Views

Firestop foam is widely used. Its unique properties allow it to be used in various types of construction. Heat-resistant foam is required when equipping baths and saunas, various stoves, boilers, fireplaces and other heating devices, that is, wherever there is significant heating or an open fire is present.

Refractory foam is highlighted in color - it is either red or pink. The color will tell you what type the polyurethane mixture is, which will avoid confusion with applying a less resistant mass to where a fire retardant option is required.

By the time of use, heat-resistant foam can be all-season and winter. The first one can be used in summer and with frosts not lower than -10 degrees. Winter foam can also be applied at lower temperatures. The lower temperature limit for this type of fire resistant sealant is indicated on the packaging. Sometimes it reaches -18 degrees.

It should be borne in mind that in the cold, the foam loses volume: the colder the air, the less the volume of the sealant.

The composition of the foam is divided into the following categories.

- One-component. The composition hardens under normal humidity conditions. Manufacturers recommend spraying treated surfaces with water to improve adhesion.

- Two-component. It contains reagents that make the mixture harden. At negative temperatures, only two-component mixtures can work.

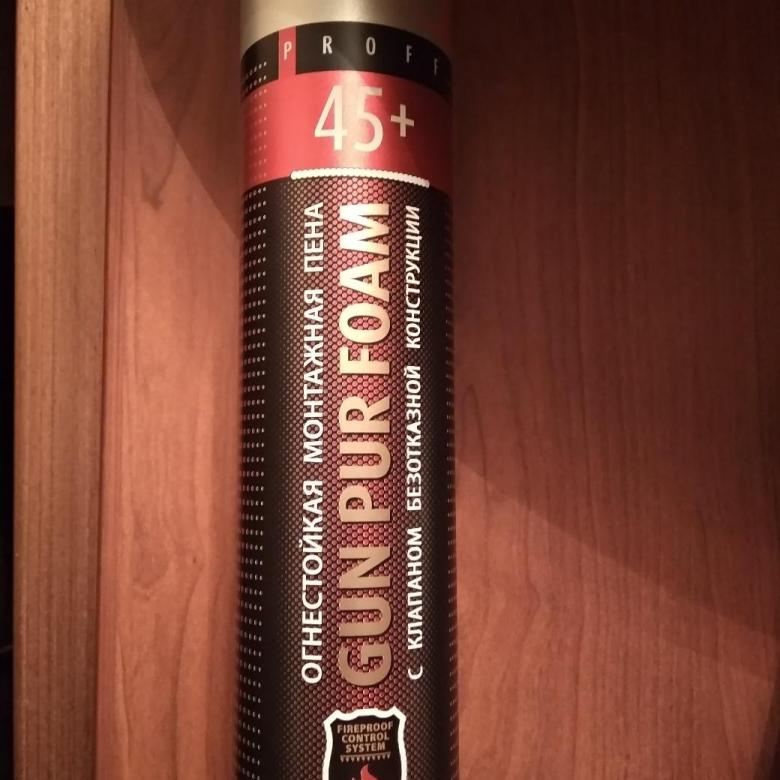

According to the method of use, foam can be used for household and professional purposes.

The material includes:

- Catalysts responsible for accelerating foam expansion. They are the ones that allow you to work in the cold winter time.

- Foaming agents that create foam, which determine the consumption of foam and the rate of setting.

- Gas, under the influence of which the thermally expanding polyurethane foam is pushed out of the tube.

- Stabilizers affecting the uniformity of foaming. The stabilizers work correctly if the can is shaken well before opening.

