Features and properties

The main components of nichrome wire are chromium and nickel. It also contains additives such as silicon, iron, aluminum, manganese.

Usually this type of product is sold in hanks, spools, if necessary, it is measured and cut off.

The main properties of nichrome can be found in the following table.

|

Options |

Indicators |

|

Heating, melting temperature |

850 - 110 degrees Celsius |

|

Strength |

650 - 700 MPa |

|

Resistivity coefficient per meter |

1100-1140 ohm |

|

Density |

Less than 8500 kg / m3 |

Nichrome has a low weight, due to this, the material is often used for the production of all kinds of electrical appliances. Wire does not suffer from loss of performance in liquids and corrosive environments. Thanks to chromium, a film forms on the material, which keeps it isolated from the negative effects of external factors. The properties of this alloy are described in detail in GOST 10994-74, GOST 8803-89, GOST 12766.1-90.

Let us mention the features due to which nichrome is considered a valuable metal.

- Does not rust, which distinguishes it from other similar materials.

- Has significant resistance to specific current. Due to this, nichrome wire is required much less than steel wire for the manufacture of any device. In addition, this feature contributes to the fact that objects made of nichrome are small in size and weigh a little.

- Does not deform, does not burn under the influence of high temperature.

- It is characterized by elasticity, which allows you to easily change the shape of the wire.

The nichrome alloy has one drawback - it is a high price, but it does not in any way reduce the demand for this refractory material.

He is not able to create connections during the application of the flux. To carry out this procedure, you will need to follow a certain sequence of using soldering tools. Solder in this case can be a tin-lead alloy.

It is also worthwhile to separately prepare a flux, the component composition of which must be dosed in severity. The main components of the substance are petroleum jelly of technical origin, glycerin and zinc chloride. In order for the mixture to get the perfect consistency, you will need to thoroughly mix all of the above components. Sandpaper will need to eliminate the remnants of dirt and oxidized formations. After that, the area should be wiped with cotton wool, apply flux and solder.

Production

The manufacturing technology is based on pressure treatment using expensive equipment - mills, presses, furnaces. There are 3 ways of obtaining:

- Rolling. Nichrome is quite plastic, which makes it possible to obtain wire from it by “cold” rolling. Large circles are produced by “hot” rolling.

- Drawing. It is a pulling of workpieces (wire rods) through a gradually narrowing hole. The working speed of the operation does not exceed 25 m / s. After obtaining the required diameter, the wire is subjected to thermal and chemical treatment.

- Pressing. Billets are obtained by extruding the heated alloy through holes in the die of the fixture.

Where to find nichrome wire?

The easiest way to find nichrome wire is to contact a special store (vape shop). True, nichrome thread is not cheap there, and you will have to pay a decent amount for 1 meter.

There are other options where you can find nichrome wire:

- radio markets;

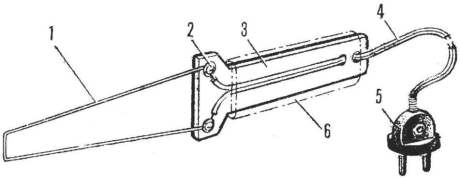

- soldering irons;

- hair dryers;

- a heater made as a fan;

- open spiral electric stove;

- the Internet.

The possibility of detecting metal on the radio market is not too great, compared to a soldering iron (working or defective).The soldering device can be found in the garage, or in the Fix Price store, where the product costs a penny. To find the one you are looking for, the device must be disassembled and the wire removed from there. As a rule, the nichrome thread in a soldering iron is thin. Winding 10 turns per pencil will help determine its cross section. The length of the coiled wire reaches up to 2.5 m.

Options with a hairdryer and heater are more expensive. The hardest thing is to get the wire out of the electric stove.

In order not to go to the market, and not to look for nichrome wire in the store, you can find information on the Internet on the sale of metal, or things containing it.

By the way, nickel in the alloy affects the price of the wire.

How to check the resistance of nichrome

The electrical resistance of nichrome wire is easily measured using household multimeters. The operation is carried out in order to calculate the resistivity. One contact is attached to the end of the conductor. The second contact joins at a different distance from the place where the first contact was created. The readings obtained are entered in the table. The dependence of the growth of resistance on the length is linear. To obtain data on the resistivity of a wire with a length of 1 m, it is necessary to measure this characteristic for a conductor of appropriate dimensions, or derive this parameter by calculation if the wire is of insufficient size. Before taking readings, the device is calibrated, or the intrinsic resistance of the device wires is measured in order to determine the correction by the value of which the data obtained when measuring the resistance of nichrome should be reduced.

