Alcohol stain: how to dilute an alcohol-based wood coating agent from manufacturers - Novbytkhim - and - Anles, how to dilute Expert stain with alcohol

Alcohol stain for wood allows you to protect the material from excessive moisture, prevent the reproduction of destructive microflora, and also give the product a beautiful intense color. The stain will renew the wood surfaces and give the whole room a new look.

Colored or transparent alcohol stain penetrates deeply into the wood structure and creates a special film on the inside and outside of the product.

Due to this, the wood fibers are lifted and the structure of the material becomes more prominent.

Alcohol stain can be obtained by diluting aniline dye in denatured alcohol. The substance can be purchased in the form of a powder or ready-made mixture.

The main advantage of alcohol stain is the quick drying time of the layer applied to the wood surface. But this property can also be attributed to the disadvantages of an alcohol-based substance.

In order for the surface to evenly absorb the applied tone, it is necessary to use a spray gun, otherwise (with the manual method of toning) greasy spots appear on the surface.

In order to maximally reveal the structure of the tree or "age" it, the surface can be treated with liquids of different colors. By diluting several varieties of wood stains, you can get the colors "Arctic oak" or "bleached oak".

Before applying alcohol stain to the surface, you need to test it on a small area of the board. This is how you can decide on the desired tone and the number of layers to be applied.

It should be borne in mind that hardwoods absorb stain well, and conifers, due to the presence of a large amount of resin, are worse.

Before choosing a tool for applying a substance to a tree, you need to pay attention to the following points:

- The choice of tools depends on the footage of the treated surface. For small areas, a brush or foam pad will work. For large surfaces, it is best to use a pneumatic spray gun. Using a spray can reduce the chance of oil stains and smudges.

- In order for the color of the tree to acquire a rich shade, it is necessary to apply a few words of tinting agent. The second and subsequent layers can be applied only after the previous ones have completely dried. The same rule applies to the finishing layer.

- The surface should be painted over wood fibers. Thanks to this, you can emphasize the pattern, avoid smudges and reduce the consumption of stain.

- The stain must be of the correct consistency.

- The varnish coating does not need to be applied twice on the same place, then too dark areas can be avoided.

- Alcohol stain needs a maximum of 3 hours to dry.

- The rules for applying the substance for external and internal decoration are the same.

