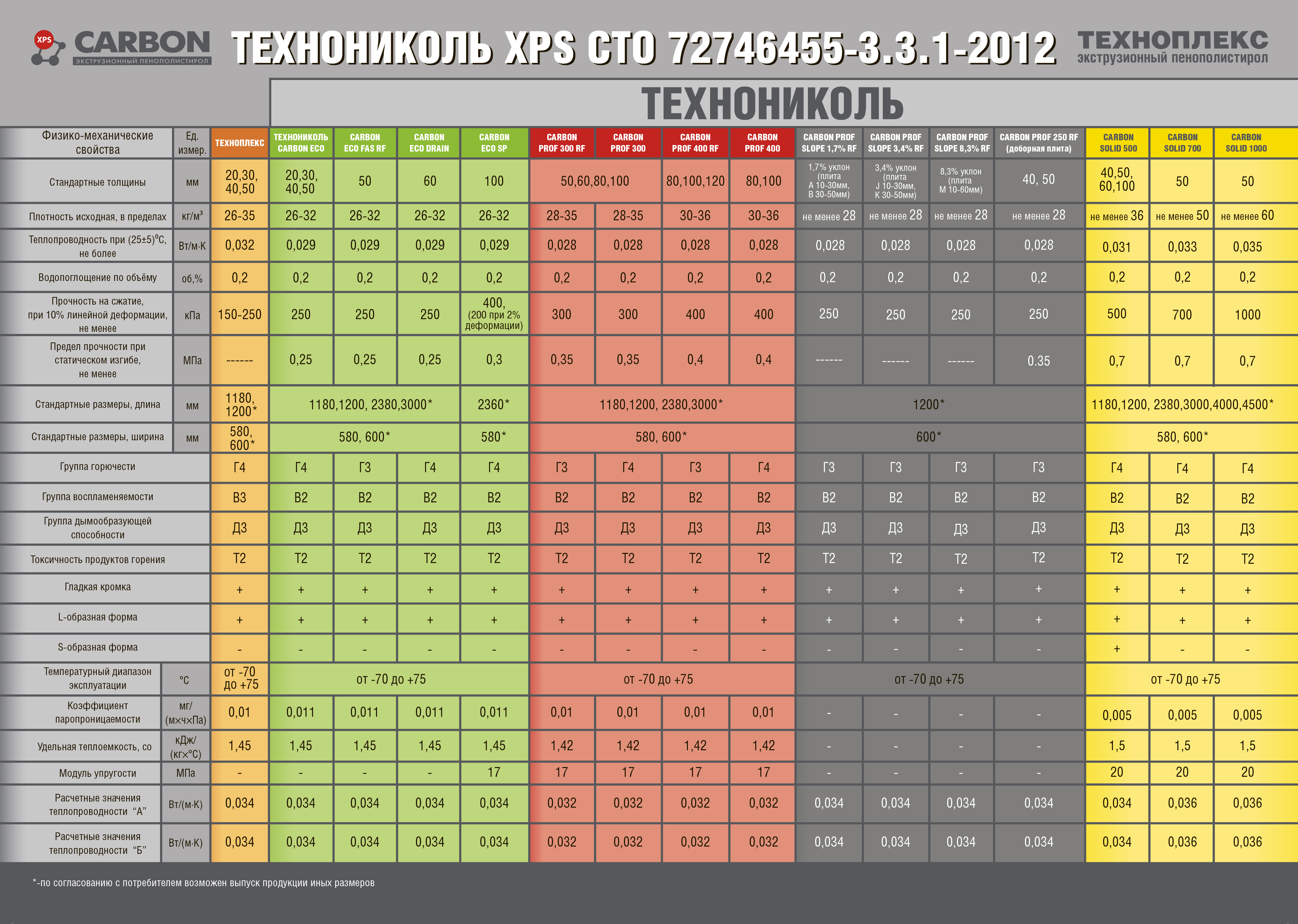

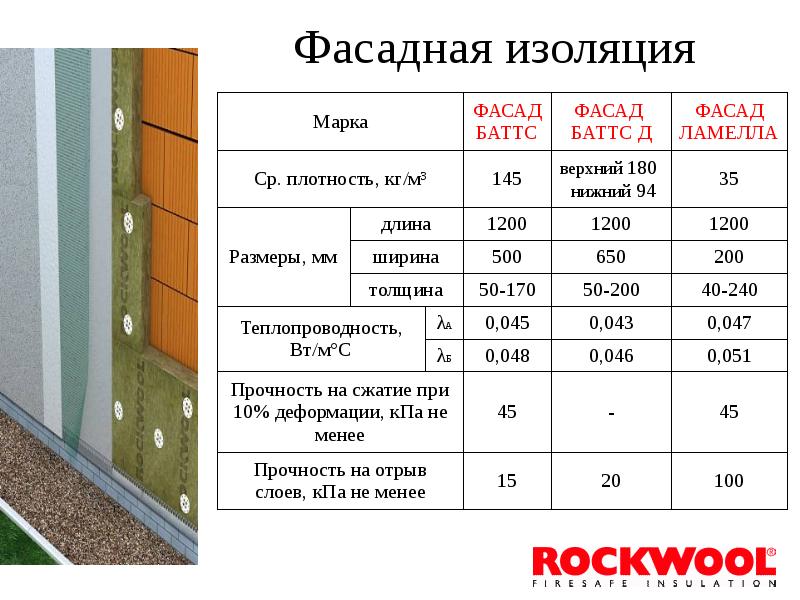

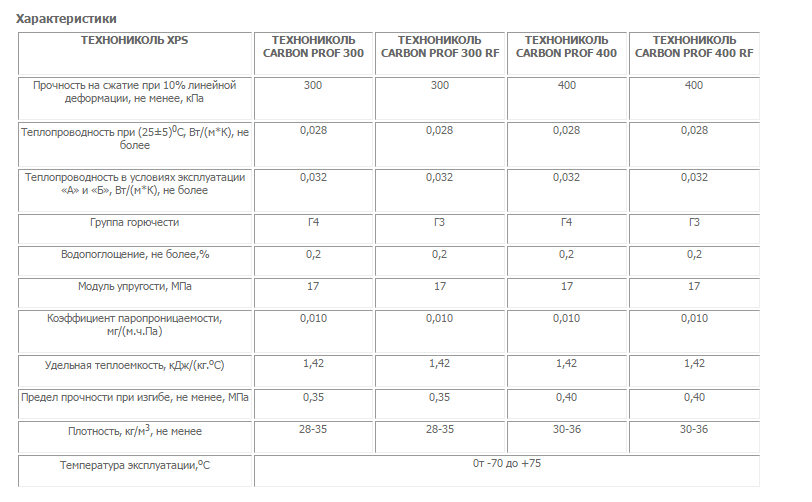

Modern manufacturers produce extruded polystyrene foam with various technical characteristics. Currently, there are three leading brands, whose products are considered the most popular and widespread:

- Penoplex;

- Technoplex;

- Ursa.

