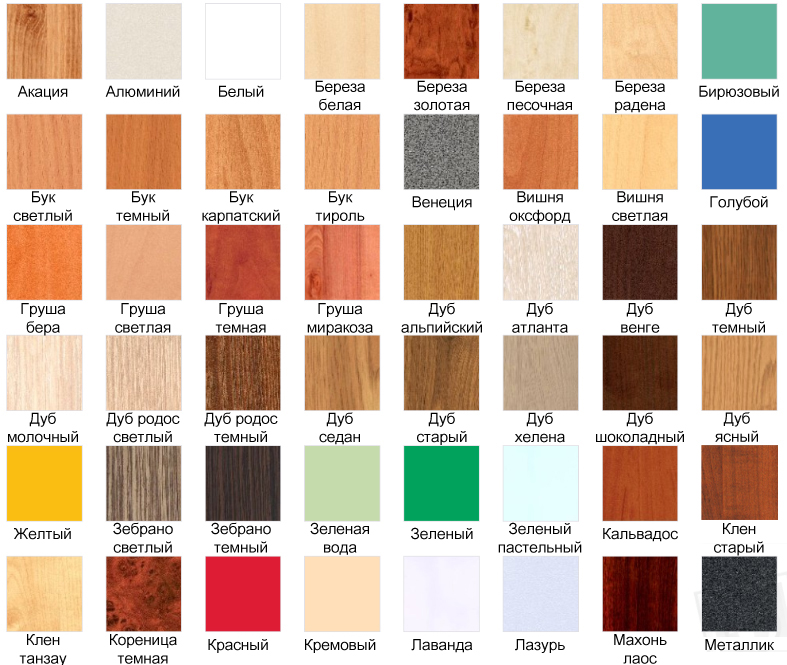

Colors

Colored MDF panels are made by applying to profile sheets using glue - the basis of a cladding made of a special composition. These compositions create various decorative surfaces, and when using paint or film of various colors - colored surfaces with or without patterns. With all their diversity, there are some so-called running panels - these are wenge, mahogany, mocha panels, as well as the usual solutions: black, brown and white panels.

MDF panels with imitation wood imitation are in great demand, namely:

- "Wild Oak Canyon";

- Oriental beech;

- "Silver ash";

- "Ash white";

- Light Pine;

- "Natural pine";

- Golden Pine;

- Alpine Oak;

- "Gnarled Oak";

- "Light oak";

- "Cedar";

- "Taiga Cedar";

- "Italian nut";

- "Milan nut";

- "Karelian birch light";

- "Karelian birch dark";

- "Snake tree";

- "Makara";

- "Multi-veneer" and others.

All of the above panels are veneered. Such surfaces consist of a cut of fine wood, painted and processed to preserve the structure. They can also consist of softer, inexpensive wood, imitating the texture and color of a noble wood surface (fine line). All variants of these panels are created using innovative methods of manufacturing wood fiber products. Many manufacturers are engaged in the manufacture of custom design panels to order.

The most popular are the following panels with stone imitation:

- "Stone of Capri";

- "Deserted";

- "Stone of Alatau" with embossing;

- "Canyon beige" with embossing;

- "Stone amber" with embossing;

- "Stone white" with embossing.

Dakota panels imitate uneven stone surfaces with small tiles and are available in white, beige and purple designs. For fireplace or arched decoration, it is advisable to use slabs with imitation of wild stone, as well as moldings of appropriate colors, textures and solutions. These specimens look good on a cave-like wall. In addition to these, photo-printed panels can be added to achieve the maximum visual effect, for example, a sunny blooming valley with a shade of green cedar.

The use of panels simultaneously with imitations of wood and stone is an excellent solution for a country interior. Colored MDF panels in muted pastel colors look good in a bedroom or nursery. And their varieties under tiles or marble are characteristic of bathroom designs. With all the variety of colors and types, you can get confused and face a difficult choice. To solve this problem, there are specialists who are not by hearsay familiar with the quality of this type of product. Many of them work directly with manufacturers of popular brands and can provide product catalogs.

