How to properly sand walls and ceilings

As you know, in order to give the surface smoothness and uniformity, only a high-quality putty is not enough. Walls and ceilings must be sanded. If this is not done, then the subsequent finish will no longer be of high quality. It is highly discouraged to apply paint on a non-sanded surface, gluing wallpaper is also risky.

In order to sand the starter putty, you need a coarse sandpaper. For the finishing putty, a small skin is needed: the smaller, the better, but the harder it will work with it and the more often it will have to be changed.

You will also need a handcrafted skinner to put on the skin. Electric tools are not recommended for sanding walls and ceilings because they do not give the desired results. Therefore, if you want to sand everything thoroughly, then use only a hand tool and be patient.

The surface you are going to skin should be well lit. If you skin in the twilight, then the result can be sad. So get a carrier and a bright light bulb ready. Form obliquely incident light onto the surface by carrying.

You need to prepare a respirator because there will be a lot of dust. When you sand the ceiling, the dust will fly straight into your eyes, so it's best to wear safety glasses as well.

It is necessary to sand the surface only with circular rotations of the hand. If you try to sand up and down, left and right, you can damage the putty or break the plane.

If you are sanding walls, then start from the top and gradually go down, so that you will not be disturbed by the dust that falls on the wall, sticks and interferes with normal operation. However, it still does not hurt to clean the walls from dust, so as not to miss all sorts of flaws and influxes.

If during sanding you find pits and scratches, then they will need to be repaired later with putty, and not try to somehow level them with sandpaper. If you do this, you can simply break the plane.

After the entire surface is sanded, it must be thoroughly cleaned of dust and primed with deep penetration soil. It is obligatory to prime !!!

What kind of sandpaper to clean a car before painting? Read and memorize

What kind of sandpaper to clean a car before painting? Before answering this question, figure out what exactly you are going to do with the car, as well as how much corrosion has eaten into the body. In some cases, there is not enough sandpaper, then you will have to use a grinder for work. In practice, the entire range of sandpaper can be used for painting. Below we will analyze the main types and methods of using sandpaper.

Before starting work on updating the exterior of the car, it makes sense to conduct an experiment. Soak a cloth with solvent and place it on the body. After waiting 20 minutes, look at the result. If the paint has not changed its appearance, then it is possible not to strip it off entirely. Only clean out areas damaged by corrosion. If the paint is warped, then you will have to clean the whole body of it. Otherwise there will be problems with swelling of the fresh coating.

Often, beginners do not know how to properly clean the body from rust and paint. A large volume is usually processed with a grinder. This will save you time and effort. If you do not have such a tool, then you will have to use sandpaper. For large volumes, take a block and wrap it with suitable sandpaper. Then, in a circular motion, the body is cleaned of paint. In areas damaged by corrosion, it is recommended to clean by hand.

Grout the primer by hand only. With this method, you can carefully sand down all the slightest irregularities. So it will turn out to make the most high-quality base for applying paint. The grouting process itself is carried out in uniform circular movements.

The putty is sanded only after complete drying. Before starting work, check the degree of drying of the substance. To do this, you need to run the sandpaper over the putty. If stuck fibers appear in the beans, it is better to wait a little longer. Sand the putty stain in a circular motion from edge to center. This work takes place in 2 stages. First, a rough leveling is performed, after which it is brought to a normal state with a finer grade of abrasive.

It is imperative to sand the housing thoroughly before priming. Often beginners do not pay enough attention to sanding before priming.

Don't hope that the primer will cover up all your jambs. This is not the case, all the little things will be seen even more. Sand the body thoroughly with medium sandpaper. A bar is used to speed up the process. It is better not to use a sander.

In the process of restoring the body, a beginner may wonder what kind of sandpaper to clean a car with before painting. In fact, almost all of the commercially available line is used. For each operation, paper with the appropriate grain is used. This makes the paintwork perfect.

Repair of serious damage to an element

Plastic is rather short-lived and easily lends itself to some types of damage, for example, scratches, chips, cracks, in some cases it can simply burst. Serious damage can be repaired in two ways: using welding or gluing the part. Welding a bumper is a more reliable way, but it can bring you a lot of hassle. First of all, you must have a set of necessary tools. You will have to purchase a special soldering iron, electrodes, hair dryer, special scissors, etc. It turns out that the method is far from cheap.