Let us consider in detail what characteristics and properties the EPS of these manufacturers have.

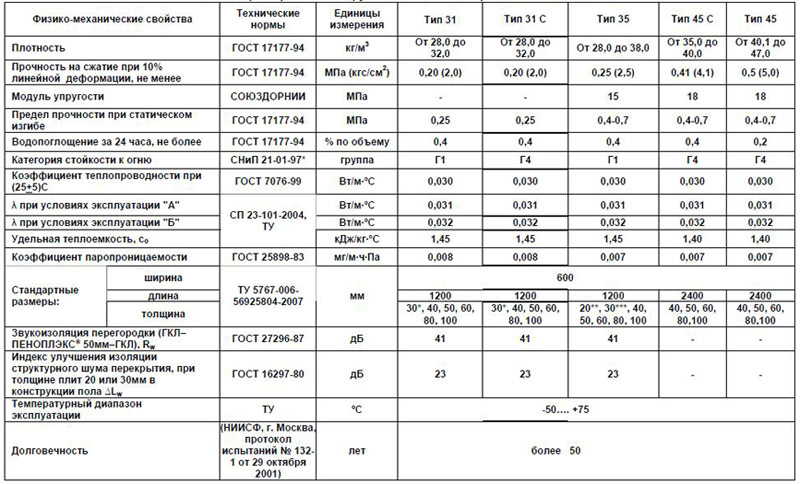

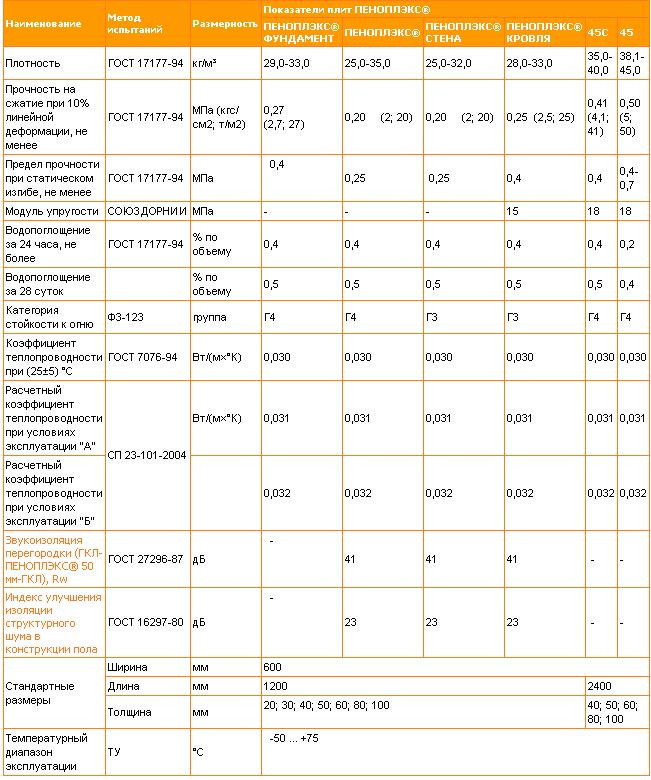

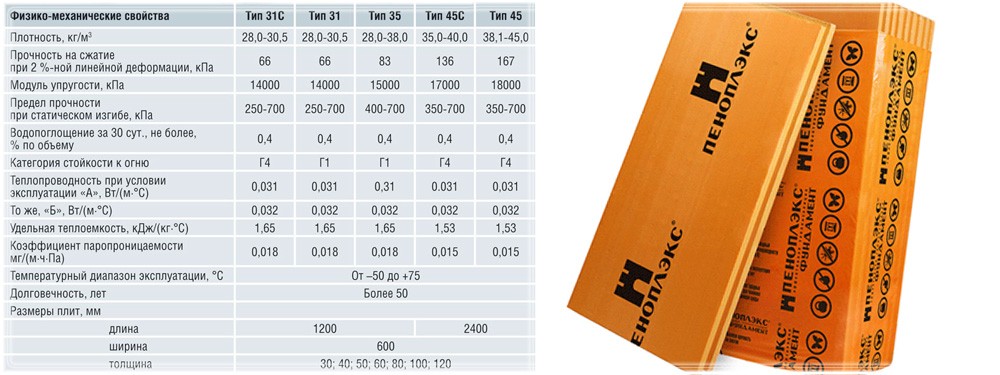

Expanded polystyrene "Penoplex" is a popular domestic product that is found in many stores and is in great demand. Such materials are used for both civil and industrial construction. Let's get acquainted with the main characteristics of polystyrene foam of this company.

- The thickness of EPS "Penopless" can be - 2, 3, 4, 5, 6, 7, 8, 10, 12, 15 cm.

- The dimensions of the sheet are - 60 x 120 cm, 60 x 240 cm.

- The level of thermal conductivity is 0.03–0.032 W / m C.

- Compressive strength is 0.2–0.5 MPa.

- The level of water absorption does not exceed 0.4%.

- The flammability class of the material is G4.

Ursa is a large international company with representative offices in Russia. At the moment, this manufacturer produces three types of extruded polystyrene foam. Ursa materials have the following technical characteristics.

- The thickness of the materials is 3, 4, 5, 6, 8 and 10 cm.

- The length and width of all EPS sheets is the same and is 60 x 125 cm (there are also other dimensions on sale, for example, 50 x 600 x 1250 mm).

- The level of thermal conductivity of EPSP sheets is - 0.032-0.034 W / m C.

- Compressive strength ranges from 0.25 to 0.5 MPa.

- The material absorbs moisture by 0.5%.

- Flammability class G4.

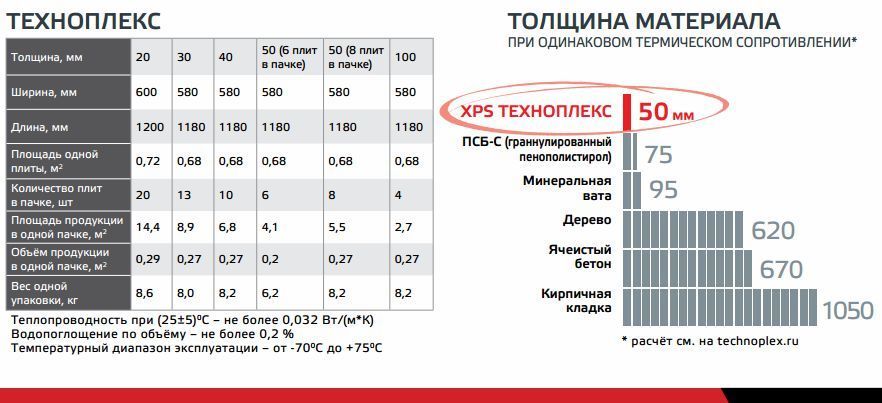

Technoplex produces expanded polystyrene sheets with the following parameters.