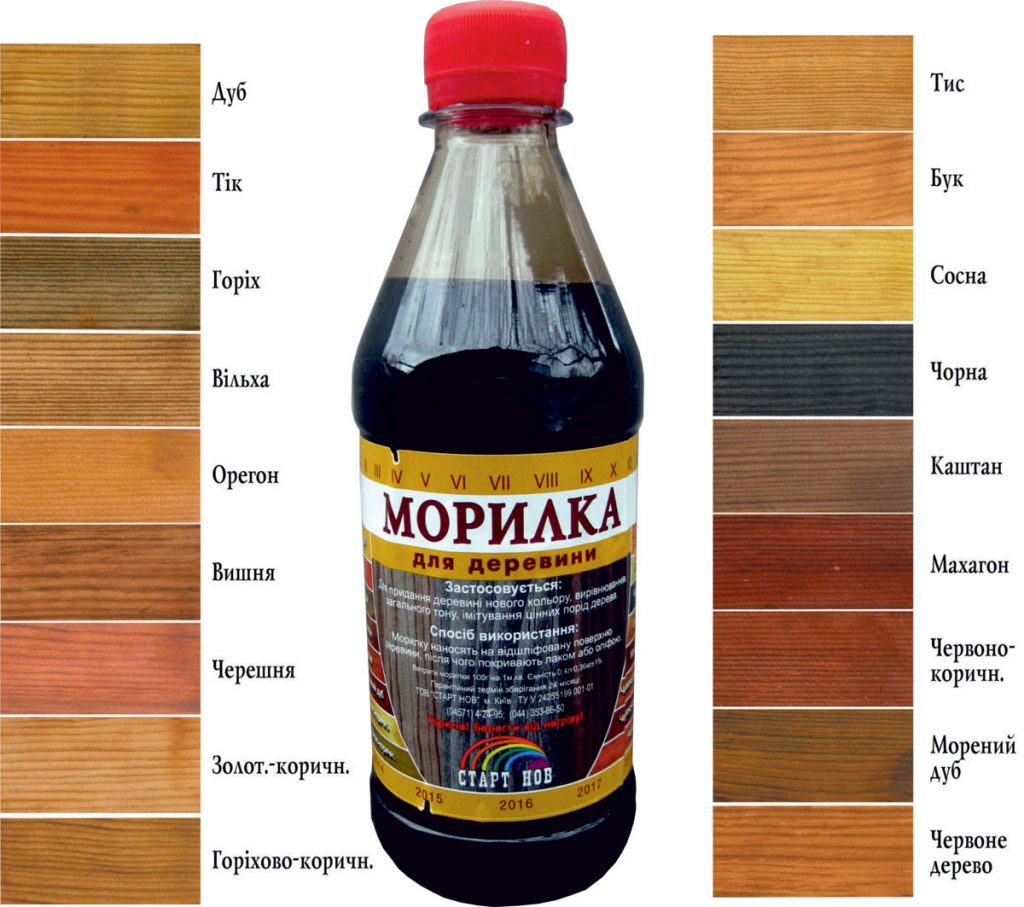

Among the most popular manufacturers of alcohol-based stains, there are three companies whose products please customers with a price-quality ratio:

The products presented by the St. Petersburg firm "Novbytkhim" can be used for tinting door panels, skirting boards and handrails indoors, as well as veneer and plywood products.

Among the advantages of the stain produced by this company, the following can be noted:

- does not require varnishing;

- is not washed off with water;

- easy to polish;

- emphasizes the wood pattern;

- prevents swelling of the coating;

- gives the wood surface non-combustible properties.

The company "Anles" produces alcohol stains, the main purpose of which is to give the wood protective properties and a certain color that imitates another wood species. The substance does not form a film on the surface of the product, but penetrates into the structure of the wood, thereby emphasizing the natural pattern of the natural material.

When working with anles stain, certain conditions must be observed.

The room temperature should not be lower than +5 degrees, and the humidity should not be less than 80%. The wood surface must be completely dry before processing.

Liquid from the "Expert" brand is suitable for processing wood surfaces indoors and outdoors, for tinting furniture, railings, log surfaces, doors.

The substance penetrates deeply into the material, allowing you to recreate the imitation of valuable wood species.

Available stain colors: maple, mocha, oak, mahogany, larch.

For more information on wood stain, see the following video.

All rights reserved, 14+

Use of any material without our prior written consent is prohibited.

Peculiarities

Stain is usually referred to as paint and varnish materials, but, unlike varnishes and enamels, it tints the surface without forming a visible film and emphasizing the woody texture. Wood fibers absorb the composition to varying degrees, due to which the natural pattern becomes more expressive, and in some cases, embossed.

This process is influenced by factors such as:

- Wood moisture. The solution penetrates better into damp and loose surfaces.

- Resinousness. Conifers are additionally degummed before staining.

- Density of wood. The higher it is, the worse the dye solution penetrates into it. Therefore, less dense areas, such as the spring part or sapwood, acquire a richer color than the kernel or summer part.

- Wood species. The same stain will differ in color on different species.

- Age. The older the tree, the higher its density.

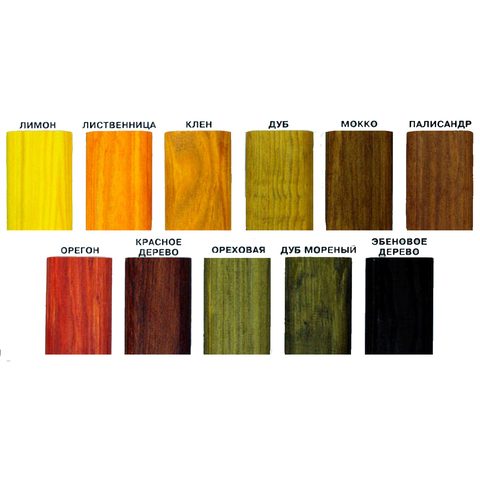

Compliance with the application technology allows you to present the structure of the tree in all its splendor. Often, with the help of stain, they imitate precious woods using natural shades (walnut, oak, ebony, rosewood, etc.). It should be noted that the color range of this type of impregnation is practically unlimited, so fans of experiments will be able to choose the option that suits them.

