Properties of water dispersion paint

In addition to water, the composition of dyes includes fillers, pigments, binding polymers and substances that give the material additional properties. Aqueous dispersion formulations are often sold as a liquid paste that is diluted with water just before use. It is recommended to dilute water emulsions with oily solvents: linseed oil or turpentine.

Main components

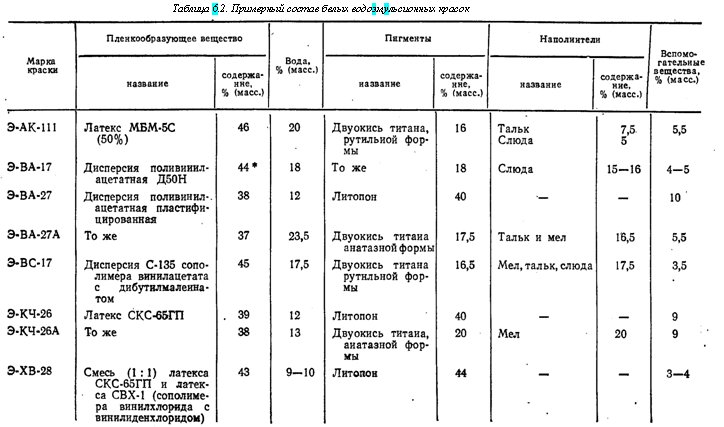

Water-based paints are formulated with materials that determine their performance and performance characteristics. These include the following components:

- Fillers - the smallest marble chips, talc or powdered chalk. These components are responsible for the hardness, wear resistance and other performance properties of the coating.

- Pigments - define colors and shades.

- Binders and film formers are polymers that hold all components together and create a surface layer of paint after the water evaporates.

- Solvents: water - for an aqueous dispersion system, water and oil - for a water-based dye.

- Supplementary components - substances that give the necessary performance properties and improve the technical characteristics of the coating.

Depending on the additional additives, a distinction is made between aqueous dispersions based on polyvinyl acetate, latex and acrylic.

Paints containing PVA perfectly fit on plastered surfaces, wood and concrete. They are inexpensive, easy to apply and dry quickly, but are not suitable for outdoor use and rooms with high humidity, as they are poorly resistant to pollution and weathering. Polyvinyl acetate stains are excellent for indoor walls and ceilings with moderate humidity.

Latex coating is more resistant to moisture and abrasion, is not afraid of dirt and can be used for painting kitchens and bathrooms.

Acrylic dyes have the best protective properties and resistance to external influences. They are not afraid of moisture and dirt. Acrylic compounds can be used indoors with high humidity and for painting exterior walls made of wood, brick and concrete.

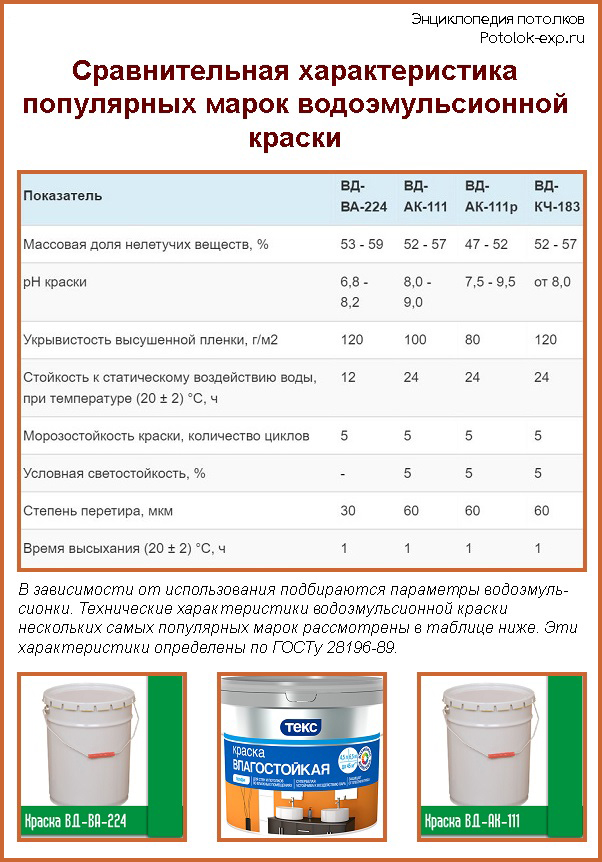

Specifications

In addition to the composition, which largely determines the operational properties of the paint and varnish layer, the main characteristics of water-based paints are:

- viscosity;

- consumption to cover one square meter;

- temperature conditions during storage and application of paint;

- drying speed.