- Their thickness can be 3, 4, 5, 10 cm.

- All sheets have standard dimensions - 60 x 120 or 58 x 118 cm.

- They are characterized by a high coefficient of thermal conductivity.

- Materials from "Technoplex" absorb moisture by 0.2% worse than raw materials from "Penoplex".

The products of these brands are in great demand in our country and comply with all GOST standards. High-quality expanded polystyrene of these companies is in demand due to its excellent performance characteristics, long service life and easy installation.

Of course, these are not all large manufacturers whose products are popular today. For example, today the products of KTpleks, Ecotherm, Onda LLC, TechnoNikol (a popular product - XPS) and many others are no less in demand.

Where are EPS boards used?

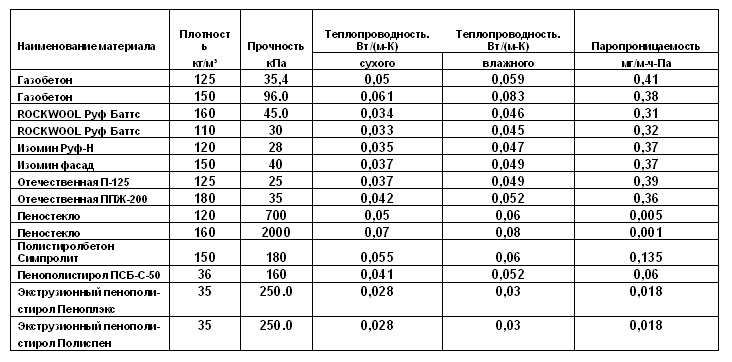

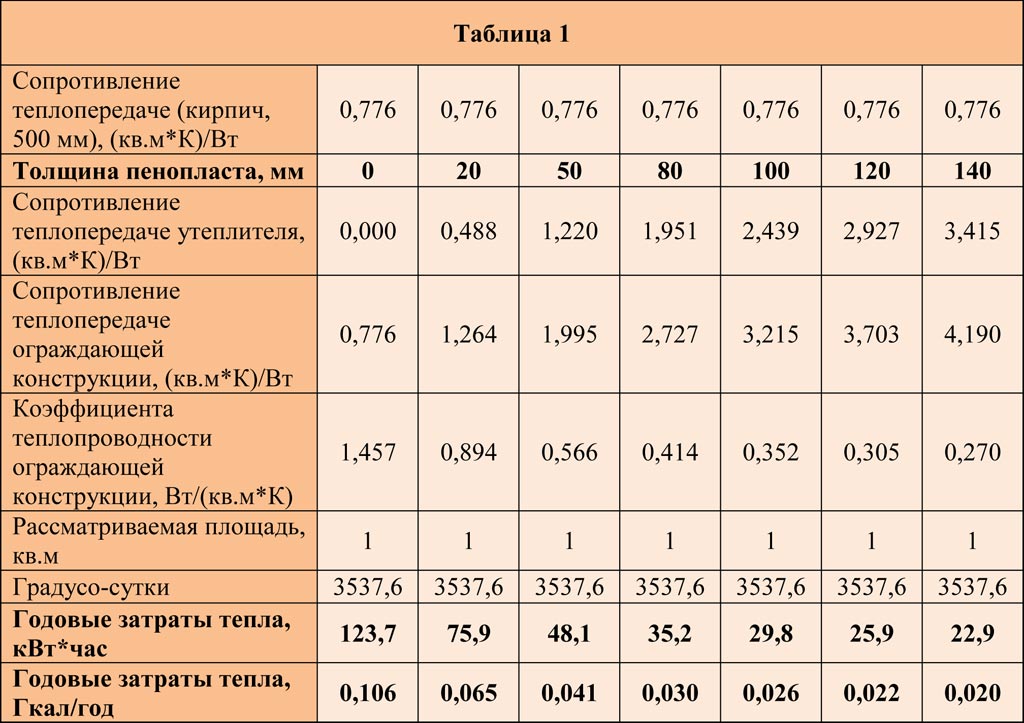

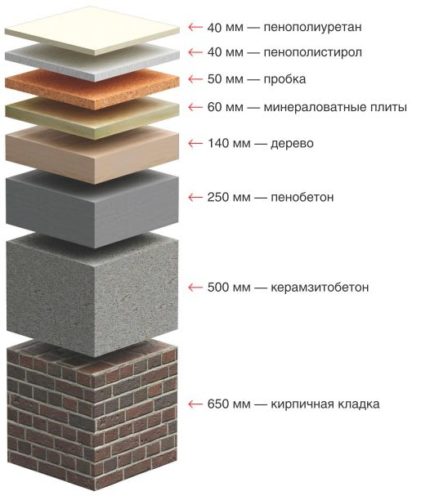

This material is actively used as the main heat insulator in the field of industrial / private construction. The key factor determining the demand for this heat insulator is its rather low cost (much lower than that of the popular mineral wool and other thermal insulation materials). However, do not think that if expanded polystyrene is cheap, then it is less useful - on the contrary, the thermal conductivity of almost all current heaters is approximately the same and is approximately 0.03-0.04 W / micron.

In reality, the difference between the minimum / maximum indicators is almost not noticed, and the difference between polystyrene foam plates and other heat insulators is not at all in efficiency, but in a number of features of the material that will be considered in this article.

In short, after analyzing the key properties of expanded polystyrene, we can conclude about its following undeniable advantages.

- Cost savings. A cubic meter of this material will cost about 2,500 rubles, while the price of the same volume of mineral wool can reach 5,000 or 6,000 rubles. Moreover, when insulating one and the same object, mineral wool will require twice as much as expanded polystyrene.

- Ease and simplicity of installation work. A special adhesive solution is used to install the material plates, making the installation procedure much easier.But, for example, in order to install the same mineral wool, you will need to equip a supporting frame, which is associated with additional time and financial costs.

In general, expanded polystyrene boards are used for thermal insulation:

- building facades (and regardless of what material was used in construction - brick, concrete, gas blocks, etc.);

- basement floors;

- sexual lags (including under the screed, but provided that the density of the material is high enough);

- foundations;

- roofs of any shape;

- loggias, balconies;

- ceilings;

- attics.