Areas of application of nichrome wire

The specific properties of nichrome have found their application in various fields of activity, both domestic and industrial.

All kinds of this alloy are used as heating elements for various devices: electric ovens, dryers, thermocouples, as well as in ceramic products, playing the role of a supporting frame.

Nichrome wire, as the main actuator of electric heating devices, in most cases is a spiral through which an electric current of a given value is passed. This form is recognized as the most optimal for these devices, since it allows you to achieve greater heat transfer by increasing the length of the conductive element. The high degree of plasticity of the presented material significantly increases the service life of such devices, due to the high resistance to deformation.

Where to get nichrome wire at home? This alloy is widely used in various household appliances. Examples include electric heaters, hair dryers, soldering irons, toasters, and ovens. In addition, they are used in electronic cigarettes.

Nichrome wire: selection criteria

The implementation of the project for the creation of various types of electrothermal equipment presupposes a thorough analysis of the nominal operating parameters, which will serve as a starting point in calculating the key indicators of nichrome wire.

First of all, it is necessary to calculate the electrical resistance of the working element. It depends on three physical quantities, namely: the resistivity of the material, its length and cross-sectional area. The formula for calculating active resistance is as follows: R = ρ l / S.

To obtain the missing data, it is necessary to calculate the length of the spiral. Depending on the voltage applied to it, you should dwell on the most optimal value for the length of the wire, its diameter, and the size of the core. In order to save yourself from time-consuming calculations, you can use the pivot table, which gives the values of the length of the spiral, depending on the diameter of the wire and core for nichrome with a diameter of 0.2 to 0.5 mm.

| D 0.2 mm | D 0.3 mm | D 0.4 mm | D 0.5 mm | ||||

| D core,

(mm) |

Coil length

(cm) |

D core,

(mm) |

Coil length

(cm) |

D core,

(mm) |

Coil length

(cm) |

D core,

(mm) |

Coil length

(cm) |

| 1,5 | 49 | 1,5 | 59 | 1,5 | 77 | 2 | 64 |

| 2 | 30 | 2 | 43 | 2 | 68 | 3 | 46 |

| 3 | 21 | 3 | 30 | 3 | 40 | 4 | 36 |

| 4 | 1 | 4 | 22 | 4 | 28 | 5 | 30 |

| 5 | 13 | 5 | 18 | 5 | 24 | 6 | 26 |

| 6 | 20 |

The presented table is applicable for calculating the length of the spiral when using a voltage of 220 V. For example, for a wire with a diameter of 0.4 mm and a core diameter of 3 mm, the length of the spiral for a household electrical network will be 40 cm.It should be noted that using this table it will not be difficult to calculate the desired value for a voltage of 380 V. To do this, it is enough to select the necessary data and make a proportion of the following form: 220 V - 40 cm / 380 V - x.

In the event that a measuring tool was not at hand and it is not possible to determine the diameter of the wire, you can always use a simple, but at the same time effective method. To do this, it is enough to take an ordinary pencil and wind a wire around it, tightly pressing turn by turn. In the event that 10 turns of the spiral fit into 1 mm. the length of the pencil, then the diameter of the wire will be 1 \ 10 mm.

How to recognize nichrome?

It looks like a nichrome thread.

The indicated alloy, as a rule, does not differ in an abundance of external signs, which make it possible to judge one or another of its varieties. For the most part, nichrome is a white or slightly silvery material. The samples used will have a dark gray tint, which indicates the formation of an oxide film.

One way or another, such conventional signs cannot serve as clear evidence indicating the authenticity of this alloy. How to identify nichrome wire in appearance. Nichrome has one specific property with prolonged use. Unlike other heat-resistant materials, a characteristic dark green film usually appears on its surface. In addition, the quality of the alloy can be judged by the degree of restoration of the spiral shape after heating. If the sample has taken its original position, which indicates its high deformation resistance, then there is every reason to believe that it is nichrome.

