Construction methods and technology

Consider in stages the technology of monolithic housing construction from wood concrete.

Foundation and plinth

The choice of the type of foundation and the calculation of its size depends on the composition and properties of the soil, local climatic conditions, the depth of soil freezing, and the level of groundwater. One of the advantages of wood concrete is its low weight, which allows you to arrange a pile-grillage base or a strip base with shallow depth under the foundation. The minimum permissible values for the height of the basement part for arbolite monoliths vary within the range of 500-800 mm. When pouring a strip base, it is recommended to make it monolithic, as a continuation of the foundation structure.

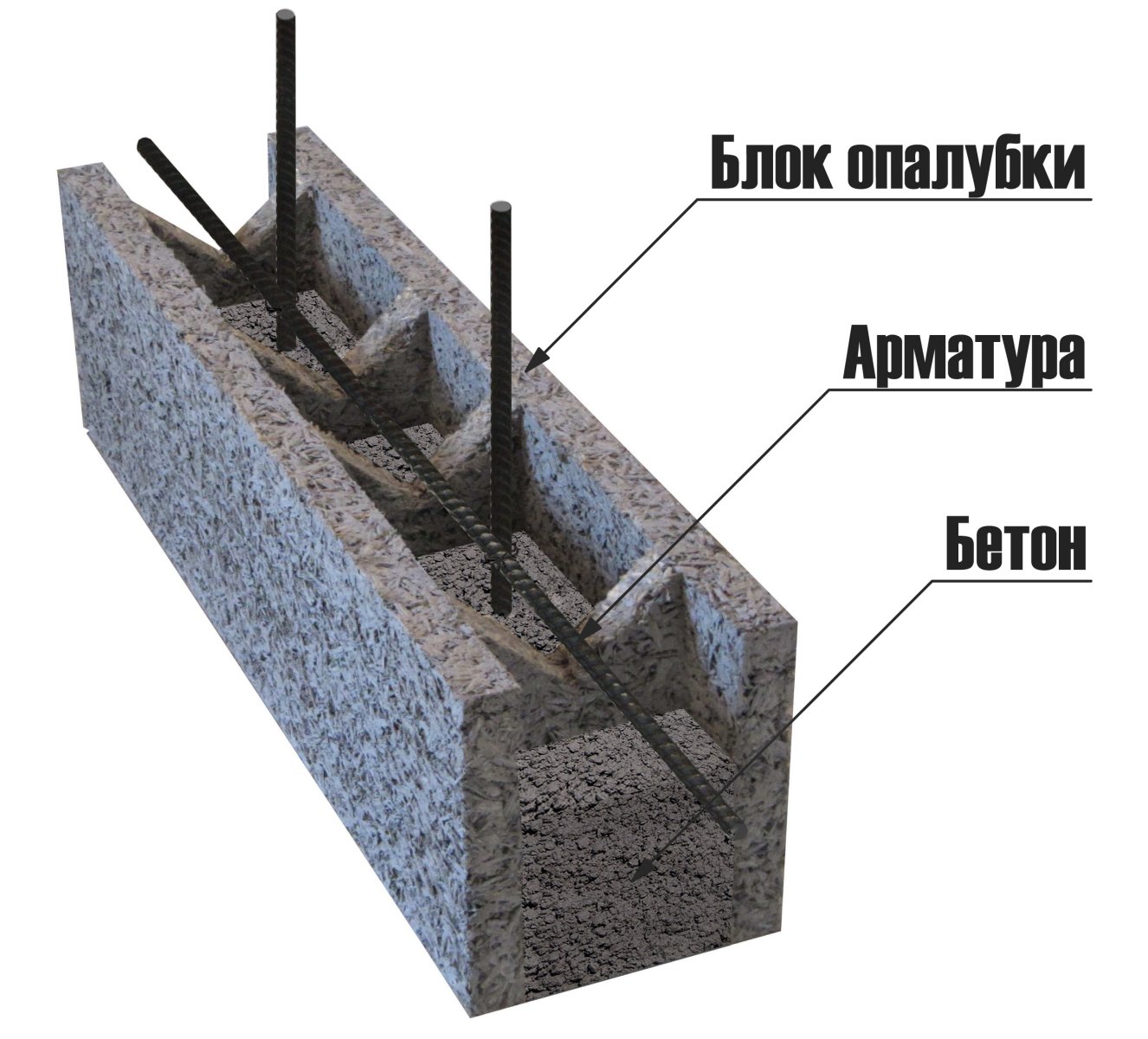

Formwork installation

The use of a non-removable formwork system leads to an increase in the cost of construction. Therefore, most often, removable disposable panel or inventory formwork is used in the form of reusable blanks from boards, plywood, plastic, metal. The shaping elements are mounted on the supporting structure of the house in such a way that their lower edges overlap it. The shields are connected to each other by means of wooden jumpers with a pitch of 0.5-0.8 m and are additionally fastened with metal studs.

Preparation of working solution

The ratio of the components in the solution for the construction of external wall structures of a one-story house made of wood concrete of class B1 looks like this:

- organic component - 200 kg;

- cement mixture of the M500 / M400 brand - 300-330 kg;

- active fillers - 8 kg;

- water - 350-390 liters.

In the manufacture of homemade wood concrete, instead of expensive ingredients such as aluminum sulfate, the use of more accessible components, lime or water glass, mixed in equal proportions, is practiced as active additives.

Walling

To date, there are three known methods of pouring monolithic arbolite wall structures.

- By floors. The monolith is erected with a non-removable formwork of the floor or foundation by the method of continuous casting. The cement mass is supplied by a local concrete-mortar plant or an automatic mixer.

- By the belts. The entire contour of the building is equipped with formwork up to a meter high with sequential movement of molds for pouring the cement mass from bottom to top.

- By segment. For one pouring, a part of the wall structure with a fixed length, height and having lateral limiters is formed.

If you plan to build a house with your own hands without involving a pro, then it is better to abandon the first two methods of filling in view of their laboriousness in favor of the latter option. It is quite possible to implement it on your own, and without using a concrete mixer.

