Geogrid

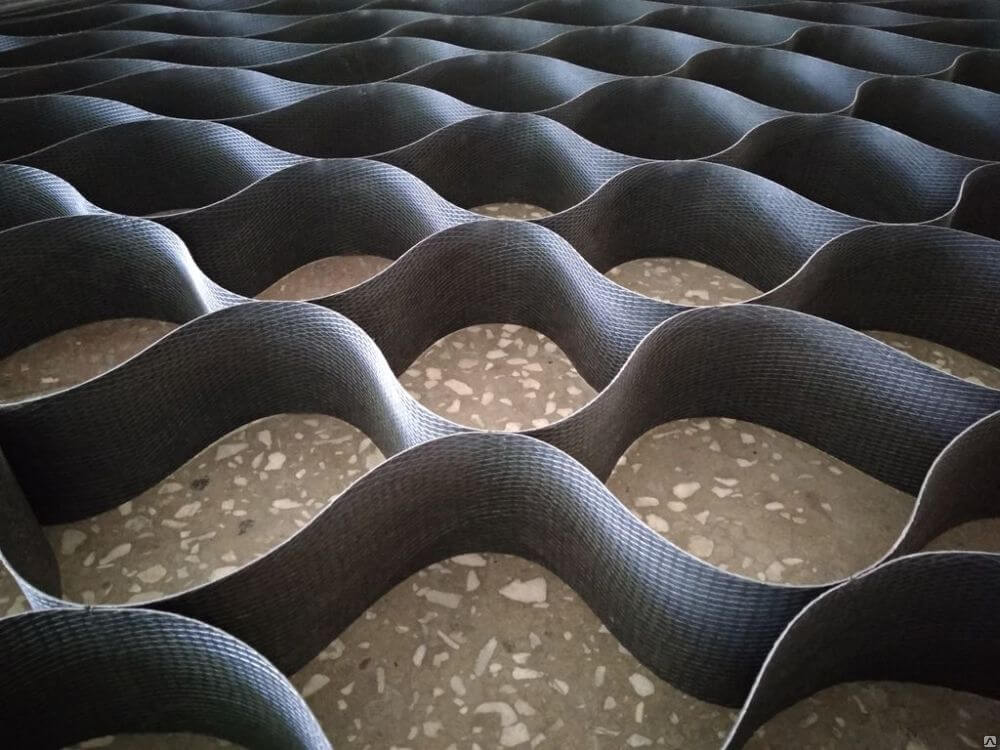

The geogrid is a three-dimensional honeycomb structure made of polyethylene tapes, 1.2-1.8 mm thick and different heights of 50 mm, 75 mm, 100 mm, 150 mm, 200 mm. The belts are connected to each other by means of high-strength ultrasonic welds at a certain interval, which determines the size of the geogrid cells. Subsequently, the cells are filled with inert material. The choice of a geogrid is determined depending on the tasks of the object under construction, on the filling material and on the angle of the slope on which the geosynthetics will be laid.

