How to process plexiglass at home?

Processing plexiglass at home is not difficult, but subject to certain rules, which will allow you to get a good result, both when cutting and when bending the material.

Processing plexiglass by cutting at home can be different depending on the tool used, which can be:

- hacksaw for metal;

- circular saw;

- a cutter purchased or made by yourself;

- electric filament.

Plexiglas has a low electrical conductivity, so processing it with the above tools should be done very carefully so as not to burn the skin. This material heats up, so thin sheets are more suitable for home cutting, you need to cut them with quick movements

It is necessary to have a container of water on hand to quickly lower the cut temperature, which needs subsequent polishing.

Below are descriptions of the most commonly used Plexiglas processing methods that can be used at home.

- Cutting with a hacksaw for metal is the easiest way. The cuts are not smooth, so they are processed with sandpaper or a file.

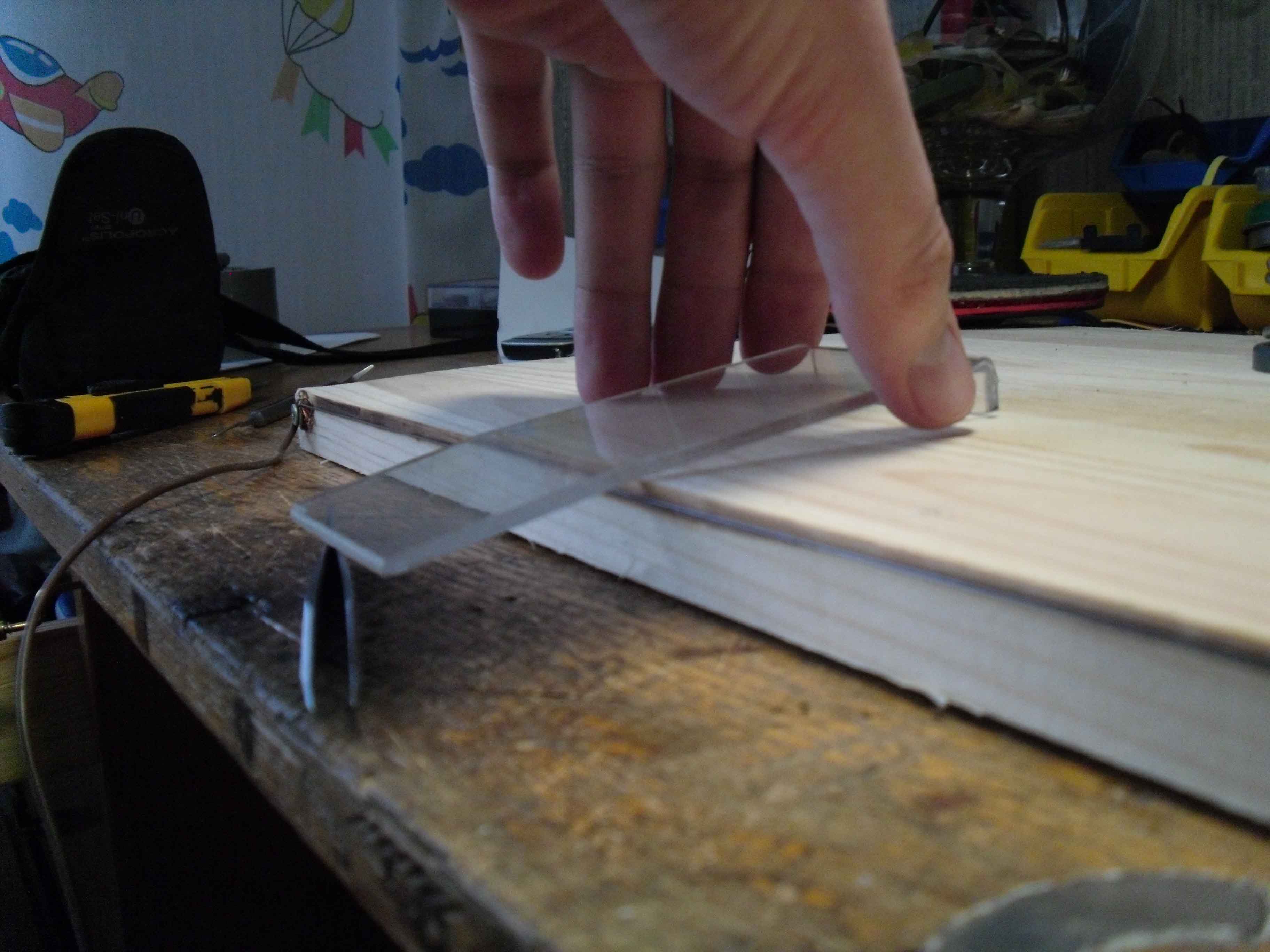

- Processing plexiglass with a cutter purchased in a store or made by yourself. Additionally, you will also need a metal ruler, it must be placed along the contour. Then press on the cutter and draw a line parallel to the ruler two or three times to cut the web by 50%. The contour on the plexiglass is "drawn" with a piece of glass, but you need to make sure that it does not hurt your skin while in your hand. They need to work in the same way as with a homemade cutter.

Using a plexiglass cutter (picture):