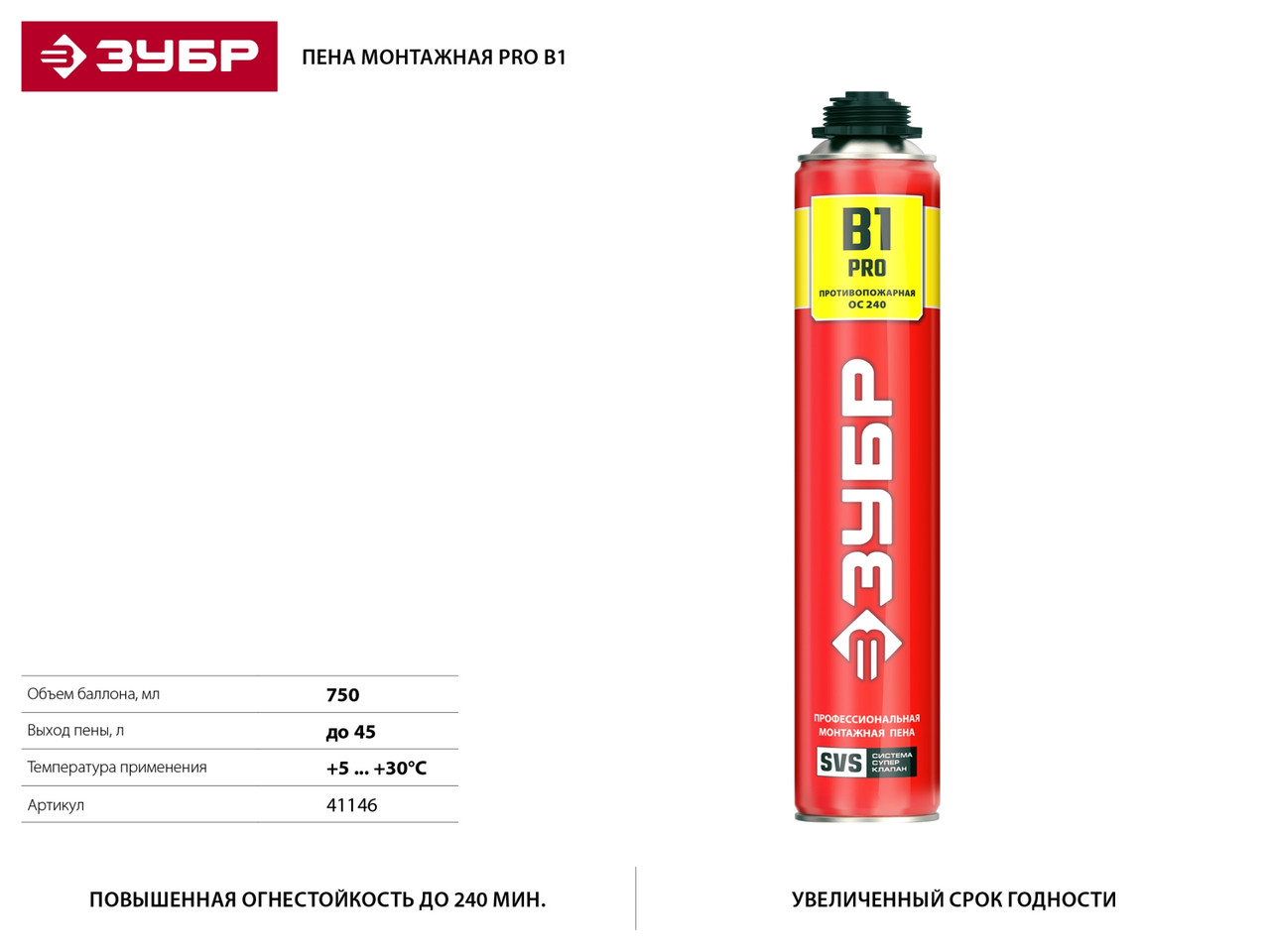

Polyurethane foams are divided into three classes of fire resistance. The most reliable material is assigned class B1. It is used in rooms with maximum human traffic.

Material with this marking has the following properties:

- resists open fire for a long time;

- does not support the combustion process;

- after removing the fire, it goes out by itself.

Less reliable foam of the second class - B2. It cannot withstand the "attack" of the fire element for a long time and begins to melt. In this case, an uncritical amount of toxins are released. It fades out on its own. Foam is appropriate in rooms with medium traffic.

Flammable sealant belongs to class B3. Its use is limited.

What it is?

Providing fire safety is the main task that is put before the builders during the construction of structures. Fire-resistant construction products everywhere displace materials that melt easily and release toxic substances during thermal exposure. Fire-fighting polyurethane foam has a specific feature that distinguishes it from conventional products - the composition is resistant to exposure to open fire.

Foam has a specific classification with respect to its flammability level, which depends on the manufacturer, brand and modification. Refractory foam is a relatively new material on the construction market. Products do not run down when applied to vertical substrates. In addition, the composition fills the cavities qualitatively.

Among the features of the material, it is worth highlighting a good level of adhesion to bricks, metal substrates, wood, various polymers, glass and cement. The product is essentially a one-component or two-component sealant based on polyurethane. The composition is being implemented already completely ready for use. Immediately after foam application, product components polymerize on contact with moisture in the air.

Among the main components of the polyurethane foam there are substances that provide products with unique characteristics in terms of heat resistance, as well as impermeability to smoke and gas.