What is Styrofoam

In fact, the two concepts of foam and polystyrene foam represent the same material, but produced using different technologies. As a result, both of them acquire differences in technical characteristics. The starting material for both polystyrene and expanded polystyrene are polymers based on:

- polyvinyl chloride;

- polyurethane;

- phenol formaldehyde;

- polystyrene;

- combinations of urea and formaldehyde.

In everyday life, the most common type of foam, called polystyrene, is produced without such a technological stage as pressing. This material was first obtained at the factories of the BASF company in the middle of the last century, where it received the first name "styrofoam" or PSB-1 foam.

Manufacturing technology

Granular styrofoam is produced using pentane, a substance that promotes the formation of tiny pores filled with gas.

Raw materials for the production of foam

Raw materials for the production of foam

At the same time, styrene itself in the total mass of the material contains no more than 2%, the rest is gas. In production, the foam is pure white in color and is extremely light due to the fact that it consists practically of air. And it is precisely this circumstance that became the reason for the use of foam as an insulating material, since there is no better insulation in nature better than air.

The entire production process for obtaining foam includes several operations:

Primary foaming of granular styrene under the influence of hot steam.

Foaming polystyrene

Foaming polystyrene

- Placement of foam in a drying chamber.

- Extract of chilled foamed granules.

- Secondary foaming.

- Cooling the resulting mass.

- Cutting products according to the specified parameters.

Foaming of granules can be performed several times, depending on the required density of the finished product.

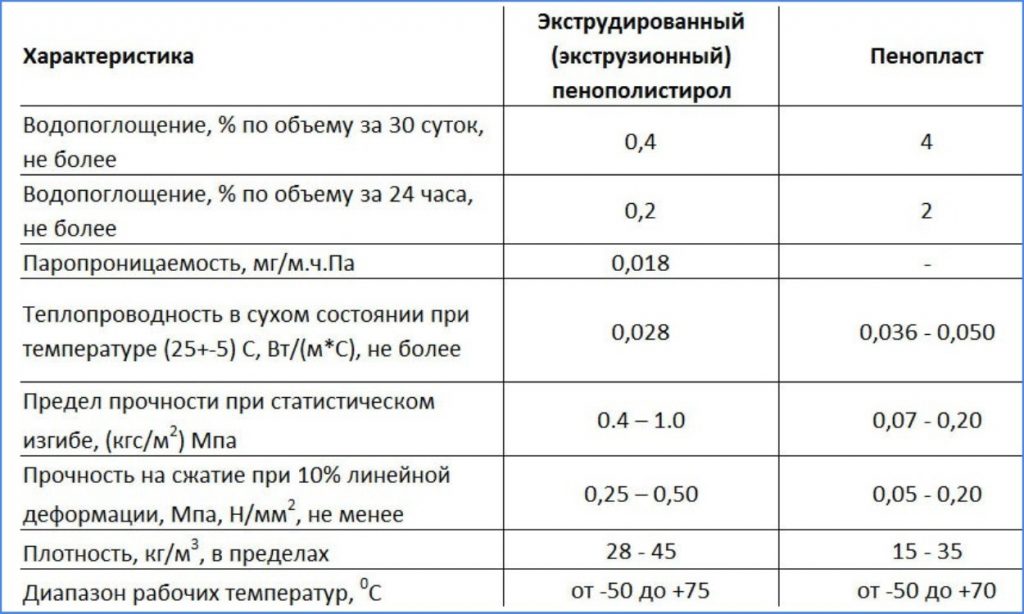

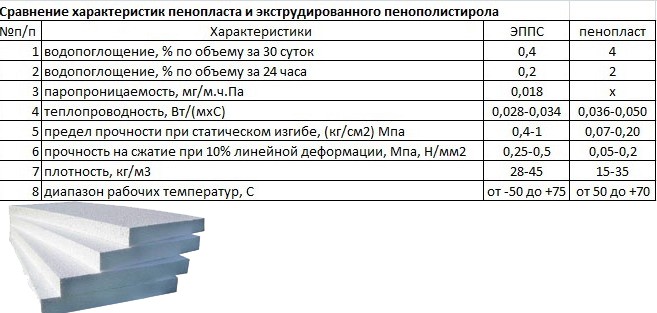

How epps is made - extruded polystyrene foam

The technological process for the production of raw materials for foam and extruded polystyrene is the same. Differences begin at the foaming stage, where special additives are introduced into the raw material.

The process takes place under the influence of high temperature steam in a special device called an extruder, where the mass under the influence of steam acquires a homogeneous and smooth consistency that can take any shape.

Production of extruded polystyrene foam (foam)

Production of extruded polystyrene foam (foam)

Through a special hole in the extruder under high pressure, the liquid mass is squeezed out into prepared forms. Finished products, after cooling, have the necessary density, rigidity and, at the same time, plasticity. On sale you can find insulation called penoplex, which is nothing more than extruded polystyrene foam.

The difference between concepts such as foam and extruded polystyrene foam lies in the production technology, as a result, the materials acquire different technical properties and characteristics.

Selection rules

Polystyrene insulation is a popular and modern building material. Therefore, manufacturers do not miss the moment to make money on it. Dozens of varieties of insulation are sold on the market. How to choose the best insulation expanded polystyrene?

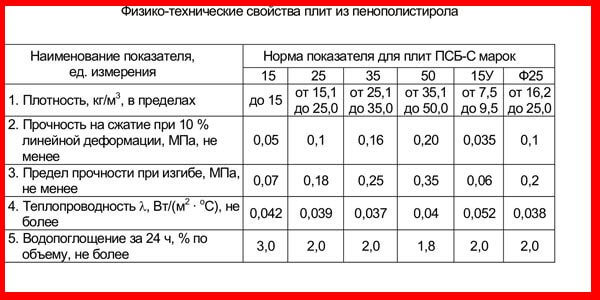

Pay attention to the brand of the material.A good indicator is 40, you can buy less, but not 25, since this is considered the lowest quality.

An important stage of selection is technology verification

When choosing any product, you should adhere to GOST. There is no need to take risks and take a heater made according to the manufacturer's own technology, because the indicators can be much lower than standard ones. For example, the PBS-S-40 grade may have a density of 28 instead of the declared 40 kg per cubic meter. As a last resort, ask for certificates that indicate the exact characteristics.

Before buying a large batch, first buy one sheet and break off a small piece. The fault should form smooth with regular polyhedrons. The presence of large balls and irregularities indicates a low quality of the material.

Of the popular and already proven companies, one can single out: BASF, Polimeri Europa, Nova Styrochem, Chemicals and domestic ones - Technonikol and Penoplex.

Despite all the shortcomings and the difficult choice of insulation, polystyrene foam is used in the construction of four out of five houses. Trusted by most construction companies

If you take into account all the precautions and follow the technology, your home will be provided with heat for 30 years or more.