Color spectrum

Alternative types of stain include white composition. This tool is the most environmentally friendly and inexpensive. Along with this, white stain is presented in a wide variety of natural shades.

Today, a range of similar products for coating and painting wooden surfaces will be able to satisfy the needs of every customer. Such products allow the craftsman to give the wood almost any color. Recently, among specialists, black stain is in demand, which gives the treated surface the appearance of a black mirror. The technology of applying the black compound requires preliminary polishing of the base.

Shades of gray will help the surface blend harmoniously with the interior of any room. However, the use of this color will be successful only if the walls and interior items in the room are bright. Gray color can cause apathy, and products painted in this color will be lost against the background of the rest of the decoration.

According to psychologists, the most optimal color for a person is green. It evokes positive emotions and is suitable for painting walls and ceilings, as well as for furniture and other things.

The blue color gives expressiveness and depth to the finished product. This stain will work well with whites and yellows.

In addition to multi-colored compositions, there is a colorless impregnation on store shelves, which makes it possible to preserve the natural color of the material.

The final color of the tree depends on the number of applied layers of the product, therefore experts advise making a final decision only after the test painting. The material for test staining is sanded and smoothed. Next, proceed to the application of the first layer of the composition. After it has completely dried, a second layer is applied, but on a smaller area. The third layer is used to process the material on a piece of wood, which will be even smaller than the space allocated for the two previous layers of wood stain.

When all areas are completely dry, comparing the results obtained, you can choose the color you like.

Tips & Tricks

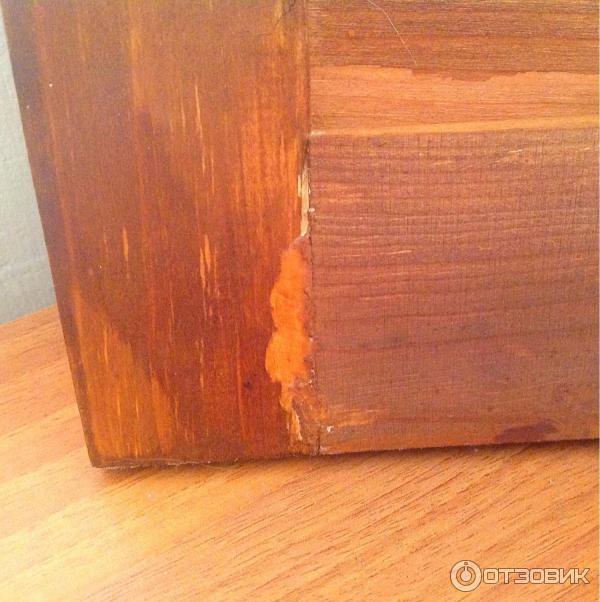

Tinting wood products with stain begins with preliminary preparation. The surface is carefully sanded, then sanded, while the old coating (if any) and defects are removed. The resulting dust is removed with white spirit, while the surface is additionally degreased. In addition, coniferous wood is degummed with special compounds.

Another obligatory preparation point is the color test. This will allow you to figure out how the chosen dye will interact with a particular type of wood. To do this, you need to apply the stain on the hidden part of the surface and wait until it dries. If the result is not satisfactory, you can apply a second layer for a more saturated color, or, conversely, thin it if you need a lighter tone.

If, for some reason, you cannot find the desired color of the stain, you can try to make it yourself. The most common recipes are strong tea and coffee. The shades will turn out to be correspondingly brown, and the saturation of the tone will depend on the strength of the drink.

Cherry and dark brown can be obtained using regular potassium permanganate. The approximate ratio is 1 liter of warm water per 50 grams of substance.

