Plastic ceiling cladding technology

Installation of the supporting frame

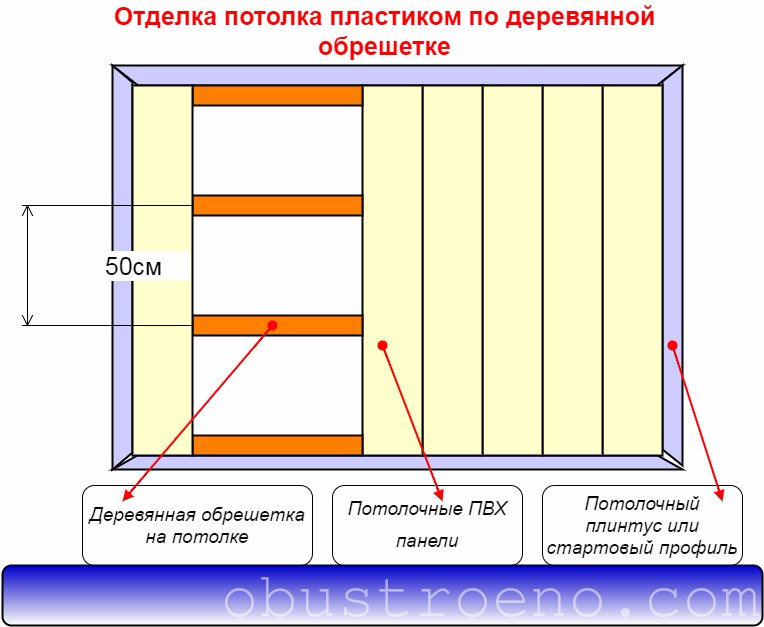

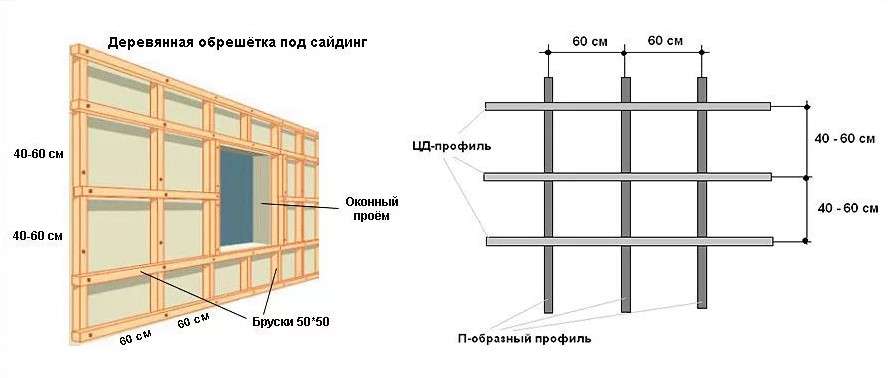

Wooden frame for plastic ceiling sheathing

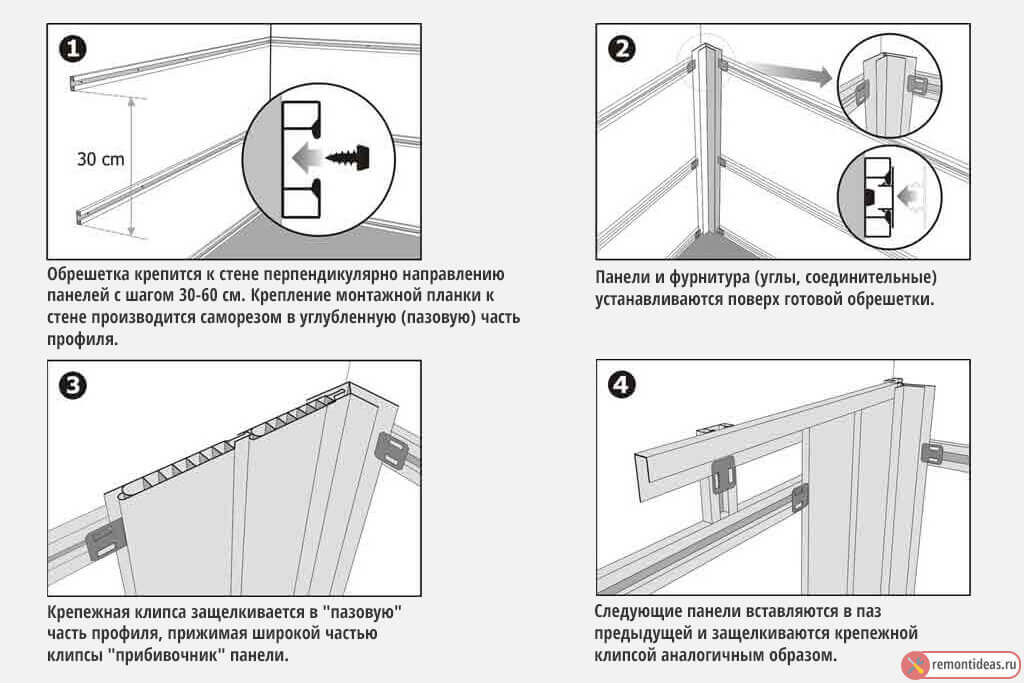

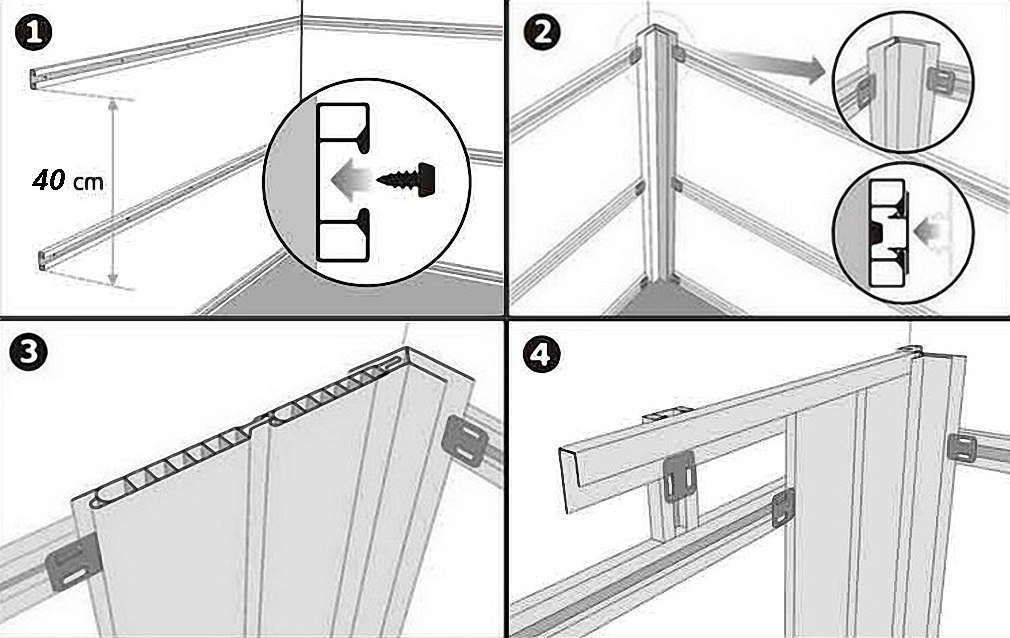

Before you hem the ceiling with plastic panels with your own hands, you need to build a supporting structure, to which the plastic trim elements will be attached. The installation process will look like this:

- Before installing the frame, the ceiling base is cleaned of the old, poorly adhered finish. If it is held securely, you can mount directly on it.

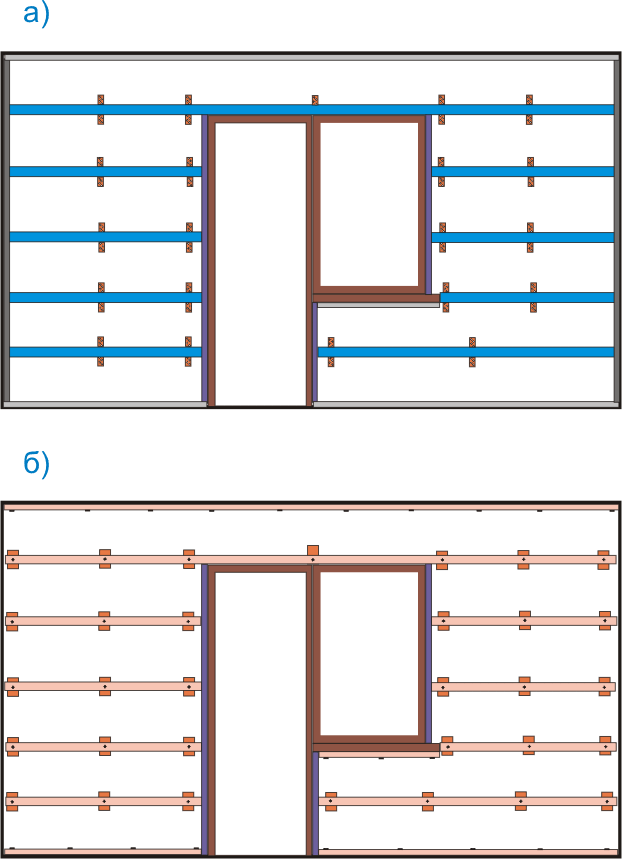

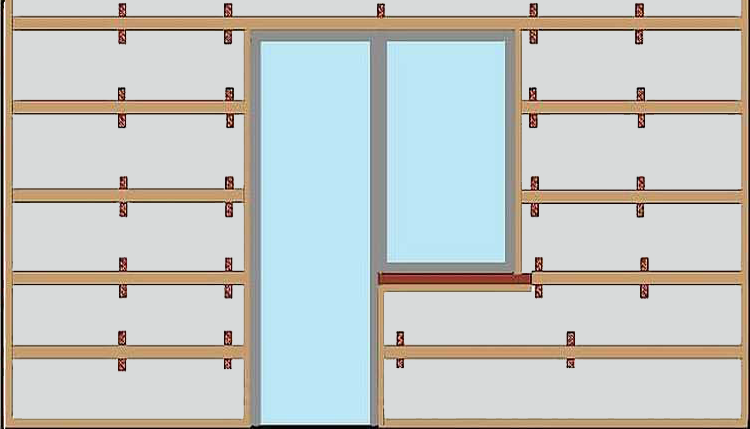

- The direction of installation of the frame slats is chosen perpendicular to the one in which the plastic panels (lining) will be installed (see Ceiling foam panels: lightness and simplicity in one bottle). Before attaching them to the ceiling base, parallel marking lines are drawn, indicating the places of the future laying of the frame slats.