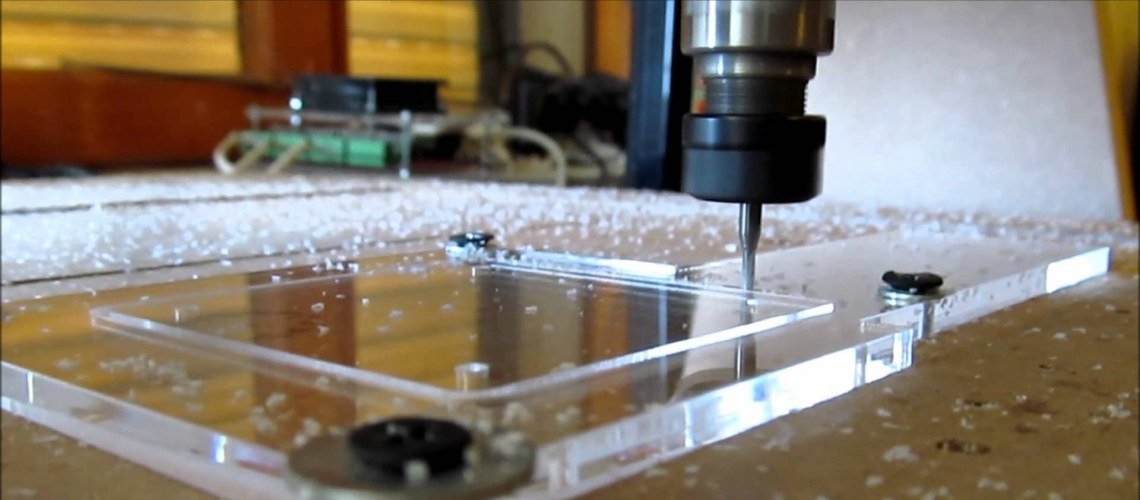

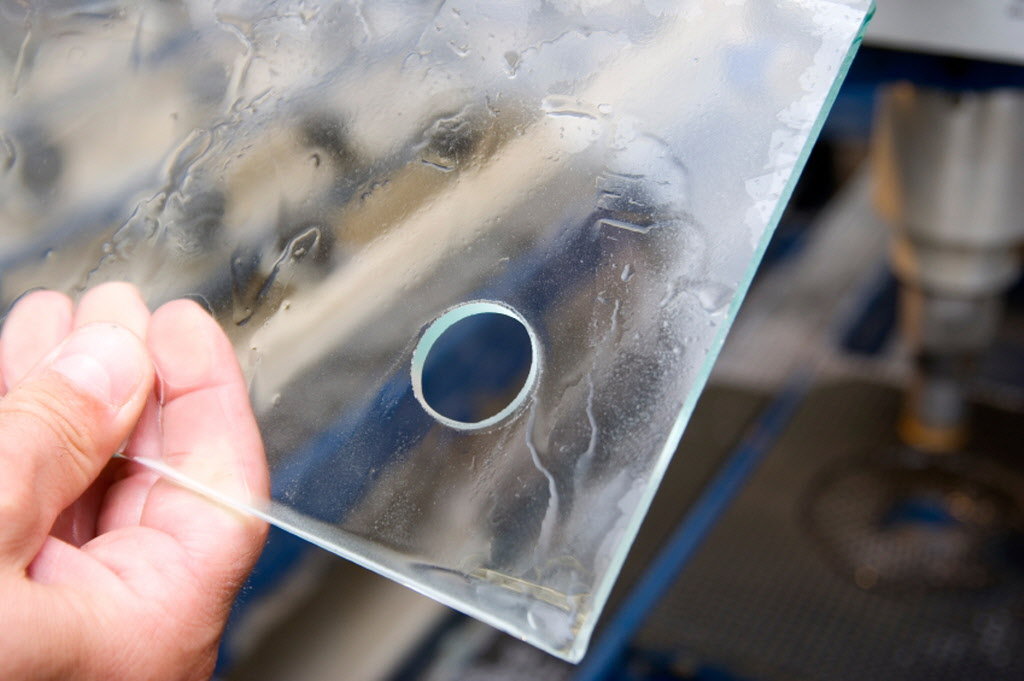

- Processing plexiglass at home can be done with a cutter, which is mounted on an electric drill to make a contour. At the same time, the material heats up and smokes, so it is necessary to cool the contact points of the tool and plexiglass with water. It is necessary to use a vice to firmly fix the cutter, while the plexiglass sheet moves forward, the cut is very even, it does not need to be sanded.

- To cut more intricate contours, tungsten tension filament is used. A step-down transformer with 220 to 24 volts is used; a voltage of 24 volts is required on the filament, which is securely fixed between two insulators. Now you can cut out the desired shape, like a jigsaw.

Cutting glass with a tension thread (picture):

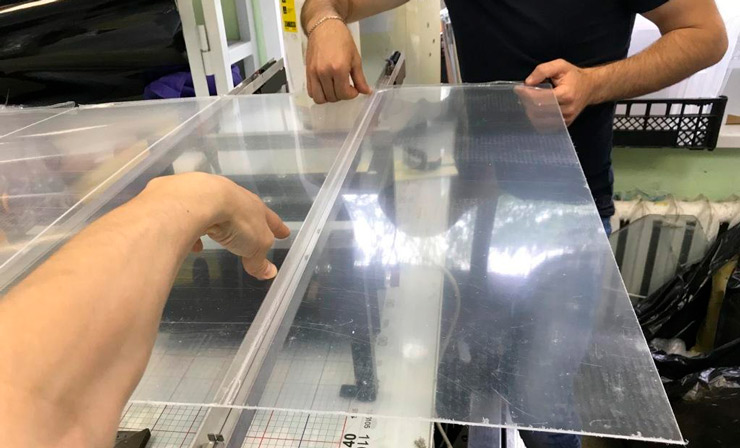

- Plexiglas processing with circular saws and milling cutters with a diameter of 200-350 mm and carbide-reinforced teeth is characterized by ideal cuts. As a rule, such methods are used to cut sheet material. In this way, it is convenient to cut sheets with a thickness of more than 3 mm, but if the sheets are carefully fastened and clear parameters for cutting are set, then high-quality processing is also possible for thinner sheets. It is better to choose discs with carbide tips with the maximum number of teeth, since they can longer service life than the same discs made of tool steel. Processing plexiglass with blunt discs or installed not according to the rules will lead to the formation of chips, and the edges will turn out to be uneven. The teeth can be straight or beveled alternately. The choice of a disc must be approached responsibly: look at its labeling and description. You can find discs that are specifically designed for processing plexiglass - they will provide a perfect cut.

- Processing with band saws used to cut wood and metal will result in a rather rough edge, which means that additional grinding of the cut will be required. The blade width used is 3–13 mm, depending on the desired shape and the type of saw used. There can be from 3 to 8 teeth per 1 cm of tape length. The correct belt and descent speed must be set to prevent overheating of the material.