Work order:

- The prepared segment is filled with wood concrete mixture. When filling the form with mortar, it is not added 4-5 cm to the upper border of the formwork panels.

- The poured mixture is compacted by hand using a pin, with which the formed mass of wood concrete is sequentially bayonetted to get rid of air bubbles inside the material.

- When the poured segment of the wall structure hardens, the formwork is dismantled and installed in the next section, repeating the same steps as in the previous pouring.

- The rearrangement of the boards and the pouring are first performed in one plane, forming a closed contour of the building, and then the entire system is raised to the higher tiers.

Floor arrangement

This can be done in several ways:

- install the formwork and fill it with wood concrete mortar in two layers;

- make an armored belt around the perimeter of the walls under the reinforced concrete slabs, and pour the leveling screed on top;

- to mount a precast-monolithic floor (SMP) for pouring a concrete mixture.

SMP is a frame system formed by reinforced concrete beams in combination with blocks installed between reinforced concrete elements. When the cement mass, poured into the lower part of the structure, solidifies, the NSR becomes a sealed monolith.

Installation of internal walls and ceilings

The construction of interfloor spaces is carried out using the same methods that were used for the floor. Partitions can be erected in a monolithic way or used to create internal walls arbolite tongue-and-groove blocks. At the end, the rafter system and the roof are installed, the facade is clad and the blind area is laid.

Arbolit: "old new" lightweight concrete

Private construction involves the use of simple technologies and those materials that do not require special equipment for processing, therefore lightweight concrete often outperforms heavier or more capricious "colleagues" in competition. Arbolite is also often referred to as lightweight concrete, but this is not an entirely correct definition, since there is no sand in it.

A brief history of wood concrete

Arbolite, another name for which is wood concrete, was invented in the Netherlands in the first half of the 20th century (in the 1930s). They named it DURISOL. In the USSR, the material appeared 30 years later: It was simply copied from the original sample.

In the 90s, timber concrete was forgotten: the factories that produced it were either re-profiled or destroyed. And at the beginning of the new century, when mankind began to think about the planet and about its future on it, the forgotten wood concrete was again remembered. And for good reason. Now it is considered as a worthy replacement for aerated concrete, blocks that are relatively fragile, and therefore not too durable.