Disadvantages of plastic facades

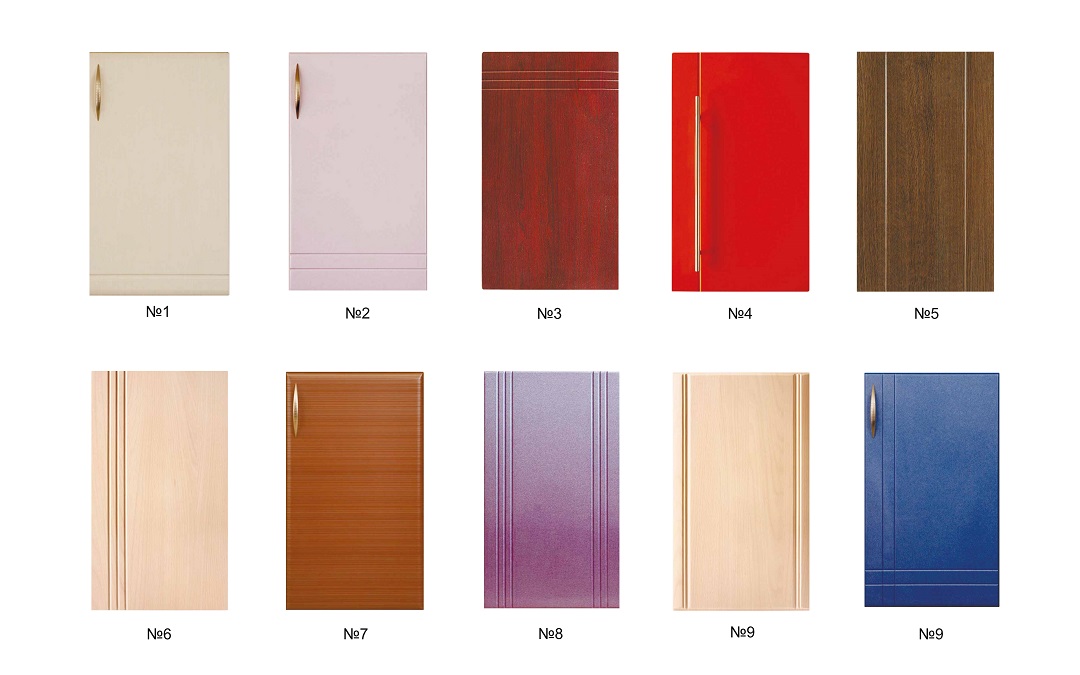

A plastic kitchen can be easily recognized by the special sheen of the facades. There are two versions of plastic: matte and glossy.

Caring for matte facades is not easy. Dirt literally eats into plastic, and it can only be removed with a lot of effort.

With glossy facades, everything is much easier. But on the shiny surface, fingerprints are clearly visible. In this case, the color of the kitchen does not matter. This is especially true for bright monochromatic facades.

The design on the doors helps to mask prints and make them less visible in the background of colored patterns. In addition, the drawings always add freshness to the interior. Look at the photo and see the aesthetics of plastic kitchens.

Drawings on plastic kitchen doors not only add practicality to them, but also add charm.

Drawings on plastic kitchen doors not only add practicality to them, but also add charm.

You need to understand that the bright plastic pattern will be only on the outside of the facade, and the inside will remain white. On closer examination of plastic facades, one more flaw can be noticed. It is associated with the features of cold pressing. The drawing in the central part may deform, so the facade may appear slightly concave.

The rest of the drawbacks are associated with low-quality plastic. If high-grade plastic does not change its configuration and color under the influence of smoldering cigarettes, then low-grade material may simply burn out in the sun. Its characteristics are similar to facades laminated with PVC foil.

Application

The scope of application of MDF sheets and panels is much larger than it might seem. This material has proven itself well in the furniture industry. It is widely used for finishing various surfaces in the form of decoration. Traditionally, MDF sheets are used before applying various types of flooring as a frame for laminate. In the wall version, it can be used for finishing walls for finishing. MDF profile is used as a lathing when installing roofs, packing material.

With all its diversity, MDF wall panels make it possible to carry out any approaches to decorate an aesthetically pleasing space. They are not limited to one reconciliation. The features of the panels allow them to be used at different angles, horizontally, vertically or herringbone.

The main areas of application of MDF panels include the following:

- MDF panels are ideal for suspended ceilings, they are laid on ceilings as a one-piece ceiling covering;

- they are the main material for the production of furniture and joinery, for example, kitchen countertops and decorative apron, as well as cabinets and shelves;

- window frames are made from MDF panels; they are used for the restoration and decoration of the window;

- panels additionally provide good sound absorption, which makes them indispensable in commercial premises; they are easily mounted with special connecting structures of the “thorn-groove” type using the same tools as when working with wood;

- MDF panels are used for the production of entrance metal and interior doors, as well as for the design of ready-made door structures and slopes;

- in unheated rooms for insulating attics, loggias and balconies, as well as for insulating summer cottages;

- decorative panels can be used as interior and exterior decoration of walls and floor coverings in any size of an apartment: in the kitchen, in the corridor, in the bedroom, in the hallway, in the hall, in the living room and even in the toilet.