- Jigsaws are a good choice for cutting thin sheets with frequent changes of direction. During operation, metal shavings are formed, it must be removed with compressed air flows. Cutting at a low jigsaw feed speed and a rubber band speed of up to 1,500 m / min will avoid overheating of the plexiglass. It is ideal to use tools that can move in different directions: up, down and horizontally.

Cutting glass with a jigsaw (photo):

On sheets of material, the thickness of which is up to 3 mm, with a cutter (cycles) along a ruler or using another template, you can apply grooves, along which you can then gently break the plexiglass. Using a scraper, it is necessary to remove the formed burrs.

Plexiglas processing in Moscow

LLC "Trekom" specializes in the design and manufacture of cases for electronic equipment. Plexiglas processing technology is used in the manufacture of accompanying structures for the housings. Plexiglas is used to make protective glasses, transparent covers, and protective panels.

Benefits of OOO "Trekom":

A complex approach.

If necessary, the specialists of our company will solve all the accompanying questions regarding the application of the finishing galvanic coating and inscriptions, the purchase and installation of elements according to your specification (legs, handles, stands, fans, limit switches), the installation of nameplates, the design and manufacture of packaging, direct packaging, storage , sending.

Flexible payment system.

Own production

The order is made on our own without the involvement of third-party contractors. This allows you to keep the entire production process under control. In addition, this approach excludes any supply interruptions and allows for maximum operational efficiency.

Developed technical processes.

Experienced specialists use only highly professional equipment that meets all technical standards. The use of software tools contributes not only to the accuracy, but also to the efficiency of the execution of orders from our clients. Taken together, all this gives a guarantee that the manufactured products will meet high quality requirements.

You can call us on the phone or

Several principles of working with plexiglass

Before you start melting and bending plexiglass, you need to learn a few principles that will help you get the job done as efficiently as possible and without unnecessary waste of material.

- So, to form a part of the required size, it is necessary to cut off a piece of material of the desired parameters from the whole plexiglass sheet. This will allow you to get an economical consumption of material at the output and a higher productivity of the work performed.

- For work it is necessary to use only pure plexiglass. For this purpose, it is recommended to wash the material.

After washing the plexiglass, do not immediately start bending work. Let the material dry. This will take at least a day in a dry room at room temperature. Or, dry it with a hair dryer at 80 degrees Celsius.

The principle of calculating the drying time of plexiglass with a hair dryer should be as follows: 1 hour per 1 mm of material thickness in each area.

- When starting to heat the plexiglass in order to deform it at the desired angle, please note that the heat treatment of the material must be carried out from the opposite side relative to the bending angle. That is, we warm the top of the material and bend it down.

- To bend the plexiglass, it is enough to use a heating temperature of 150 degrees, and to melt the material and pour it into the prepared forms, a temperature of at least 170 degrees is needed.

Important: for proper bending of plexiglass at home, you need to warm up an area of the material three times its thickness. That is, if your plexiglass has a thickness of 3 mm, then for its even and beautiful bending you need to warm up such an area along the line of the supposed bend, the width of which will be equal to 9 mm

With this thickness of plexiglass, it will be enough to treat with a heat device on one side of the material. If the thickness of the plexiglass exceeds 5 mm, then it will be necessary to carry out the process of heating it from both sides along the line of the supposed fold.

After bending the plexiglass, it is important to let it cool naturally. Do not use water or cold air as a coolant

This can damage the finished product in the form of cracks, bubbles, etc.

Method three - circular saw or cutter for metal

Cutting plexiglass with your own hands can also be done using a circular saw or a cutter for metal

If you choose a milling cutter, please note that its thickness should be no more than one millimeter. In the process of work, the cutter is very quickly triggered

When cutting plexiglass with this method, it is necessary to take into account that a lot of smoke will be emitted, and the material will warm up rather quickly, possibly foaming at the processing site. To avoid possible consequences, you should take care of cooling the material with water in advance. Cooling can be organized in this way: take a regular bottle and fill it with water, fix it near the cutter and supply water to the work surface using a plastic hose. If you use a hose with a thickness of 2.5 mm, about one liter of water will flow out per hour. With this cooling method, you will be able to get a neat and transparent cut.

