What is this material and its types

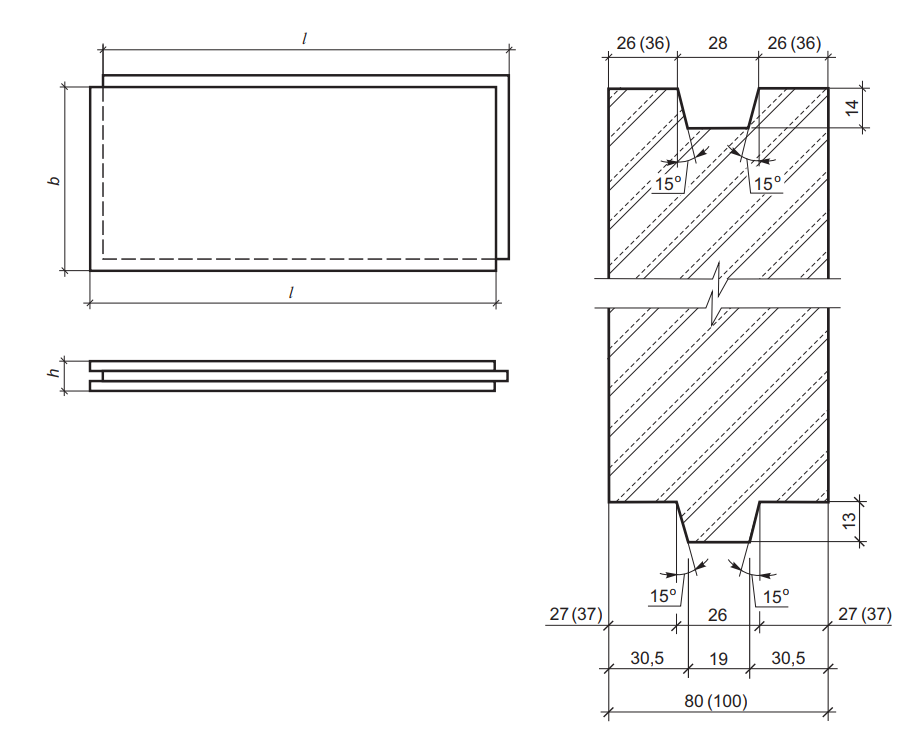

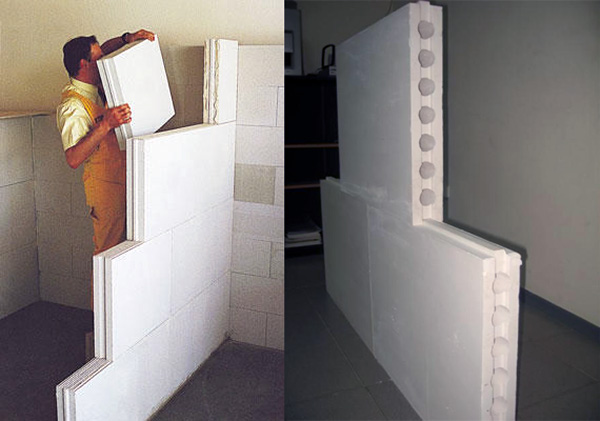

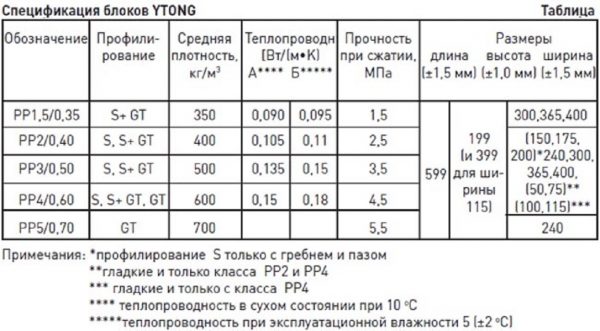

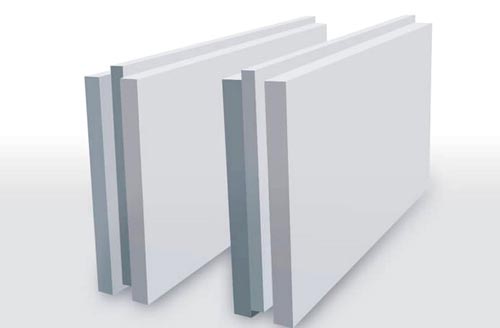

Tongue slabs (abbreviated as PGP) or blocks are large-format building material for erecting partitions in the form of a slab, at the ends of which a ridge (spike) and a groove are formed. Hence this name - tongue-and-groove slabs. They are:

- gypsum-based (cast gypsum);

-

from sand and quicklime, pressed under a certain pressure and steam-treated in an autoclave (silicate).