If you decide to fix the bumper of your car using the gluing method, then it will cost you much less. To do this, it is enough to purchase a special repair kit in any car store. It includes about 2 meters of reinforcing glass fabric, epoxy resin and hardener. The extended kits also include a plastic-like putty, emery cloth and a mixing tank.

They cost about $ 50-60, so each of you can afford to buy them. If you find any tears, cracks or holes on the bumper of your car, apply reinforcing fiberglass to the outside of the bumper. In order for the repair coating to be more durable, it is advisable to glue 3-4 layers of material.

About abrasive mesh and sandpaper

Good results are obtained using a special grinder, but are often limited to the manual method. The second method, if you need to grout the ceiling after puttingty, is the most frequently used by professionals, since this is the easiest option to remove roughness in areas that are difficult to access. The choice in favor of the machine polishing method is logical if you need to process a large area. But even after such work, there may be a need for manual processing - anyway, when checking, bumps of different sizes are found.

Inspect the treatment surface before purchasing the material. Then you will understand how to sand the ceiling after putty without interruption. If it seems complex and uneven, more coarse mesh will be needed.

Let's see how you can skin the ceiling for painting.

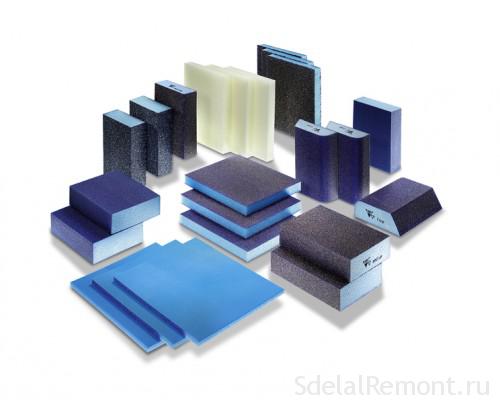

Abrasive mesh

Grinding mesh is a material with many advantages. Dust does not clog the cells it consists of as much as sandpaper. The removed putty goes through it.If it is worn out, it is easy to understand by its appearance, and then it is better to simply replace it. The sanding mesh is water resistant.

At retail, the mesh is sold in size for a bar. It is better to choose materials of the same size. The bar should be smaller than the mesh. The folded edges are secured using nails. Also, the stores sell a special holder.

The grinding mesh is available in several cage sizes. When working with a normal surface, two types are enough.

The main disadvantage of the abrasive mesh is its high cost.

Sandpaper

Sandpaper is characterized by the fact that its surface is filled with dust faster. It needs to be replaced more often. But the cost of the material is significantly less. It is also easier to sand the corners with sandpaper than a mesh.

When choosing what kind of sandpaper to rub the putty on the ceiling, you need to focus on the size of the grain - it is this indicator that will tell you what type of work can be done. Understand the labeling. In our country, there is a special GOST, FEPA and ISO 6344 standards used abroad are also in effect. The degree of "graininess" is indicated by a number. The larger the abrasive, the lower the indicated figure.

You can save money by choosing rolled emery - the material consumption is not small, and the sandpaper cut under the bar is more expensive (although the price is worth the saved time, which does not have to be spent to cut the paper).

Sandpaper is divided into categories:

- the size of the sandpaper, its grit

- scope of use

- form of issue

There is a certain amount of abrasive particles on one square inch of sandpaper. They are indicated by the numbers of sandpaper. According to this indicator, the material is divided into several categories:

Coarse-grained

Sandpaper that cleans surfaces from old coatings (varnish, paint) and traces of initial processing. It consists of coarse abrasive, coarse fractions, and after removing the top layer, grooves and scratches remain on the material. Further processing is required. With this material, the surface grinds well, but it is very difficult to achieve final evenness. With its help, the first grinding is carried out. Numbers 12-80.

Medium-grained

Multilayer processing becomes smoother and better. The surface can be smoothed and leveled, but traces will still remain. Numbers 80-160.

Fine-grained

It is necessary to remove defects from previous polishes, when the surface needs to be prepared for final processing (for example, before applying paint). A suitable option is zero. Numbers 160-4000.

Each material is different, but the order of work is the same for them

When deciding which sandpaper to sand the ceiling with before painting, it is important to remember that the coarse particles are used first. Then they switch to using paper with a finer abrasive, and at the final stage, polishing is performed.

Wall grinding technology

In the first step, use a spatula to go over the entire surface of the wall. Remove bumps, all kinds of protrusions, nodules. If you find large depressions or pits, fill them up, do not try to remove them by sanding.