- If wooden beams are chosen as load-bearing elements, then they are fastened directly to the ceiling, using a perforator and dowels with self-tapping screws for this. In this case, they certainly make sure that the bars eventually form a flat horizontal plane. To level the beams, if necessary, use thin wooden substrates and control the degree of evenness using a building level.

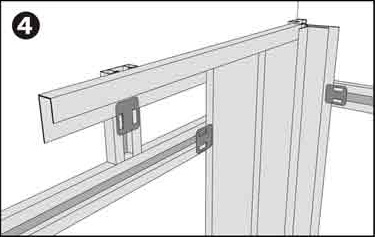

Installation of hangers by marking

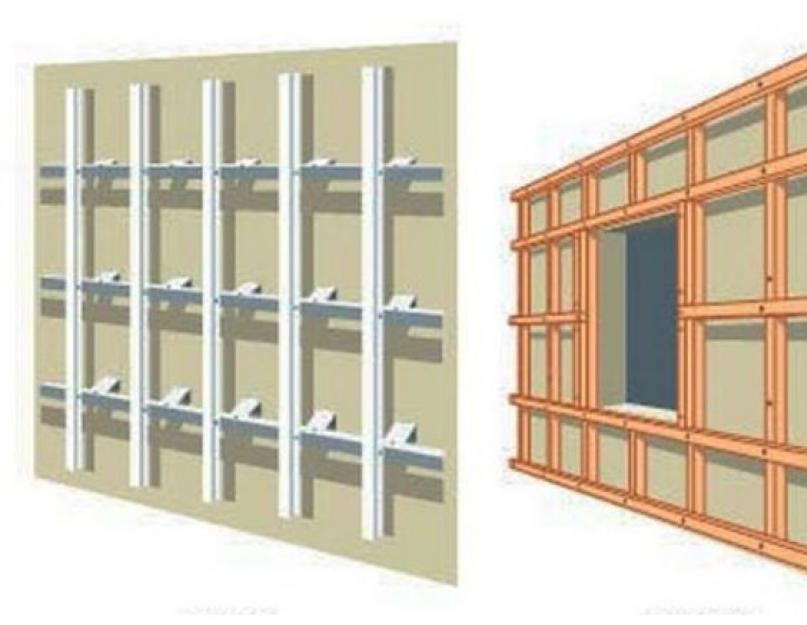

- When choosing a profile frame system, the strips are fastened by means of special metal suspensions. In addition, a guide profile is preliminarily mounted along the perimeter of the room under the ceiling, which serves to more easily create a flat plane of the frame system.

- The hangers are fixed to the ceiling along each marking line in 0.6m increments. After that, the strips of the main profile are inserted from both sides into the guide and attached to the suspensions along the entire length. If necessary, the length of the profiles is adjusted using metal scissors.

Now it remains only to consider how to sheathe the ceiling with plastic - a video lesson will allow you to understand all the subtleties of the sheathing process with your own hands (see Plastic ceilings: installation features).

Something like this will look like a frame, prepared for sheathing with plastic

Sheathing the frame with plastic

So, we will describe how to sew the ceiling with plastic panels with our own hands:

- Elements of plastic lining or panels are cut using a fine-toothed hacksaw (for metal) or an electric jigsaw to the desired length. The cut must be perpendicular to the element axis.

- Plastic ceiling cladding begins with how the ceiling plinth (corner) is horizontally attached to the walls under the guide profile (or beams). A small gap is provided between the profile and the skirting board (for the thickness of the plastic panel or lining). The plinth is fastened to the wall using dowels and self-tapping screws.

- The first element of plastic sheathing is installed by introducing its spike between the plinth and the guide profile (bar) attached to the starting wall (see Ceiling sheathing with plastic panels, features, advantages, DIY installation). The ends of the element are inserted in the same way into the gaps of the walls adjacent to the starting wall.

Alternative means of attaching plastic to the ceiling

- When the positioning of the first panel is completed, it is rigidly attached to the frame strips. This is done using a construction stapler or self-tapping screws. The fasteners are inserted into the wall of the groove of the plastic element closest to the frame and screwed (driven in) it almost flush. The panel should be fastened to each of the perpendicularly outgoing frame strips.

- Next, the spike of the second is inserted into the groove of the first element, and the ends of the panel (lining) are hidden behind the plinth, and fasteners are made in the same way.

The scheme of how to attach the plastic to the ceiling surface should already be clear for a simple and understandable plating of the entire ceiling surface. The last plastic panel (lining element), if necessary, is cut already in width, inserted with a spike into the groove of the penultimate panel, and the other side is hidden behind the plinth, mounting the element in an interference fit. At the same time, there is no need for a rigid attachment of the last plastic element.