Plasticizers and hydrophobic (water-repellent) additives are added to the solution to improve the properties. Gypsum GWPs have another name - gypsum boards. It is understandable: the gypsum solution is poured into molds. Here is the "source" of this variant of the name.

Moisture resistance and voidness

According to the area of use, tongue-and-groove plates can be designed for normal operating conditions (normal, standard) or for damp rooms (moisture resistant). Moisture resistant for better identification tinted greenish.

Solid and hollow differ in weight and strength

Both gypsum and silicate tongue-and-groove slabs are solid and hollow. Full-bodied, more durable, hollow due to lower weight, create less load on the floors. The choice between corpulent and hollow must be made based on several factors:

- Soundproofing characteristics. A monolithic material without voids conducts sounds better, so it is used if sound insulation will be made in a separate layer (the best option) or if it is not so important.

- Partition loads. If you need to hang shelves, furniture on the walls, fix some heavy objects, it is better to use a monolith.

- Floor or floor loading. It is better to place less heavy (hollow) blocks on wooden floors or old wooden floors.

Considering several factors, sound insulation is the last thing to consider. It is possible to increase noise protection using a special mounting technology (on vibration damping pads), as well as by making an additional layer of soundproof materials.

Specifications

If we compare ordinary and moisture-resistant tongue-and-groove plates, the differences in characteristics are only in water absorption and strength. Moisture resistant, due to the large amount of hydrophobic additives, they almost do not absorb moisture. Because of the large number of these additives, they are more expensive, since these additives are expensive. At the same time, they increase the strength (M50 compared to M35).

By the way, you can check "without leaving the checkout" if you really have moisture-resistant GWP or just standard green-colored ones. Just pour some water on the surface. Standard plates will quickly absorb it, and on water-repellent plates it will stand for a long time in a puddle.

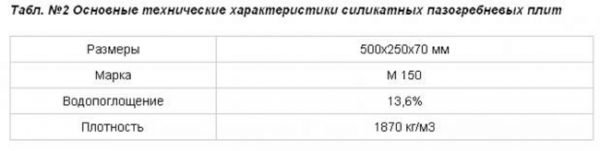

Main technical characteristics of gypsum and silicate PPGs

If we compare gypsum and silicate partition blocks, the increased strength of the latter immediately catches the eye - M150 compared to M50 and M35. That is, the strength of silicate slabs is comparable to concrete of not the worst grade. If you are going to hang something very heavy on the partition, it is better to use silicate. Manufacturers also produce blocks with a thickness of 115 mm, which are called inter-apartment blocks.

Technical characteristics of tongue-and-groove gypsum partition blocks

How else do silicate boards differ from gypsum counterparts? The fact that in the standard version they do not have such a high absorbency. It is not as low as that of moisture-resistant blocks, but this material can be used without problems in any damp room (13% versus 26-32%).The disadvantages of this material are more weight (with equal dimensions) and lower thermal insulation characteristics.

Silicate GWP

The production of silicate products is based on quartz sand, slaked lime and water. The method of pressing with the processing of products with steam under high pressure is used. The structure of the building material ensures flatness, smoothness of the surface, correct geometry of the workpieces. The tongue-and-groove fastening system increases the strength of fixing the elements.

Raw materials and production methods contribute to weighting, increasing the density of the boards. The coefficient of thermal conductivity and strength characteristics of the material increase. The sizes of silicate products are different, depending on the manufacturer. If we compare it with a gypsum analogue, they are less.

Silicate

Silicate

There are two types of slabs produced: solid and hollow. In the second case, there is an increase in sound insulation characteristics. One unit of building material weighs less.

Determining the type of slab material for the construction of partitions, the type of floor and the purpose of the room are taken into account. Arrangement of silicate raw materials for wooden logs, work in a children's room, requires a lightweight version of the void. In the case of concrete wall cladding to which heavy furniture or decor is attached, durable solid silicate products are used.

Sometimes a two-layer partition is required to protect the room from heat loss and noise. Mineral wool is placed in the cavity between the two balls of the slabs. Engineering communication lines are being laid. Insulation building material may be different.

Technical characteristics of silicate products

The physical and technical parameters of silicate bricks make it possible to actively use it in construction. Silicate resists fire. Does not emit toxic vapors into the air. Does not pass electric current, good insulator. Gas permeability of the structure ensures good microclimatic conditions in the room. Under the influence of insignificant fluctuations in humidity, it does not give in to rotting, deformation.

Technical properties

Technical properties

Dimensions, weight of silicate GWP

Slabs with good geometry. But the size table depends on the manufacturer. Compared to the overall size of the blocks, they are smaller than gypsum blocks. Everything is explained by the large weight of the building material.