It is necessary to highlight the main technical characteristics of the composition.

- The products are resistant to moisture, as well as the development of mold and mildew on the substrate.

- The foam is resistant to temperature fluctuations in the range from +1000 C to -60 C. The available additives enable the material not to lose its strength and elasticity.

- Based on the type of product, the time interval varies during which the product retains its resistance to elevated temperatures and does not ignite.

- Self-extinguishing flammability is inherent in foam. Upon contact with a fire source, the substance does not drain from the base, and during the termination of contact with fire, the material itself dies out.

- The products have sound insulating qualities - the limit for most compositions is about 41 dB.

How to calculate the expense?

Through the use of Internet resources, it is possible to perform calculations related to the consumption of fire retardant polyurethane foam using online calculators. In addition, the information provided by product manufacturers can also help in resolving this issue. However, the values obtained do not always coincide with the real consumption figures, therefore, when receiving the results, they should be increased, in order to avoid situations when the cylinder with the material runs out before the scheduled time, and untreated areas remain.

In addition, different types of foam may have different consumption.

Therefore, when calculating, you should take into account the following points:

- quality and type of material composition;

- the depth of the voids that must be filled with the product, taking into account the abutments or recesses;

- foam treatment method (when using a plastic tube or a special gun);

- master's qualification;

- the presence of a dispenser in the cylinder;

- uniformity of the applied layer of the composition;

- an indicator of an increase in the volume of foam;

- temperature regime and humidity level at which the site will be processed.

In the estimate documentation, the material consumption is indicated when the work is carried out in optimal conditions by a professional specialist, as well as when using a pistol. The actual working conditions may be different.

There are three types of sealants:

- weakly expanding;

- medium expanding;

- highly expanding.

Composition

The composition of heat-resistant products includes the following components.

- Catalysts. Due to the presence of such substances, the foam after application is able to expand and fill the designated area as quickly and efficiently as possible. In addition, they provide the material with low thermal conductivity. It is the catalysts that make it possible to use foam in operation even at sub-zero temperatures.

- Foaming agents impart a porous structure to the composition and enable it to quickly solidify, taking the shape of an opening. Such ingredients are responsible for the adhesion of the material to the working surface; the consumption of the composition and the coefficient of expansion directly depend on them.

- The stabilizers included in the composition are responsible for the uniform distribution of the foam and the tightness of the formed layer of substance. In order to activate the effect of the stabilizers, the can with the foam must be shaken before use.

- In addition to the above components, the foam contains a gas that allows it to escape from the cylinder.The substance is a mixture of gases dissolved in a polymer.

Other characteristics

All polyurethane foams are divided into two groups, taking into account the resistance of the substance to low temperatures

- Winter heat-resistant polyurethane foam. Its use is permitted in buildings or in open areas where the air temperature can be -10 C. Such material is used as an all-season product.

- There are also products that can be used at temperatures not lower than +5 C.

Based on the number of active components of the polyurethane foam, there are two types of sealant.

- One-component materials. The solidification process of the substance occurs under the influence of air humidity. Professional installers advise to additionally moisten the working base to increase the adhesion of the compound to the surface.

- Two-component polyurethane foam is produced in accordance with GOST, its thermally expanding ability is manifested without the participation of external factors in the chemical process. The material solidifies due to the inclusion of a special reagent in the composition. These products are frost-resistant and therefore used for work in the winter.

Installation temperature

You can work with winter assembly compounds in frost, at temperatures from -5 to -10 ℃. In many regions of the country, winter frosts are accompanied by a large drop in temperature.

At strongly negative temperatures, installation work should be delayed. Manufacturers do not guarantee the declared properties in case of non-fulfillment of the specified conditions.

Fire resistant summer foams can be used at temperatures above +5 ℃. The upper limit of temperature values is usually not limited, although experts recommend not to carry out installation at temperatures above +35 ℃.

Advice

When choosing foam, preference should be given to well-known trusted manufacturers.

You need to pay attention to the cost of the goods and the volume of the container. The volume of different manufacturers differs significantly, while the price may be the same

The better the foam, the longer it is able to withstand a fire. For the installation of fireplaces and stoves, it is worth purchasing foam of the flammability class B1. If foam is required to insulate heating, water supply or sewer networks, you can limit yourself to the flammability of B2.

Work surfaces must be cleaned before applying foam. Adhesion will be better if the foaming spots are moistened with water. However, the presence of water droplets is unacceptable. Priming the surfaces will also help the sealant adhere better.