Its composition, production

Arbolit is a composite material with a complex composition. It includes:

- Wood chips, usually softwood. In addition to it, stems of hemp, flax or cotton can be added. Organic filler takes up approximately 80-90% of the volume. Arbolite differs from sawdust concrete in a certain size of chips.

- Cement, a traditional binder found in all concretes. For wood concrete, maximum strength is important, therefore, in its production, only high-quality cement is used - M400 or M500.

- Mineralizers. Their task is to neutralize sugar in wood, improve the adhesion of organic matter with mortar, and give concrete strength. This role is played by aluminum sulfate, water glass, calcium chloride.

Crushed chips are soaked, treated with chemicals. Another, more environmentally friendly way is air drying for 4-6 months. Such a long period allows you to get rid of sugar without the use of additives. Then a mixture of organic matter and cement is prepared, it is poured into molds. Blocks with mortar are compacted on vibropressing machines, then dried in air.

Block is made of wood concrete, panels, plates. Products differ in density, different content of chips. Products are divided into structural, used for the construction of walls, and thermal insulation, they are used to insulate structures inside the building. The density indicator is expressed in numbers (5-50). Blocks are narrow, wide, medium and connecting.

Basic properties of wood concrete

Since the material is 90 percent wood, it has assumed its best qualities: low thermal conductivity, good sound insulation and thermal conductivity. In addition, the material belongs to the category:

- environmentally friendly;

- highly resistant to fungi, mold, aggressive substances;

- having good heat transfer and high heat capacity;

- easily amenable to mechanical processing.

Timber concrete is lightweight and has excellent impact resistance. Resists bending well.However, due to the porosity, like all lightweight and cellular concrete, it requires a particularly careful finishing of the facade.

Solid wood concrete is not the most common technology. Private developers prefer heavy concrete. The properties of wood-concrete make it possible to use it for the construction of buildings as the main molding composition. This construction allows you to achieve optimal costs.

What foundation is needed for a house made of wood concrete blocks

One of the important features of this material is its good flexural strength. Thus, wood concrete blocks quickly recover after even heavy loads. This option lowers the bounding box for choosing the type of base for the house.

When choosing a foundation option, you need to understand the following: wood concrete is lightweight and the base may not be as powerful as in other buildings. And you don't need to go deep down so that the walls are protected from moisture.

Varieties of foundation for a house made of arbolite

One of the best base options is the pile type.

This base option is optimal for construction in areas where soils have low density or difficult terrain. The piles used are specially made rods made of reinforced concrete or steel. They are deepened to the level specified by the project in order to create sufficient structural strength. The foundation for an arbolite house requires a careful approach to the choice of the type of rods-piles. The most commonly used are bored piles and screw models.

The foundation for a house made of wood concrete on bored piles is one of the most durable types of structures. Monolithic reinforced concrete rods are erected directly on site. Preliminarily, special holes are made in the soil of the corresponding diameter, into which the piles are immersed. The technology for arranging a pile foundation is absolutely identical for an arbolite house and for any other type of structure. The step between the supports is set at 3 meters. This allows you to create sufficient bearing capacity.

Many designers and customers choose wood concrete on screw piles. This technology is also strong and durable, but requires minimal effort and time. A house made of wood concrete on screw piles has a long service life. The pile rods are created in a special way, each of them has blades and can be easily screwed into any soil. Installation is extremely simple and does not require special equipment.

Construction of the foundation for a house made of wood concrete

Among these options, the bored method is preferred. This technology allows cost savings without compromising structural strength. In addition, when erecting a foundation for an arbolite house, it is recommended to use additional fasteners for the building. This is done using reinforcement rods of a given length. The grillage is firmly bound to the rods and the result is an excellent and durable structure. The grillage itself is designed so that all piles are combined into a single system. This way it is possible to evenly distribute the load and create a really powerful and common foundation.

When building a house from wood concrete blocks, you should carefully study the varieties of grillage structures. For housing construction from wood concrete used:

- Recessed grillage (depth 20 cm into the ground).