We can assume that we figured out how to fix a plastic ceiling with our own hands. Let's hope that you will understand this simple technology and put it into practice without any particular difficulties. And to consolidate the stated material, we once again recommend watching the video presented on our portal - how to sheathe the ceiling surface with plastic panels.

The choice of lathing material

The material for the lathing should be selected based on financial capabilities and preferred service life.

Wooden bars

For the lathing, straight and smooth slats are suitable, without various defects with a cross section of 20x20 mm. During installation, there will be no particular difficulties, since they are easily processed and can be fixed in any suitable way.

To prevent mold or mildew from forming on the surface, you need to apply several protective layers: antiseptic and varnish or paint.

In addition, it is recommended to use hardwoods such as acacia, beech or aspen, which are resistant to high humidity and high strength.

The service life of the structure, while ensuring the optimal level of humidity, will be up to 5 years.

Metallic profile

Provides high structural strength. All elements are standardized and therefore do not need to be adjusted.

Besides:

- The profiles are highly protected against moisture and high temperatures, so their service life can be up to 15 years, provided that there was no damage to the outer layer during installation.

- The products are significantly less weight than when using wood, therefore they do not create critical loads on the walls and ceilings during their installation.

Also interesting: How to grind the seams of ceramic tiles in the bathroom

The cost of installing metal profiles will be minimal, so this option is optimal in terms of price / quality ratio.

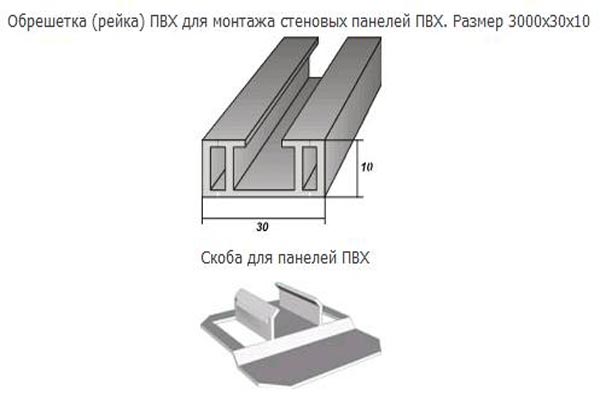

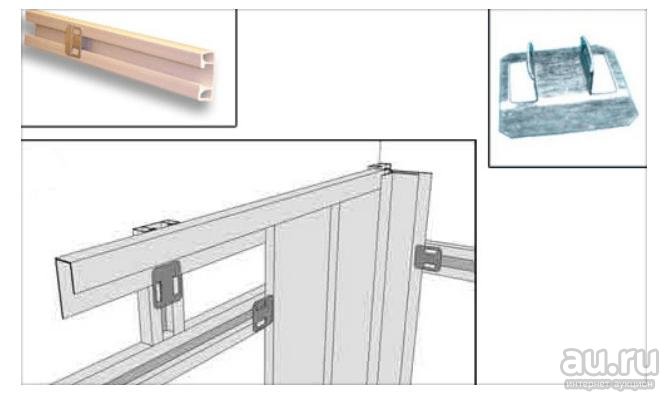

Plastic elements

Such material for the lathing appeared relatively recently, so it is not widespread.

Plastic structures have maximum protection:

- from moisture;

- from mold;

- from pests.

They are characterized by extremely simple installation due to clip-on connections. No additional treatments, adjustments or protective layers are required.

Plastic slats are plastic, so they can take the shape of a wall.

However, this does not mean that the installed PVC panels will be installed crookedly or skewed, since the advantage of clips is the impossibility of triggering with such installation errors.

Plastic slats can be installed on all types of ceilings and walls. The disadvantages include their high cost and relatively low strength.

We recommend reading! Collection of 3d PVC panels for bathroom

Fastening PVC panels to the ceiling

First, mount the installation profile by attaching its large "shelf" to the guide rails using self-tapping screws. It can be installed both around the entire perimeter of the room, and at the points of attachment of the starting and finishing PVC panels.

Fastening PVC panels to the ceiling

Now it is necessary to cut off the PVC panels according to the previously developed plan and applied markings.At the same time, many experts advise to make the length of the sheet slightly smaller than the width of the room, since PVC can expand even at low temperatures, which means that installation "back to back" can lead to future deformations of the suspended ceiling.

If you are planning to make recessed lighting for a false ceiling - it's time to cut out the cutouts for the lamps in the PVC sheets.

Installation of spotlights in the ceiling made of PVC panels

Once the material is fully prepared, you can start attaching the first (or starting) panel. To do this, you and your assistant need to insert the start panel into the installation profile from the side of the mounting shelf, and then fix it with self-tapping screws on the rails. At the same time, make sure that they do not go too deep into the PVC, otherwise there will be a risk that the screws will damage the sheet.

Then carefully "join" the next panel using the mounting shelf from the starting one, and fix it with the fasteners. Thus, the PVC panels are fixed to each other in turn. They should be connected together with great care to prevent damage. Also, you cannot leave gaps or crevices, the PVC panels must fit snugly against each other. If necessary, you can make a "fit" with the help of gentle blows with a rubber mallet.