The second stage includes surface treatment with coarse sandpaper or sanding mesh. The consumable is attached to a sanding block.

Surface grinding is carried out from top to bottom, processing small areas with rotary movements. The size of the plot should not exceed 1 × 1 m.

It is better to grind from top to bottom in strips no wider than 1 m. Hand movements during grinding are performed in a circle, but you can also move up and down or left and right.

Do not press hard on the tool and sand in one place for a long time. You can wipe off the entire layer of putty.

After sanding the entire surface with a coarse abrasive, continue sanding with fine sandpaper. When using finer emery material, be sure to bring the light source as close to the wall as possible.

Hard-to-reach places are sanded with sanding sponges or the old-fashioned method, folded in several layers with sandpaper.

Never work corners or hard-to-reach places with a skin trowel. You will only spoil the surface.

If the abrasive material leaves scratches, choose a finer sandpaper. Under the wallpaper, slight scratches are allowed on the sanded surface after putty. But for painting, the surface of the walls must be absolutely flat. Read how to prepare a wall for painting.

The grinding process is laborious and requires a lot of effort to complete. It can be mechanized using a special grinder. Grinding machines are available that provide for the connection of a vacuum cleaner, which makes the grinding process almost dust-free.

Do not use a belt sander. They are good for working with wood. An eccentric or orbital sander will do.

Although the use of a grinding machine speeds up the grinding process, it is very difficult for a novice builder to get a high-quality sanded surface without special skills.

It is necessary to feel the tool not only to move it correctly, but also to regulate the pressure of the tool on the ground plane. And such a tool is quite expensive.

After sanding, remove the dust layer, do a damp mop and check the surface quality. Before finishing, a layer of primer must be applied.

Sanding a ceiling is no different than sanding a wall. The process is more time consuming and requires patience and accuracy.

Once again about the abrasive material

The sanding mesh is more convenient than sandpaper because it does not get clogged with debris and dust during operation. But the right sandpaper also gives good results and is significantly cheaper. When sanding walls after plastering with your own hands, it is best to use sandpaper numbers 120 ... 180 (coarse-grained), and finish grinding with abrasive numbers 220-280 (fine-grained).

The sandpaper and mesh are marked the same way on the back of the material.

How to quickly perform a dust-free grout?

On the walls

For the walls, you first need to pick up a tool. For initial sanding, it is sandpaper with a grit number 60, for subsequent sanding - 120 and above. If you need to grind large areas, it is best to do this with a grinder. Although you will have to spend some time for manual grouting of the formed depressions, corners, recesses.

After puttingtying, it will be correct to sand the walls in the following order:

First, the entire surface is examined for flaws. To do this, you need to provide bright lighting in the room: take a powerful searchlight or a hand-held flashlight, install it as close to the workplace as possible

The hollows, darkened due to the refraction of light, are outlined with a pencil, so that later you can pay special attention to these places.

Start sanding from any angle. But the angular origin is necessary to get a uniform result.

First, they define a strip about 1 meter wide and move from the corner from top to bottom in movements resembling a spiral. At the end of work with one strip, proceed immediately to the other part.

The finishing putty should be cleaned in the same way as the starting coat. Sandpaper helps a lot here. It evenly cleans off the formed bumps, makes the surface smooth.

Advice

All movements should be smooth and accurate. No strong pressure is needed to avoid damaging the fresh layer of putty.

To level the grooves, you should not use a general level, since the grouting process is perfectly performed without it. The walls are smooth and beautiful.

Video on how to grind walls after plastering with your own hands:

On the ceiling

To work with the ceiling, you need to have sandpaper and an abrasive mesh.It is best to use wet sanding. The method is long in time, since you have to wait for each individual layer to dry. But it is very convenient for independent work. Many people find it convenient to use a sander, although you can just do everything by hand.

Stripping sequence:

- First, sandpaper with a grain of 60 is taken, after the starting layer - 120, when you need to clean the finishing paint. You can use any other methods, but the proposed ones will be the most convenient, and work with paper of the desired grain will finish quickly.

- As well as on the walls, the ceiling must be additionally illuminated. This is the only way to identify all the flaws, to correct them. In this case, grouting should also start from one corner, gradually moving to another corner. It is necessary to allocate a separate lane along which the work will be carried out.

- After sanding, the ceiling is primed. Once the primer coat is dry, repeat the process if necessary. Only then is it treated with an antifungal agent.

