Professional advice

Experts consider the first start-up to be one of the most significant moments on which the operability of the equipped system depends.

Its algorithm is presented below:

- The first day. The temperature controller is set to 20 ° C.

- 3 next days. The temperature rises by 2 ° C daily.

- Fifth day. The warm floor is ready for full use.

If the installed equipment does not heat up, then first of all, the owner of the room needs to check if the cable is broken using a multimeter

When making resistance measurements with this device, it is important to take into account that it should not deviate by more than 5% from the manufacturer's declared values. If there are serious discrepancies, there is only one solution - to find damage or breakage, "armed" with a device for finding hidden wiring in the walls

Having found the problem area, you can start repairing it (in this case, it is better not to solder, but to use a coupling that provides the most reliable connection).

Another common cause of underfloor heating malfunction is the temperature controller, or rather, the weakening of the contacts of its terminal block. In order to repair the device, it is enough to remove its front cover and carefully tighten the screw connections.

In conclusion, it remains to add that experts do not advise saving on the cost of purchased products. A cheap cable can quickly become unusable, which is explained by its low operational resource. Given this circumstance, it is better to buy good-quality products from a top manufacturer, capable of "boasting" the best reviews. Having made such a choice, there is no doubt that the warmth and comfort in the home will be provided, and for a very long time.

For information on how the heating cable differs from the heating mat, see the next video.

Mounting

In most cases, a heating cable for a warm floor is mounted in the form of a snake, taking into account the following rules:

- the formation of loops in the cable must be avoided, as well as the intersection of individual sections;

- the distance between the warm floor and metal structures should be 5 cm (for wood, this value is less than 3 cm);

- the recommended distance from the heating system to other heat sources is about 50 cm;

- average laying pitch - about 8 outer diameters of the heating cable;

- the material used as insulation for heating elements must be homogeneous;

- the cable connector and termination must be placed in a concrete screed.

In addition, during the installation process, any kind of damage to the laid conductors must not be allowed.

As for whether it is possible to shorten or lengthen the heating cable and whether it is allowed to cut it, then such measures should be treated with extreme caution. The reason for this is very prosaic: the length of the kit assumes a specific resistance value, a change in which can lead to incorrect operation of the system and even to its failure.

- The most common installation of the heating cable in a screed. To implement it, you need to step by step perform the following steps:

- Preparation of the base. Provides for pouring a 3-cm layer of cement-sand mixture.

- Cold wire laying. Allows you to connect the thermostat to the underfloor heating system by creating a channel with a section of 20x20 cm.

- Installation of a socket for the temperature controller.

Placement of a substrate capable of reflecting heat.The use of this element under the cable allows you to accelerate the heating of the system and reduce the consumption of electrical energy.

Installation tape laying. An alternative solution to ensure reliable cable anchorage is mesh reinforcement.

Pouring with a cement screed having a thickness of about 40 mm

It is important that the solution fills all cavities tightly: this way you can achieve the best heat transfer rates.

Resistance measurement - insulation and ohmic.

This event can be carried out after the screed has completely dried - after about 3 decades from the moment it was poured.

Primary requirements

Before proceeding with the selection of a cable for a warm floor, a property owner should draw up a detailed plan of his home. It should include accurate information about the location of stationary interior items, the surfaces under which it is inappropriate to warm.

Next, you need to determine the heated area by following a simple sequence of actions:

- multiplying the length of the room by its width;

- calculation of the total area occupied by furniture and appliances;

- subtracting the second result from the first.

After that, it is necessary to calculate the total capacity of the planned system. It's very simple: for example, for a 100 W carbon heating cable in a 25 sq. m this value will be 2.5 kW.

As for the power of the conductor, sufficient for full heating of the room, then, depending on the specifics of the latter, its values are:

- living rooms, bedrooms, hallways and kitchens - 100 W;

- bathrooms and toilets - 150 W;

- balconies and loggias - 200 W.

If the homeowner plans to use the cable in coils, then in his situation the calculation will be more complicated. This is due to the need to take into account several additional parameters, the main of which are the steps of the turns, the length of the heating cable and its specific power.

In addition, the following requirements should be taken into account:

- for apartments, a warm floor should play the role of an auxiliary heating source, and not the main one;

- in buildings made of wood, a cable with a power not exceeding 2 kW is needed;

- if the underfloor heating is installed to heat stairs, ramps and other architectural elements located on the street, its rated power should be 4 kW;

- the section of the cable used to create one contour must not be interrupted;

- the transition of the conductor from room to room is unacceptable in order to avoid its refraction;

- installation of one circuit is most justified for rooms with an area not exceeding 25 sq. m.

Peculiarities

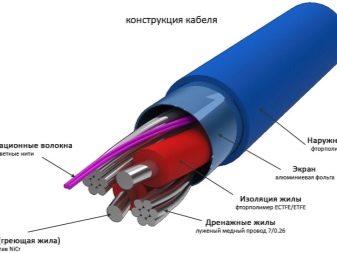

The carbon fiber heating cable is one of the characteristic components of underfloor heating. The principle of operation is very simple. As soon as the electric current is turned on, and it begins to flow to the wire, the resistance of this element leads to the appearance of a large amount of heat. But according to the laws of physics, heat cannot remain in a closed volume - it begins to spread. The heat flux is transferred by a contact method to the floor surface, then the heat enters the air in the room.

However, the problem is that it is almost impossible to influence the resistance. It also fails to adjust the length of the resistance level. The two-stage transfer of thermal energy significantly increases the current consumption. In addition, you will have to wait a long time for the air in the room to warm up from scratch.