- Hanging grillage. This type of construction raises the walls 10 cm from the ground surface.

Before dwelling on a certain type of grillage, it is necessary to carefully study all the parameters of the soil obtained from the results of engineering and geological surveys.

The strip base is also often considered as a basement option for an arbolite house.

Before developing the project and moving on to work on the building site, it is important to carry out all the necessary preparatory work and surveys.If the indicators of soil density are large enough, then when arranging, you can stop at a shallow design version

In other words, the concrete belt can not be lowered below the freezing depth.

Choosing a base for a house made of wood concrete

The recessed type of foundation is optimal for low soil density. In such situations, the use of increased depth contributes to the creation of sufficient structural strength. The wear resistance and durability of such a project deserves high marks from specialists.

When building any of these options, it is imperative to use a heat-insulating material between the ground and the walls of the foundation.

The foundation for wood concrete is calculated individually each time. The building site has many factors that affect the strength, technical and operational characteristics of the future building. At the design stage, the technical parameters of the structure are also taken into account.

Scopes of the monolith

As mentioned above, the composition of foam concrete has properties that allow it to be used in a wide variety of areas of construction.

Walls

Thanks to the permanent formwork, the walls become three-layer: a layer of foam concrete and two layers of the frame (inside and outside). This makes it possible to obtain very high thermal insulation without additional insulation.

If a building of several floors is being built, then two brick walls can act as permanent formwork. Later, the gap between them will be filled with foam concrete.

The frame from the inside can be mounted from plasterboard sheets. They are very convenient in interior decoration, therefore they are an irreplaceable material for permanent formwork. You can also use fiberboard sheets for the inside of the formwork and metal for the outside.

We put the formwork for the walls

Wood or plywood can be used as formwork. Such materials are most often found in removable formwork. In order to subsequently they could be used for other purposes, the formwork should be carefully covered with polyethylene before pouring the liquid mixture.

Whichever option is chosen, the frame should be made so that monolithic foam concrete in fixed formwork does not exert excessive pressure on the walls, as a result of which the structure could bend or bend. To do this, place all the frame supports at a distance of no more than 60 cm.

Floors

A difficult task in construction is the filling of the leveling screed of the floors. However, monolithic pouring of foam concrete allows you to solve this problem. A high-density mixture, grades D800-D1200, is perfect for screeds. Due to the porosity of the material, firstly, the load is reduced, and secondly, the sound insulation characteristics are improved.

The thickness of the screed should be at least 3 cm, sometimes it is up to 5 cm, and in some cases up to 10 cm. An effective option is also when the lower part of the floors is filled with foam concrete with a density of 300-500 kilograms per cubic meter, and the upper part with a mixture of more high density or even concrete screed. Of course, there is a correct solution for each individual case.

Roof

If we talk about the insulation of a flat roof, then monolithic filling with foam concrete is an excellent option. Thanks to this method, there are no cold bridges, and the poured layer is both a leveling screed and insulation.

This material is fireproof, which is very important for the roof of the building. This makes it stand out among the commonly used insulation.

Also, it is not susceptible to decay, mold or mildew. Therefore, it is used on the roofs of private houses and businesses, as well as on damaged roofs.

Overlapping

Monolithic foam concrete can significantly reduce the load of floors on the foundation. Also, thanks to this technology, sound insulation increases, which is especially valuable in multi-storey buildings.

When aerated concrete is poured into a framework for overlap, accelerators, plasticizers, and hydrophobic ingredients are added to the concrete mix.

Industrial use

Since foam concrete has thermal insulation properties, it is advisable to use it for pipe insulation. Moreover, this can be done both at the facility itself and during manufacture. There are also no restrictions on the length or diameter of pipes that need to be insulated.

Another option for using foam concrete for industrial purposes is to fill voids with it, formed during tunneling or digging trenches. Also, this material can serve as the basis for the road surface. Of course, the density of the material in such cases must be high.

Wall insulation

When a building was built a long time ago and it needs insulation, you can use the thermal insulation properties of foam concrete for these purposes. In this case, it is necessary to attach a light frame to the walls at a short distance equal to the thickness of the insulation. For sheathing the formwork frame, you can use DSP sheets. At the end of work with the formwork, pour the liquid mixture into the formed wall.