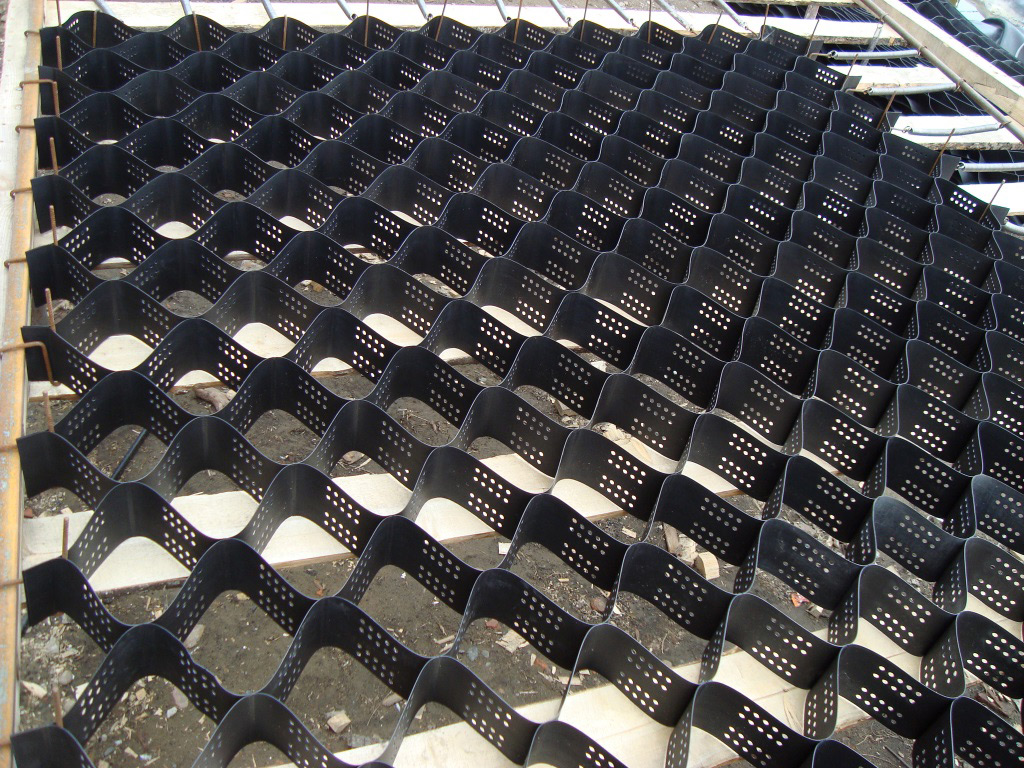

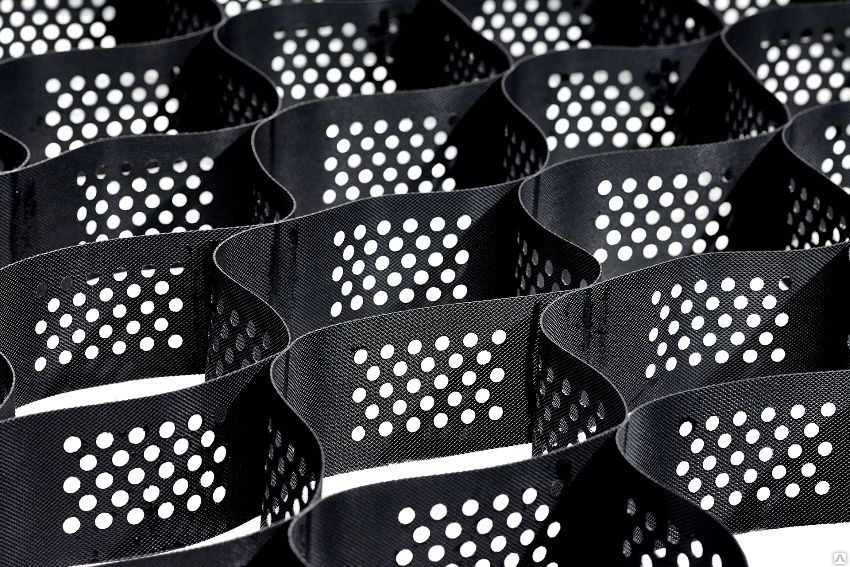

With the help of a volumetric geogrid, the issue of protecting the cones of overpasses, anti-erosion protection of slopes, reinforcing weak foundations, building retaining walls, and arranging temporary roads is solved. Geogrid cells can have an embossed surface and perforation, which increases friction with the filling material and improves drainage of the structure. Temperature range of geogrid installation is from -40 ° С to + 60 ° С. The material is environmentally friendly and neutral to aggressive environments.

According to the technology of laying the geogrid, a layer of geotextile fabric is laid in the base. The geogrid is fastened with special anchors, fixing it in the working position and connecting the modules to each other. Material modules can be stacked easily on top of each other. The cells are filled with sand or gravel with layer-by-layer compaction.

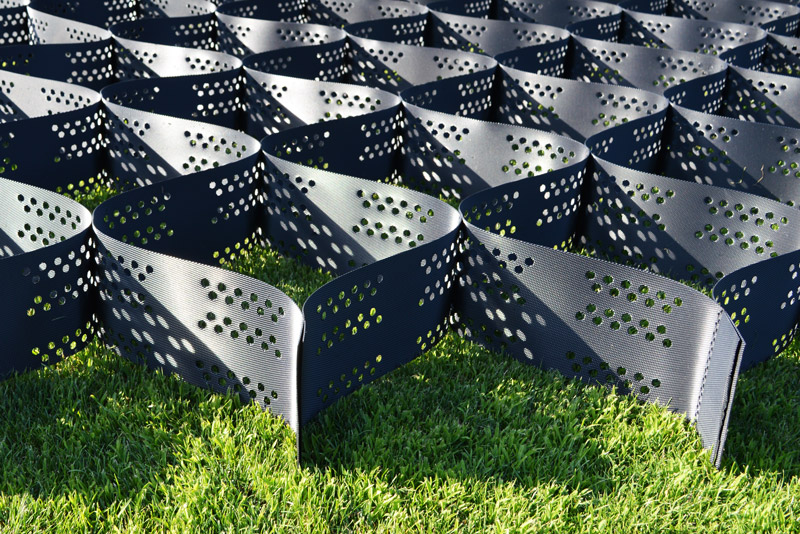

The slopes reinforced with a polymer geogrid represent a reliable, environmentally friendly, continuous structure with cells filled with plant soil, which is subsequently sown with perennial grasses. When building roads on weak foundations, the geogrid evenly distributes the load and prevents uneven settlement of the roadway.