Options

Options

Mounting

First you need to calculate the number of plates required for the partition. Today it is very easy to do. On any building Internet portal, you can find an online calculator, in the cells indicate the size of the selected block, the length and height of the walls, as well as the area of door and window openings. Then click "Calculate". The calculator will give a total of the total area in cubes and the required number of slabs of the specified sizes.

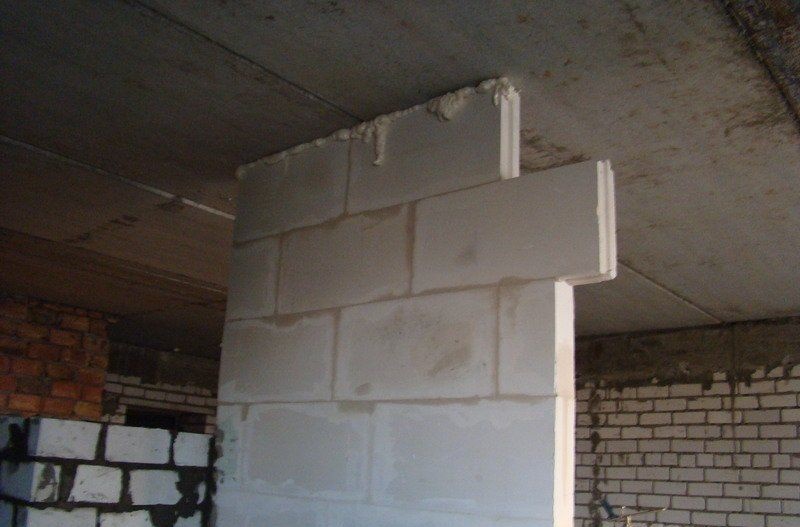

It is necessary to start raising the PGP partitions after carrying out rough work on finishing the walls and ceiling, but before pouring the screed

It is important to take into account that the humidity in the room where the GWP-walls are being installed should be 55-60%, and the temperature should not be lower than 5 degrees. Before starting the installation of the slabs, you should prepare the base.

The adjoining elements must be even, located strictly in a horizontal and vertical position. If there are flaws, concrete or cement-sand mortar will help to fix them, which, after drying, will need to be primed.