Manufacturing features

The porous material meets all thermal insulation standards and helps to create a rigid frame. Moreover, it is light enough and does not sink in water at all. This makes working with monolithic blocks comfortable and convenient. These features make the material popular with builders and homeowners.

Foam concrete blocks meet all thermal insulation standards. They include many parameters, including frost resistance and strength.

Foam concrete is made at any site. But for the accuracy of the process and the creation of high-quality material, certain standards must be observed. Therefore, without proper experience, it is advisable to entrust the production to professionals and purchase finished products.

The monoliths include sand and cement. The composition is mixed in certain proportions and lends itself to aeration

At the same time, it is important to maintain the temperature regime on the site. The air must not be cooled below 100

The process of enriching the sand-cement mixture with oxygen must be carefully controlled. It is extremely difficult to do this on your own. In production, special electronics are used for control purposes. This greatly facilitates the process and improves production quality. The finished mixture is poured into hardened molds. If necessary, it thickens with a finish. For greater strength of structures, reinforcement is sometimes used in the manufacture.

Another advantage of a ready-made foam concrete block purchased in a store is the ability to measure density and conduct tests. This helps to ensure the strength and strength of a structure made from such a material. The ideal density should be 200kg / m3.

Monolithic construction technology

For monolithic buildings made of wood concrete, there is no need to build a reinforced concrete floor. Lightweight wood concrete is installed on a strip foundation. Its width should correspond to the thickness of the walls.

The technology for the construction of monolithic buildings is not particularly complex. Often this type of house is erected by hand:

- When pouring the foundation, the reinforcement bars are exposed to the floor level of the next floor of the building. The more floors are planned to be built, the thicker the details of the reinforcing structure are selected.

- The knocked-down formwork of the required size is laid on the foundation so that its lower part overlaps the strip base. The details of the casting mold are connected with metal studs. All side slots are closed with wooden trimmings. After the wood concrete has completely solidified, the formwork is removed, and the fasteners are cut so that there are no unnecessary holes.

- An arbolite solution is poured into a correctly installed formwork.The composition of the mixture is prepared according to the type of wall - internal or external. The form should be filled so that its edges from the top cut remain five centimeters free.

- The poured solution is carefully tamped over the entire surface. For this, a metal pin is used. Such a seal will eliminate air bubbles from the material, thereby increasing its strength.

- The formwork is removed only after a part of the wall has completely solidified. After that, it is cleaned, impregnated with an oily substance and exposed to fill the next area. The movement of the form is carried out in one plane until the perimeter is closed. Further, the ascent to the upper sections is carried out.

Monolithic wood concrete, view inside the formwork during filling and ramming When the lower walls are completely filled, the floor of the next floor is installed. For this, a formwork is specially mounted, which is filled with an arbolite mixture or laid out to overlap a slab of reinforced concrete. Then, similarly to the first floor, the upper walls are poured.

Insulating wood concrete mortar is used to fill the openings between the walls made of double bricks. This design significantly reduces the heat transfer of brick structures and greatly simplifies the construction of the building.