- You can build a tool to cut this material. You will need a nichrome thread. As a result of heating, it will be able to cut the plexiglass due to melting. To build such a tool, take a nichrome thread, a transformer whose power is 24 V. Connect the thread to the transformer, having previously fixed it on both sides or attaching a handle on one side, and hang a weight on the other. When the filament is hot, you can cut the acrylic along the marked line.

- Slotted screwdriver. Press the screwdriver against the sheet of material, hold it by the edge of the handle. Heat the tool blade with a soldering iron. When the sheet of material begins to melt, you can cut it by moving the tool with a movement of your hand. Use a metal ruler to get a straight line. After drawing a line across the surface of the acrylic, it can be easily broken in the right place.

In addition to the listed methods, plexiglass at home can be cut using other tools, it can be a jigsaw (you need to choose the right mode) or a glass cutter. Each master, by trial and error, selects his own, suitable method for him. After studying the proposed information, it became clear that cutting Plexiglas products is not such a complicated process as it might seem at first glance.

In addition to the listed methods, plexiglass at home can be cut using other tools, it can be a jigsaw (you need to choose the right mode) or a glass cutter. Each master, by trial and error, selects his own, suitable method for him. After studying the proposed information, it became clear that cutting Plexiglas products is not such a complicated process as it might seem at first glance.

How is plexiglass or acrylic cut at home?

In small workshops, usually there is no solid equipment, so home craftsmen get by with an improvised tool. This can be a regular jigsaw or cutter. In the case of using a jigsaw, use a file for wood. The cut edge turns out to be rough, it has to be additionally polished. It is advisable to use a jigsaw in cases where it is necessary to cut a complex contour from a thin sheet.

The cutter (a sharply sharpened knife with a sharpened end of the blade) for cutting plexiglass gives a clean cut, it is not necessary to modify it, but the process itself takes a lot of time: a ruler is laid along the cut line, and then along it carefully, with little effort, the tool is drawn. And so on until the plexiglass is cut through to the full thickness

It is especially important to correctly apply the first cut: the ruler must be pressed very tightly against the sheet and, while drawing a knife over it, make sure that the blade does not slip off the marked line

Home bending techniques

Necessary materials

In order to give orsglass the desired configuration, you can use one of several popular methods:

- Heating the material with a building hair dryer;

- By boiling;

- With the help of nichrome wire.

Depending on how the plexiglass is folded, you will need a heating element (a hair dryer, nichrome wire, or a saucepan of boiling water). In addition, prepare:

- A hacksaw for metal;

- Vise for secure fixation of the plexiglass plate;

- Thomas for bending (pipe, bar, countertop, etc.);

- Abrasive material for grinding the edges of the product;

- A little water (to cool the material while cutting).

Preparatory work

If your future product requires the use of a small piece of plexiglass, then first you need to cut it off from the common canvas. To do this, securely fix the plexiglass in a vice and cut off the desired piece with a metal hacksaw. Do not forget to lay soft material in the places of fixation, which will prevent damage to the plexiglass.

For cutting plexiglass, you can use both a hand hacksaw and a jigsaw

Important: use only a sharp hacksaw.

Otherwise, the material may be damaged and deformed. When cutting plexiglass, cool the cutting line with water

This will avoid overheating of the plexiglass and its possible melting.

Boil flexion

This is the easiest way to bend plexiglass, requiring virtually no additional tools.

5. Leave the part formed from plexiglass until it cools completely.

Using a construction hair dryer

If you have to bend a large enough piece of plexiglass, then use a building hair dryer for this purpose. Its power will allow you to process a large area of organic polymer material in an extremely short time.