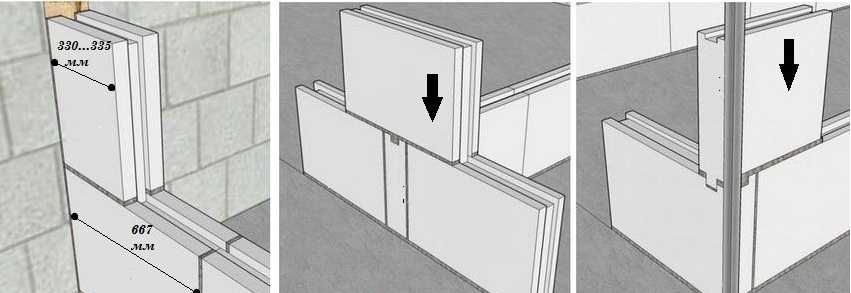

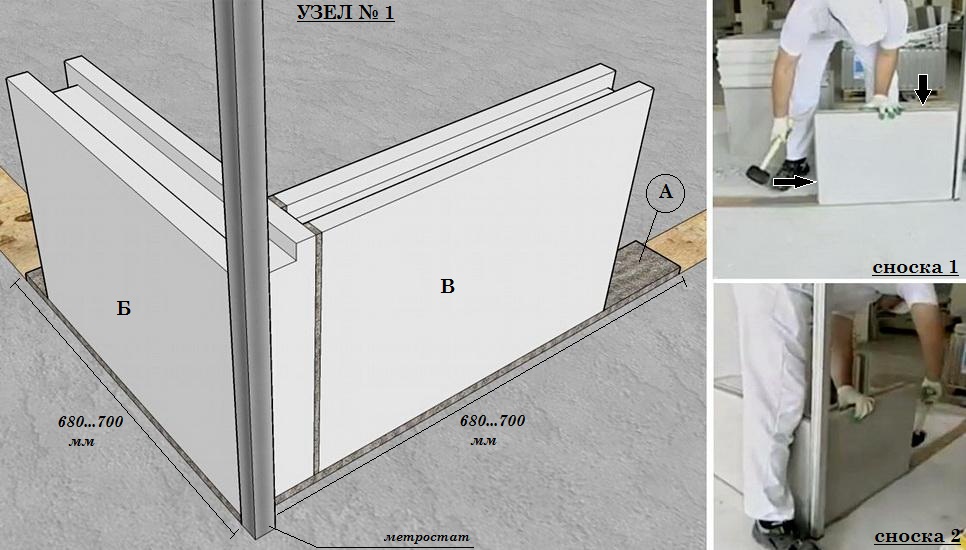

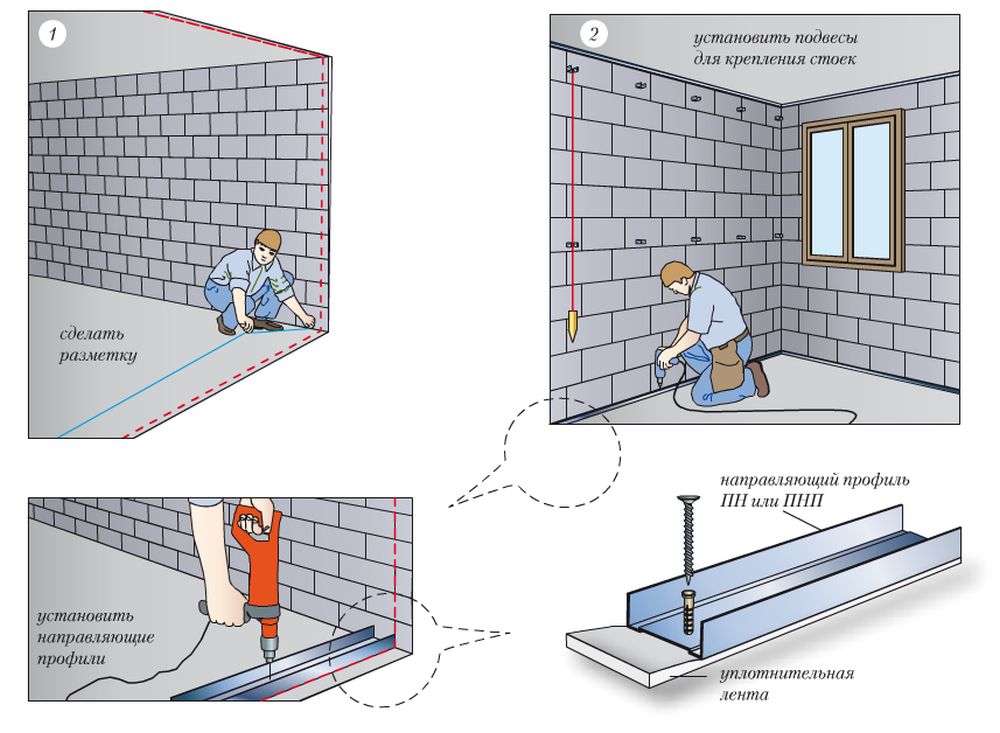

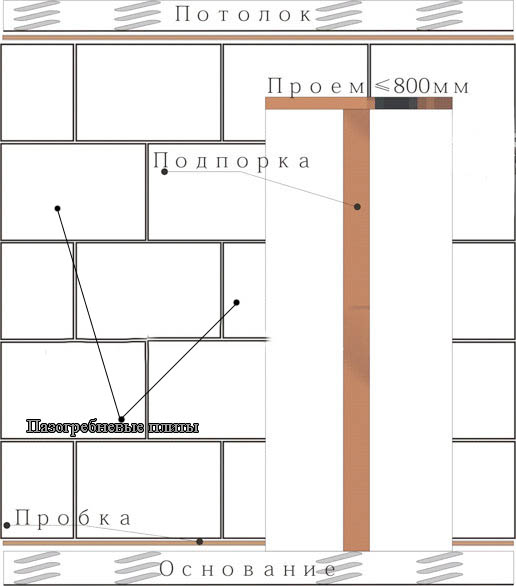

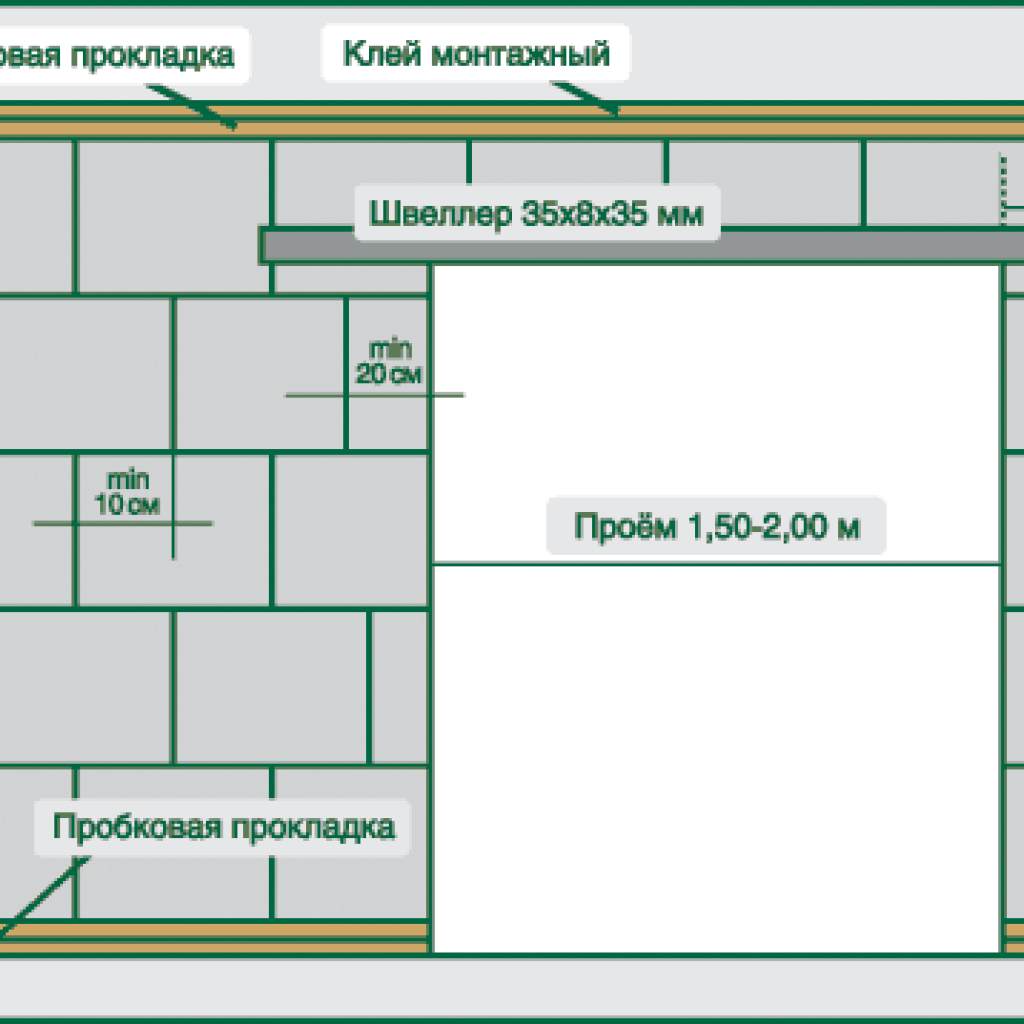

Marking is made on the basis of the floor. The coordinates of the future door are also set there. Using a level, floor markings are transferred to the ceiling and walls. To increase the noise insulation parameter, an elastic cork gasket is glued to the adjacent partitions, and a backing is attached to the floor

It is important not to forget about purchasing special fasteners. They are fixed with self-tapping screws, anchors or dowels.