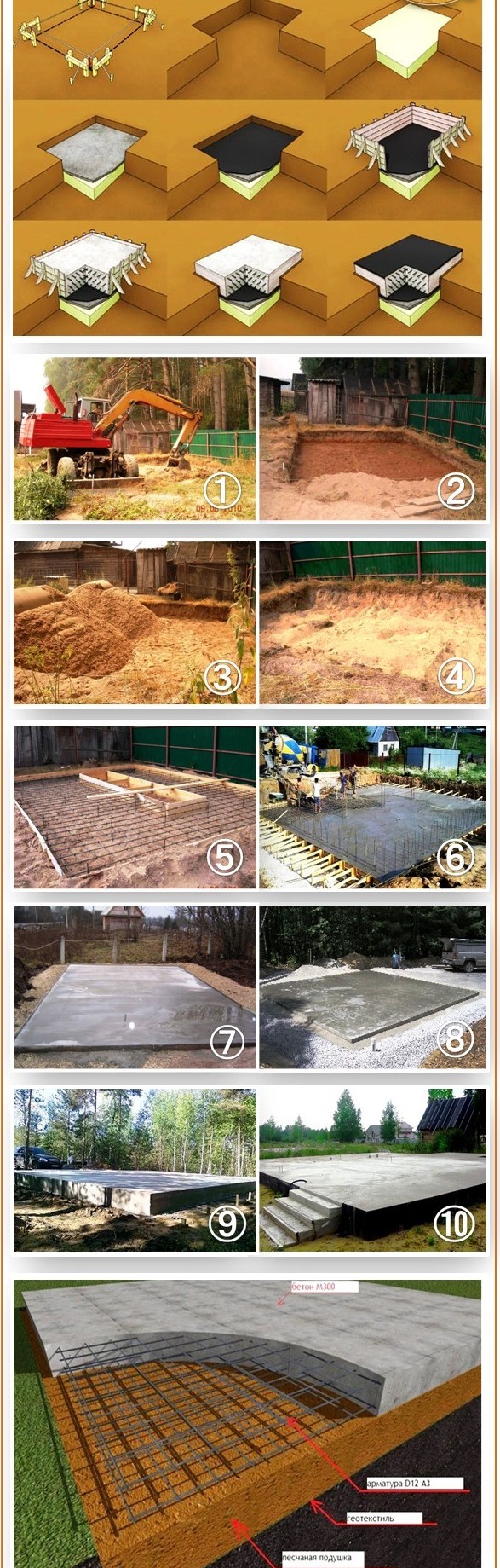

Varieties of monolithic foundation structures

Varieties of monolithic foundation structures

Varieties of monolithic foundation structures

As already noted, a monolithic foundation is a slab laid in a previously prepared place. But, nevertheless, there are several ways to make such a base. Between themselves, they differ in the options for hydro and thermal insulation. As you already understood, a strip monolithic foundation is a little different. There, the earth is dug out only for the foundation, if there is no basement, but the earth remains under the space of the rooms. Here, the entire volume is dug out, under the entire area of the house.

The simplest of this kind of foundations is performed according to the following scheme:

At the bottom of the pit, on a pre-rammed sand cushion, a reinforcing structure is installed and then poured with concrete. More complex structures include structures in which sheets of waterproofing material are used, geotextiles, in addition, depending on the type of soil, it is possible to make an additional cushion from crushed stone.

The most complex monolithic foundation looks like a multi-layer sandwich in cross-section:

- sand pillow;

- geotextile layer;

- crushed stone layer;

- the so-called preparatory concrete layer;

- waterproofing layer;

- monolithic slab.

Such complex structures are used on difficult soils, for example, with a high level of groundwater. Builders with extensive experience say that a monolithic foundation can be applied up to peat bogs.

Arbolite house: what kind of foundation is being erected for the building

When choosing a foundation for a house from wood concrete blocks, one should take into account the composition of the natural soil on the site where the construction of a residential building is planned, the number of storeys of the building, the size of the building area. Particular attention should be paid to the depth of soil freezing, the presence of a high level of groundwater, as well as to the composition of the soil under the future house

Tape

Shallow strip foundation

Shallow strip foundation

It is customary to erect a shallow strip foundation for a house from an arbolite block on dense soils with a low level of groundwater and a shallow depth of soil freezing.

The technology for erecting a strip base (foundation) for a residential building does not differ from the classical technology for arranging strip foundation supports.

To begin with, the construction site should be cleared of shrubs, grass and debris. Then the surface of the site should be planned.

The future foundation is marked out on the site with the help of hammered pegs and a stretched cord. According to the marking, they dig a trench, the depth of which should be at least 0.5 m. The bottom of the trench is leveled, cleaned and rammed.

Then they proceed to the construction of the formwork for the foundation - it is very convenient to use wooden boards or thick plywood. The height of the formwork above ground level is 0.5 m.

The bottom of the formwork is covered with a layer of coarse sand and carefully rammed (the thickness of the backfill of coarse sand in the rammed state is 0.15 m). The waterproofing layer is laid over the sand cushion, for which a roll roofing material is used.