- A sanding block is used to effectively sand the corners between the ceiling and walls. It is also used for grouting curly objects and protrusions.

A sanding mesh or emery material is suitable as a trowel base. If you plan to paint the ceiling later, then you need to process it simultaneously with filling. The places of the deepening must be reworked with putty.

From the video you will learn how to rub the ceiling after puttingty before painting:

On the floor and large plane

After the putty layer has dried, you should walk over the entire working surface with a medium-sized spatula. With this tool, you need to remove all the protruding tubercles, the formed nodules, and the volumetric, deep pits must be carefully putty again. Such large flaws cannot be simply rubbed with an emery tool.

After the putty layer has dried, you should walk over the entire working surface with a medium-sized spatula. With this tool, you need to remove all the protruding tubercles, the formed nodules, and the volumetric, deep pits must be carefully putty again. Such large flaws cannot be simply rubbed with an emery tool.

Grinding begins only after the floor surface has completely dried. Provide ideal lighting in which all imperfections and irregularities are visible in order to eliminate them. First, use coarse sandpaper or a sanding mesh. At the same time, it is convenient to attach the consumable to the sanding bar.

Movements should be of the same direction and strength. You can start grouting from any corner of the room and move in spiral circles along the entire area, while choosing small pieces. After grinding one spatial area, you should gradually move to the second, while ensuring a smooth transition (there should be no restrictions or patterns).

After sanding the entire surface with a coarse abrasive, continue sanding with fine sandpaper. When sanding, bring the light source as close to the floor as possible.

Advice

Corner places should be additionally processed with sanding sponges or by folding sandpaper in several layers. This method will provide a gentle and thorough sanding of hard-to-reach areas.

Wet sanding

If you don't have the desire or the ability (or both) to dry-sand, in this case, you can resort to the old grandfather's method: take some water and go through the entire surface with a waterproof sandpaper. First with a bar, and then by hand (with even pressure, without leaning on the fingers).

Only in this case it is necessary to take a finer abrasive: P800-P1000. You can preliminarily knock down the shagreen and cut down irregularities with a coarser sandpaper, for example P600, but then you still need to interrupt the risk with a smaller abrasive, taking into account the grinding step (after P600 it increases to 200 units).

When sanding soil, it is important to monitor the integrity of the coating, especially when working wet - it is clear that water can become a source of corrosion. In addition, such an unpleasant defect as "bubbling" and other problems may occur.

Be that as it may, after working with water, the part must be thoroughly rinsed, removing the remnants of the grinded material and dried thoroughly.

And the last thing. The part sanded for painting should stand no more than 24 hours. If after a day it is not painted, it must be re-grinded with a final abrasive.

This is necessary for the reason that the risks on the filler (those that are not visible to the naked eye) begin to crack during the drying process, drawing in moisture, dust and dirt from the environment. It is then impossible to get them out of there and they have an extremely negative effect on the quality of the paintwork.

Therefore, if the part has stood waiting for painting for more than a day, the old cracked micro-layer must be knocked down. Remember to degrease the surface before doing this.

Dry sanding

If we are a proponent of progressive dry sanding, we can do most of the work with a sander. However, we still will not be able to completely avoid "manual labor".

Firstly, there are quite a lot of zones on the car body where you simply cannot crawl with a machine. Secondly, those areas of the soil that are applied to the filled places must first be sanded by hand in order to "outline" the plane and even out the unevenness of the layer. To do this, we need a sanding block and an abrasive strip, for example P320.

If the layer thickness allows, you can take a slightly coarser abrasive, for example 240 or P280, this allows in some cases to better "cut" the plane. But you need to grind carefully so as not to break through the filler, and then you definitely need to interrupt the risk with the gradation P320 (you can do this already on a typewriter). Remember the 100-unit rule!

In order to facilitate the finishing of the surface, it is recommended to apply a developing coating to the primed area before sanding. Both dry and spray development can be used.

If you use a spray-on development coating (sometimes the remains of the base enamel are used for this), then it can be applied to the surface only after the soil has completely dried. Otherwise, it can negatively affect the strength of the soil, it can become looser and prone to shrinkage, and when sanding it will heavily clog the paper.

Grinding itself must be performed with diagonal movements so that the irregularities are “cut down” evenly over the entire area.