Viscosity determines the fluidity of a material and depends on the concentration of water. The viscosity index of the dye for application with a brush or roller should be about 40-45 St, and for a spray gun - about 20 St.

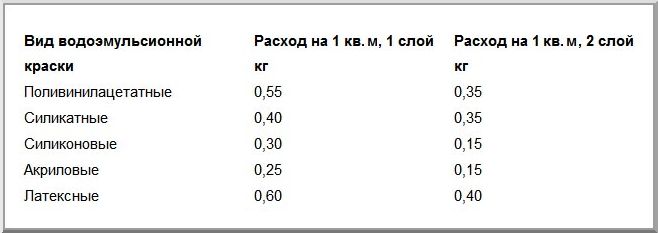

Material consumption per square meter determines the ability to completely paint over the surface in one layer. Water dispersions have good hiding power, so an average of 170 to 220 ml is consumed per square meter. The indicator depends on the viscosity and characteristics of the painted surface.

Water-based paints must not be frozen and used at sub-zero temperatures. It is undesirable to work with the material at temperatures below five degrees Celsius and at high air humidity.

Water-based dyes dry quickly. After 30-45 minutes, the surface layer no longer sticks, and after 8-12 hours the coating dries completely.

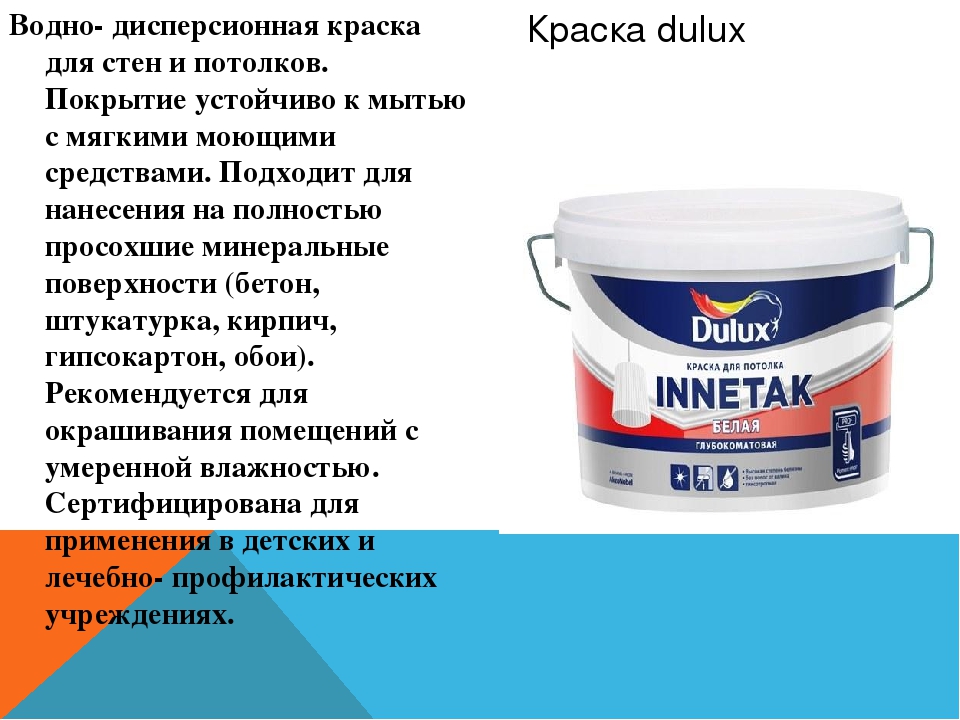

Features of acrylic compounds

The main constituents of this group are acrylic composite and water.During the drying process, not only moisture evaporation occurs, but also the polymerization of the components, due to which a coating with high strength is formed.