A different tone for wood products can be given with the help of decoctions from plants. Larch bark or onion skins will give a reddish hue. A strong brew of oak or alder bark will produce a deep black color.

Do-it-yourself staining does not require the use of any specific tools. For these purposes, a regular brush, paint roller, rags, spray gun are suitable. True, there is a small nuance: quick-drying alcohol solutions are applied with a spray, since it is difficult to achieve a uniform coating with other tools.

For details on working with wood stain, see the next video.

Application Tips

The most efficient and simplified way to apply the stain is by spraying. This technique is considered to be of very high quality, since the coating in such cases falls on the surface as evenly as possible. Both regular wood and plywood can be coated with this method.

If the wooden product does not differ in its large size, you can distribute the colored stain over it using a roller.

A popular coating method is also a brush, but it is not always suitable for quick-drying solutions, as they can leave behind streaks if the surface is not painted as quickly as possible. Which of the staining methods is right for you is hard to say. Here you should proceed from what material you will cover, and the stain with what composition you will use.

- When diluting and applying this or that mixture, be sure to read the instructions that come with the product. Do not forget about safety precautions and be sure to use protective gloves.

- The number of layers of stain will depend on how intense the shade you want.

- When processing wood, especially when it comes to conifers, do not forget that it must first be degummed. Also, many experts believe that it is best to apply the stain along the grain of the tree.

- Powdered mixtures should only be dissolved in pure and distilled water.

- In order for the stain to penetrate as deeply as possible into the structure of the tree, many professionals recommend heating the ready-made mixture. Some stains are added to wood varnishes. The same effect is obtained, but with improved protective properties. However, this technique does not work with all types of wood stains. Information on this issue should be checked with the store's consultants.

For information on how to choose a stain for interior woodwork, see the next video.

Varieties of toning stains

Before starting work, you need to choose the right composition. Based on the type of base, several varieties are distinguished.

Alcohol solutions

For their manufacture, aniline dyes are used, which are diluted in alcohol. Their range of colors is wide enough. Available in liquid or powder form. The latter must be dissolved, thereby preparing for work. Alcohol mixtures are favorably distinguished by their high drying speed, which takes about half an hour. In addition, the coloring pigment penetrates the wood structure very quickly. This must be taken into account when applying.

It is inappropriate to use a tampon or brush, the risk of defects: spots, uneven tone, etc. is too high. It is optimal to treat the surface with a spray gun, which allows you to get a good result. Alcoholic liquids are good for decorating large surfaces: they are easy to apply and dry quickly. Almost similar to them in properties of nitromorilacs, which are produced on the basis of solvents.

Water preparations

Water-based stains are indispensable for interior work. They are non-toxic, there is no pungent smell. At the same time, they have good adhesion, penetrate deeply into the structure of the coating, emphasizing its texture. The color range of water-based wood stains includes, perhaps, the widest range of tones. The drugs are sold in a liquid or powder state.

They dry for a relatively long time. This process takes at least 12-14 hours. Of the minuses, it is worth noting the uneven impregnation of resinous wood. Therefore, stains may form on the painted surface. To prevent this from happening, a degumming procedure should be carried out before processing. Another problem is raised pile, which also requires additional processing before painting.

Oil products

Coloring pigments are dissolved in oil, most often in linseed. Thanks to this, the material is distinguished by uniform application. The liquid easily lies on the base in any way possible. Both spray gun and manual methods can be used: roller, swab or brush. The rate of drying of oil stains depends on their concentration and several other factors. On average, this is 2-4 hours.

Instagram @konvoors

Linseed oil most often becomes the basis of oil stains. Thanks to this, the material is characterized by uniform application.

The advantageous difference between the compositions: they do not fade in the sun. There are not very many colors, but they are UV resistant and retain their color saturation for years. Like any other oily remedy, stains can thicken over time. To return to their previous consistency, they are diluted. Uyat spirit is used as a solvent.

Acrylic and wax stains

They are made on the basis of wax or acrylic resins. In terms of characteristics, they are similar to oil solutions, however, unlike them, they give the material water-repellent properties. The coating closes the pores and prevents moisture from entering them. Compositions of this type have a wide palette of tones, it is very easy to find the right one.