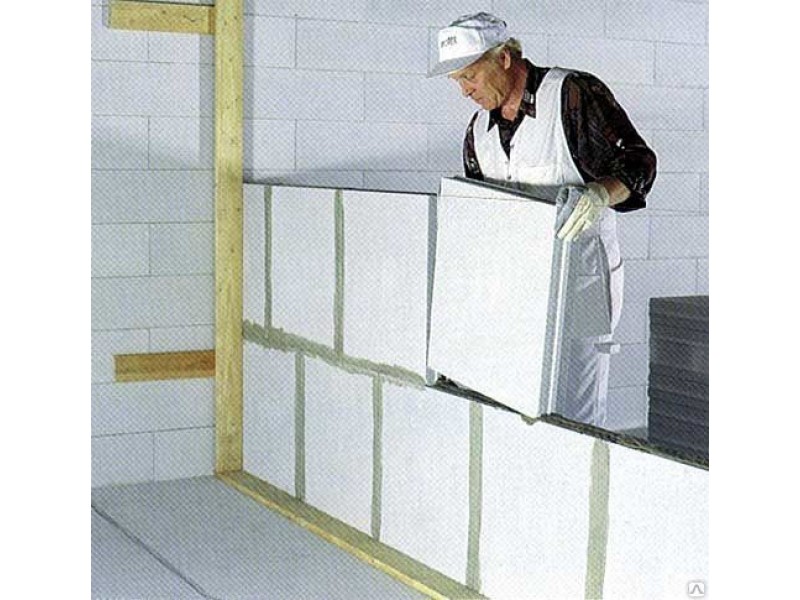

If the ceiling height is 2.8 m, it is sufficient to fix the partition at three points. In the horizontal direction, the distance between the fasteners should be 70-100 cm.Corner slabs should be connected to each other with perforated tape. Next, the laying of blocks begins. The panels can be laid up or down in grooves. In the first case, the solution should be evenly laid at the point of contact of the elements, while the lower protruding ridge will have to be carefully cut off.