It should be understood that this approach is not entirely convenient. It allows you to get only blocks of exactly the same size. Docking can be difficult due to the impossibility to fit completely a whole number of panels in a given volume. If you use carbon fiber instead of traditional electrical wire, both problems are effectively solved. Carbon rods have a very high resistance, when the current passes, radiation is generated from 5 to 20 microns.

As a result, the energy will not be transferred to the air itself, but to people and various objects. Adding graphite and silver elements to the design will help increase efficiency. You can adjust the temperature using polymer inserts. As soon as the air warms up to 18-22 degrees, the resistance increases. The current will be reduced, and accordingly the rod becomes colder.

Views

Among all forms of cable production for underfloor heating used in apartments, the most popular are mats - products that do not require the owner of the dwelling to perform most of the calculations. If you highlight the decorative coating, which is rightfully considered optimal, then it is a tile or ceramic granite. Two types of heating cables used in modern systems deserve special mention:

Resistive. Such elements can provide for the presence of one or two wires. The two-core version is less difficult to install, but its cost is slightly higher than that of a single-core version. In such cables, one conductor acts as a heater, while the other provides power. Regardless of the number of cores, the presented type is ideal for a floor with a screed, due to the fact that concrete cools extremely slowly.

The mats are also worthy of consideration, the most popular varieties of which are:

- Cable. This solution is a single-core resistive cable that is attached to the mesh with a snake. It is reasonable to use such mats under the tiles, due to their small thickness.

- Carbon (carbon fiber). The described type of mats assumes the presence of rod heating elements connected in parallel. Their main feature is infrared radiation generated by the action of an electric current and acting as a source of heat. It is noteworthy that the rods function independently of each other, providing heating according to a self-regulating principle. Carbon fiber mats, like the ones mentioned above, make sense to lay under ceramic tiles.

- Film. This mat, which also uses infrared radiation for heating, includes carbon rods in a plastic film.

Another noteworthy point is the impossibility of laying tiles on top of film mats. The fact is that the glue used to fix the coating in question does not provide a connection with the film, which is why experts recommend using plywood or chipboard under carpet or linoleum instead of tiles.

Peculiarities

First of all, it should be noted that the high popularity of the heating cable is due to its impressive efficiency. It converts almost all electrical energy into heat, minimizing losses and achieving optimal use of available resources.

If we single out the situations for which a warm floor is considered the best solution, then their list will look like this:

- the use of cold coatings (optionally, ceramic tiles);

- high level of humidity in the premises (most often these are bathrooms);

- lack of the ability to connect to central heating (relevant for dressing rooms and hallways, as well as insulated loggias and balconies);

- the need for heating suburban real estate objects.

Another remarkable feature of floors equipped with heating cables is the ability to install them under a variety of types of coatings. It is enough just to get acquainted with the principle of operation and arrangement of such heating systems, as well as with their main varieties.

Where is it used?

The use of carbon wire for heating is widely practiced. This solution is appropriate for residential and non-residential premises. Common examples are:

- brooders;

- incubators;

- aquariums;

- insectaries;

- terrariums;

- other objects of economic and farm profile.

Regardless of the specific type and brand of cables, strict safety standards apply. However, this also applies to infrared films and rod devices.

Attention should be paid to compliance with electrical protection standards. Ideally, the heating wire should be equipped with a special mesh, which also has to be grounded.

There are no other special requirements. The main thing is to choose the right power for a particular product.

To equip incubators, such a property of carbon fiber as the ability to provide uniform heating, to exclude jerks and drops, is important. It has no thermal inertia

Therefore, warming up occurs quickly, but there is no danger of harming the bird.

It is also worth noting:

- compatibility with any thermostats;

- the ability to obtain arbitrary power by varying the length and number of sections;

- ease of installation;

- kink resistance;

- compatibility with any power sources (voltage 12 or 220 V - does not matter).

Experts advise:

- make connections only with high-quality clamps;

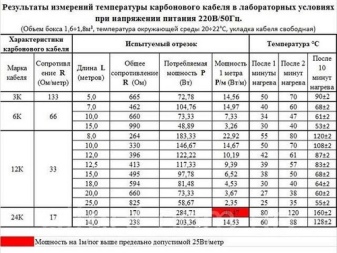

- avoid overloading the heating cord (maximum 15 W per 1 m);

- carry out the initial start-up under control, monitoring the condition of the braid;

- refuse to wind the cord on uninsulated steel objects.

As long as these guidelines are followed, carbon fiber cable can be placed under any material in any room. It is allowed to install it inside the wall. The service life of such a solution is much longer than that of metal structures. Rather, the thermal regulator or temperature sensor will fail.

Operating principle

The functioning of heating cables presupposes the ability of their material, which is a special alloy, to convert electricity into heat. All of them have maximum moisture resistance, and their power is in the range of 10-30 W per 1 meter.

As for the forms in which such cables can be presented, these are:

- coils;

- sectional systems;

- rolls (mats).

The last option is fixed with a snake on a reinforcing mesh, which can be cut, but provided that the wires providing heating and power are not affected. Thus, heating mats allow you to easily bypass furniture, appliances and other interior items. In most cases, such heating systems involve the use of a two-core resistive cable, and the termination of their supply conductor is performed by means of a heat-shrinkable tube.

It is also worth adding that the underfloor heating includes:

- cable;

- temperature controller - manual or programmed;

- thermal sensors - internal or external.

Typically, at maximum load, the cable heats up to a temperature of 60-65 ° C. Its standard values, which are relevant for normal daily use, are much lower - about 30 ° C.