Acrylic is suitable for working with glass, metal, wood, canvas, canvas and other materials that have a non-greasy base. Fresh stains of this type of paint can be easily washed off with plain water. However, if the stain is already dry, you have to resort to the help of a solvent.

Advantages of acrylic paints.

- The products are non-toxic and are considered environmentally friendly. They are practically odorless and do not contain harmful substances in their composition.

- A wide color palette allows you to choose an option for every taste. In addition, you can prepare the shade you need in a special machine.

- Acrylic paints are resistant to ultraviolet light, high humidity and temperature extremes. They can be used for decoration both indoors and outdoors. Also, this group of paints and varnishes has a vapor-permeable coating layer, which excludes the accumulation of moisture in the walls.

- The acrylic coating is durable (it stays in excellent condition twice as long as an oil coating).

- The layers dry very quickly. There are brands, the compositions of which dry in 1 hour.

- The quality and aesthetics of the appearance of the painted surface will satisfy the most demanding buyers. After drying, the layers do not crack.

- The paints are resistant to freezing (freeze at temperatures below -40 °). However, it should be remembered that thawing should be gradual, even if it takes several days. This process cannot be accelerated with the help of heating devices, hot water, etc. After the paint has thawed, it is necessary to check whether thickened particles have appeared in it, whether it has delaminated. Then you should thoroughly stir the composition and dilute it with water, if necessary.

The disadvantages of this group of paints and varnishes include their high cost. Also, acrylic paints will not allow the artist to work "raw". They cannot convey the full depth of the work, but skillful handling of them allows you to work on a quickly drying layer.

Properties and features of both types

In order to determine what water-based and water-based paints are, as well as how they differ, several important factors must be taken into account:

- their constituent components;

- specific gravity;

- viscosity;

- consumption;

- application features;

- expiration dates.

Water emulsion

First of all, we will get acquainted with water-based paint and its main characteristics. This type of coating contains water with particles of special polymers and pigments. Sometimes mineral, acrylic or silicone resins may also be present. You can change the viscosity of such a paint by adding a special solvent in various quantities.

The average consumption of water-based paint is about 210 ml of the product per 1 square meter of the painted area. However, this figure may vary depending on the type of surface, the degree of dilution and some other factors. The specific weight of this type of coating, as a rule, is no more than 1.5 kg.

The important advantages typical for this type of paint are:

- high level of environmental safety;

- absolute absence of odor when the coating dries;

- ease and simplicity of application;

- convenient color change by tinting;

- a wide range of tools for application;

- favorable and affordable cost.

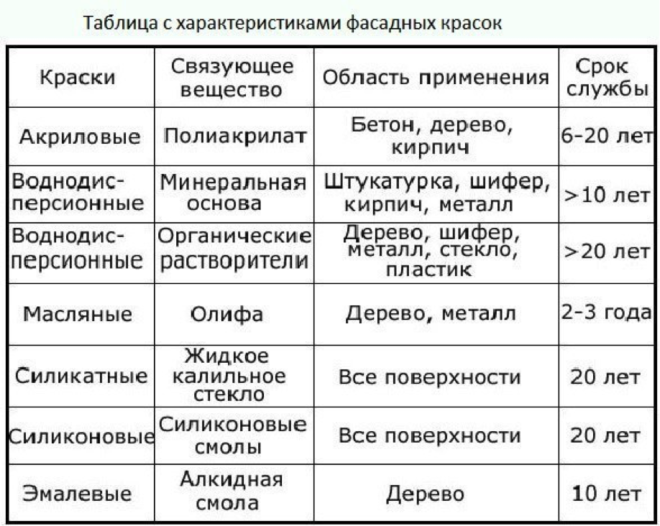

Today there are several varieties of water-based paint, each of which has its own unique properties:

- mineral;

- acrylic;

- silicone;

- silicate.

All of them differ from each other both in composition and in scope. The most budgetary option is mineral water-based coatings.They are usually based on cement or slaked lime. Such coatings are used for painting many types of surfaces, but they cannot boast of a long service life.