Then you can start editing

When erecting an interior partition with your own hands, it is very important to adhere to the installation technology, otherwise the work will have to be redone

- To begin with, the glue solution is mixed.

- The adhesive mass is applied to the walls and floor according to the markings made.

- The first block is placed. A level is applied from above. When irregularities are detected with light knocks of a mallet, flat horizontality and verticality are adjusted.

- The protruding excess of the solution must be immediately removed.

- If necessary, the slab can be fixed to the enclosing structures.

After the first row has been laid, subsequent slabs can be mounted

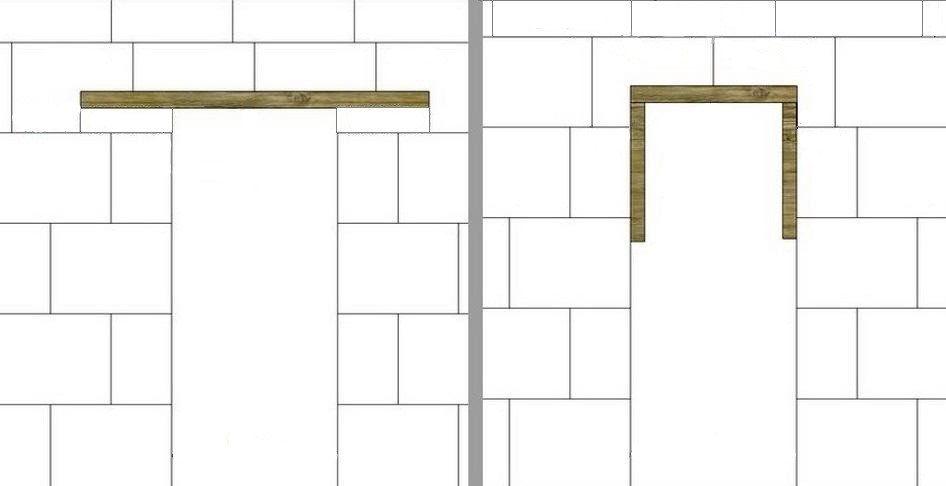

And here the technology for the construction of GWP blocks requires paying attention to some nuances. The connecting seams must not line up with the contact points of the upper rows

To do this, you need to cut one block exactly in the middle. One part of it will be the beginning of a new row, and the second will be the end. Otherwise, the principle of operation is similar to the installation of the first row of blocks.

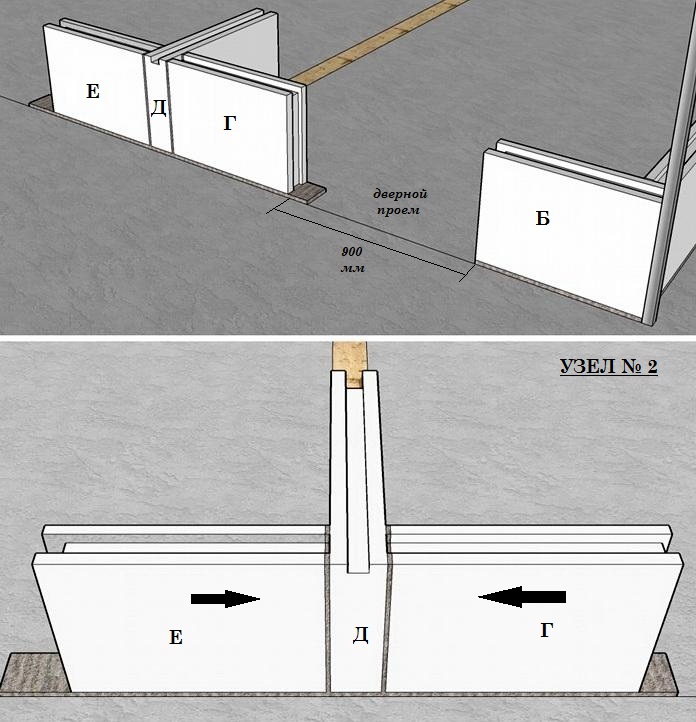

Particular attention should be paid to the formation of the doorway. If you need to install an opening less than 90 cm, additional supporting structures can be omitted.

But we must not allow a whole slab to hang over the doorway. For such situations, it is recommended to draw up a plan in advance and set the lines correctly. In the process of raising the wall, it is necessary to install a temporary lintel. It can be made of wood or profile. When the adhesive is completely dry, the lintels can be removed.