Characteristics, pros and cons of foam ceiling insulation

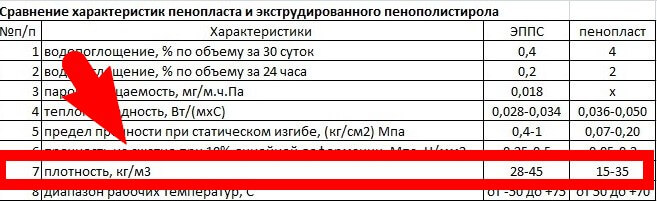

Polyfoam (chemists call polystyrene foam) is a modern building material widely used in the construction industry. It is a light, white sheet made of polystyrene (styrofoam). It has a highly visible grain structure, where each individual grain consists of many air chambers filled with carbon dioxide.

It is produced without a press. Many professionals confuse it with insulation made from the same raw material - polystyrene, but produced using a different technology: by extrusion. A typical representative of extruded polystyrene is Penoplex.

Currently, a liquid foam plastic, penoizol, has appeared on the building materials market. The technology of its use is fundamentally different from traditional methods of foam insulation. Therefore, according to the editorial staff of StroyGuru, it deserves a separate material, and therefore will not be considered in this article.

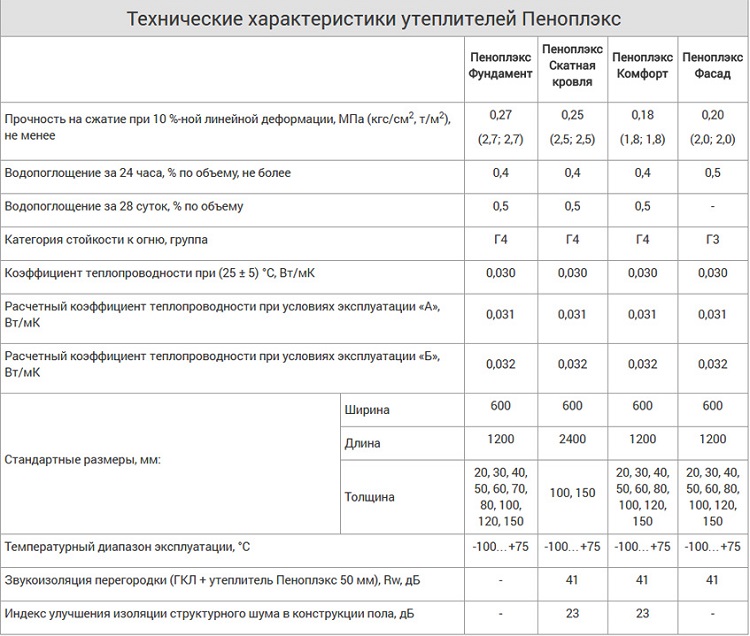

Specifications

The widespread use of foam in various areas of the national economy is due to its technical and operational characteristics:

- low coefficient of thermal conductivity - 0.037-0.043 W / (m × ° K);

- low weight - 8-40 kg / m3;

- high level of compressive strength - 0.04-0.16 MPa;

- low level of water absorption - 2-4%.

Expanded polystyrene is produced in different thicknesses, from 10 to 100 mm, with a step of 10 mm. In case of a non-standard order, the equipment can be reconfigured for any sheet thickness, up to 500 mm. Dimensions have two standards: 500x1000 mm and 1000x1000 mm. On sale you can find, however, rarely, the size of 1000x2000 mm.

Advantages and disadvantages

Like any building material, expanded polystyrene has its pros and cons. The strengths include:

- durability - due to various additives, the service life is 20-50 years;

- low thermal conductivity;