Despite the fact that the working temperature of heating nichrome wire is high, its quality characteristics can significantly decrease, if you do not take into account the modes of long-term and short-term use, each of which prescribes certain operating parameters. Compliance with these requirements will help to significantly increase the service life of the heating elements and will serve as a guarantee of high performance.

Distinctive characteristics

Among the most demanded electrical products on the market is nichrome wire. The resistivity of this component of electric heating technology is extremely high, which allows it to be in great demand.

An important feature of the metal is its resistance to high-temperature oxidation under normal and aggressive conditions. Chromium plays a key role here.

The element forms a corresponding oxide film on the surface, which performs a protective function. She is also responsible for the corresponding dark color of the material, which is replaced by a characteristic white-gray when mechanically removing the oxidized layer.

It should be noted that direct contact with acids still destroys it, even more than corrosion-resistant tungsten.

The two-component alloy is non-magnetic. They arise for its multicomponent modifications, but have weakened indicators.

Nichrome wire is stiff and does not lend itself to simple forceful influence.

We systematize the information on how to determine the wire nichrome, mainly, how to distinguish it from externally similar materials:

- The white color of the new metal, the dark color of the previously developed one.

- Negative or minimal magnetism.

- Rigidity.

- Destruction by acids, resistance to oxidation under the influence of high temperatures.

Calculation methods

By resistance

Let's figure out how to calculate the length of the nichrome wire in terms of power and resistance. The calculation starts with determining the required power.Let's imagine that we need a nichrome thread for a small-sized soldering iron with a power of 10 watts, which will work from a 12V power supply. For this we have a wire with a diameter of 0.12 mm.

The simplest calculation of the length of nichrome by power without taking into account heating is performed as follows:

Determine the current strength:

P = UI

I = P / U = 10/12 = 0.83 A

The calculation of the resistance of nichrome wire is carried out according to Ohm's law:

R = U / I = 12 / 0.83 = 14.5 Ohm

The length of the wire is:

l = SR / ρ,

where S is the cross-sectional area, ρ is the resistivity.

Or by this formula:

l = (Rπd2) / 4ρ

But first you need to calculate the resistivity for a nichrome wire with a diameter of 0.12mm. It depends on the diameter - the larger it is, the less resistance.

L = (14.5 * 3.14 * 0.12 ^ 2) / 4 * 1.1 = 0.149m = 14.9cm

The same can be taken from GOST 12766.1-90 table. 8, where the value is indicated at 95.6 Ohm / m, if you recalculate it, you get almost the same:

L = Rdemand/ Rtabl= 14.4 / 95.6 = 0.151m = 15.1cm

For a 10 watt heater, which is powered by 12V, you need 15.1 cm.

If you need to calculate the number of turns of a spiral in order to twist it from a nichrome wire of this length, then use the following formulas:

Length of one turn:

l1= π (D + d / 2),

Number of turns:

N = L / (π (D + d / 2)),

where L and d are the length and diameter of the wire, D is the diameter of the rod on which the spiral will be wound.

Suppose we wind nichrome wire on a rod with a diameter of 3 mm, then we carry out the calculations in millimeters:

N = 151 / (3.14 (3 + 0.12 / 2)) = 15.71 turns

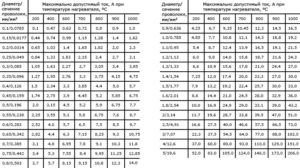

But at the same time, it is necessary to take into account whether nichrome of such a cross section is capable of withstanding this current at all. Detailed tables for determining the maximum allowable current at a specific temperature for specific cross-sections are given below. In simple words - you determine how many degrees the wire should be heated and choose its cross-section for the calculated current.

Also note that if the heater is inside the liquid, then the current can be increased by 1.2-1.5 times, and if in a closed space, then on the contrary, it can be reduced.

By temperature

The problem with the above calculation is that we calculate the resistance of the cold spiral by the diameter of the nichrome thread and its length. But it depends on the temperature, while at the same time it is necessary to take into account under what conditions it will be possible to achieve it. If this calculation is still applicable for cutting foam or for a heater, then it will be too rough for a muffle furnace.

Let's give an example of calculating nichrome for a furnace.