Other types of furniture fronts

Glass furniture fronts - processed (polished) glass along the edges (including curved glass) with various coatings, are most often used as a decorative element of furniture.

Facades made of artificial stone based on acrylic resin are distinguished by high reliability, durability and ... cost.

Louvered furniture facades are made of solid natural wood. Promotes excellent ventilation of the interior of the furniture.

Roller shutters are a modern version of vertically opening furniture fronts, the so-called furniture blinds. Manufactured from a plastic profile with different coating colors, including those imitating valuable wood species.

Facades covered with leather (natural or artificial) - they look impressive, practical, functional and unpretentious in maintenance.

3D facades - made of MDF board with surface milling imitating waves, sand dunes, flames, bark of natural wood and other ornaments. Lined with PVC foil, or painted in a color that emphasizes the desired special effect.

Facades with photo printing - an image is applied to the surface of the MDF facade using a special technology, which is covered with a protective layer of glossy or matte acrylic varnish.

Acryline facades - a new direction, is a MDF board covered with high-gloss acrylic plastic, which has a variety of colors, is unpretentious in maintenance and is an environmentally friendly material.

Furniture facades made of specific materials (plywood, OSB panels, stainless steel) are suitable both for arranging utility rooms and for creating a unique interior style.

In conclusion, I would like to say that when choosing a furniture facade, it is not so important to know which facade is better in terms of technical quality characteristics, how much it is necessary to have an idea of its appearance, the ability to harmoniously create a comfortable environment or integrate into the existing interior, in the end, it is simply pleasing to the eye and cheer up

Frame fronts made of aluminum profiles

Understanding what kind of facades for furniture are and which facade is better, one cannot but touch upon the topic of frame facades made of aluminum profiles, which are an aluminum frame with inserts of fillings made of various materials: MDF, glass, plastic and others. The best use of facades is the manufacture of modern or hi-tech furniture. Facades with filling of various glass with decorative films, stained glass, engraved, textured or mirrored look especially original. Most often, aluminum profile facades are used in combination with other furniture facades designed in the same style.

Understanding what kind of facades for furniture are and which facade is better, one cannot but touch upon the topic of frame facades made of aluminum profiles, which are an aluminum frame with inserts of fillings made of various materials: MDF, glass, plastic and others. The best use of facades is the manufacture of modern or hi-tech furniture. Facades with filling of various glass with decorative films, stained glass, engraved, textured or mirrored look especially original. Most often, aluminum profile facades are used in combination with other furniture facades designed in the same style.

A unique feature of aluminum facades is their high moisture resistance. The disadvantages include the high cost of both the profile itself and the filler. In addition, for the manufacture of facades from an aluminum profile, special special fittings are required.

How to paint?

If necessary, MDF panels can be painted at home with your own hands. This is done in order to provide them with additional properties of resistance to temperature extremes and moisture. You can paint the panels before and after installation. But it is still preferable to use the second option, since it is much simpler and easier. It is advisable to paint the panels in the bathroom and in the kitchen, since then they can then be washed and wiped down more often. Such surfaces will not warp or swell from moisture and other substances. In addition, colored panels look brighter and more juicy, illuminating the interior, and an increase in service life is also an additional plus.

You can paint the surfaces of MDF panels with a brush or using a colorful machine, which is much more convenient. In this case, the result will be much better. The disadvantages of painting panels include their tendency to fade. If you have already begun to paint, then you will have to tint all the time. And this is much more expensive than using a decorative film.

The paints should be selected based on the characteristics of the structure of the surface material. Often it imitates wood, therefore, its structure is rough. That means we need paints on wood. In general, for the ideal option, you need to use special compounds for this type of wood fiber surfaces. But it doesn't matter.

It is best to use polyurethane enamels for staining. They are also called MDF enamels. The surfaces painted with them can withstand the impact of destructive factors as well as possible. The process itself does not require any special skills; it can be done independently with a brush, roller or paint sprayer. Instead of polyurethane enamel, you can use regular alkyd enamel or oil paints.