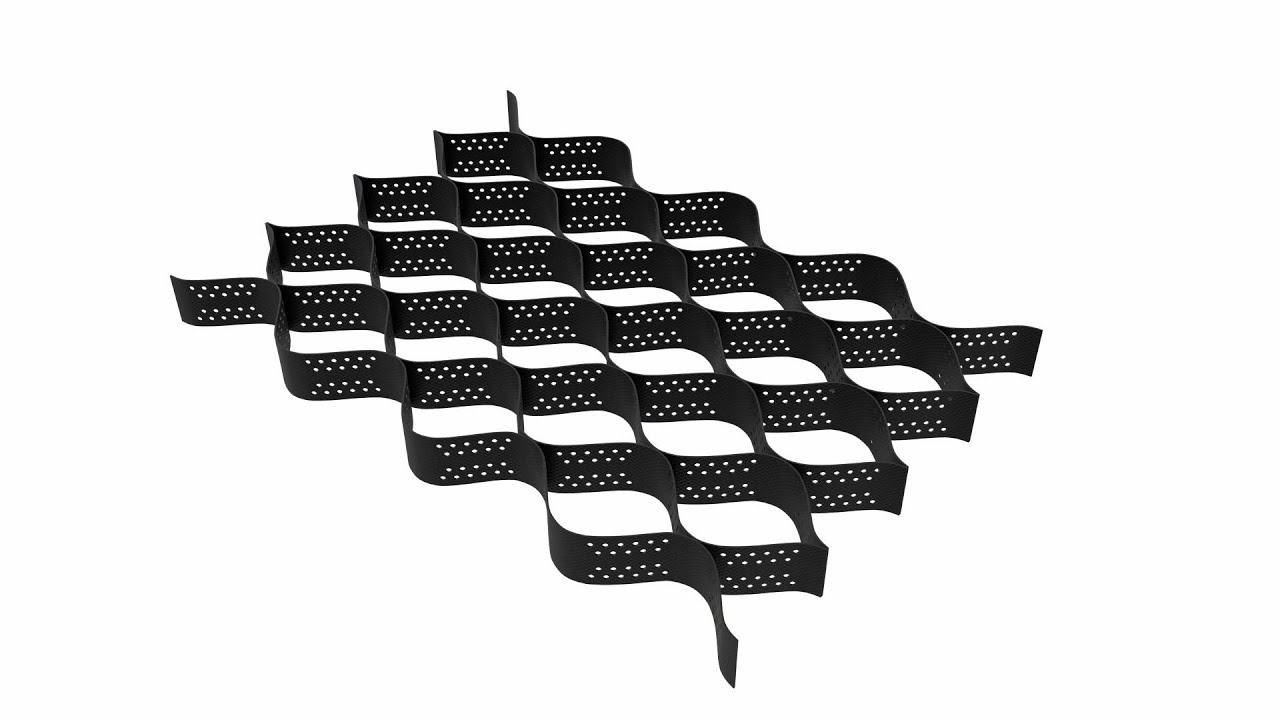

A volumetric geogrid is also called geocells or geocells. When manufacturing geogrids, different geometrical parameters are set for the future structure, thereby obtaining geocells of different sizes. Geocells of a volumetric lattice are formed by bonding polymer tapes in a checkerboard pattern.

When folded, the plastic geogrid forms a compact module that is easy to transport to the construction site. In the process of laying, the module is stretched and the geogrid becomes a three-dimensional structure. Filled with crushed stone, stone or other filler, geocells (geocells) form a plate of medium hardness, which redistributes the load during operation, increases the strength and service life of the facility under construction.

Important characteristics of geogrids

After showers and hurricane winds, all efforts to equip the garden are often nullified. Polymer geogrid is a relatively inexpensive tool for arranging slopes. The simplest cell structures easily cope with the task of strengthening the soil surface. Especially when they are used in a complex - geogrid, reinforced soil plates and volumetric geomats.

Positive characteristics of geosynthetics:

- the simplest cell base, which rolls into rolls, is easily stacked and transported;

- lying in the ground, for a long time does not decompose under the influence of moisture and natural acidity of the soil;

- follows the contours of slides and rock gardens for landscaping the landscape;

- does not prevent the penetration of moisture and nutrients to the roots of ornamental plants and lawns planted on top of the reinforcing mesh;

- polymeric materials from which the geogrid is produced are not subject to corrosion, delamination or decay;

- does not affect the ecological balance of the site and the natural redistribution of groundwater;

- moles and rodents do not start under the geogrid, although the reinforcing canvas is environmentally safe;

- under the influence of rapidly growing plants, it receives additional fastening in the soil surface;

- laying a geogrid is a simple process that even a beginner can handle;

- it is easy to stretch it, fixing it with anchors, and dismantle it if it is covered from above with only pebbles or sand;

- can be reapplied if the need arises to transform the surface.

Due to its tensile strength, 3D mesh geosynthetics does not undergo destructive changes after installation, even when exposed to unfavorable natural factors. Such materials, thanks to the special arrangement of the geogrid, will be in demand in decades.

On how to fix the geogrid canvases with anchors, we offer an illustrative example in the video.

Review of prices for the most popular models

A fairly large number of domestic manufacturers specializing in working with polymer materials are engaged in the production of geogrids.

Among them, the most famous are companies such as:

- Geotech, Moscow;

- LLC "Geomaterials", Novocherkassk, Rostov region;

- GeoSM, Nizhny Novgorod;

- NPO "Slavros", Moscow;

- PSK "Geodor", Engels, Saratov region;

- LLC "Dialogue St", Protvino, Moscow region.