Installation of panels on self-tapping screws

Before installing the last PVC panel, measure the remaining uncovered space of the ceiling with a tape measure - often the plastic panel does not completely fit there, so it must be cut. At the same time, make sure that the cut is as even as possible, and there should be no gaps between the PVC finish panel and the installation profile.

The scheme of gluing the ceiling plinth

The final stage is the glue-planting of the ceiling skirting boards. After that, the suspended ceiling made of PVC panels can be considered complete. Further, it is already possible to carry out the installation of lamps, wall decoration and cleaning of construction debris.

Video - Making a ceiling from PVC panels

As you can see, fixing PVC panels to the ceiling is a fairly simple task that does not require you to have a lot of knowledge and experience in construction. Therefore, for self-finishing a room and, in particular, a ceiling, plastic panels are the best possible option.

Required materials and tools

So that during the installation of the structure there are no downtime moments due to the search for missing parts, all the necessary tools and materials should be prepared in advance. For work, you will definitely need:

stepladder or stable bench;

level or laser level;

screwdriver or screwdriver;

hammer drill or hammer drill; It is important to make sure you have the necessary tools in advance.

plumb line;

marking pencil;

tape measure or meter;

grinder or hacksaw.

The following materials are used for mounting the lathing:

- wooden blocks;

- galvanized profile;

- plastic guides.

Each of these samples is quite simple to install and has proven itself perfectly during operation. There is no single recommendation on how to choose the right material for installation; preference should be given based on your financial capabilities or available leftovers from previous repairs.

Features of mounting plastic panels on the ceiling

Now let's look at how to attach plastic panels to the ceiling. Before installation, you need to decide on the distance between the panels and the ceiling. This gap will depend on the type of lighting. If you plan to install recessed lights, then the distance should be at least 10-15 cm, so you can completely hide the wiring. Mark in advance with a pencil the places of the lamps, cut out the holes and install the bases of the lighting fixtures.

Metal lathing for the installation of plastic panels on the ceiling in the bathroom.

Next, you follow the same steps as when installing panels on walls.In a room with a flat ceiling, you can do without lathing. Install the ceiling plinth on three walls before starting work. Use a building level to place the panels evenly.

When installing plastic panels in a damp room, fill the ceiling gaps with silicone sealant to ensure complete waterproofing.

Material used for the installation of the battens

Since the crate performs two main tasks - the basis for fastening the panels and the creation of a flat surface for them, then the material for it must also be strong, stable and durable. Today, the construction industry offers fasteners for mounting ceiling battens under plastic panels made from:

- Wood.

- Become.

- Plastics.

Each has its own pros and cons. More about this. Wood is the most popular material for making ceiling lathing for PVC panels. This material has worked well over the years. The tree is characterized by:

- strength;

- durability;

- pliability and ease of processing.

With proper treatment, it is resistant to decay, combustion and mold. The negative qualities of wood include its ability to change shape when it dries. Considering that the fastening of PVC panels to a wooden frame is rigid, then if the rail is driven, this will entail the curvature of the plastic surface. Steel profiles are very popular with builders due to the positive properties of this material, such as:

- high strength;

- durability;

- the ability to manufacture structures of any complexity.

The disadvantage of steel products is their instability to corrosion, which in humid rooms can lead to dirty streaks on the plastic. The cost is also not the last thing. Ceiling lathing for plastic panels made of plastic is characterized by:

- precision of forms;

- the ability to use for laying electrical wires;

- resistance to corrosion, decay and mold.

Plastic profiles have a fairly high cost and a narrowly targeted range of applications. In addition, they will not be able to withstand heavy weight.

Soft lathing

Double-sided foam tape

Installing plastic panels on a soft crate seems flimsy, but in fact, it is precisely such skins that have come out of the hands of the greenest, but neat beginners, and stand for 10-15 years without signs of damage. Why? The soft crate is made of double-sided foam tape, see fig. In terms of thermal deformation properties, it exactly corresponds to PVC, and its adhesive layer is very viscous and elastic: it stretches behind the board, and then returns it to its place.

In order for the sheathing on the soft crate to come out really reliable, three conditions must be met:

- Clean the wall from wallpaper, paint and level with a rough, durable putty (Hercules, Prospector, etc.) with an accuracy of half the thickness of the adhesive tape, 2-4 mm. Sharp shallow protrusions and depressions are acceptable, so the putty, which is not complicated anyway, is still simplified.

- Stock up on a high-quality finishing profile, without it, sheathing on a soft crate cannot be made. However, see the penultimate section.

- As much as possible, to an instant, reduce the contact time of the adhesive layer of the adhesive tape with air. We need to talk about this in more detail.