First, determine its volume, say 50 liters, then determine the power, for this there is a rule of thumb:

- up to 50 liters - 100W / l;

- 100-500 liters - 50-70 W / l.

Then in our case:

P = Pemp* V = 50 * 100 = 5 kW.

Further, we consider the current strength and resistance:

For 220V:

I = 5000/220 = 22.7 Amperes

R = 220 / 22.7 = 9.7 Ohm

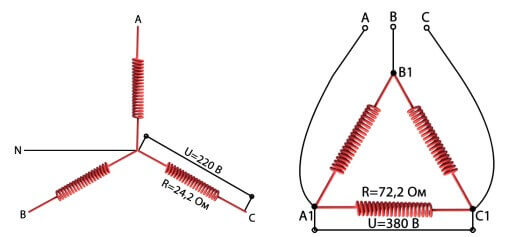

For 380V, when the spirals are connected with a star, the calculation will be as follows.

We divide the power into 3 phases:

Pf = 5/3 = 1.66 kW per phase

When connected with a star, 220V is applied to each branch (phase voltage may differ depending on your electrical installation), then the current:

I = 1660/220 = 7.54 A

Resistance:

R = 220 / 7.54 = 29.1 Ohm

To connect with a triangle, we calculate according to line voltage 380V:

I = 1660/380 = 4.36 A

R = 380 / 4.36 = 87.1 Ohm

To determine the diameter, the specific surface power of the heater is taken into account. We calculate the length, we take the resistivity from the table. 8. GOST 12766.1-90, but first let's determine the diameter.

To calculate the specific surface power of the furnace, use the formula.

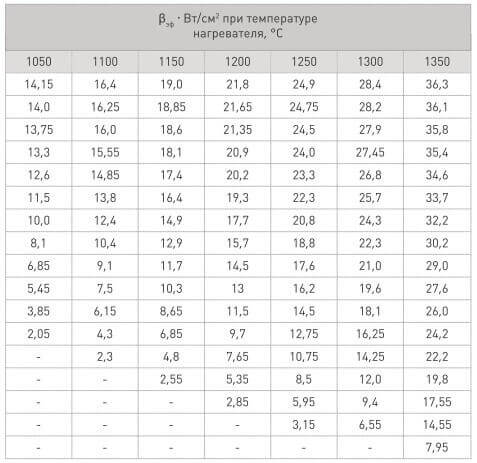

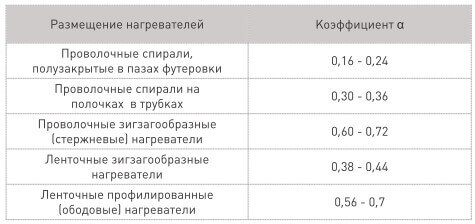

Beff (depends on the heat-receiving surface) and a (coefficient of radiation efficiency) - are selected according to the following tables.

So, to heat the furnace to 1000 degrees, take the temperature of the spiral at 1100 degrees, then according to the selection table Bef we select a value of 4.3 W / cm2, and according to the selection table for the coefficient a - 0.2.

Vadd= Bef* a = 4.3 * 0.2 = 0.86 W / cm2 = 0.86 * 10 ^ 4 W / m2

The diameter is determined by the formula:

RT - the specific resistance of the heater material at a given t, is determined in accordance with GOST 12766.1, table 9 (given below).

For nichrome Х80Н20 - 1.025

RT= p20*R1000= 1.13 * 10 ^ 6 * 1.025 = 1.15 * 10 ^ 6 Ohm / mm

Then to connect to a three-phase network according to the "Star" scheme:

d = 1.23 mm

The length is calculated using the formula:

L = 42m

Let's check the values:

L = R / (p * k) = 29.1 / (0.82 * 1.033) = 34m

The values differ due to the high temperature of the coil, the check does not take into account a number of factors. Therefore, we will take for the length of 1 spiral - 42m, then for three spirals we need 126 meters of 1.3 mm nichrome.

Application in industry and in everyday life

Nichrome products are used in places that require high-quality metal. Especially in demand in industrial production.

In industrial production

One of the first places is occupied by metal products in the market of industrial and household electrical equipment. It has found wide application in industrial sectors using electric heating furnaces, kilns for roasting and drying, furnaces that heat up to high temperatures, and devices that have a thermal effect. It is used in welding machines, household heaters and heating systems for glass and car rear-view mirrors, in resistors, resistance nodes and rheostats as a heating or resistor element. As noted above, the material is widely used among home craftsmen.