Apply a dry development coating

Apply a dry development coating We sand the surface with hand sanding and an abrasive strip P320. Grinding should be done with diagonal movements so that irregularities are "cut off" evenly over the entire plane

We sand the surface with hand sanding and an abrasive strip P320. Grinding should be done with diagonal movements so that irregularities are "cut off" evenly over the entire plane

After the alignment on the sanding is completed, you can proceed to the surface finishing. With this operation, we will remove the directional marks left after manual grinding and create the necessary roughness on the surface for the adhesion of the cover enamel.

For finishing the filler, we need a sander with a small eccentric stroke (optimally 3 mm) and a soft sole. The small eccentric stroke and the soft sole are due to the fact that the surface for painting requires more delicate processing, so that we only repeat the general contour of the part, knocking down the risk, but not breaking the shape and not grinding the filler.

With regard to the choice of abrasive materials for finishing:

- for the application of acrylic enamel, it is enough to process the surface with P320-P400 circles, applied successively;

- if the "base + varnish" coating is applied, the surface is processed with P400-P500 wheels;

- for some complex colors, for example light mother-of-pearl, if the manufacturer's recommendation is made, finish the treatment with the material of gradation P600.

When sanding, make sure that the working surface of the grinder is completely in contact with the surface to be treated, and the pressure on the sole is uniform. Many people cannot get used to this - they just want to press harder on the edge of the sole to “speed up” the process. Some do so, thereby creating irreparable "holes".

Before sanding, you can reapply the developer coat to make it easier to identify under-treated areas.

Reapply the developing coating

Reapply the developing coating We consistently lower the risk with circles of gradation P400-P500

We consistently lower the risk with circles of gradation P400-P500

Processing of hard-to-reach places

The main surface is finished. But what about those places where it is impossible to carry out processing with a machine or a bar due to the risk of ruining the surface? These can be the edges of a part, curved surfaces, various hard-to-reach places. For processing such areas, it is convenient to use special abrasive sponges made on a foam rubber base - they are elastic and do not cut sharp corners.

For soil treatment, sponges of P600-P800 gradation (Superfine / Ultrafine) are suitable, applied successively. You need to sand with the entire surface of the palm with even pressure and in one direction. If you grind with your "fingers", you can make stripes.

After grinding, the part is blown with compressed air and degreased. Ready!

How to sand the ceiling after putty?

The ceiling draws no less attention than the walls, and every flaw on its surface will be conspicuous. The technology for sanding this surface is no different from sanding walls, except that it is much more difficult to carry out work on the ceiling. Therefore, in the question of how to sand the ceiling after putty, it is better to understand, having in the arsenal of grinding machines.

A mesh for grinding putty # 60–80 is put on the machine, if a rough cleaning is performed; mesh # 100 if finishing sanding. To reach the surface, you need to use a stepladder. If a machine with a special bar is used, the surface treatment is carried out directly from the floor. How to properly putty a door for painting?

Grinding the surface in a circular motion until it is perfectly smooth.

Primary sanding of the putty allows you to remove large defects. After its completion, you need to remove construction debris, debris, dust and check the surfaces for cracks and minor flaws, and then you can apply a layer of finishing putty. When the surface is dry, you can proceed with the final sanding with a fine-grained abrasive.

The technology remains the same as described above, but in this case all movements should be less sweeping and more accurate.

Additional Information:

- Grouting the putty with a grid is the most optimal option, since it allows you to quickly and efficiently prepare the walls for finishing work without dust, quickly and efficiently. Of the advantages, it should be said about the high wear resistance of the material. Among the disadvantages is a periodic change. In construction hypermarkets, nets of various qualities and sizes are sold today.

- Sandpaper is much inferior in quality to a sanding mesh, while it allows you to effectively process walls. There are materials on the market with grain numbers 60, 80, 100, 120 - which one is right for you is difficult to guess. As a rule, 120 grit is used for the final sanding, but sometimes 60 is suitable. For this reason, it is recommended to purchase the material in small quantities.

All abrasive materials differ in grain size, the larger it is, the rougher the surface of the sandpaper, and the smaller it is, the finer the processing is. This indicator is marked with the letter "P" and a number, the larger it is, the less graininess. That is, the P80 variant is much rougher than the P180, and so on.

Polishing must be done very carefully. Any oversight can ruin all the work done earlier. If you are not confident in your abilities, then it is better to turn to a more experienced person.

Polishing is carried out in several stages. First, a coarser sandpaper is used (2000-3000), after that the smallest one (4000-5000) is used. Finishing is done with felt.