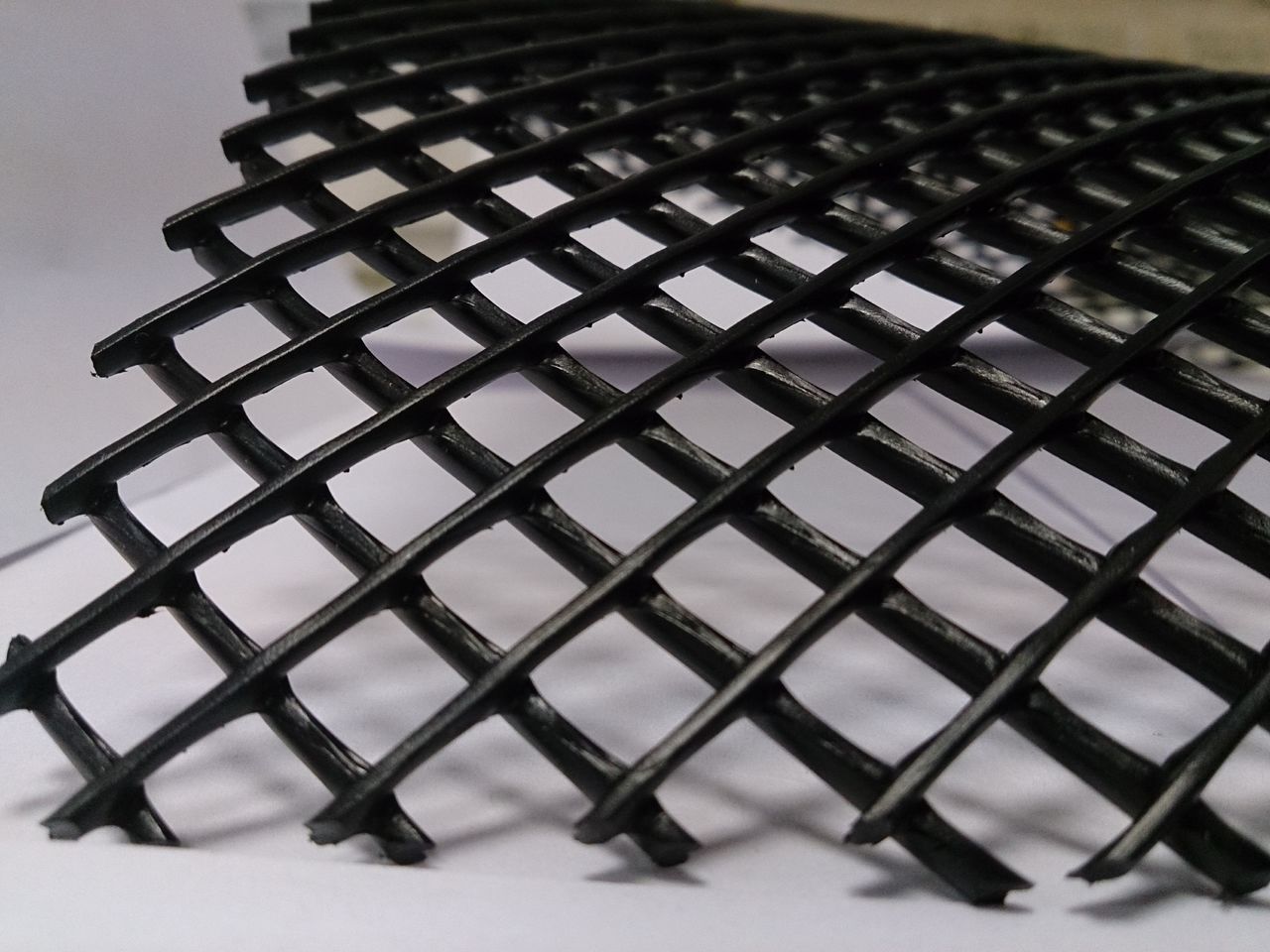

Geogrid appearance in transport position

Geogrid appearance in transport position

The cost of the product depends on its geometric dimensions and materials used in the manufacture, as well as the place and region of purchase of the product.

The average price, as of the III quarter of 2018, when sold through a retail network is:

| Geogrid brand | Cell size, mm | Rib height, mm | Wall thickness, mm | Cost (as of September 2018), per 1.0 m², rub. |

| volumetric | 320×320 | 50 | 1,35 | 75 |

| road geogrid | 39×39 | — | — | 72 |

| geomat | — | — | — | 178 |

| volumetric | 210×210 | 50 | 1,42 | 100 |

| lawn | 65×65 | 33 | — | 800 |

A variety of proposals allows you to choose a geogrid of the desired size and in accordance with its purpose, but the following video will tell you how to install it in case of need to strengthen slopes of various types:

Previous Market newsSelf-cooling building blocks "CoolBrick": air conditioning of premises without electricity

Next Market noveltiesModern fire protection of building structures: protection of buildings from destruction

Geogrid, geocells, geoframe

Volumetric polymer geogrid Armogrid (TU 2246-002-68781351-2011) is a geotechnical material that is a volumetric honeycomb structure made of plastic tapes of a given height and thickness. It is used to strengthen weak, unstable soils.

The geogrid strips are fastened together at the points of contact by ultrasonic or thermal welding. The sizes of the cells, the height of the structure, can be different. Geogrids with an insignificant edge height are commonly called flat. Polyethylene, polypropylene, polyester filaments can be used for the manufacture of geogrids. There are gratings made of geosynthetic needle-punched fabric, they differ from their plastic counterparts in water permeability.

A variety of soils, crushed stone, sand and other building materials are used as a filler for Armogrid plastic or polymer geogrids. The grille not only strengthens the bonds, strengthens the materials placed in the honeycomb, but also reinforces the soil layer on which it is laid.

Geogrid - what is it and its types

Geogrid is a building material, which is a honeycomb structure made of durable polymer materials. The size of the formed honeycomb can be different depending on the need and the type of use; it is determined by the width of the strip of the polymer used and the pattern of welding of these strips to each other.

For the manufacture of such products, materials such as are used:

- polypropylene and polyethylene;

- polyester materials;

- fiberglass;

- basalt.

Option for use in strengthening the banks of gutters, stream beds

Option for use in strengthening the banks of gutters, stream beds

This building material is presented on the domestic market in three versions, these are: geogrid, geogrid and geomats.

Geogrid and Geogrid

Depending on the manufacturing technology, geogrids are classified as follows:

- in the form of honeycombs - products are of two types: uniaxial, when during the production process the material is stretched in one direction (longitudinal), and biaxial - when this process is performed in two directions;

- by volume - flat and voluminous.

A flat geogrid is a web made of polymer strips with bulges at the points of their connection, which ensures the strength of the structure and improves its adhesion to the ground at the place of use. Such products are called geogrid.

Geogrid appearance

Geogrid appearance

Bulk products are made from tapes connected to each other in a checkerboard pattern using welding, chemicals or weaving technologies.

The tapes used can be perforated, which improves the interface of the finished product with the soil and other inert materials at the location on the construction or improvement site.

Geomats

A distinctive feature of this type of synthetic material is its two-dimensional structure, which consists of several layers of lattices, thermally interconnected using polymer threads.