Using nichrome wire

With the help of a nichrome wire carefully stretched under the plexiglass, it is possible to achieve bending of the material in a straight line without effort. To do this, follow these steps:

Video: bending plexiglass with nichrome wire

We bring to your attention a short video that will clearly demonstrate how to bend plexiglass using nichrome wire.

Plex) is a transparent plastic that looks very much like glass, but, compared to glass, has more advantages:

- Twice lighter in weight;

- Stronger and more shock-resistant;

- Has the best thermal insulation properties;

- More transparent.

Acrylic has two major drawbacks - it is more expensive and, when exposed to direct fire, begins to melt and burn. Also, when working with it, it is necessary to avoid heating, since acrylic reacts poorly to high temperatures and this can lead to significant stresses in the material, which, in turn, can lead to the formation of cracks.

In what ways is it possible to process plexiglass

Plexiglas has a low weight, but at the same time it is highly durable, it can be of various colors. It is used to make accessories for the bathroom, kitchen; you can even build a gazebo in the courtyard of a private house from it. And that's not all - plexiglass serves as a material for the manufacture of product cases, decorative panels, volumetric figures and letters, it is used for the "modding" of computer cases and light-dynamic installations. A characteristic feature of plexiglass is that the streams of light are distributed in it evenly, it looks very beautiful at night. Thus, plexiglass is used everywhere, but at the same time it is necessary to process it in a way convenient for you.

The main advantages of plexiglass:

- transmits light well - 92%, this indicator does not change over time, and the product itself does not lose its color;

- high impact resistance - five times more than glass;

- moisture resistance;

- harmless to the environment, no harmful gases are emitted during its combustion;

- plexiglass processing is a simple process;

- can take various forms when exposed to an industrial hot air gun, the optical properties will not change, the detail is very good;

- mechanical processing of plexiglass is no more difficult than wood;

- stable in the external environment;

- not afraid of low temperatures;

- 73% of ultraviolet rays penetrate through it, from which the material does not change color and does not deform;

- resistant to chemical influences;

- possesses electrical insulation properties.

Processing of plexiglass must be done very carefully, otherwise it can be scratched very easily. But at the same time it has an indisputable advantage over ordinary glass - plexiglass does not break and it can be given any shape. For accurate processing of this material, you need to know how this can be done, to have a special machine and tools.

Processing of plexiglass must be done very carefully, otherwise it can be scratched very easily. But at the same time it has an indisputable advantage over ordinary glass - plexiglass does not break and it can be given any shape. For accurate processing of this material, you need to know how this can be done, to have a special machine and tools.

Such glass differs in that it is at the same time beautiful, transparent, durable and at the same time not heavy, in some cases it is suitable for replacing glass and plastic. Plexiglas processing can be carried out by sawing, planing, turning. Its cutting differs from the conditions under which it is carried out - on special equipment in the workshop or at home.

It is important not to scratch it in order to prevent micro cracks.

Plexiglas can be produced by one of two methods: extrusion (extrusion plexiglass) or casting (injection molded, cast plexiglass).

Plexiglas processing can be done by cutting, drilling, grinding, milling, polishing, welding and gluing. In order to create a special design for a product, thermoforming (hot forming) and cold folding are used.

A convenient way to transform plexiglass - turning

Plexiglas processing can be carried out in various ways, since it has such properties that allow it to be considered a universal material.

In any processing of this material, an extremely important rule must be observed - the stress on the plexiglass must be moderate, it must not be overheated, otherwise cracks and breaks will form. Consider the turning of organic glass - for this, a lathe is used, as for wood

Machine tools for metal can also be used. Turning resembles drilling, during which a part moves, and not a drill, as we are used to

Consider the turning of organic glass - for this, a lathe is used, as for wood. Machine tools for metal can also be used. Turning resembles drilling, during which a part moves, and not a drill, as we are used to.

It is important that the processing takes place at a very high speed. It is necessary to observe certain parameters - the spindle speed and the feed of the cutter - then you will get high quality products, no worse than their metal counterparts

After turning, the product can be polished. This method of imparting certain shapes to plexiglass is not as popular as for metal, but if we are talking about dielectrics or you need to use a transparent material, then turning the plexiglass becomes indispensable.