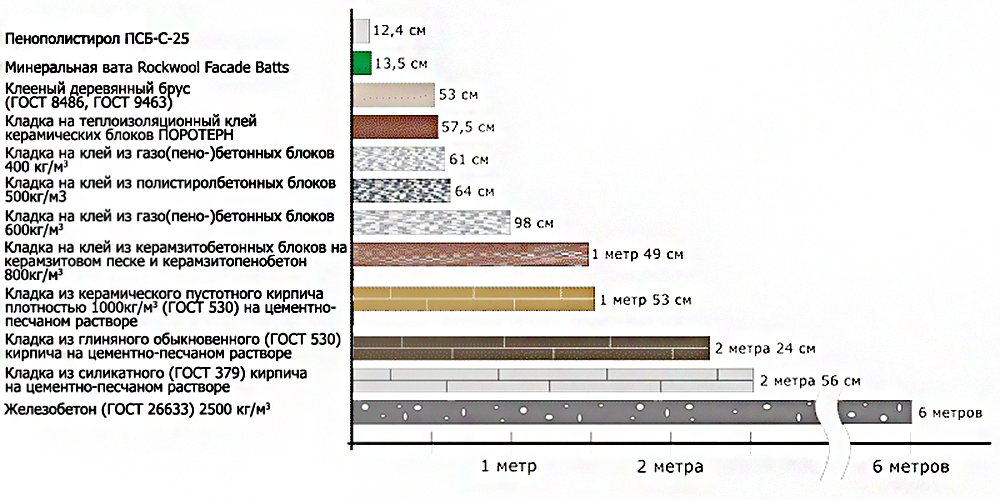

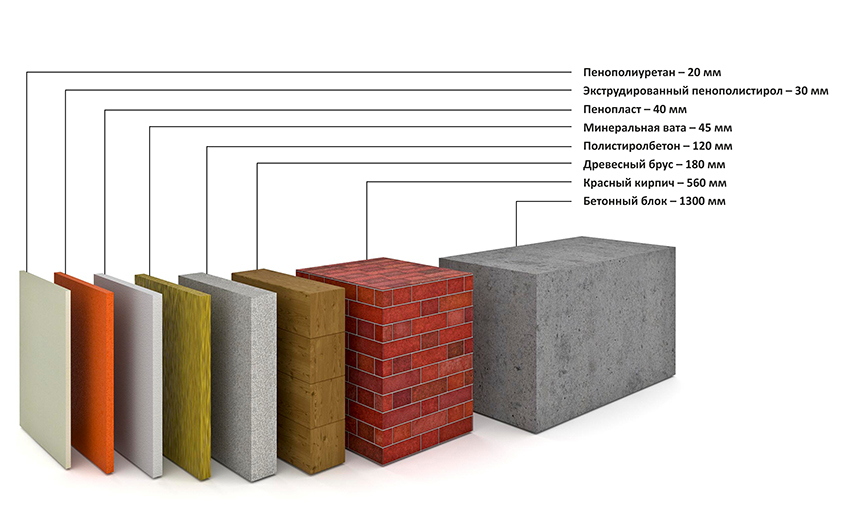

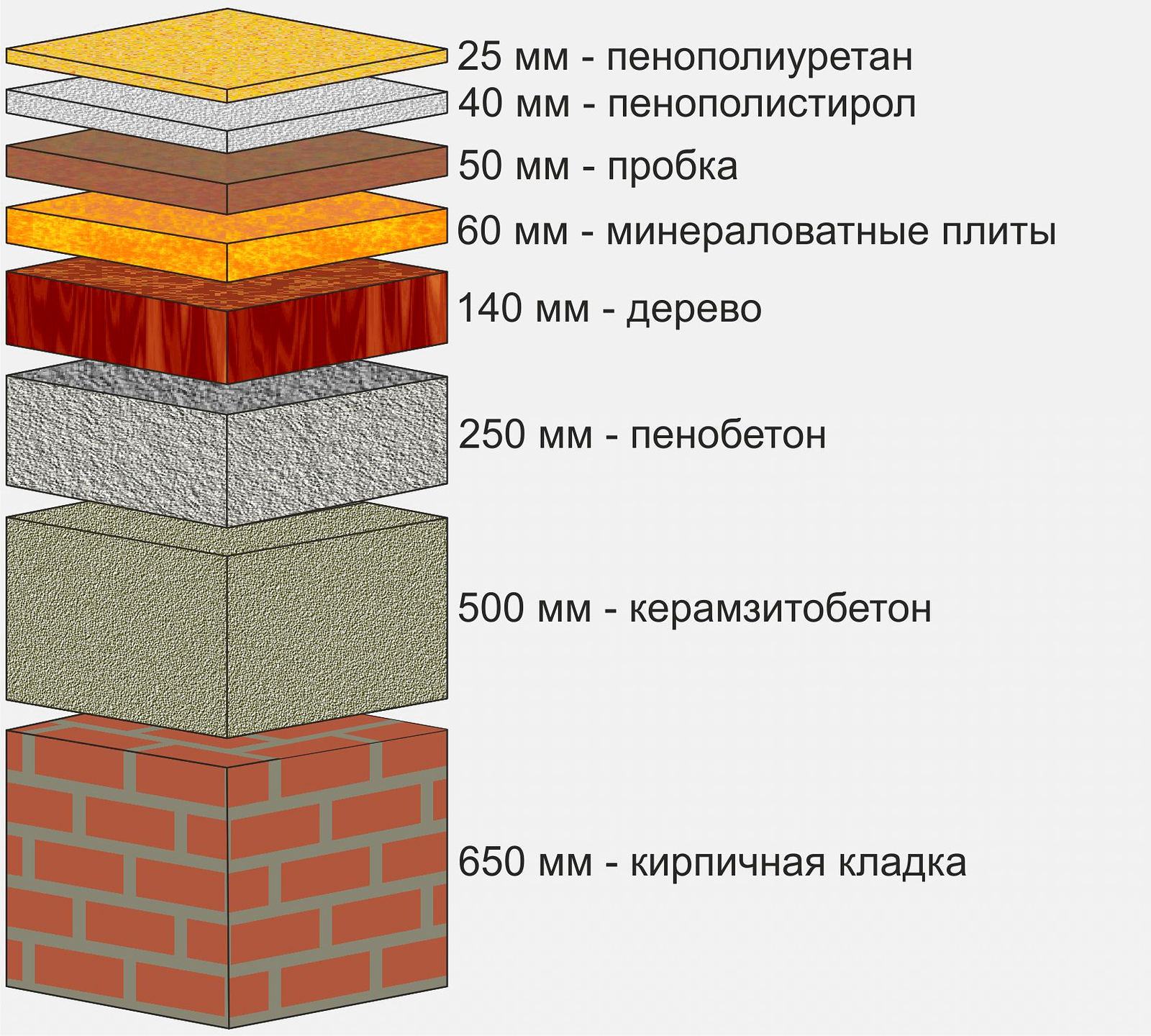

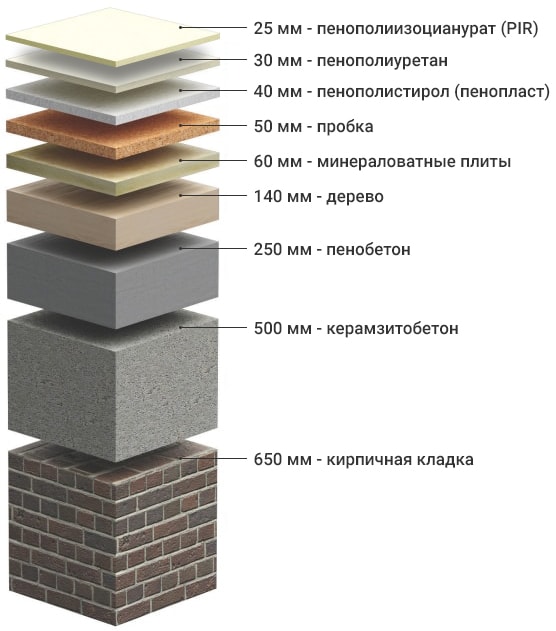

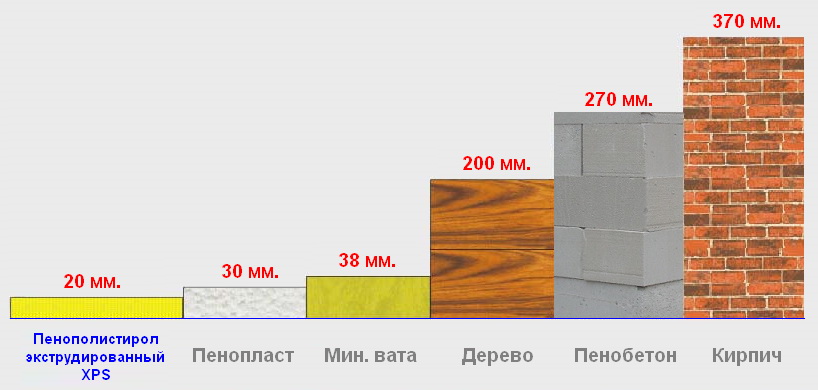

Comparison of thermal conductivity of different materials.

Comparison of thermal conductivity of different materials.

- affordable cost for a mass buyer;

- ability to withstand frost up to 50oС and heat up to 75oС;

- simple insulation technology - all work can be done by hand;

- low density, as a result of which it is possible to insulate all structural elements of the building, without exception;

- resistance to cement-sand and gypsum mortar, fungi and mold.

The insulation also has weaknesses:

- despite the introduction of fire retardants into the composition, it burns perfectly with the release of harmful and toxic substances;

- melts during a fire, spreads over structures, increasing the area of fire;

- in a state heated above 30oC, it begins to release harmful styrene;

- contrary to popular belief about good noise-absorbing properties, it actually resonates, amplifying the sound flow;

- melts when it hits the surface of most types of solvents;

- intensively destroyed by sunlight;

- does not let steam through;

- has low flexural strength.