At the bottom of the formwork, a spatial frame made of reinforcing bar with a diameter of 10 mm is placed

It is very important that the foundation frame does not touch the bottom of the trench, for which it is raised on bricks

Ramming tool - vibratory rammer

Ramming tool - vibratory rammer

The top of the poured foundation structure is leveled by ramming the concrete mixture with vibratory rammers. The surface of the foundation should be as smooth and even as possible.

The base for the house made of wood concrete is left to gain strength for 28 days, providing care for the concrete surface - periodic moistening.

So that the concrete surface of the foundation does not dry out, it is sheltered from the sun and wind with plastic wrap. Moistening of the base surface is continued for several days.

Budget fill option

Instead of a concrete mixture, the formwork of the foundation structure can be filled with an arbolite mixture, which is prepared from sawdust and shavings that have been aged in air for 3-4 months, mixed with cement and lime mortar. Proportion of wood concrete solution: 1 part of lime, 9 parts of wood waste, from 2 to 4% of other additives are taken for 1 part of cement. You can mix the composition in a conventional concrete mixer.

Filling with arbolite

Filling with arbolite

The formwork is filled with a solution by analogy with a concrete mixture. The sides of the strip foundation made of wood concrete are insulated with brickwork, a belt is made along the upper plane of the foundation 5 rows of bricks over the entire width of the strip base. A belt of brick under the walls of wood concrete blocks is made regardless of the material from which the foundation is poured for the construction of a residential building.

Pouring the foundation with wood concrete mixture, even with the most thorough insulation, is not able to ensure the strength of the foundation for a long time.

The finished foundation for a house made of wood concrete must be insulated along the surface of the vertical walls along the entire height of the basement. The best result is obtained by warming the foundation with ordinary foam or extrusive polystyrene foam. layer thickness 100 mm.

Pouring concrete into the formwork - the whole process from "A" to "Z"

Pouring concrete into the formwork

How to pour concrete into the formwork? In the presence of large volumes (when the solution is delivered from the factory on a mixer), concrete is poured immediately around the perimeter to a predetermined height. At home, there is usually no way to prepare a large amount of solution. There are two methods of how to properly pour concrete into the formwork with manually prepared portions of the solution:

- pouring the entire perimeter of the formwork with concrete to a thickness of up to 0.5 meters, while the presence of too thin layers is not allowed;

- pouring a separate section with a solution to the entire height of the formwork. The side edge of the poured concrete should be chamfered for more reliable adhesion of the individual parts of the structure.

How to pour concrete into the formwork? Concrete supply is carried out:

- manually, carrying buckets of solution;

- direct pouring from a concrete mixer;

- imported concrete is poured directly from the mixer tray; if necessary, the tray can be extended with wooden or metal gutters.

The concrete surface is leveled with a shovel or building rule. If, for any reason, the work on pouring the formwork with mortar is stopped for more than 24 hours, they can be resumed only after the concrete has completely dried. Before starting a new concreting, the concrete working joint is wiped with a brush and rinsed with water.

Features of use in construction

Due to the high moisture absorption, monolithic wood concrete requires specific measures for waterproofing the walls:

- the distance from the planning mark of the ground to the mark of the bottom of the wall must be at least 50 cm;

- on the top of the foundation or basement, it is necessary to lay a layer of waterproofing material or a cement-sand screed with hydrophobization with liquid glass;

- protect facade surfaces with plaster, cladding or curtain wall;

- overhang of the cornice - at least 50 cm.

Structural wood concrete is used for the construction of monolithic external walls with removable or non-removable plywood formwork, moisture resistant chipboard or OSB, boards. Permanent formwork serves as a finishing layer. When using removable or sliding formwork to level the layer and reduce cement consumption for subsequent finishing, it is better to wrap the boards with PVC or polyethylene film.

Installation of permanent formwork. Immediately we get the finishing of the facade.

Installation of permanent formwork. Immediately we get the finishing of the facade.

Structural wood concrete during the construction of 2-storey cottages will require additional reinforcement or a supporting frame, as well as the device of reinforced belts for floor slabs and coverings.