You need to store cylinders in an upright position, you also need to monitor the expiration date. Shake the packaging before use.

The first foam outlet is a trial one. When the mixture supply is leveled, you can start sealing, while the cylinder should be at an angle of 90 degrees to the surface to be treated. The groove needs to be filled one third, two thirds will be filled when the foam expands.

Using a professional gun instead of a tube allows you to perform work efficiently, while the foam is fed into the grooves more evenly.

You should not engage in sealing in cold weather, if this is not absolutely necessary, because winter work is much more expensive. In warm weather, costs are reduced due to the fact that the foam expands much better at positive temperatures. The optimum temperature for work and foam is in the range from +20 to +23 degrees.

For information on the difference between ordinary polyurethane foam and fire-resistant, see the next video.

Consumption

Approximate material consumption per 1 sq. m is indicated on the sealant container. It is not worth taking the manufacturer's data as a panacea - the foam stock will never be superfluous. Not all foams will give the same results when applied to surfaces.

The flow rate varies depending on the following factors:

- components included in the mixture;

- the sizes of slots, grooves, recesses, that is, on the parameters of the space to be filled;

- method of applying the sealant (professional gun or special tube);

- presence or absence of foam handling skills;

- the presence of a dosing device;

- temperature and humidity in the working area.

In construction organizations, when calculating the need for polyurethane foam, estimators proceed from the fact that work is carried out exclusively by qualified workers, professional pistols under normal climatic conditions.

The following circumstances are taken into account:

- obligatory moistening of the treated cavity;

- periodic shaking of the container;

- even application of the material from bottom to top.

When determining the number of cylinders of sealant for treating a window frame, it is assumed that the thickness of the seam is about 35-40 mm. It is believed that for laying block insulation for 1 sq. m account for about 10 liters of foam. As a rule, builders lay a decent stock, referring to certain specific conditions.

None of the instructions give an accurate determination of the consumption of sealant. All instructions are calculated approximately, averaged, adjusted to ideal parameters for all possible indicators. Therefore, the manufacturer's data can be taken as approximate test results. In each case, you need to remember that only a starting point is given, and the "extra" balloon will never be truly superfluous.

Parameters such as the depth and width of the joint to be treated have a significant influence on the consumption of the sealant. If the seam is uneven, and its width in places increases up to three times, then the foam consumption can increase several times. A decrease in consumption will follow with additional filling of the seam with other materials.

We must not forget about the expansion capacity of the foam itself. Strong, medium and weakly expanding species give results that are very different from each other. Some in the process of polymerization can increase fivefold, others - only three or only two times.

Fire resistance classes

Fireproof construction products must be used in all premises that will be used by humans. The polyurethane foam has several fire resistance classes.

- B1 is a composition that has the highest physical and fire-extinguishing characteristics: the substance does not support combustion at all, spontaneously extinguishes after the termination of contact with fire, retains its properties for a long period of time when exposed to flame. The products are recommended for use in buildings with a large crowd of people.

- B2 is a material that has average flammability indicators. Foam can release toxins when it melts, but stops burning as soon as the fire is removed from it. It can be used for rooms with an average level of traffic.

- B3 is a compound that is rarely used for construction work due to its flammability.

Another indicator that is assigned to products is the fire resistance coefficient. This indicator is marked as follows - EI, where the letters are followed by numerical values inherent in one or another polyurethane foam. There are the following products.

Scope of application

Seams, gaps, including blind ones, in fire partitions are filled with foam.

In order to impart smoke tightness and fire resistance to structures with foam:

- seal window and door frames;

- fill voids in walls and ceilings;

- Foam holes around electrical conductors, switches, plugs and sockets;

- used as a gap sealant when installing a chimney and dormer windows.

With its help insulating materials are glued. It absorbs noise and sounds, improves the quality of heat insulators in air conditioning systems, as well as in cooling networks. The fire-resistant mixture is used for cable penetrations, it is used to process the seams when installing furnaces and other heating equipment.

Regardless of what material the foam is applied to (concrete, brick or wood), the preferred joint width should be in the range of 3 to 10 cm. The optimum temperature of the treated surface for high-quality sealing of cracks and gaps is considered to be a positive temperature range of 5-30 degrees.

Persons who have started repairs on their own need to know that they cannot use foam until the cylinder and its contents have warmed up to +10 degrees. The sealant will perform the functions assigned to it if its temperature is established within 10-30 degrees.