The liquid adheres well to the base by any manual method. It is better not to use a spray gun. The formulations do not raise the pile, they keep the same shade. There are practically no spots, streaks and other defects. Acrylic and wax dries in 4-5 hours. The preparations have worked well for furniture restoration.

Instagram @vladislavdiy

Stain possibilities: multi-colored painting technique

Few people know that one and the same surface can be covered with a stain of different colors - this technique is often used to emphasize the structure of wood or artificially age it. Take, for example, the newfangled colors "bleached oak" or "Arctic oak" - this color and structure is achieved by using two types of stain. First, a so-called wood bleach (water-based white stain) is used, and after it dries, all pits and pores in the structure of the tree are filled with oil stain containing hard wax. Colored wax clogs into these pores, making them gray or black, depending on which oil color you choose. The most interesting thing is that the rest of the bleached surface remains unchanged in color, despite the fact that it is covered with a thin protective film of wax and oil.

How to apply photo stain

In this way, by combining the types of stains and their colors, you can achieve interesting effects. The main thing is to understand the basic principle of performing such work - first, the entire tree is covered with a stain, the so-called main background is laid, and only then the finishing touches are applied to it in the form of staining the wood structure with a different color. But not the other way around - a tree opened with wax oil is no longer able to absorb the stain. In addition, do not forget about the protective varnish coating - you cannot do without it.

In conclusion, a few words about how to correctly make a color test and choose exactly the desired shade of wood. It's not a secret for anyone that the final color of the wood depends entirely on the number of layers of stain applied - you can only decide on it by making a color test. First you need to prepare a piece of board and grind it thoroughly. After that, the entire board is covered with one layer of stain. After it dries, only two thirds of the board is covered with a second layer. And only one third is covered with the next layer. When the last layer of stain is dry, the board is opened with varnish in two layers, allowing each of them to dry thoroughly. Only then can you choose the shade that suits you best.

Do-it-yourself wood staining photo

That's basically everything you need to know about wood stain and how to work with it. Of course, each type of wood reacts in its own way to this type of impregnation - deciduous trees absorb well any compositions, but conifers, due to the large amount of resins, do not have very good absorbency

Wood stain is very popular and is designed to make various wood products aesthetically pleasing and decorative, change their tone and emphasize texture, and most importantly - to increase their service life. This can be achieved by the antiseptic properties of wood stains. There are also wood stains that can protect the treated surface from insect pests, mold and mildew.

This article discusses in detail not only what a wood stain is, but also its main types, properties, advantages, and also why it is needed.

Depending on the purpose and composition, wood stain has the following advantages over a number of other paints and varnishes:

- The ability to combine shades (for example, dark colors, walnut or pine, light colors, black, etc.).

- Coating with stains strengthens the structure of the material.

- Increase the service life of products.

- Partial moisture resistance to sawn timber.

- It makes it possible both to give the wood a noble shade, and to obtain a different color scheme (there are a variety of stain colors).

- Preservation of the wood structure.

Peculiarities

Stain is a special tinting mixture, with the help of which any wood product can be given the desired shade.

There are several features of such funds:

- Almost all stains dry very quickly.

- All mixtures are safe for humans and non-toxic.

- They are easy to apply; when using them, it is not necessary to contact a specialist.

- The composition of the stain is evenly applied to wooden surfaces. At the same time, there are no stains and streaks, like from paint.

- Acrylic stains and wax variants do not lift wood grain after application.

- When choosing a high-quality mixture, you can be sure that it will protect the tree not only from excessive moisture, but also from negative influences from the outside.

- When using one or another type of wood stain, you can easily emphasize not only the beauty of the tree, but also its structure.

- For very soft wood species, many manufacturers offer special stains-gels, which not only improve the appearance of the products, but also reduce the porosity of the wood.

- The average price for such toning mixtures ranges from 70 to 250 rubles, depending on the manufacturer. Therefore, anyone can buy this type of product.