The most popular universal option is an acrylic water emulsion. It is ideal for coating plaster, wood, brick and concrete surfaces as well as glass and metal.

The most expensive coating is a silicone water emulsion based on high quality silicone resins. You can cover any kind of surfaces with such paint.

For rooms with a high level of humidity, it is recommended to use silicate water emulsions, which contain liquid glass, as well as coloring pigments.

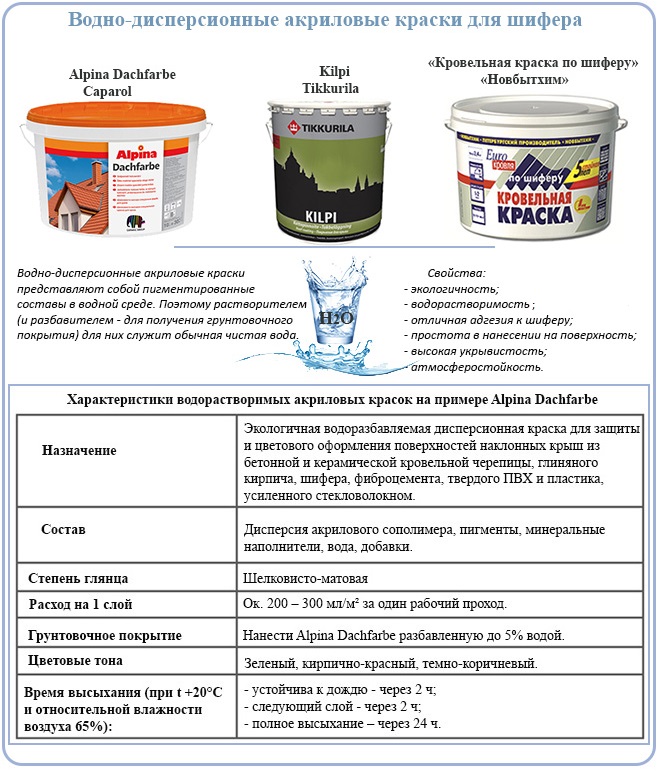

Water dispersion

Now let's move on to water-based paints. These coatings are based on aqueous dispersions, as well as acrylic, latex or polyvinyl acetate binders. In this regard, the scope of application of the paint differs, as well as its strength and moisture-resistant properties.

The simplest and most inexpensive option is a water-based paint based on PVA - polyvinyl acetate. In most cases, it is she who is used to paint ceilings in various rooms. It is highly undesirable to use it in the bathroom and in the kitchen due to its low moisture-resistant abilities. Another significant drawback of this type of paint is its tendency to get dirty rather quickly.

The second type is latex water dispersion. The coating it creates is stronger and more durable. In addition, it is absolutely not afraid of either dirt or water.

And finally, the third type of paint is acrylic water dispersion. Thanks to its high protective properties and ideal resistance to adverse weather conditions, it is ideal for use both inside and outside buildings of various types. It can be applied to concrete and wood surfaces of walls and ceilings. High humidity does not threaten such a coating at all.

Acrylic copolymer based product

The acrylate binder in the composition of these paints can have a varied composition and contain copolymers - additional chains that modify the quality parameters. The number of copolymers available is extensive to cover most of the needs for specialty materials.

The acrylate binder in the composition of these paints can have a varied composition and contain copolymers - additional chains that modify the quality parameters. The number of copolymers available is extensive to cover most of the needs for specialty materials.

The latex component improves the characteristics of acrylic, making the paint more in demand, albeit expensive.

Features and characteristics

Common positive properties inherent in both acrylic and latex paints include:

- strength and durability of the resulting polymer layer;

- saturation of colors that do not lose brightness over time;

- resistance under the influence of ultraviolet radiation of the sun;

- water base, which ensures the non-toxicity of the dye mixture and the absence of unpleasant odors during work.