Peculiarities

Fire resistant foam is a relatively new material. When applied to vertical surfaces, the sealant does not run down under its own weight. It penetrates perfectly into cavities, filling them up to 100%. Refractory polyurethane foam adheres tightly to all types of surfaces: glass and polymers, wood and cement, brick and metal, natural stone and cement blocks.

After insertion into cavities, grooves or cracks, the volume of the sealant increases, and upon completion of the solidification process, the mass acquires rigidity. A similar property is used to fix in a certain position various frames, boxes, door and window blocks. Building elements, enclosed in a tight sealant ring, do not change their position in any direction. The foam space does not allow gas and moisture to pass through. In addition, the sealant serves as an excellent sound insulator.

When considering the characteristics in detail, the following points are highlighted:

- Preservation of useful properties after final polymerization in a wide temperature range (from -60 to +100 degrees).

- Complete inertness to moisture. Neither fungus nor mold takes root on the cured fire retardant substance.

- Increased strength in relation to other polyurethane foams.

Manufacturers

The presence of a large number of manufacturers contributes to the appearance on the market of an abundance of polyurethane foams with different characteristics. For example, DF foam (article DF1201) is classified as combustible with a fire resistance of 150 minutes. It has a pink color, packed in a 0.740 liter can. At the exit, it forms about 25 liters of foam.

Unlike DF foam, CP 620. This material is thermally expanding, two-component. The foam output is 1.9 liters. It is used in hard-to-reach places and where it is necessary to create reliable insulation from smoke, steam and water. It is used for insulating cables.

Nullifire - professional foam with a red tint, has the highest fire resistance class B1. The period from the moment of exposure to open fire to fire is 4 hours. Formed on modified polyurethane and non-combustible gas.

It is used for arranging chimneys, pipe and cable wiring, fire doors. It adheres perfectly to all surfaces. The mixture yield is about 42 liters.

Hilti 660 two-component foam is used in a variety of applications. It is versatile, capable of protecting any penetrations from fire and smoke. Fire resistance is maintained for three hours. The thermally expanding mass is red and is supplied in 325 ml cartridges. The material yield is 2.1 liters.

Rush Firestop Flex 65 is a single component, moderately flammable foam. Differs in the uniformity of the mixture exit from the container, high heat-insulating properties of the seams.

The scope of this composition is translucent structures. Used for sealing building structures. Low adhesion to fluoroplastic, polyethylene and propylene. High adhesion to brick, stone, concrete, wood.

Estonian foam brand Penosil is designed for sealing and insulating joints of fire-resistant structures. The product is suitable for sealing tile roofs. The material retains its tightness when heated for three hours. Recommended for installation of fireproof doors.

Nullifire FF197 is a one-component mixture of flammability class B1.It is used for insulation, sealing, filling and insulation of joints and seams of fire-hazardous structures. Suitable for plastics, including foam, cable sheaths, plastic. Perfectly adheres to stone, concrete, metal, brick, wood.

Profflex is a Russian manufacturer. The polyurethane foam of the same name is intended for both domestic and professional use. The material is all-season, can be applied at sub-zero temperatures (up to -15 degrees).

Remontix is a flame retardant material with a flammability limit of 240 minutes. It hardens in 10 minutes, completely polymerizes after application in a day. Requires processing, as it is afraid of ultraviolet radiation. Output at a temperature of +23 degrees can reach 65 liters.

Helpful tips from the pros

In order to do the job as efficiently as possible, it is worth adhering to the basic rules for operating fire-resistant polyurethane foams.

- When using ordinary material, the optimum surface temperature should be between +5 C and +35 C.

- The operating temperature of the cylinder is +10 C - +30 C. It is not worth heating the composition, it is enough to hold the cylinder indoors for a while.

- Store products neck down at room temperature.

- Before starting the process of filling the seams with polyurethane foam, the cylinder must be thoroughly shaken and the level of the compound output must be checked.

- It is best to work with a damp surface, but the presence of drops on the base should not be allowed.

- Seams must be filled with material for no more than a third of the entire area.

- After 24 hours, the foam should completely harden, which allows it to be covered with plaster or other composition.

When buying, you need to focus on the following points

- Balloon weight. The cost of production directly depends on the volume.

- Brand name. Today you can find Chinese-made products, the name of which, at first glance, will be very similar to well-known brands. In this case, you need to be vigilant.

- The fire resistance class should be selected based on the requirements for the level of fire safety at a particular facility.

See below for more details.