It remains to make the top row. It is inconvenient to lay the slabs close to the ceiling, which is why it is allowed to change the direction of the installed blocks from the horizontal position to the vertical one. The fastening system of the plates does not make it possible to put the blocks close to the ceiling - a small gap is required. 2-3 mm will be enough. If you plan to arrange a stretch ceiling, the gap can be filled with polyurethane foam.

Fastening to ceilings should be done with brackets or corners, otherwise the upper part of the structure will loosen. As it became clear, GWP panels are the best material for building new walls. With them, the device of load-bearing partitions takes very little time.

For information on how to build an interior partition from tongue-and-groove slabs, see the next video.

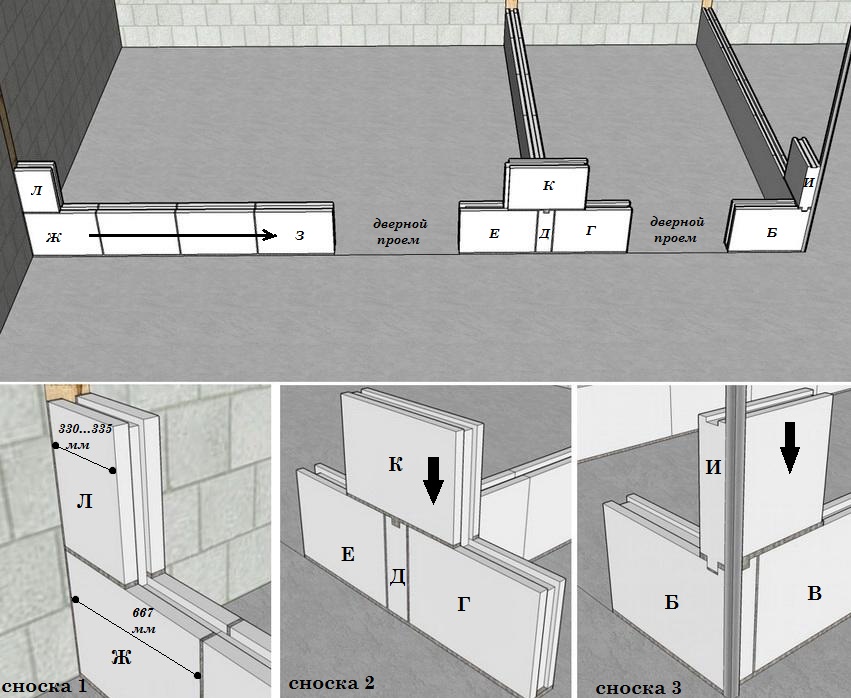

Installation of the first row

Installation of GWP is carried out strictly in rows, starting from the bottom. The first row is basic and must be correctly oriented in space, vertically and horizontally. The most common mistake during installation is the "waviness" of the partition, which occurs due to a slight displacement in the grooves. To eliminate this phenomenon, when laying each slab, you need to use a rule-rail and check the general plane of the partition against it.

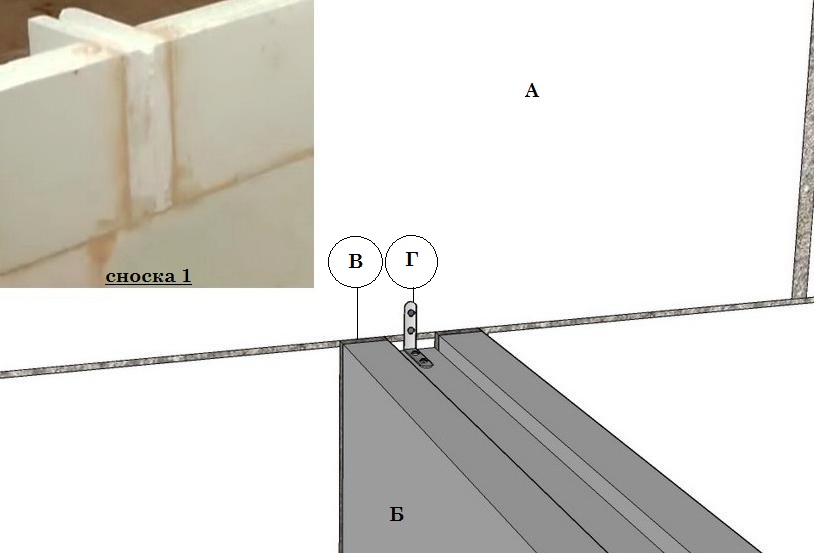

The first row should be laid from the corner. The place where the slab touches the floor and the wall is covered with GWP glue, then the block is installed with the comb upward and its position is leveled. It is convenient to use a rubber mallet to move the plates. It is imperative to fix the first block to the wall and floor with the help of L-shaped plates, the role of which is successfully performed by direct suspensions. To use them, you need to cut off the toothed comb from the edges and bring the thickness of the plate to the width of the comb. The plates are first attached to the base using quick-fix dowels with a length of 80 mm, then to the plate with black self-tapping screws at least 60 mm long.