Latex additives modify the strength and visual properties of acrylic paints, giving them the following characteristics:

- high elasticity - latex paints can be applied over embossed walls and wallpaper, since they follow any curves of the base well;

- aesthetics - rubber additives give the surface a visual silkiness;

- resistance to abrasion and water. Most latex paints are suitable for intensive washing, which cannot be said about ordinary acrylate formulations.

Product types

There is no strict classification of mixtures with rubber additives, although manufacturers usually indicate their properties and purpose in the information on the packaging. The following types of paints are most often distinguished:

- matt, semi-matt and glossy - used for various purposes and surfaces. The glossy mixture is applied only to perfectly flat walls or ceilings, since even minor irregularities and defects under the gloss will become clearly visible.Matt paint is better for less even walls and floors, and semi-matt latex paint based on acrylic copolymer has intermediate properties;

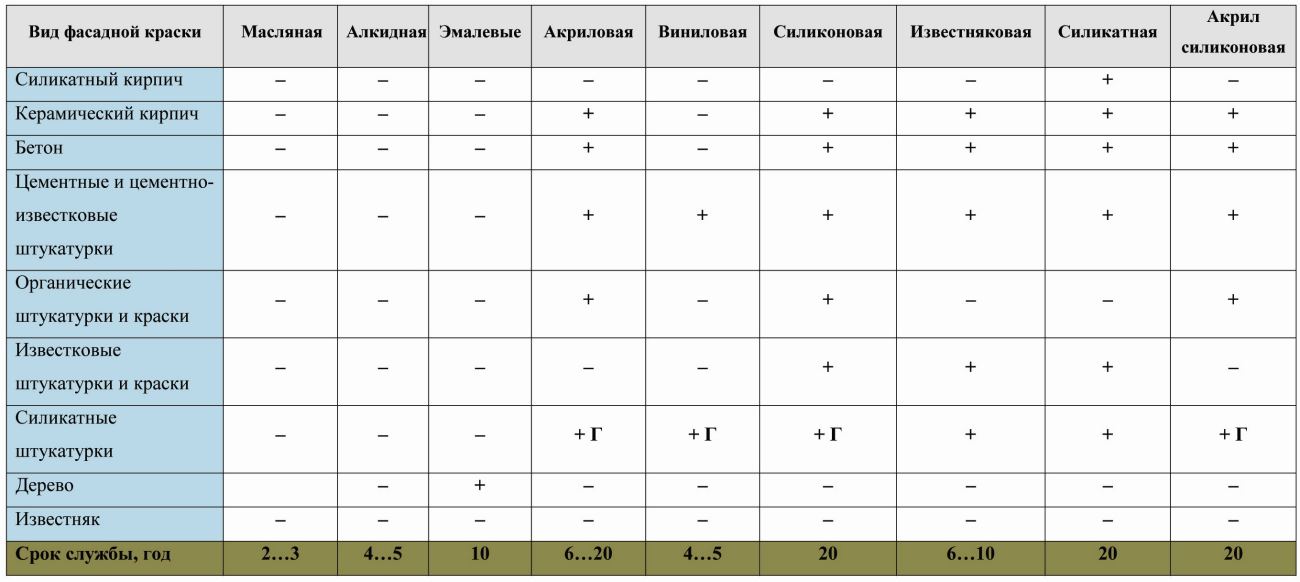

- facade, for walls, ceilings or floors - determine the main purpose of the paint. While most formulations are versatile and can be used for identical purposes, it is best to follow the manufacturer's advice and apply paint to suitable surfaces. And yet, the question often arises as to whether acrylic or silicone facade paint is better suited;

- washable, shock-resistant and moisture-resistant - characterize the main parameters of the coating after evaporation of the diluent (water). The properties of latex acrylic paints are similar to each other, so even compositions of the middle price category will provide high quality of the painted layer.

Material cost

The minimum price for acrylic latex paint is about 200 rubles / liter. The cheapest is the production of little-known firms. Sometimes ordinary acrylic dispersion is sold under the guise of latex paint, and the word "latex" appears only in the inscription on the label.

In order not to be mistaken with the choice, you should purchase products from more well-known manufacturers. The highest quality compositions can cost up to 1000 rubles / liter and more, fully performing the functions assigned to rubber decorative coatings.