Geomat appearance

Geomat appearance

Related article:

IX-2. SCHEMES FOR REINFORCEMENT OF HIGH EMBANKMENTS WITH THE APPLICATION OF GEORETS "Prudon-494"

The presented figures show

Reinforcement schemes for slopes with a slope of 45 ° using geogrids "Prudon-494".

At the same time, as measures for securing the surface parts of the slope

their continuous reinforcement with geogrids of the "PRUDON-494" type is envisaged. V

in accordance with the results of the calculations, the horizons were determined at

which instead of more durable reinforcing materials (like STABILENKA

200/45) geogrids can be applied. Calculations were carried out in the proposal

stable non-deformable base, no external load. Schemes

reinforcement of slopes were calculated based on the condition of ensuring the strength Ktr

= 1,3.

From the calculations

it follows that there are horizons in the embankment, on which, instead of high-strength

rolled synthetic materials, you can use a volumetric geogrid

"Prudon-494". In the "Methodology for calculating embankments reinforced with various

materials ", published by JSC" 494 UNR "in 2001, a new approach to solving

problems of calculating reinforced soil embankments. The calculation is based on direct accounting

joint work of soil and reinforcing layers on each horizon, taking into account

joint work of potential surfaces of collapse of the left and right slopes

embankments. In addition, the set of tasks, the results of the sequential

solutions of which make it possible to substantiate a reliable and economic reinforcement scheme

designs with various materials.

Construction of slopes

If you have slopes on your site, then do not be discouraged. You can securely reinforce them and decorate them elegantly. Moreover, both gentle and steep slopes can be reinforced.

Reinforcement work on the slope is carried out in several stages. First, the slope must be leveled, and then its boundaries must be marked. At the next stage, a layer of geotextile is neatly laid.

Strong anchors are fixed to fix the grille. Reinforcing material is stretched on them. You need to start the process of mounting the geret from the top of the slope. Then it is additionally fixed with L-shaped anchors with a step of 1-2 m.At the end of the work, the cells are filled with filler with a slide of 3-5 cm.

The considered material for strengthening the surface of the site is widely used in suburban construction. Ease of fastening and reliability in operation make it indispensable for high-quality arrangement of a summer cottage landscape.

Strengthening slopes of varying degrees of steepness

Gentle slopes up to 8 ° do not need reinforcement. They are well strengthened by germinating plantings. Their roots grow deeper and are fixed by stones in the soil. This is enough to keep the slope from sinking.

On average slopes of 8-15 °, plants appear in a natural way, but they can be washed out by downpours, so it is advisable to strengthen them with a geogrid, especially slopes of complex shapes.

To strengthen slopes of varying degrees of steepness, polymer geogrids with different honeycomb sizes are used:

- when the angle of inclination exceeds 45 °, use the edge of the cell with a size of 200 mm;

- up to 45 ° - 150 mm;

- up to 30 ° - 100 mm;

- up to 10 ° - 50 mm.

Geogrid with substrate (geocomposite)

Composite geogrids with a substrate occupy a worthy place among geosynthetic roll materials. They are created from high-strength polyester or fiberglass threads, forming a stitched biaxially oriented mesh tightly, connected to a non-woven polymer geotextile. The size of the cells can vary from 20x20 to 50x50 millimeters, depending on the technical characteristics of the geogrid.

This geotextile has found a worthy application among materials for reinforcing the foundations of asphalt concrete highways. Due to the presence of a substrate during laying, the geogrid does not wrinkle, does not form creases and folds, which favorably affects the creation of an even base for the road.

Based on the differences in the structure of the threads that are used to make the geogrid, the elongation at break coefficient and the degree of creep can change. All models, without exception, are resistant to moisture, acids and alkalis, do not deteriorate under the influence of biological factors (that is, they do not grow moldy and are not affected by fungi). They are also not afraid of ultraviolet radiation.

Due to their stable mechanical strength, various types of geogrids with a substrate are used in the construction industry. They are most in demand in order to create the upper reinforcing layer of highways, bridges, and airport runways. First, it allows you to reduce the thickness of the coating, since crushed stone or other filler used to create a base cushion does not move and does not mix with soil, sand and other layers. Which is definitely economically beneficial. Secondly, the road surface wears out less, so that the intervals between repairs are significantly increased. Geogrids with a substrate allow it to withstand heavy loads (including from truck wheels and aircraft chassis), so deformation, including cracking, is minimized. The elasticity of the road surface increases, the level of its resistance to all types of horizontal loads and some vertical ones increases. Potholes and ruts, which often "decorate" unreinforced highways, are not formed in this case.

Basalt and fiberglass geonets impregnated with bitumen-based compounds are most in demand for reinforcing freshly laid asphalt pavements. In the event that asphalt will be laid on top of a concrete base, latex impregnation is recommended. Thanks to the geotextile backing, the contact area of the material with the road surface increases, and it also performs a gas venting function.

Even strong heating is not capable of damaging this type of geogrids, fiberglass, without changing its properties, perfectly withstands heating up to 400 degrees, and basalt - up to 600.

Along with reinforcing roads, geogrids with a substrate are needed to strengthen the banks of reservoirs and ravine slopes. In this case, the grating does not allow the soil to move, and the geotextile prevents the soil from being washed away by melt, ground or rainwater. So this material is recognized as one of the best for soil erosion control.

To buy a geogrid with a substrate at a bargain price in Moscow, Krasnodar, Rostov-on-Don, Sochi, Voronezh, Volgograd, Novosibirsk, Omsk, St. Petersburg, Yekaterinburg, Kazan, office order through a special form on the page "Make a request" or contact the sales department by calling toll-free 8-800-700-70-51

Next: Apply geogrids

Laying technology

From all of the above, we can conclude that the geogrid is a very important structural element both when installing a new road surface and when strengthening slopes, the correct installation of which affects not only the quality of work, but also the duration of operation of the entire structure.