Subsequently, the slabs are attached through one: on the one hand to the floor, on the other - to the previous slab with a preliminary coating of the joint with a thin layer of glue and strong pressure.To control the placement of the slabs in the project, it is convenient to use lacing or a laser level. It will also not be superfluous to mark the partition on the floor and walls, indicating the places for doorways.

How to choose a stove

As noted above, tongue-and-groove plates are produced in two versions:

- hollow;

- monolithic.

No one will argue with the fact that monolithic slabs are more functional than hollow slabs. But at the same time, they have a lot of weight. That is why it is undesirable to use such plates for partitions that must be installed on a floor with wooden joists.

Meanwhile, hollow GWPs show excellent sound insulation performance. They do not allow extraneous noise to pass at a level of up to 43 dB. And at the same time, due to their low weight, there is no overload of the floor construct. Meanwhile, some developers are confident that harmful bacteria and various insects can safely live in hollow parts. But studies have not confirmed these concerns.

Both types of GWP are used for the construction of partitions or wall decoration in those rooms where the humidity level can be attributed to a dry climate. For the construction of such structures in rooms with a high moisture content, it is necessary to use slabs that successfully resist water. They have a greenish tint. When creating a project, it must be borne in mind that these slabs are slightly heavier.

4.2 Component materials and products

4.2.1For fastening partitions

and cladding to enclosing structures with elastic abutment, as well as

fastening to the partitions of door frames, it is recommended to use brackets,

the nomenclature of which is given in the table.

4.2.2For fastening

It is recommended to use self-tapping screws with a length of

35 mm countersunk head and sharp end, made of steel grade 10,

10KP, 15, 15KP, 20 and 20KP in accordance with GOST 10702, and for attaching them to the enclosing structures -

expanding anchor dowels, the nomenclature of which is given in the table.

Table 4.3

Product and material designation

Appointment

Staple C-1

For fastening partitions with elastic

adjoining

Staple C-2

For fixing the door frame to the partition

Corner protection profile for external finishing

corners of partitions

Table 4.4

Name

Length, mm

Diameter, mm

Self-tapping screw

countersunk head and pointed end (screw)

35

3,5

Dowel

anchor plastic

35

6,0

40

55

8,0

60

10,0

65

Dowel

anchor metal

70

75

12,0

4.2.3 With the elastic connection of partitions with other fencing

structures, it is recommended to use an elastic cork gasket with a density

not less than 250 kg / m3 or bituminized felt with a density not less than

300 kg / m3. The width of the spacers must be at least 75 mm with slabs

80 mm thick and not less than 95 mm for slabs 100 mm thick.

4.2.4 When laying gypsum tongue-and-groove plates, as well as for fastening

elastic gaskets it is recommended to use glue from

dry putty mixture based on gypsum binder "KNAUF-Fugen-Fuller"

TU 5745-011-04001508-97 and TU 5745-021-03984362-2001. When laying

hydrophobized (moisture-resistant) gypsum boards are recommended to be used

putty mixture "KNAUF-Fugenfüller hydro" according to TU 5745-021-03984362-2001.

4.2.5 For the protection of interior corners in partitions and plasterboard claddings

tongue-and-groove slabs should use a reinforcing tape (serpyanka), and for

outside corner protection - profile

corner protection PU 31/31 according to TU 1121-004-04001508-2003 (table).

4.2.6 For the device of a heat and sound insulation layer in partitions,

apply the materials provided for in the design documentation for a specific

building.

4.2.7 For surface preparation of partitions and gypsum facings

tongue-and-groove plates for finishing it is recommended to use a primer

"KNAUF-Tiefengrund", supplied by the enterprises of the KNAUF group.

4.2.8 For surface preparation of partitions and gypsum facings

tongue-and-groove plates for high-quality painting are recommended to be used

putty composition "KNAUF-Finishpasta" supplied by the enterprises of the group

KNAUF.

4.2.9 In rooms where the surfaces of structures made of gypsum tongue-and-groove

boards are directly exposed to moisture, they must be protected

waterproofing mastic "KNAUF-Flechendicht", and at the junctions

structures made of gypsum boards between themselves and with the floor are recommended to be used

self-adhesive sealing waterproofing tape "KNAUF-Flechendichtband",

supplied by the enterprises of the KNAUF group.