Below you will find a useful video on how to treat walls with Snezhka acrylic latex paint, as well as learn about the benefits of this kind of materials:

Next, we'll talk about whether you can mix acrylic and latex paints.

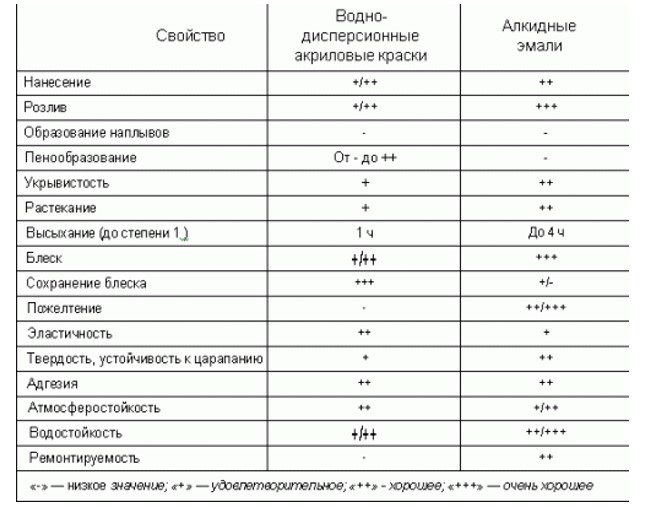

Differences between water-based and acrylic-based paints

There are many types of paints on the market today. Some are only suitable for a specific application on a specific surface, and some are universal.

Any paint is applied for a long period, so it is very important to choose the right not only the right color, but also the composition of the dye

Paints with acrylics

The widespread use of acrylic paints used to create a glossy or matte surface is due to their ability to create a durable opaque finish on almost any primed surface.

The main component in this group of dyes is acrylic resin. The silky structure of this material, which is similar to plastic, allows you to create special paint structures with high strength and decorative properties.

Resin, in combination with a colored pigment and other components, gives paints such additional positive qualities as:

- excellent adhesion or adhesion performance;

- shortened drying times;

- preservation of working and decorative qualities at various ambient temperatures;

- increased resistance to aggressive media and mechanical stress.

The coating is resistant to abrasion and retains well even in high humidity conditions. Most often, flexible polymer paint is used for painting metal and wood surfaces. However, it also fits perfectly on the plastered primed wall after the plaster is completely dry.

Characteristics of water-based paints

Water-based or water-based paints are formed by crushing large particles into small ones. The liquid and the pigment form a compound in which not diluted, but liquefied components are located. The complete set of emulsions of various colors includes polymers.

After the layer has dried, the liquid evaporates, and a hardened polymer film remains on the painted surface. The slurry has no pungent odor, so it can be used at any time of the year.

Its package may include components such as:

- film formers. Polyvinyl acetate and others;

- colored or white pigments such as zinc oxide or titanium dioxide;

- fillers. Chalk, calcite, talc and others;

- thickener. KMTs glue;

- solvent. Water purified from mineral impurities;

- antiseptics and other additives.

The percentage of all included elements turns out to be a decisive factor in determining the purpose of coloring slurries.

Comparison of two types of paints

When comparing the two types of paints, it is worth considering that both of them belong to the category of water-dispersive paints. Composition with acrylic is one of the subspecies of water emulsion.

Improved technical characteristics of the polymer base make it possible to quickly paint smooth and textured surfaces. Such a mixture cannot be washed off with water, even with the help of chemical solvents.

The aqueous suspension is easily removed without the use of special preparations.

The main similar properties of the two mixtures can be considered:

- ease of use;

- almost instant drying;

- ecological cleanliness;

- lack of unpleasant odors;

- slow burnout under the influence of time and ultraviolet radiation.

The composition with the polymer can be used to paint not only wood or plaster, but also metal surfaces. The cover, based on water, absolutely does not adhere to metal and all types of enamels. In addition, an already painted surface cannot be painted with an emulsion on water. In this case, a composition with polyacrylates will work perfectly.

The disadvantage of acrylic dye is its increased cost. But it should be borne in mind that paints containing polyacrylate are consumed much more economically than water-containing ones.