Installation of lathing

The lathing pattern is the same as for the others. The width of the tape is best taken from 25 mm, and best of all - from 60 mm. Technology:

-

From the initial end of the adhesive tape in the roll, 300-350 mm of the upper (outer) protective tape is removed, and the adhesive tape with the lower tape is cut off, as shown in the figure;

- The master (it is he!) Presses the initial end to the wall, and the assistant pulls the final strip;

- The master peels off the lower (adjacent to the wall) end of the protective tape and carefully pulls it out from under the tape, immediately pressing the tape against the wall;

- At the final end, a tail of the upper protective tape 100-120 mm is left;

- The remaining strips of adhesive tape are applied in the same way.

Installing profiles

The principle is the same - the shortest possible contact of "naked" scotch tape with air:

- The long tails of the protective tape are pulled back and attached to the "back" of the strip with ordinary, narrow and cheap, stationery tape;

- The upper installation profile (horizontal) is applied, the protective tape is carefully pulled out from under it by the tail, immediately by pressing the profile, the assistant supports it;

- The lower installation profile is also glued;

- A starting profile (vertical) is applied, the assistant holds, and the master pulls out the protective tape from under the profile, immediately pressing the profile to the tape, the operation goes from bottom to top so that the profile does not hang on the tape even for a short time;

- The finishing profile is also installed.

Panel mounting

Panels are mounted similarly to profiles, but with some subtleties:

- Trim to size must be very clean and precise to avoid jamming.

- The next panel is brought to its place by hands in concert at two ends; you cannot use a mallet and the rule.

- The tails of the protective film are re-glued after installation of each board, and too long, so as not to interfere with the work, are cut off.

Installation of a false ceiling with insulation

The suspended ceiling, lined with clapboard or plasterboard, allows for additional construction with insulation. How to make a crate for a ceiling with insulation, the stages of installation of such a ceiling are performed in the following steps:

- make markings on the ceiling to install a part of the frame, taking into account the width of the heat-insulating material;

- The lathing of wooden elements is fixed to the main ceiling with screws;

- a metal profile is attached with suspensions. This design allows you to lower the frame to a distance that takes into account the thickness of the insulation;

- strengthen the insulation between the bars;

- mineral wool is distributed over the entire ceiling area without gaps. Insulation in the form of strips and blocks is mounted using polyurethane foam. It fills the gaps between the frame and the insulation block;

- the vapor barrier film must be installed over the insulation. The vapor barrier is fixed to the wooden crate with a stapler. Scotch tape is used on the metal profile.

Correct implementation of all stages of work will result in a house or apartment with ideal living conditions in cold or hot weather.

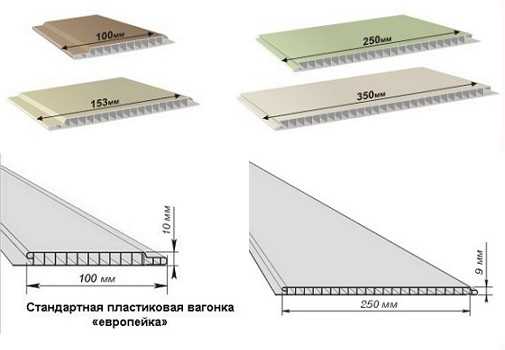

Types of plastic panels for wall decoration

This type of finishing material is made of PVC - polyvinyl chloride. In a semi-liquid state, this polymer is extruded into a mold. A drawing is applied to the finished panels. It can be first printed on foil, then glued and varnished (laminated panels). Moreover, these panels may not have a flat, but a textured surface. The drawing applied using this technology retains the paint for a long time, but such materials cost about two times more expensive.

Several samples of PVC laminated panels for wall decoration

Another technology is to apply the pattern directly to the plastic, and then cover it with two layers of varnish. Cheaper technology, but the service life and quality of the pattern is lower.

Ceiling and wall

There are two types of plastic panels - for ceilings and for walls. Those that are intended for the ceiling have a thickness of 5 mm and thinner partitions, and wall ones - from 8 to 10 mm and a greater thickness of walls and partitions. You can determine which view is in front of you by looking at the cut. This type of finishing material differs in that it has a flat surface and with a tight joint the seams are not very noticeable.

Plastic panels for wall decoration

There is another standard size, which is also called plastic lining - with a thickness of 10 mm, the panel has a width of 10 cm and shaped edges, which are more characteristic of plastic lining. If you finish the walls with this material, the surface will not be even, but embossed, similar to a wooden lining.

Sizes and prices

| Name / photo | Options (width / length / thickness) | Dyeing type | Manufacturer | Price for 1 panel |

|---|---|---|---|---|

Violet pink |

250mm * 2700mm * 8mm | V-Plast, Russia | 120 rbl | |

Kanamala |

250mm * 2700mm * 9mm | lamination | Vivipan | 220 rbl |

PVC Panel Mosaic Turquoise  |

950mm * 480mm * 3mm | Russia | 128 rbl | |

Scarlet |

250mm * 2700mm * 8mm | Cronoplast (Russia) | 215 rbl |

Thin PVC Wall Panels

Above we were talking about products that consist of two layers of plastic, connected by jumpers. Along with a lot of advantages, they have a rather serious drawback: if you make enough effort, they can be pushed through. This is often the reason for the refusal to use them. Therefore, thin plastic wall panels have appeared on the market not so long ago. Their thickness is 3 mm and no cells. Only a layer of plastic with a pattern applied to the surface. Accordingly, there is nothing to push. The dimensions of this type of panels are 950 * 480 mm or so.