Despite the introduction of various additives against mice and rats, it is still their favorite habitat.

How does foam plastic products affect the environment?

Of course, such a spread of the material and its daily participation in human life make one ask the question: is foam plastic harmful or safe?

Manufacturers declare environmental friendliness as one of the most important performance characteristics of expanded polystyrene. But their interest is understandable. That is why, when determining whether polystyrene foam is actually harmful to the environment, it is better to turn to scientific research.

Styrofoam under a microscope

The environmental friendliness of any material is determined by its own impact on the environment, exposure under certain conditions and when interacting with other substances.

Moreover, it is necessary to consider both momentary and long-term impact. Here are the main influencing factors:

- Expanded polystyrene practically does not absorb water and does not interact with it at all. Therefore, its use, for example, in the decoration and insulation of facades, is not only effective, but also safe. From this it follows that the ceiling tile is made of polystyrene, if it is not heated, it does not pose any harm.

- Expanded polystyrene does not oxidize when exposed to air and does not decompose under the influence of ultraviolet radiation. These qualities allow the foam to be disposed of in a household waste dump, and not at a specialized chemical landfill.

- Expanded polystyrene does not dissolve by any substances with which it can come into contact at a household waste dump. Solvents for it are acetone, initial styrene, aromatic and chlorinated hydrocarbons. These substances do not occur (at least should not occur) in the landfill of household waste.

- Expanded polystyrene is a very durable material. Cyclic stability tests with annual temperature changes in the range from -40 ° С to + 40 ° С with exposure to ultraviolet radiation and water showed that even after 80 cycles (which corresponds to 80 years), the structure of expanded polystyrene remained unchanged.

- Temperature extremes are not typical of Styrofoam environments, but have also been studied. When heated without a source of open flame, even expanded polystyrene that has not been treated with fire-fighting substances begins to collapse only at 300 ° C, and with an open flame - at 210 ° C. The effect of low temperatures can generally be ignored, since destruction occurs only superficially, and even then at -310 ° C.

Unfortunately, the bulk of the used polystyrene foam is disposed of in household waste dumps. When buried, expanded polystyrene is practically harmless to the environment, since it does not interact with water and air, but it does not decompose either.

The situation is complicated by the fact that the collection and processing of polystyrene today is not economically profitable enough. During processing, expanded polystyrene can be used to obtain polystyrene, although the cost of this process is comparable to the production of polystyrene from primary raw materials, but requires a more complex organization of the process.

Another method of processing expanded polystyrene is its crushing for use in the production of concrete - expanded polystyrene blocks, filler for heat-insulating mixtures and similar materials. This is a promising area of recycling, which gives hope for the reduction of landfills.

Pile of old styrofoam

It is too early to say what kind of polystyrene really does or will do harm to the environment. It is a very durable material.Even the first mass-produced foams, long buried in landfills, have not yet reached the threshold of decomposition.

# 1. What is polystyrene ceiling foam?

Decorative tiles are made from polystyrene, which foams during the heating process. During production, flame retardants and carbon dioxide are added to the material, substances that increase resistance to high temperatures. A tile made of polystyrene foam made in a similar way, although it melts under the influence of fire, still shows itself better than ordinary foam. By the way, you can also find foam ceiling tiles on sale: they are not only less safe, but also more rough in appearance. The presence of fire retardants in the composition of the plates is indicated by the marking: domestic manufacturers add the letter C, foreign - F.

Material can vary greatly in size, shape, color and appearance. On sale you can find square, rectangular and designer tiles. The surface can mimic country-style decorative plaster or exquisite baroque stucco. The classic color of the tiles is white, but color options and products with mirror and laminated surfaces are also sold. The standard sizes are 50 * 50 and 100 * 16.5 cm, but there are also other formats.

Pros and cons of ceiling tiles

If you are considering the option of decorating the ceiling with polystyrene and foam tiles, then you can finally decide by getting acquainted with the positive and negative sides of this material.

Ceiling tile advantages:

- foam can be glued to any surface;

- light weight of the material and ease of cutting ensure ease of installation;

- sound and heat insulation properties;

- material safety - absence of substances harmful to health;

- low cost of tiles and glue for installation;

- a properly selected finishing material has a long service life;

- the large sizes of individual elements allow the ceiling to be clad in a short period of time;

- installation of foam tiles practically does not reduce the height of the ceiling;

- the possibility of multiple staining - up to 7 times;

- easy dismantling.

Disadvantages:

- fragility of the material;

- vapor tightness - the ceiling is deprived of the ability to absorb excess moisture;

- difficulties in masking the seams between individual ceiling elements;

- cheap styrofoam turns yellow quickly.

Advantages and disadvantages

Today, extruded polystyrene is known as a reliable and practical material you can trust. Its relevance is due to many positive qualities, which should be discussed in more detail.

- This material is waterproof. In case of unfavorable contact with liquid, the floors of expanded polystyrene are filled - no further movement of moisture occurs.