For additional protection, it is recommended to paint the painted surface. Some doubt whether it is possible to varnish MDF.It is necessary to cover, as this will consolidate the protective property of the paint and preserve its color. After choosing a certain color scheme and composition, preparation should be carried out. The painting process is preceded by a number of preparatory steps: sanding or leveling, puttying and priming. In the process of surface preparation, the panels are rubbed, chips and other defects are closed, then a layer of primer is applied for better adhesion to the paint composition. The paint is applied in several layers from the periphery to the center, each of the layers of paint is dried.

It is best to use a spray gun as this tool prevents the accumulation of streaks and streaks. After complete drying, the painted surface is varnished in several layers. To achieve the optimal variant, it is enough to use 2-3 layers. Next, the surface is sanded again with water. Now you need to wait a week to carry out the final stage - polishing with special tools. Subject to all the rules and recommendations, painting MDF panels is easy and simple.

Leading manufacturers: choose quality

If you are planning to purchase high-quality wall panels, we advise you to pay attention to the products of leading manufacturers. Such companies offer a decent MDF finishing material that can harmoniously fit into any interior.

Products deserved positive feedback:

- Swiss krono group. A large wood processing enterprise has offices in many countries around the world. High-quality products that meet the requirements of European standards are also manufactured in Russia;

- P&M Kaindl. The Austrian manufacturer occupies a leading position among peers. The availability of modern equipment, high-quality raw materials and compliance with technological requirements make MDF boards from Austria in demand all over the world;

- Sonae Industria. One of the largest companies, located in Portugal, has been on the market for almost 30 years. Produces high quality finishing materials;

- LLC "Master and K". The domestic manufacturer has been producing MDF wall panels for over 20 years. Due to the high quality, the finishing material is sold not only in Russia, but also abroad.

Swiss krono group - excellent quality products

Swiss krono group - excellent quality products

Types and forms

MDF can be divided into several types depending on the method of surface treatment. Sanded with one or both sides of the slab well suited for putty and paint. They are most often used for wall and ceiling decoration. Panels with a thickness of more than 12 mm can also be used for flooring, they are used instead of laminate.

PVC film is made from synthetic polyvinyl chloride, which becomes plastic when heated. Under the influence of vacuum, the heated film is tightly pressed against the facade blank, and when it cools down, it retains the resulting relief.

Veneered boards are boards covered with thin wood cuts (veneer). Such slabs are very similar to solid wood of valuable species, and therefore their price is quite high.

Another type of MDF, which is mainly used in furniture production, is plastic-coated panels

They do not fade under the sun and can be easily cleaned with any cleaning agent, which is especially important for kitchen furniture. Plastic panels allow the production of curved contours and rounded shapes

3D panels are a novelty in the building materials market. The processing of such facades is carried out not only along the contour, but also in the depth of the surface. With the help of milling on the front surface of the facades, various patterns are created "under the tree", "under the waves", "under the sand dunes". The second option for obtaining the 3D effect is repeated painting of MDF, which is then laminated or covered with veneer.

By its shape, MDF can be divided into three types:

- Rack - panels 15-32.5 cm wide and 240-270 cm long.Light strips of material, similar to long laminate planks.

- Tiled - square panels with dimensions from 30 × 30 to 95 × 95 cm, similar to large ceramic tiles.

- Sheet - moisture resistant panels with a height of 2800, 2440, 2344 and 2070 mm, width - 1220, 1035 and 695 mm. It resembles a wall surface faced with small and medium tiles.

What inserts can be made

It is very uncomfortable to be in a room with furniture, whose facades are painted in the same color. It "presses" on people and seems very oversized. To avoid this, use a variety of inserts. In this case, the facades are made from an MDF profile located along the perimeter of the future element. The required element is inserted into the groove of the profile. The standard groove size is 8 mm. If, according to the designer's idea, you have to use a smaller insert, then a special seal is used to help firmly fix all parts of the structure. There are several types of inserts that allow you to create original furniture facades:

- MDF inserts - the inner part, enclosed in profiles, completely repeats their color and texture. The element is used together with other inserts and allows the closed part to stay in the overall design;

- Glass can be placed in framed facades. The furniture set will become much more interesting. Depending on the wishes of the owners, they select film, transparent or patterned glass. The fragile part is secured with a silicone seal. Thus, showcases of any size and shape are created;

- Lovers of bright colors can choose frame facades with MDF inserts, with bright finishes: matte, glossy, metallized, structural. The choice of coating options in this case is limited only by the designer's imagination;

- Inserts from materials unusual for cabinet furniture look original: tapestry or leather. Both of them are incredibly durable and will not lose their original appearance for a long time. Each product wears out the most on the edges, and in this case they are covered with a frame made of MDF and the service life of the textile material is very high.