In the household

In the domestic sphere, it is used for cutting foam and polystyrene. Cutting these materials at home is quite problematic. There are several ways. Often a knife is used for these purposes, from which the material begins to crumble.

Craftsmen know how to cut foam at home so that it does not crumble. This will require a nichrome wire. It is needed in order to make a machine, the cutting tool of which is a heated string. With its help, you can cut polystyrene and make products from it with your own hands.

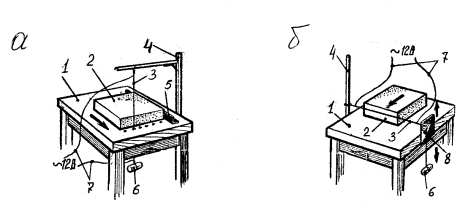

For cutting foam in a household, you can design a simple machine with a vertical or horizontal cutting tool

For cutting foam in a household, you can design a simple machine with a vertical or horizontal cutting tool

How to make a DIY Styrofoam Cutter

It is not difficult to make a machine. This will require:

- a step-down transformer;

- pipe lining (pipe with a thickness of at least 20 mm, foam thickness - at least 2 cm);

- springs for string tension;

- metal string.

For the manufacture of countertops, you will need a table, a board and a sheet of corrugated board.

The simplest version of a foam cutting machine that you can do yourself

The simplest version of a foam cutting machine that you can do yourself

The step-down transformer can be made by hand from transformer iron. You will need to make a rheostat to pick up the current value. To do this, you can take a spiral from an electric stove, having previously stretched it into a string. The winding frame is constructed of an asbestos-cement or ceramic pipe 15-20 mm thick and about 80 mm long.

For curly cutting, a thermal cutter is used from a piece of nichrome wire. It is fixed to a handle made of insulating material. A homemade foam cutter does an excellent job, including curly cutting of material.The device allows you to make recesses, cut out cavities, work with foam the way a sculptor works with clay.

A styrofoam cutter can be compared to a sculptor's tool working with clay.

A styrofoam cutter can be compared to a sculptor's tool working with clay.

With the help of home-made devices, in which nichrome wire has found application, it is possible not only to cut the foam, but also to burn it on wood. It can also be used in home-made household heaters, welding machines, and heating systems for car windows and rear-view mirrors.

How to solder nichrome

You can solder a nichrome spiral in the following ways:

- Heating the winding in the form of a thin copper wire.

- Using lapis (nitrogenous silver).

- Application of special solders and acid-containing fluxes.

- A mixture of petroleum jelly, glycerin and zinc chloride.

- Lemon acid.

- Aspirin.

- Factory made fluxes, type F-38N PET.

- Measurement with instruments.

- Tabular way.

The first method is the simplest and most affordable, but it is only suitable for connecting high resistance conductors with a thickness of no more than 0.5 mm. Copper wire for winding is best taken with a thickness of 0.1 mm. Heating is done with a gas burner, but a conventional turbo lighter can also be used. The copper wire heats up red hot and sticks to the nichrome, creating electrical contact at the atomic level.

The soldering method using lapis is used to enhance the mechanical twisting contact if the operating temperature of the heating element in the device does not exceed 200 ° C (silver nitrate fusion limit). The substance is applied to the twist when it is heated by current. The most reliable results are obtained by the soldering method using special solders and fluxes. The oxide film that forms on the surface of chromium-nickel spirals is the main obstacle to high-quality tinning. In industrial conditions, it is advisable to use vacuum chambers or neutral gaseous media to solve this problem.

At home, acid-containing fluxes are used: the surfaces to be joined are cleaned of oxide film, degreased and coated with fluxes using a soldering iron. After that, preliminary tinning and soldering are performed using POS 40/50/61 solders.

Calculation of nichrome spiral. We are ready to make a nichrome spiral for you

When winding a nichrome spiral for heating elements, the operation is often performed by trial and error, and then voltage is applied to the spiral and by heating the nichrome wire, the threads select the required number of turns.

Usually, such a procedure takes a long time, and nichrome loses its characteristics with multiple bends, which leads to rapid burnout in places of deformation. In the worst case, nichrome scrap is obtained from business nichrome.