- inability to move easily and comfortably;

- discomfort when going up and down stairs;

- unpleasant crunching, clicking not on their own;

- pain during or after exercise;

- joint inflammation and swelling;

- unreasonable and sometimes unbearable aching pain in the joints.

2. A set of spatulas. Be sure to choose a trowel of different sizes. In work, you will have to use both large spatulas (40-50 cm) and very small ones. Indeed, in problematic hard-to-reach places, it will not be possible to properly putty the wall with a large spatula.

How to properly putty styrofoam on the outer wall of the video? This is exactly what small spatulas are used for.

The sandpaper used to smooth the putty has one significant drawback - it quickly clogs up with dust and has to be changed quite often. Therefore, masters advise using a sanding mesh instead. It costs a little more, but this is fully justified by the lower cost.

The marking of this material is exactly the same as that of imported sandpaper.

There is a dust collector on the motor shaft of the grinder. It is here that all the dust that is released during the work is sucked in. The machine is connected to the dust collector by means of a corrugation.

As the reviews note, when sanding the walls after puttingty with a grinder, dust is practically not formed. And therefore, wet cleaning will be much easier at the end of the work. But such a unit has a drawback - it is high cost.

Buying such equipment for the sake of one time is unprofitable, so it makes sense to rent it.

Conclusion

Almost any home renovation work can be done on your own if you know how to do it right. Grinding is the simplest of them, albeit a rather messy and laborious one. The video in this article will help you master it perfectly.

The process of processing walls or ceilings involves many stages. It all starts with preliminary preparation, which depends on the state of the surface. This can be removing the old layer or the work from the beginning, which is always much preferable. In any case, the last step will be sanding the walls after the putty. This is the final stage of processing, further finishing is assumed.

(ceiling) means two types of finishing work - plaster and putty. After plastering the surface, even if everything was done as best as possible, there are still various uneven areas on it. This is due to the fact that the tool for such work has sharp corners. Even if you work with an exceptionally wide trowel, this cannot be avoided. Therefore, before starting finishing, you should carefully level the desired area.

Based on the area that needs processing, the choice of the best method and the necessary tools is made. How to sand the walls after putty:

- a small surface can be processed with a sanding bar;

- the presence of large areas of work requires the use of an electric tool (flat sander), but you need to understand that all hard-to-reach places, corners will have to be adjusted by hand;

- on complex structures where there are bends and protrusions, it is advisable to use an eccentric grinding machine;

- the ceiling can be evenly sanded with a power tool.

Grinding bar

This tool is pretty easy to use. It is a flat base with clamps and a handle. Sandpaper is used as an abrasive material. You can also use a special mesh. Both of these materials are equally attached to the timber. It is impossible to say for sure what is best to use. Each specific case should be approached individually.

The sanding mesh has several advantages: it is sold already cut belts, its service life is much longer, due to the fact that dust does not linger in it, but it is much more expensive than sandpaper. The latter, in addition to its low price, does not have noticeable advantages, but it suits well for small works. For large-scale projects, sandpaper is required a lot, which significantly slows down the process itself (it needs to be changed often). It also affects the final cost.

When the choice falls on paper (emery), and not on the mesh, then it should be correctly selected. This is done empirically. Take a piece (grain size 60 to 100) and sample it on the wall. On an abrasive that copes with the task, and you need to opt for.

Painting walls and ceilings requires a lot of sanding effort. First, a coarse-grained abrasive is used, and then a fine one. This is the only way to eliminate all flaws.

Sander

This is a very handy tool. With such a tool, you can do the job in a short time.

It is very important to choose the right model that will meet all the necessary parameters. As grinding materials, sandpaper is also used here, but you can purchase ready-made "consumables" that will be much more effective

The convenience of the machines lies in the fact that it is not so hard to work with them, you do not need to make so much effort, especially at a height.

Grinder - it is advisable to use on large areas

Grinder - it is advisable to use on large areas

The process of filling the abrasive is individual, it depends on which brand (manufacturer) the tool is used. For correct operation, read the instructions.

DIY tool

You can make a do-it-yourself grinding attachment. To do this, you need a block of wood, a piece of plastic profile, from one centimeter thick. The main thing is a flat surface, preferably on both sides. To get a "grater" with different grain sizes, two types of sandpaper are used. It is cut into strips. On each side of the bar, double-sided tape is glued, abrasive on it. Everything, you can use it. Of course, such a device can be improved. It is suitable for urgent or small jobs. But the grid cannot be used.