Leather

Leather

Bright panels

Bright panels

Glass

Glass

Standard sizes and scope of their application

If you purchase a standard panel, it can be successfully used to make:

countertop;

Table top

Facades

Aprons

door panel;

Door panel

cabinet drawers;

Cabinet drawers

profiled surfaces.

Due to the smoothness and stability of the material, it becomes a good choice for areas such as:

- painting;

- applying a decorative film;

- gluing veneer of natural type.

Natural materials are expensive enough to be widely used, especially for wall decoration in public buildings. And in the installation there are also difficulties with a robot with wood.

Therefore, panels have successfully conquered the construction market as an alternative to solid wood. In addition to wall mdf, some slabs are ideal for creating structures such as:

- furniture;

- retail store equipment;

Retail store equipment

- exposition for the exhibition;

- lining;

- elements of architectural compositions.

These and many other designs can be created if you purchase an mdf panel, the wall dimensions of which are presented in a large assortment. This material has high performance:

- resistance to moisture and fire;

- high density;

- correlation with other types of materials.

If it is necessary to make repairs, decorate the room in the desired style, it is advantageous to use mdf panels, the dimensions of which can be selected at your discretion.

Moisture resistant

Here about moisture resistant mdf for walls. They are characterized by a high level of resistance to moisture, steam and wetting.

Due to the fact that mdf has an increased level of density, the ability to process this material is improved. In the recent past, they were made only from wood, and now they are successfully using mdf to create:

kitchen furniture;

Furniture for kitchen

doors;

Doors

skirting boards;

Skirting board

details.

The panels are coated with powder-type melanin. Thus, versatility and great functionality is ensured. When painting, you can get metallic colors, mother-of-pearl and many other shades. This allows you to successfully create original residential and commercial interiors.

For more information about the dimensions of mdf panels, see the video:

Interesting: MDF panels for walls - types and colors

Advantages of plastic facades

- High resistance to mechanical damage (scratches, chips, impacts).

- Increased abrasion resistance.

- Thermal stability.

- Moisture resistance.

- Heat resistance and resistance to thermal shock.

- UV resistance.

- Reliability and durability.

- A wide range of colors and a selection of patterns.

- Relatively low cost (plastic is more expensive than PVC, but cheaper than enamel).

Plastic kitchens will not lose their shine and color after years of active use. Its finish will not fade in the sun, will not deform from moisture, heat and cold. Facades will not peel off from the base and will retain their shape in the most difficult conditions.

Plastic kitchens will not lose their shine and color after years of active use. Its finish will not fade in the sun, will not deform from moisture, heat and cold. Facades will not peel off from the base and will retain their shape in the most difficult conditions.

Characteristics and manufacturing of furniture facades

Before starting a conversation about facades from an MDF profile, it is necessary to explain the composition of the MDF slab - the main element of this entire structure. What is this material that is so popular among furniture manufacturers?

To obtain this component, they use the process of processing the smallest sawdust from different types of wood, which are first dried and then pressed using a hot method. It turns out a medium density fiberboard.

Before pressing, the wood is treated with a special adhesive composition, which includes paraffin and lignin. Therefore, we can safely say that MDF is an environmentally friendly material and does not cause allergic reactions.

These panels are most widely used for interior decoration. Ceiling decoration is also produced with MDF plates. Nowadays, 3D panels for walls have also become popular.

Here is about moisture resistant mdf for walls. MDF panels can be glued to the wall. Manufacturing of frame facades from MDF profile is present in any furniture production. A profile, the thickness of which can be 15-22 mm and a width of 50-80 mm, is connected in a square or rectangular frame. The profile groove has a size of 4 to 10 millimeters.

The appropriate material is installed in it, depending on the style of use of the part. For example, an mdf profile can be filled with a mirror, laminated mdf panels for walls, colored, transparent glass or facade chipboard.

Frame facade with mirror

If the thickness of the filling is less than ten millimeters, a silicone sealant is added to the basic filling material. Let's say the stained glass that will be inserted has a thickness of 7 mm. Then the silicone base will hold the facade filling well enough in the grooves.

The frame profile itself can be laminated with pvc film, painted or finished with natural veneer. The pvc film protects sharp corners during the operation of the part, as they are more often subjected to physical stress.