Paints will work equally well after work in the interior. Acrylic paint is more suitable for processing the facades of structures. The coating can last for about ten years. The water-based composition will be washed away by the first rain.

Considering that the acrylic-based version does not crack and is resistant to moisture on all kinds of surfaces, its use is considered more popular.

The uniformity and ease of application of the water-based emulsion will help to quickly paint walls and ceilings made of concrete or brick in the interior.

In order to guarantee to get a uniformly colored layer, it is necessary to buy the necessary coloring chemical compositions only in specialized specialized companies or stores. Managers in such trade organizations carefully observe the rules of storage of goods and track the end terms of use.

Advantages and disadvantages

We examined what dispersion paint is. Now let's highlight its advantages and disadvantages. The first thing worth noting is that the product is safe and environmentally friendly due to the use of water as a solvent.

The paint does not have an unpleasant odor, it does not burn, mold and fungi do not form on the painted surface - this indicates that the paint is breathing.

The life of the dye is about 15 years. In this case, the material will not swell, will not crack. It takes about two hours for the layer to dry completely. Also, among the advantages, an affordable price is distinguished.

There are also disadvantages - the quality of the treated surface depends on the weather.

Do not paint in precipitation or low temperatures. With precipitation, the water will not evaporate. It is also not recommended to paint at high temperatures. Before starting work, it is necessary to prepare the surface - you need it to be flat. A thin layer of paint cannot hide the unevenness. Another disadvantage is that the price can be higher than those products where other solvents are used.

Water-based paints

The most popular tool for applying water-based and water-based paint

This category of paints and varnishes in a wide range is presented on the domestic market and is in obvious demand.

And this is not surprising, since water-based formulations are characterized by the following advantages:

- fast drying (a few hours on average);

- environmental cleanliness and safety and, as a result, no need to use personal safety equipment when carrying out finishing work;

- lack of a specific pungent odor characteristic of most traditional enamels.

- the ability to give the coating a particular color by adding special pigments.

- simple instructions for applying paintwork and the availability of tools necessary for painting;

- affordable price.

Main characteristics

In the photo, the use of water-based paintwork materials as a coating for decorative plaster

- The composition of water-based paints includes components such as filler, latex, thickener and antiseptic additives.

- Viscosity determines how diluted the dye mixture is with water. To measure this parameter, a special tool is used - a viscometer. On average, the viscosity should not exceed 45 Art.

- Consumption of water-based paints when applied in one layer, on average, is 200 ml per square meter. However, consumption is largely determined not only by the characteristics of the coating, but also by the absorbency of the base.

- The specific gravity of paintwork materials does not exceed 1.40 kg / l.

- Drying times depend on air humidity and room temperature. Depending on the brand of paintwork materials, drying can last from 2 hours to a day. The optimum temperature during painting is considered to be + 20 ° C with a humidity of no more than 65%.

Types of water-based paints

On the photo is a water-based composition with the addition of latex

The difference between water-based and water-based paint is the difference in composition.

In accordance with the composition, the following types of water-based paintwork materials differ:

- acrylic;

- mineral;

- silicate;

- silicone.

Acrylic compounds are the most common and sought after. The main component in this case is acrylic resins. To increase the hydrophobicity of the coating, latex is added to the paintwork materials.

Acrylic coating can be applied equally well to wood, masonry, concrete, plaster, glass and metal. A typical example is the fire-retardant paint for metal Polistil. These paintwork materials, despite their specific purpose, are universal and can be applied to any pre-primed surface. (See also How to Putty Walls: Features.)

The composition of mineral water-based coatings includes cement or slaked lime. Such paints and varnishes are used for application to most different surfaces. The disadvantages of these compositions include a small operational resource.

Water-based silicate materials are a mixture of liquid glass, aqueous solution and pigments. Such coatings are characterized by a high degree of vapor permeability, as well as resistance to atmospheric precipitation and temperature extremes. On average, a properly applied coating will last about 20 years.

In silicone water-based paints, silicone resins are used as a binder. Such compositions are an order of magnitude more expensive than analogues, but also have high strength and durability.