In order for the geogrid to function as efficiently as possible, it must be laid correctly, adhering to all installation standards. It is mounted in accordance with the design and technical requirements, which are individual for each case. But there are certain stages that must be performed during installation:

- prepare the base;

- perform cutting of the initial deepenings;

- distribute the geogrid over the site and lay it;

- fix if necessary;

- cover with an exfoliating layer, tamp.

Fastening of the structure is carried out using special U-shaped anchors, for the manufacture of which wire with a thickness of up to 3 mm is used. Every 10 meters, fasteners are installed along the length of the lattice, and every 2 meters - along the width.

How the lattice is laid is shown in the next video.

Volumetric lattices

Thanks to the three-dimensional honeycomb structure, the volumetric geogrid has become an indispensable tool in strengthening soft soils. To form a honeycomb convenient for filling, the elements are fastened in a checkerboard pattern. The resulting frame is very strong in two planes. It is believed that the bond strength can be about 70% of the base strength of the synthetic tapes themselves.

Anchors or metal brackets can be used to connect individual elements of the module. In the construction of country houses, gratings with cell size 210x210 mm... However, the height of the honeycomb can be different - from 50 to 300 mm.

In addition to modern polymer gratings, varieties made of concrete or textile geotextile are sometimes used. The structure of the first type has elements made of concrete with a void inside for soil. The use of this option is limited by the large mass of blocks, the complexity of installation, and additional transport costs.

Geotextile gratings are used not only to reinforce loose soils, but also to reduce the negative impact on the surface from groundwater and soil heaving under the influence of frost.

Characteristics of species

In the modern construction market today there is a wide selection and assortment of volumetric geogrids. Many manufacturers are engaged in the manufacture of this material. We list only the most popular and well-proven products.

Fortek

The volumetric polymer geogrid of this company is used in the process of soil reinforcement in the construction of highways and railways to strengthen slopes and embankments, coastal zones. It is characterized by strength, resistance to aggressive effects, long service life, good water resistance. The geomodule has the following technical parameters:

- strength - not less than 21 MPa;

- seam breaking load factor - 925-1300N.

The model range of construction for strengthening "Fortek" is quite diverse. It is worth noting products such as volumetric geogrid 22/15, 30/5, 44/5.

"Geospan"

This is an ideal solution for strengthening the roadbed, slopes, and forming a drainage system. The range of plastic volumetric gratings of this company is quite wide and varied, but they all have excellent technical characteristics and comply with the standards.

The main functions of the Geospan 3D geogrid include:

- protection of soil from erosion;

- increasing the coefficient of waterproofing;

- reinforcement of the entire structure.

The most commonly used models are OP 20/20, OP 30/10, OP 40/15.

Rittex

Geogrids under this name are manufactured by Ritten Geosynthetics. Structures are manufactured in accordance with all regulatory requirements, GOST. The products are certified, the products are of high quality, reliable.The most modern and durable materials are used for manufacturing. Before entering the consumer market, they undergo a series of laboratory tests, which must confirm the compliance of the technical parameters with all requirements.

The big advantage of the Rittex volumetric plastic geogrids is their long service life - 50 years. The following models are in demand:

- 50/420 1.35 mm thick;

- 22/75 with a thickness of 1.22 mm;

- 22/75 1.35 mm thick.

III-3. CONSTRUCTIONS OF ROADWEAR ON ROADS ON A WEAK BASE

Road pavement construction

"D-1-1 (1)"

Traffic intensity - before

300 cars / day

(First stage)

Coating - Private suboptimal

a mixture of highly active (active) materials with a maximum particle size of 70 mm.

M> 800 (Blast furnace slag)

Sandy bed - Sand (sandy soil) with

Kf. > 1 m3 / day, reinforced with the "Prudon-494" Geogrid, type AR-1

Separating layer - Geosynthetics

Drainage - dividing

layer - Geosynthetics

Earth bed (See Construction of earthen

canvases)

1. The type of geosynthetic material is determined

water-thermal regime of the subgrade (properties of the subgrade soil,

the conditions of the road route, the properties of the sand of the sand layer).

Road pavement construction

"D-1-1"

Traffic intensity - before

750 cars / day

Coating - Private suboptimal

a mixture of highly active (active) materials with a maximum particle size of 70 mm.

М> 800 (blast furnace slag), reinforced with cement (6%), reinforced with a Geogrid

"Prudon-494" type AR-1.

Separating layer - nonwoven geotextile

Sandy underlayment -

Sand

(sandy soil) with Kf. > 1 m / day

Drainage - dividing

layer - non-woven

geotextile

Earth bed (See Construction of earthen

canvases)

1. The type of geosynthetic material is determined

water-thermal regime of the subgrade (properties of the subgrade soil,

the conditions of the road route, the properties of the sand of the sand layer).

Road pavement construction

"D-1-0 (1)"

Traffic intensity - before

200 (300) cars / day

Coating - Sandy soil, reinforced

geogrid "Prudon-494" AR-2 -150 mm. (AR-3 - 200 mm.), With embedding of crushed stone

Fr. 40 - 70.

Separating layer - nonwoven geotextile

Sandy underlayment -

Sand

(sandy soil) with Kf. > 1 m / day

Separating layer - nonwoven geotextile

Earth bed (See Construction of earthen

canvases)

1. The type of geosynthetic material is determined

water-thermal regime of the subgrade (properties of the subgrade soil,

the conditions of the road route, the properties of the sand of the sand layer).

Road pavement construction

"D-1-2"

Traffic intensity - before

750 cars / day

Double

surface treatment.