To correctly calculate the nichrome spiral (mains voltage 220 V), we suggest using the data given in the table, based on the calculation that the resistivity of nichrome = (Ohm mm2 / m)

With its help, you can accurately determine the length of winding turn to turn. Depending on the Ø of the nichrome wire and the Ø of the rod on which the nichrome spiral is wound. It is not difficult to recalculate the length of the nichrome spiral to a different voltage using a simple mathematical proportion.

The length of the nichrome spiral depending on the diameter of the nichrome and the diameter of the rod

| Ø nichrome 0.2 mm | Ø nichrome 0.3 mm | nichrome 0.4 mm | Ø nichrome 0.5 mm | Ø nichrome 0.6 mm | Ø nichrome 0.7 mm | ||||||

| Rod Ø, mm | spiral length, cm | Rod Ø, mm | spiral length, cm | Rod Ø, mm | spiral length, cm | Ø of the rod, mm | spiral length, cm | Ø of the rod, mm | spiral length, cm | Rod Ø, mm | spiral length, cm |

| 1,5 | 49 | 1,5 | 59 | 1,5 | 77 | 2 | 64 | 2 | 76 | 2 | 84 |

| 2 | 30 | 2 | 43 | 2 | 68 | 3 | 46 | 3 | 53 | 3 | 64 |

| 3 | 21 | 3 | 30 | 3 | 40 | 4 | 36 | 4 | 40 | 4 | 49 |

| 4 | 16 | 4 | 22 | 4 | 28 | 5 | 30 | 5 | 33 | 5 | 40 |

| 5 | 13 | 5 | 18 | 5 | 24 | 6 | 26 | 6 | 30 | 6 | 34 |

| 6 | 20 | 8 | 22 | 8 | 26 |

For example, you need to determine the length of a nichrome spiral for a voltage of 380 V from a wire Ø 0.3 mm, a core for winding Ø 4 mm. It can be seen from the table that the length of such a spiral for a voltage of 220 V will be equal to 22 cm.Let's make a simple ratio:

220 V - 22 cm

380 V - X cm

then:

X = 380 22/220 = 38 cm

After winding the nichrome spiral, connect it without cutting it to a voltage source and make sure it is wound correctly. For closed spirals, the winding length is increased by 1/3 of the value given in the table.

Calculation of electric heating elements made of nichrome wire

The length of the nichrome wire for the manufacture of the spiral is determined based on the required power.

Example: Determine the length of the nichrome wire for a heating element of a tile with a power of P = 600 W at Umains = 220 V.

Solution:

1) I = P / U = 600/220 = 2.72 A

2) R = U / I = 220 / 2.72 = 81 Ohm

3) According to these data (see table 1) we choose d = 0.45; S = 0.159

then the length of nichrome

l = SR / ρ = 0.15981 / 1.1 = 11.6 m

where l is the length of the wire (m)

S - wire section (mm2)

R - wire resistance (Ohm)

ρ - resistivity (for nichrome ρ = 1.0 ÷ 1.2 Ohmmm2 / m)

| Permissible current (l), A | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Ø nichrome at 700 ° C, mm | 0,17 | 0,3 | 0,45 | 0,55 | 0,65 | 0,75 | 0,85 |

| Wire cross section (S), mm2 | 0,0227 | 0,0707 | 0,159 | 0.238 | 0,332 | 0,442 | 0,57 |

Conclusion

Thus, you can calculate the length of the wire for the nichrome spiral and determine the required diameter by power, cross-section and temperature.

It is important to take into account:

- environmental conditions;

- location of heating elements;

- coil temperature;

- the temperature to which the surface should heat up and other factors.

Even the above calculation, despite its complexity, cannot be called accurate enough.Because the calculation of heating elements is a solid thermodynamics and a number of factors can be cited that affect its results, for example, the thermal insulation of the furnace, etc.

In practice, after the estimated calculations, the spirals are added or removed depending on the result obtained, or temperature sensors and devices are used to adjust it.

Related materials:

- How to make an induction boiler with your own hands

- Calculation of the cable cross-section for power and current

- How to calculate wire resistance

Posted:

23.02.2019

Updated: 23.02.2019