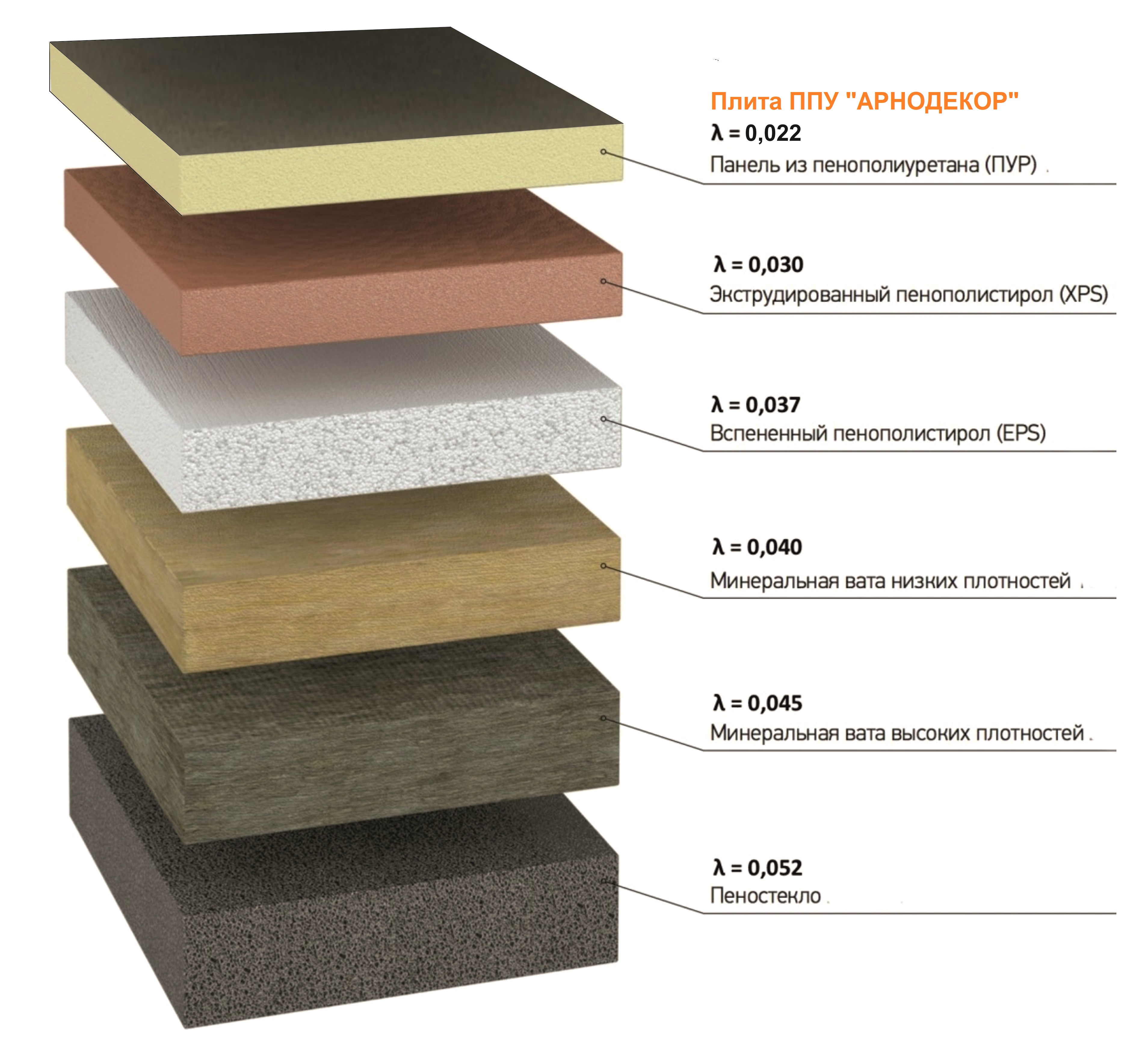

- Extruded polystyrene foam is characterized by a low level of thermal conductivity. If we compare it with other insulating coatings, we can conclude that the thermal conductivity coefficient of EPS is less or equal (the only exception to the rule is polyurethane foam).

- A characteristic feature of EPS is low vapor permeability. The coefficient of this parameter is considered to be the lowest among the insulating components.

- Expanded polystyrene is not subject to deformation even after a very long time.

- This material is not afraid of temperature jumps. In such conditions, he does not lose his useful qualities and remains as practical / effective. Its working temperature ranges from -100 to +75 degrees.

- Installation, as well as dismantling of expanded polystyrene, is not difficult, and it does not take as much time as it seems to many.

- This material boasts a long service life, during which it does not deform and does not lose its qualities.

- During operation, extruded polystyrene foam is not subject to destruction.

- Extruded polystyrene foam is not afraid of inorganic solvents.

- It is very easy and simple to work with this material, as it is light in weight and low in thickness.

- Such material is relatively inexpensive. Many consumers can afford it. In this case, the price-quality ratio is good news.

- When installing EPSPS, you can do without the use of additional hydro and thermal insulation coatings, which will significantly save money.

- According to experts, EPPS is not dangerous to human health. Moreover, when working with it, the master will not experience allergic reactions.

- Such material is not afraid of low temperatures, therefore it is ideal for finding in the harsh and changeable Russian climate.

- The durability of extruded polystyrene foam is also confirmed by the fact that it is not subject to decay - not every building and finishing material can boast of this quality.

As you can see, EPS has a lot of advantages. That is why today it occupies one of the leading positions in the insulating materials market. However, such a practical and reliable coating has its own drawbacks, which you should also be aware of before purchasing it.

- This material is flammable.

- Being at temperatures above 75 degrees, polystyrene foam can emit harmful substances that are dangerous to human health.

- According to experts, this material is afraid of contact with infrared rays.

- Mice can start in EPSS, although many manufacturers deny this fact.

- When interacting with various solvents, this material can be destroyed.

If the listed disadvantages do not scare you, then you can safely proceed to the acquisition of this modern material - it is used in many areas.

The effect of foam on human health

Questions about whether expanded polystyrene is harmful to health or not have worried consumers almost from the very beginning of its use. Each new styrofoam-based finishing and building material has rekindled these controversies.

Proponents of the use of expanded polystyrene cite the research of scientists - chemists, physicists and materials scientists as an argument for the safety. Expanded polystyrene, without external influences on it, practically does not interact with the environment.

Its molecular structure is very stable. The experiments described above show that, under normal human conditions, expanded polystyrene does not emit any harmful substances. Actually, it does not emit any substances.

It might be interesting

Opponents of the use of expanded polystyrene declare the existing possibility of styrene separation. Even if not under normal, but under extreme conditions. Extreme conditions refer to exposure to high temperatures. Indeed, when burning, expanded polystyrene, like many other substances, emits a large volume of toxic substances, among which styrene is considered especially poisonous.

The effect of styrene on humans:

- dizziness;

- irritation of the mucous membrane of the eyes;

- high concentrations lead to lung damage and even fatal poisoning;

- the work of the kidneys, liver, hematopoietic system is disrupted;

- oncology.

The combustibility of the initially created polystyrene foam was quite high. At temperatures above 210 ° C, the foam was able to independently support surface combustion and spread fire. That is why fire retardants (substances that restrain the ignition and spread of flame) are now used for the production of construction and finishing polystyrene foam.

Thanks to this, it was possible to reduce the flammability and increase the ignition temperature to 440 ° C. In addition, most modern expanded polystyrene products do not allow the flame to spread and do not support self-combustion.

I must say that, like many other dangerous in large doses, but harmless in small substances, styrene is naturally found in many products we use every day - coffee, tea, cinnamon, cheese, strawberries, and so on.

Polystyrene foam melting

The harm of expanded polystyrene to human health can also be associated not so much with the qualities of the material, but with its improper use in decoration. Expanded polystyrene is a very popular heat insulator, but at the same time it does not allow steam and moisture to pass through well. It happens that people, unknowingly or out of economy, insulate the walls between the apartment and the street with sheets of expanded polystyrene from the inside.

This situation is serious in that the moisture of the warm home air collides with a cold wall just below the foam and condenses there. The wall on the surface of the concrete is constantly wet, which will inevitably lead to the development of fungus and black mold, the spores of which are a dangerous allergen. Black mold can trigger the development of asthma, chronic bronchitis and other diseases.