Coating - Rubble Fr. 40 - 70,

reinforced by the Geogrid "Prudon-494" type AR-1 (100 mm), arranged according to the method

impregnation with organic binder

Dividing

layer - non-woven

geotextile

Sandy

underlying layer - sand (sandy soil) with Kf. > 1 m / day

Drainage -

separating layer - nonwoven geotextile

Earthen

canvas (Cm.

Subgrade structures)

Peculiarities

It is not for nothing that the geogrid is called a new generation material. Even landscape design professionals did not even know what it is a few years ago. A wide range of materials are used as the basis for the geogrid - from artificial stone and basalt to non-woven fibers. In road construction, HDPE or LDPE products are most often used with standard wall heights from 50 to 200 mm and a module weight of 275 × 600 cm or 300 × 680 cm from 9 to 48 kg.

The geogrid device is quite simple. It is made in the form of sheets or mats with a cellular structure, belongs to the category of geosynthetic structures, is performed in a flat or three-dimensional form.The material can stretch vertically and horizontally, forming a frame for filling with reinforcing components. In this capacity, sand, crushed stone, various soils or a mixture of these substances usually act.

The size of the honeycomb and their number depend solely on the purpose of the product. The connection of the sections to each other is carried out by a welded method, in a checkerboard pattern. Geogrids are attached to the ground using special reinforcement or anchors. In volumetric geogrids, the height and length of the honeycomb varies from 5 to 30 cm. Such a structure retains its functionality for 50 years or more, it is resistant to various external influences, withstands significant temperature drops - from +60 to -60 degrees.

Where and what you can use

This device is used for soil reinforcement, when construction work is underway at a summer cottage or during the arrangement of roads and access roads. Also, soil strengthening using a geogrid is carried out during landscape activities. Additionally, the possibility of effective filtration and arrangement of high-quality drainage is created.

At the same time, the height of this slab will correspond to the dimensions of the polymer geogrid. Its application can significantly reduce the thickness of the soil layer of the embankment without reducing the strength of the surface and while maintaining the basic operational parameters.

What is a geogrid?

It is a three-dimensional structure consisting of honeycomb cells, which are formed from a polymer tape fastened in a special way. The size of the honeycomb is determined by the purpose of the material. Moreover, it is quite resistant to various types of influences - chemical and mechanical, as well as the influence of atmospheric factors.

The geogrid device allows for fastening on the ground as quickly as possible and without special skills. As a result, the developer receives a strong reinforcing frame. It is effective during construction work, since the cells are easily filled with rubble, sand or ordinary soil.

The advantage is not only ease of fastening, but also ease of transportation to the place of installation.

Views

Reinforcing geogrid is divided into types, according to several classification criteria. Division is performed by type of construction, type of material, presence of perforation

All these factors are important for choosing the right type of geogrid.

By stretching

The uniaxial structure is produced in the form of ready-made rectangular sections, stretching in only one direction. When deformed, the fabric retains sufficient rigidity, in the longitudinal direction it is able to withstand high loads. The cells are elongated longitudinally; their transverse side is always shorter. This product option is one of the cheapest.

The biaxial geogrid has the ability to stretch in the longitudinal and transverse directions. In this case, the cells have a square shape, better withstand deformation loads. The biaxially oriented version of the grating is the most resistant to breaking action, including soil heaving. Its use is in demand in landscape design, when arranging slopes and slopes.

Triaxial Geogrid is a polypropylene construction that provides 360-degree even load distribution. The sheet is perforated during processing, acquiring a cellular structure, stretched in the longitudinal and transverse directions. This variety can rather be called a reinforcing element; it is used where the soil is unstable in composition.

By volume

A flat geogrid is also referred to as a geogrid. The height of its cells rarely exceeds 50 mm; products are made of rigid polymer, concrete, composite compounds. Such structures are used as a reinforcing base for lawn and garden structures, paths, driveways, and can withstand heavy mechanical loads.

The volumetric geogrid is made of polyester, polyethylene, polypropylene with sufficient elasticity.Such structures are strong, durable and elastic, they are not afraid of the aggressive effects of the external environment. When folded, they look more like a flat tourniquet. Straightened and fixed on the ground, the grille acquires the required volume. Such products can have a solid or perforated structure.

By type of material

All geogrids marketed today are manufactured industrially. Most often, they are based on plastics or combined substances. Depending on the subspecies, the following basis is used.

With rolled geotextile. Such geogrids have a volumetric structure, are suitable for strengthening crumbling soil areas, help to avoid soil heaving due to frost and groundwater. The non-woven structure of the material provides the best conditions for resisting chemical and biological external factors.

Specifications

Geocell material "ARMDOR GR" is manufactured in accordance with the organization standard STO 70950163-002–2013 "GEOSOTE MATERIAL" ARMDOR GR ". Technical conditions "dated 01.03.2013.