Their installation method is different - they are glued to the walls. Due to the fact that this finishing material has a very small thickness, it is cut with scissors and, moreover, takes away a little space from the room - 3 mm.

How to make openings for windows and doors

To fix the plastic panel from the window to the corner, it is better to mount a horizontal profile. If the gap between the window sill and the wall is too small, then ordinary boards are used instead of a profile. They are glued to the wall with liquid nails. As the glue cools down, additionally:

- foaming the joints;

- when the material seizes, the boards are attached to the wall using dowels.

In the same way, the rail is installed vertically to the window.

For better adhesion to the window, the panel is placed as follows. The part where the fasteners are twisted is cut off. This creates a beautiful factory edge. With this edge, the panel is attached to the window. That is, then there will be no need to draw up the joint, it will look complete. On the other sides adjacent to the window, the panels can be cut:

- with trimming with a broach;

- on a conventional tile cutter.

Do the slopes of the doors in the same way.

DIY installation of plastic panels in the bathroom

If you have decided on a purchase and selected suitable panels, and are going to carry out the installation yourself, then you need to carry out a preparatory stage, with measurements of the room. It is required to purchase materials with a margin. During the work, damage to the polyvinyl chloride cloths is possible. Therefore, it is advisable to purchase 10-15% more.

What do you need

Bathroom cladding with plastic panels begins with the preparatory stage. To work, you will need the following tools and things:

- Building level or plumb line;

- Perforator or drill;

- Marker or pencil;

- Roulette;

- Hacksaw for working with metal;

- Construction stapler;

- Screwdriver;

- Marking cord;

- Adhesive or liquid nails.

Additionally, you need to purchase a ceiling plinth, materials for the frame, if you plan to attach it to the crate.

Required set of tools

Wall and ceiling markings

Do-it-yourself installation is carried out with markings only if you plan to install the frame. If the walls are flat enough, and you are going to use an adhesive for installation, then the step can be skipped.

Ceiling markings

For the lathing, it is enough to mark the places in which the wooden or metal profiles will be fixed. For walls, the distance between the planks should be less than 50 cm, for the ceiling, less than 30.

How to mount on the ceiling

Before starting work, you need to choose the distance between the sheets and the ceiling.If you need to install additional lighting, then you will need to provide a distance of at least 10 cm. To do this, you will have to assemble a full-fledged metal frame, which provides a place for laying wires. Mark with a marker or pencil the places of the fixtures, then cut holes for them, and install the basement parts of the fixtures.

Plastic panels on the ceiling

After that, the installation process repeats the work with the walls. If the ceiling in the room is flat, you do not need to install the lathing. Attach the ceiling plinth to three walls before proceeding. After each placed panel, check the condition with a level.

Ceiling mount

If there is high humidity in the room, it is worth additionally purchasing a sealant with which to fill the cavities. Thus, you can protect against moisture penetration and damage to the structure.

How to mount on walls best

How to glue plastic panels to the bathroom wall? The best method for fixing is direct mounting without installing the battens. However, this is only feasible in rooms with flat surfaces and low humidity, which is rarely seen in bathrooms.

Finished bathroom finishes

Therefore, you have to install a crate or frame made of metal. Wood as a material does not withstand moisture well. After installing the frame, the sheets are fastened with construction clamps, which greatly simplify the dismantling of the wall structure if the element has been damaged.

Bathroom installation

When installing a frame made of a metal profile, it should be borne in mind that when heated, the material expands. Therefore, a gap must be left during fitting.

How to sew faster

To fix the facing materials faster, you can additionally prime small irregularities. Compared to the process of installing a batten or frame, installation with glue is much faster. So get rid of the old tiles and line up the walls. Then you can attach the cladding with liquid nails.

Bathroom plastic cladding

For faster installation, you can also use drywall structures, which greatly simplify the work.

How to properly mount plastic panels on the walls in the bathroom

In order to fix the panels on the walls, you can use two different methods, each of which is widely used today.

The first method is the installation of plastic on the crate, and the second - with the help of glue "liquid nails" directly on the wall. As you yourself understand, panels can be attached to liquid nails only in the case of fairly even walls, which is extremely rare. Therefore, more often they use the method of installation with a lathing device made of a plastic profile, to which PVC panels are attached. In addition, when decorating with lathing, under the casing, you can hide the electrical wiring, as well as pipelines supplying water to plumbing devices - a toilet, shower, washbasin, bidet. The lathing device does not require special skills, and you can easily do everything yourself. The main thing is to check with a level and a rail whether it is mounted evenly enough. Let's take a look at how editing is done step by step.

How to make a crate

From racks

The lathing is a frame that serves for the installation of slabs. Using it, you can avoid such preparatory moments as leveling the surface to be finished. But it all starts with the preparation of material for the structure.