Application

Is it difficult to paint the walls or ceiling with your own hands? Let's find out.

To learn more about how to paint the ceiling perfectly, the video in this article will help you.

Surface preparation

It consists of three stages:

- Cleaning from old coatings. In general, a water-based emulsion can be applied only over the same paint, on the same binder. Acrylic paint will not adhere to nitro enamel or oil paint;

- Elimination of defects. Potholes and chips are putty, protrusions are removed by grinding. After puttingtying, the wall is sanded and cleaned of dust (see);

- Padding. The penetrating primer reduces paint consumption (primarily during the application of the first coat) and makes the surface more durable.The primer must be of the same type as the paint (silicone, acrylic, silicate, etc.).

Painting

What tools can be used for painting?

Quite standard: brushes, rollers and spray guns. The author uses a wide roller with a medium bristle and medium width with a brush for painting corners and other problem areas for the roller. A paint tray is useful for rolling out the roller, and masking tape is useful for protecting non-paintable surfaces.

For painting surfaces in residential premises, water-dispersed or water-based paints are most often used. Despite the fact that the basic substance in both cases is water, these compositions are still different.

Below we will consider the main differences between water-dispersion and water-based paints. To understand what they are, it is necessary to take into account the technical indicators: composition, consumption, viscosity, hiding power, specific gravity, durability, as well as features of the use of materials.

This type of paintwork materials is widely known to the domestic user and has found application in many areas due to the following advantages:

Among the disadvantages should be noted exposure to low temperatures, especially at the time of application. The working temperature should be above 5 degrees. In addition, this type of material should not be applied to metal products or surfaces that absorb a lot of moisture. In the first case, the paint will cause corrosion, in the second - premature destruction of the surface.

Water-based paints are intended exclusively for interior or facade work

Water-based paints are intended exclusively for interior or facade work

Specifications

Ingredients such as latex, thickeners, fillers and optional additives to increase resistance to water, ultraviolet rays and so on are included in the composition of water-based paints and varnishes. The viscosity of this material is controlled by water. To determine this indicator, a special tool is used - a viscometer. The optimal viscosity index is 40-45 St when using hand tools (rollers, brushes, sponges, etc.). If you plan to apply the material by means of a spray gun, then this indicator should be no more than 25 Art.

If we take the average data provided by manufacturers, then the consumption of water-based paint is 200 ml per 1 square meter of the treated surface. But in fact, this characteristic may be different due to the absorbency of the base, the degree of its preparation, the tool used, and so on.

The average specific gravity of this type of paint does not exceed 1.4 kilograms per liter. Drying time directly depends on the humidity and temperature in the room. Also, different compositions can dry for different times: from 2 hours to a day. It should also be noted that it is better to carry out painting work at a temperature of about 20 degrees Celsius and a relative humidity of 65-70%.

Types of water-based compositions

The modern construction market offers the following types of materials:

- Acrylic.

As the name implies, the material is based on acrylic resins. These compounds are considered to be of sufficient quality, strong and durable. - Mineral.

Slaked lime or cement are additional ingredients. Paints are capable of hiding small defects in the surface to be treated, but at the same time they do not last long. - Silicate.

They are a mixture of liquid glass, dye and solvent. They can last up to 20 years without losing their original appearance. - Silicone.

The strongest and most durable materials, but, unfortunately, very expensive. This is mainly what distinguishes formulations from water-based paint.

Feature of water-based dyes

Humanity invented paints many millennia ago.Initially, they were used to apply various drawings: they were primarily a means of displaying the inner and outer world.

Later, people realized that by coating a certain material with a dye, it is possible to protect the surface from negative environmental influences. In addition, the aesthetic qualities of the product are improved as a result.

Since then, the world's population began to actively use paints, most of which consist of drying oil, solvents and inorganic pigments. These include oil and many others. Water-based paints, which appeared only at the beginning of the 20th century, stand apart here. And this is already a more perfect view.

Such dyes in their structure contain ordinary water, color pigments of an insoluble type and polymers that perform a binding function. Some other elements can be added to improve or change the quality.