In the process of turning, it becomes necessary to cool the plexiglass with purified water or a 2% solution of cutting fluid.

Processing of plexiglass with lathes must be carried out with the observance of the rule of thumb: the speed is 10 times higher than when processing steel.It is quite simple to check if this rule is fulfilled - there should be a continuous flow of chips, and this also proves the correct turning angle of the tool.

The radius of the cutting edge of the tool must be at least 0.5 mm. To obtain a fine finish, you need to use tools with rounded cutters, saw at high speeds, but at low feed rates and a minimum cutting depth.

Plexiglass, which has the shape of rods or circles with different diameters, is quite difficult to acquire. You may encounter such a problem: the cost of a blank in the form of a circle is an order of magnitude higher than the cost of sheet plexiglass. It is for this reason that circles and rods obtained as a result of processing sheet blanks are more often found on sale.

The direction of the fibers in the extruded round billet and the sheet / block billet are different. It is more advisable to choose extruded polycarbonate blanks, which are easy to buy in a store. You can choose a workpiece of a suitable size with the required technical characteristics, in addition, polycarbonate rods are advantageous to use instead of plexiglass.

When roughing, you can use carbide turning tools with a cutting depth of up to 6 mm. If a finer machining is required, then tool steel cutters will be needed. Cutting speed and feed rate have a direct impact on the resulting surface.

It can be cooled using a drilling emulsion or emulsion oils, which can be combined with acrylic. To obtain a perfect glossy surface, it is necessary to perform processing on high-precision lathes using carefully polished diamond tools.

In such cases, the cutting speed is allowed to be higher than when working with other turning tools. Do not cool the material to avoid the formation of optical defects.

To remove burrs, you can use new files and fine rasps, triangular and regular scrapers. This can also be done on planers that are used for woodworking.

Sharpening and machining should be performed as follows: gap angle 5-10 °, main rake angle 0-4 °, cutting edge angle 45 °, cutting speed 20-300 m / min, feed 0.1 to 0.5 mm / turnover, cutting depth up to 6 mm.

It is important to check that all tools required for machining are sharpened and have the correct geometry. Otherwise, excess stress will arise, which means that the part may crack during processing or during its operation.

The result of the processing performed depends entirely on whether you follow all the rules and monitor compliance with the required parameters.

Equipment and tools

Plexiglaz is processed using the same equipment as wood or metal. A clean cut is obtained when processing material on high-speed machines.

The only requirement is that plexiglass cutting machines and circular saws must be equipped with an extractor to quickly remove chips and waste.

For cutting plexiglass, a tool made of tool steels, hard alloys, diamond is used

It is very important that the cutting edge is sharply sharpened, since the use of a low-quality blunt tool leads to chips, burrs and stresses in the cut zone. For the same reason, you cannot use a tool with which previously cut metal or wood.

Cutting rules

In order to qualitatively cut plexiglass with your own hands at home, experienced craftsmen advise you to adhere to some rules (they apply not only to acrylic, but also to plexiglass, as well as cellular polycarbonate).

It will be much easier to cut a curly workpiece to size or saw off an even piece of acrylic glass if, before starting work, you warm up the material over a heat source: a gas burner or a hair dryer. This must be done at a considerable distance so as not to melt the material.

Cutting out a workpiece from plexiglass of small thickness from 2 mm to 5 mm can be done using an electric jigsaw. With its help, you can not only make a straight cut, but also cut a circle. For work, you need to take a narrow and thin canvas with fine teeth.

It is easier to cut the glass with a blade marked MP. S. The sheet steel is hardened and highly durable.

Sawing glass is necessary at low speeds of the cutting blade feed. You can choose the speed for each tool in the process of work in a practical way.

During the sawing process, it is important to ensure that the acrylic glass does not start to melt.

Work on cutting organic glass should be carried out in goggles or a mask. When cutting the material, a large amount of fine chips is formed, which are scattered in different directions at a high speed.