Materials for lathing

Traditionally, the frame is made of strips with a minimum shape of 20x20 mm. Reiki is chosen with flat surfaces, without any flaws. It will be almost impossible to remove broken components from the assembled structure and replace them. Having prepared the slats, you can start the step-by-step installation of the frame:

- First, the slats are conscientiously impregnated with an antiseptic material;

- Then they are exposed around the perimeter of the surface to be trimmed.A quadrangle of slats forms the basis for the frame;

- Plates are fixed perpendicular to the guides, placed at a distance of at least 50 cm from each other. Self-tapping screws are usually used for installation. Fixing step - no more than 400 mm.

Important! With the help of a special level, the frame battens are aligned in parallel with the boundaries of the walls. To fix the rail at a certain distance from the wall, you can use the "butterfly" mount

We make the crate

Made of plastic components

A frame made of plastic plates is slightly more expensive than a wooden lathing for PVC panels. Its advantages include absolute immunity to fungi, quick assembly and impeccable construction. The ready-made strips of the standard design are equipped with a double-sided slot-to-slot lock. This simplifies assembly and gives a graceful beauty when finished.

Starting bar

Plastic is not subject to antiseptic processing, so installation immediately begins with surface cladding. At the first stage, a plastic profile is mounted, which is called "crate molding", also known as "PVC mounting strip". To increase the strength of the structure, in addition to plastic guides, side racks are mounted around the perimeter of the room. The planks must be perpendicular to the installed panels.

According to the technology, the clips-latches do not work at the slightest deviation of the panel - in this case, the entire structure must be altered. Such a frame is mainly installed in small wet rooms such as a bath, steam room, where, due to high humidity, wood is not used for the frame.

Important! The quality of the plastic cover from the panels depends on several factors, including the installation of the battens. A rash decision or an unsuccessfully mounted frame should not be trimmed with plastic panels - such an installation must be reworked

PVC profile

Made of metal

Metal lathing for PVC panels is mounted on any surfaces, including those with roughness and defective slopes. Sheaths made of metal profiles for attaching plastic panels in wet rooms are considered very popular. Metal lathing for PVC panels is made in the same way as from wood:

- A starting profile is installed along the walls or ceilings;

- Perforated metal guides are inserted into it;

- Plastic fittings are installed.

After installing the frame, proceed to the main installation as follows:

- the frame is attached to suspensions, the optimal number of which for each profile is about 3-4 pieces;

- maintain a distance between profiles of at least 600 mm;

- align the frame with a building level;

- fasten the panels.

At the corners, the walls are fixed in one profile, setting them strictly according to the level. Then a strong rope is pulled between them and the rest of the profiles are installed, focusing on the lighthouse threads and checking with the level.

The first panel is slightly more difficult to insert than the next, because it is necessary for the panel to fit into all corners and skirting boards at the same time. Correct and level the panel with an ordinary spatula. When the panel enters to the end, a characteristic click is usually heard.

Installing the frame

Frame installation

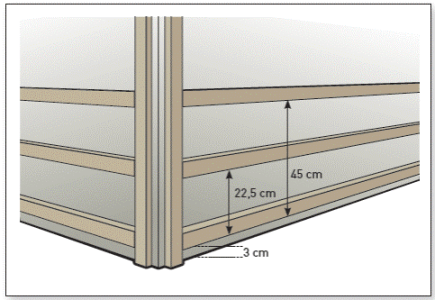

Along the lines drawn, holes drilled with a perforator are marked every 50-100 millimeters. After that, dowels are inserted into them. Along the holes drilled in the wall with self-tapping screws (for example, a 6x40 mm self-tapping screw), the main frame made from the UD-27 profile is attached with a lid to the wall. In this case, do not forget to use a level and make sure that the frame elements are located strictly horizontally.

Wooden lathing for installation of PVC panels

Then, using hangers and a CD-60 profile, guide rails are created, to which the PVC panels will be attached. The optimal distance between them is 500 millimeters. The metal profile CD-60 is installed with a cover to the floor, the ends of the slats should be inserted into the profile of the main frame.

Having finished with the installation of the frame, check it several times for horizontalness and the absence of a difference in height - the future ceiling made of PVC panels should be perfectly flat, and this largely depends on how well the crate is installed.

Profile lathing

Next, you should proceed with the installation of electrical wiring (if you plan to make ceiling lights). It is advisable to put it in a corrugated plastic sleeve that protects the wiring from moisture.

An alternative to a metal profile can be a frame made of wooden beams. Such a design will cost less, but at the same time it is susceptible to moisture. The technology for its installation is in many ways similar to the technology for a metal profile.

- We draw two strictly horizontal lines on opposite walls.

- We drill holes on them with an interval of 5-15 centimeters.

- We insert dowels into the holes.

- We fasten the beam of the main frame to the wall using self-tapping screws and the aforementioned holes.

- We mount guides from a wooden bar with the help of hangers.

- We attach the guides to the main frame using corners.

- We check the entire structure using a level and tape measure.

It is worth noting that for a wooden frame, the more optimal fasteners for plastic panels will not be self-tapping screws, screwed in with a screwdriver, but brackets, for which a construction stapler is needed. Also, metal fasteners can be replaced with "liquid nails" - building glue that can firmly hold a plastic panel and a frame together, even under relatively heavy loads.