Heat-insulating material is used for an insulating layer in the walls of well masonry or three-layer ones. Also it can be used when building houses frame structure to fill the sinuses.

Attention! When installing reliable waterproofing, a screed made of monolithic arbolite can be used to insulate the floor of the first floor on the ground, along the ceiling, including the attic.

The elements of the frame in contact with the wood concrete mixture must be protected: metal - from corrosion, wood - from decay. The frame racks are installed with a step of 1.2-1.5 m, at the openings of windows and doors. Overlappings to reduce the load on the walls and foundations are recommended to be performed on wooden beams.

The front and inner surfaces of walls made of wood concrete require protection from moisture. This can be plaster, wall cladding, façade tiles or bricks, plasterboard cladding, plaster or interior wall cladding.

Preparation of wood concrete mixture

The quality of the wood concrete mortar for monolithic construction depends on the observance of the proportions of the mixture and its correct manufacture.

Preparation of components

The composition of the mortar for pouring from wood concrete contains more than 80 percent of coniferous wood chips. It has a certain size and shape. The standard size of raw materials is 25 * 5 * 10 millimeters. If the wood particles have a larger volume, then the strength of the material decreases. Smaller sizes require a larger amount of cement mixture and thus the level of thermal insulation properties decreases.

The composition of the mortar for pouring from wood concrete contains more than 80 percent of coniferous wood chips

The composition of the mortar for pouring from wood concrete contains more than 80 percent of coniferous wood chips

Portland cement is used for the cement base. Mostly they use brands M500 or M400. For quick hardening of the mixture, mineral additives are added, such as aluminum sulfate, calcium chloride or water glass. Slaked lime has also proven itself well.

For pouring monolithic structures, wood concrete mortar is prepared depending on its type. For structural wood concrete per 1 cubic meter, the following proportions of the main components are required:

- for density B1 - 210 kilograms of cement and 210 kilograms of chopped wood are used for 360 liters of water;

- B2 - combines 350 kilograms of cement, 230 kilograms of wood chips and 400 liters of water;

- class B2.5 requires 250 kilograms of coniferous filler, 440 liters of liquid and 380 kilograms of Portland cement.

For mixing wood concrete, which is used for thermal insulation purposes per 1 cubic meter, depending on density is required from 280 to 300 kilograms of cement, 300-430 liters of water and from 170 to 190 kilograms of wood chips.

All calculations are used subject to the addition of cement grade M400

If a dry mortar M 500 is used, then the ratio of 0.96 is taken into account.

Solution manufacturing technology

The kneading process consists of the following stages:

- Chips and a mineral or chemical additive are mixed dry. After that, Portland cement is added. All components are mixed until smooth.

- Water is poured into the prepared composition in a small stream. In this case, the solution should be continuously mixed with a construction mixer or a concrete mixer. In the finished wood concrete material for pouring, all chips must be covered with a cement mixture. The mixing process of the components takes at least 5 minutes.

A properly made mortar should be moist, but not very wet. When adding lime as an additive to completely extinguish it, the solution is mixed for 20 minutes.

Brief information about the material

Arbolit belongs to the group of lightweight concrete. The blocks contain up to 90% organic aggregates, as well as cement and chemical additives that do not allow organic matter to influence the binder hardening process. Environmentally friendly material has high heat and sound insulation with a low weight of the erected structure.

The unique characteristics of wood concrete make it possible to significantly reduce the thickness of the walls and allow its use in regions with a harsh climate. Despite the fact that the production of blocks in the USSR was established in the 60s of the last century, the material did not receive wide distribution, and in the 90s the factories were completely redesigned or simply destroyed. During that period, developers paid little attention to energy-saving technologies, focusing on other areas that seemed more promising.

Modern conditions associated with the search for more economical construction methods made people remember about wood concrete. There is a resurgence in the industry right now, and not in vain. The objects built from wood concrete more than half a century ago are in excellent condition, which means that the material has passed the test of time. In Europe and America, they used and continue to use analogs, since ordinary residents of capitalist countries value such concepts as "efficiency" and "energy saving", "environmental friendliness" and "quality".