The greatest difficulties when cutting organic glass at home arise when creating complex curved cuts. The easiest way to solve this problem is using laser industrial equipment, where automated control allows you to perform all the necessary functions with the highest accuracy and without human intervention. Hand curly cutting of acrylic is performed according to a pre-made template. The easiest way to make such a cut is a cutter. The contours of the resulting workpiece will be jagged and rough, which are removed by grinding.

At home, you can accelerate the cutting process of organic glass using a hot nichrome wire connected to a voltage source of 24 V. The heated nichrome wire melts the acrylic material through and through in the right place of the cut. At the same time, the cut edges are smooth.

Home bending techniques

Necessary materials

In order to give the orsglass the desired configuration, you can use one of several popular methods:

- Heating the material with a building hair dryer;

- By boiling;

- With the help of nichrome wire.

Depending on how the plexiglass is folded, you will need a heating element (a hair dryer, nichrome wire, or a saucepan of boiling water). In addition, prepare:

- A hacksaw for metal;

- Vise for secure fixation of the plexiglass plate;

- Thomas for bending (pipe, bar, countertop, etc.);

- Abrasive material for grinding the edges of the product;

- A little water (to cool the material while cutting).

Preparatory work

If your future product requires the use of a small piece of plexiglass, then first you need to cut it off from the common canvas. To do this, securely fix the plexiglass in a vice and cut off the desired piece with a metal hacksaw. Do not forget to lay soft material in the places of fixation, which will prevent damage to the plexiglass.

For cutting plexiglass, you can use both a hand hacksaw and a jigsaw

Important: use only a sharp hacksaw. Otherwise, the material may be damaged and deformed.

When cutting plexiglass, cool the cutting line with water. This will avoid overheating of the plexiglass and its possible melting.

Boil flexion

This is the easiest way to bend plexiglass, requiring virtually no additional tools.

- Take a container of water and put it on fire.

- Bring water to a boil.

- Dip the workpiece into it and boil for 3-5 minutes.

-

Then remove the well-heated material from the water and bend it in the desired direction.

5. Leave the part formed from plexiglass until it cools completely.

Using a construction hair dryer

If you have to bend a large enough piece of plexiglass, then use a building hair dryer for this purpose. Its power will allow you to process a large area of organic polymer material in an extremely short time.

-

So, we place the plexiglass sheet in a vice, having previously laid the fixation points with a soft cloth.

-

We carefully warm up the marked fold line with a construction hairdryer.

-

As soon as the material becomes plastic, we begin bending it using a pre-prepared shape (pipe, bar, countertop).

- Leave the finished part to cool completely.

Using nichrome wire

With the help of a nichrome wire carefully stretched under the plexiglass, it is possible to achieve bending of the material in a straight line without effort. To do this, follow these steps:

- Fix a sheet of plexiglass on one side on a workbench or table so that the fold line is as close as possible to the edge of the table or workbench.

-

Place the nichrome wire under the marked fold line so that it does not come into contact with the plexiglass surface, but is at least 5 mm away from it.

- Connect the nichrome thread to the transformer and wait for it to glow.

- When the nichrome wire is heated, its heat will be transferred to organic glass. In turn, the heated material in the fold line will begin to bend under its own weight. In this case, in order to prevent possible bending to a larger side, place a limiter in the form of a bar or other abutting surface on the bendable side of the plexiglass. The bent glass will assume the specified angle.

- Leave the finished part until it cools completely.

Video: bending plexiglass with nichrome wire

We bring to your attention a short video that will clearly demonstrate how to bend plexiglass using nichrome wire.

As you can see, the process of bending organic glass is not as complicated as it might seem at first glance. Having studied the methods of work and having passed a small "industrial practice", you will probably be able to professionally manufacture the parts and products you need in the very near future. In addition, working with such a polymer material opens up a lot of scope for creating unique masterpieces of design art. Especially if you use colored glass in your work. So a well-chosen shade of material and some effort in tandem with imagination can completely transform the atmosphere of your home. Go for it, try it and be satisfied with the results of your efforts!