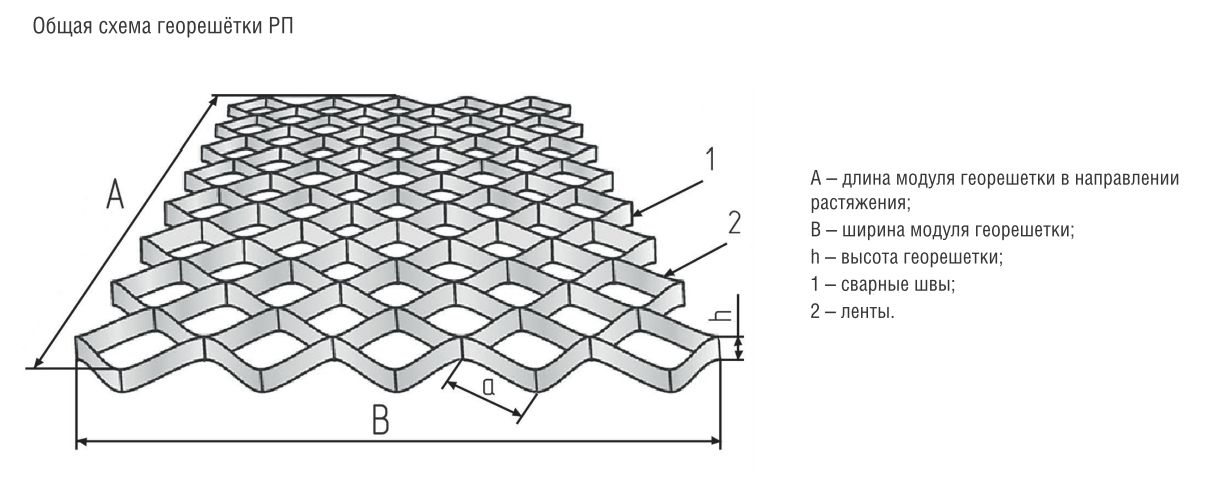

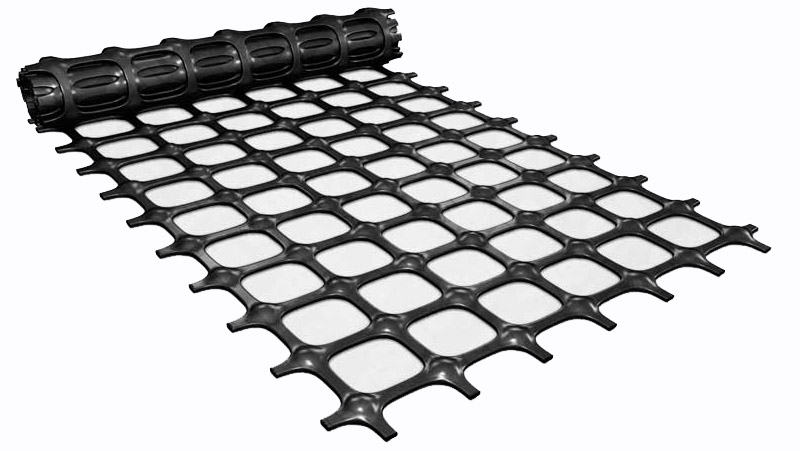

General view of geocellular material in a stretched (working) state

А - module width; B is the length of the module; h - module height; C is the diagonal size of the cell; a - cell width.

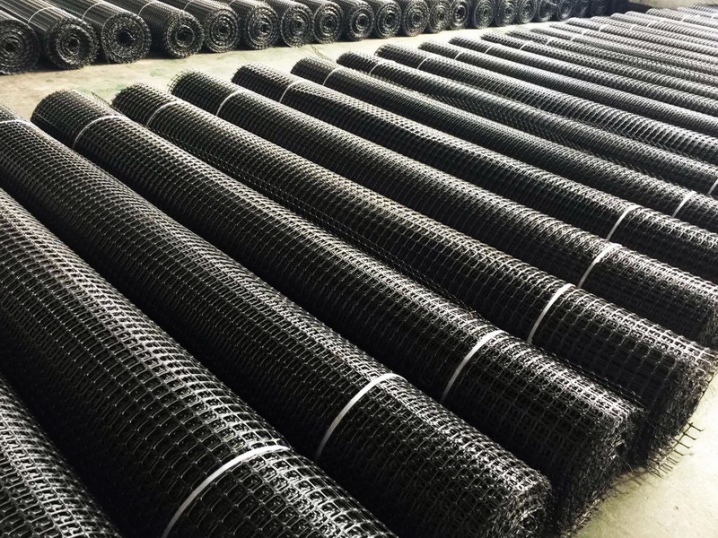

General view of "ARMDOR GR" folded for ease of transportation

A1 - module width; В1 - module length; h - module height;

ARMDOR GR is subdivided into types depending on the presence or absence of perforation and geometric dimensions. Perforation is indicated by the letter "P"

|

Geocell brand material |

Height h, mm |

Diagonal cells, mm |

Dimensions in stretched condition А´В, mm |

Dimensions in transport condition А1хВ1, mm |

Stretched area condition S, m2 |

|---|---|---|---|---|---|

|

50 100 150 200 250 300 |

220 | 2900x6250 | 1350x500 | 18,10 |

|

50 100 150 200 250 300 |

290 | 2900x6250 | 1350x500 | 18,10 |

|

50 100 150 200 250 300 |

440 | 3050x9550 | 1350x500 | 29,10 |

| Indicator name | Indicator value |

|---|---|

|

18 |

|

16 |

|

250 |

|

18 |

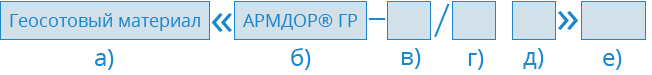

The structure of the symbol "ARMDOR GR" includes:

- product name designation ("Geocell material");

- brand designation ("ARMDOR GR");

- designation of the cell size: the size of the cell height (in millimeters) separated by a slash with the cell diagonal (in millimeters);

- perforation designation - П (if any);

- designation of this standard.

The structure of the symbol is presented below.

a) - product name; b) - grade of material; c) - cell height, mm; d) - the size of the cell diagonal, mm; e) - perforation mark; f) is the number of the organization's standard.

Example of a symbol

without perforation

"ARMDOR GR - 100/290" STO 70950163-002–2013.

perforated

"ARMDOR GR - 200/220 - P" STO 70950163-002–2013.