In addition, the processing of the profile with this compound gives it even greater strength than processing with a melamine film. In the manufacture of frame mdf facades, it will not be difficult to manufacture custom-made parts. The profile can be easily made in the format of the dimensions provided.

A huge palette of colors for filling the frame allows you to create a large selection of colors for frame facades from mdf, while the price will remain invariably affordable for a wide range of consumers.

Various colors

Color laminated MDF board

Colors of laminated MDF can be absolutely any. The main advantage of PVC film is that it can be created with absolutely any pattern and shade. The assortment is simply colossal.Manufacturers produce the following laminated materials:

- transparent and translucent films with a "lace" pattern resembling stained glass or glass decorated with a frosty pattern. An unusual decoration method is used on the radius parts of facades or individual components as an accent

- dense monochrome films of bright clean or pastel colors. More than 200 options are possible in a smooth and textured design. Manufacturers offer 12 different options in white alone (boiled white, ivory, pearl and others)

- films with a pattern for solid wood, marble, fabric, metal. With the help of such films, quite interesting products are created, for example, embossed, 3D, metallized, patinated or brushed.

Experts note that the most popular among customers are such finishes as bleached oak, natural or tinted walnut, ash, cherry.

HPL plastic decors from ARPA INDUSTRIALE (Italy).

(The complete collection of decors is presented in our showrooms!)

- Fantasy decors of ARPA plastic

Paprika mediterranean

Mediterranean pomegranate

Bronze (art. 2527)

Green jasper (art. 2200)

Sea surface (art.2600)

Saffron (art. 2593)

Karkadian sea (art. 2594)

Velvet greens (art.2572)

Polished gold (art.2003)

Cuprite (art. 2201)

Mineral dark red (art.2207)

Natural linen (art.2618)

Cream linen (art.2619)

Pastel Verlaine (art. 2591)

Fantasy (art.2558)

Beige fantasy (art. 2525)

Red fantasy (art. 2526)

Cream tweed (art.3385)

Iced cappuccino (art.9172)

Galaxy white (art.9141)

Universal design - frame facades made of MDF

Furniture manufacturers on all continents have successfully used this new and convenient type of furniture design.

Its use has become so widespread and in demand that it is simply impossible to imagine modern furniture without introducing this unique component into the technological process. It is difficult to point out all the directions where the MDF profile is used for framed facades.

Due to the great versatility and variety of assortment of frame mdf facades, it is possible to work on individual orders of customers and create unique furniture compositions, taking into account special wishes and individual requirements of customers.

Frame facades

The high efficiency of using the MDF profile also lies in the fact that the creation of furniture takes place taking into account such parameters as - the size and interior of the room, the general direction of the design.

Absolutely incredible opportunities for the manufacture of exclusive furniture "to order", provides the use of frame facades from MDF profiles, a photo of beautiful and modern furniture only emphasizes this statement.

For more information about frame facades from mdf, see the video:

Technological features

The technology for the production of plastic facades involves gluing chipboard or fibreboard with thin plastic under a press. The edges of the canvases are pasted over on an edge-hemming machine.

There are different types of plastic for facades:

- roll plastic of medium and cold pressure (CPL);

- high pressure cladding (HPL) plastic sheet.

An interesting novelty is acrylic-based plastic. This material looks impressive. All the beauty comes from a pattern combining a matte background and glossy patterns, or vice versa. The photo below shows samples of plastic facades.

And this is not the whole palette of colors.

And this is not the whole palette of colors.

HPL plastic for facades

The price of sheet laminated plastic is higher than roll, but the quality of the facades will be impressive. The material is made of tough and hard sheets that hold their shape well and have excellent processing characteristics. They are labeled as HPL (English - high pressure laminate). This is an environmentally friendly material. Consumer reviews about him are positive.

Photo: HPL plastic looks pretty nice on the headset

Plastic sheets are produced by pressing special grades of paper.The sheets are impregnated with an absorbent to absorb the polymer resins. They transform paper into a durable multi-layer material.

CPL plastic for facades

Decorative plastic CPL (Continuous Pressure Laminate) resembles leatherette in its structure. Roll material has lower technological properties, but its price is also significantly lower.

In the photo - the kitchen doors are lined with CPL plastic. Looks pretty good too.

In the photo - the kitchen doors are lined with CPL plastic. Looks pretty good too.

Roll plastic is made from polyvinyl chloride. On the net you can find reviews that it is less resistant to damage and in some cases it can fade in the sun. But outwardly, this finish looks harmonious.