What it is?

After its appearance, hammer paint was used only in production. Due to its exceptional durability, it has become indispensable for painting equipment operating in harsh conditions. Moisture corroded the beds of machines and machines, and forge paint reliably protected the mechanisms from rust and premature failure.

The vast majority of paints and varnishes fit well only on specially prepared surfaces. Preparation consists in cleaning and subsequent priming.

The dye perfectly "gets along" with metal damages, tightly combines with them, and stops the negative process that has begun.

After multi-colored enamels appeared, blacksmith's dye began to appear in areas of human life that were previously inaccessible to him.

First, doors painted by them in private houses appeared on sale. Dull dark colors were replaced by original bright colors with sparkles and tints. The first products were so attractive that they simply did not put others in the new cottages. Since then, the entrance to each new house has been distinguished by its hammer color.

Demand gave birth to supply. The well-proven dye has become widely demanded. This means that a vast field of activity has opened up for designers. And they were not long in coming.

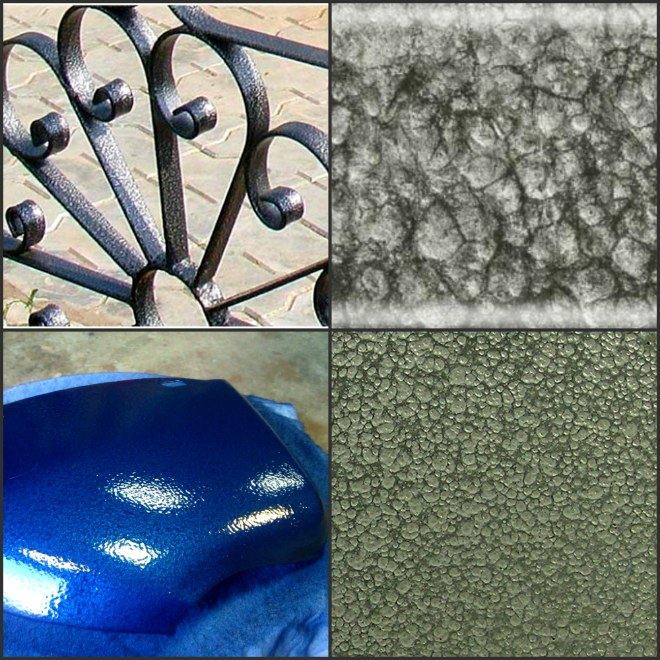

Today hammer paints and enamels are present on forged products, including:

- fences;

- gate;

- metal furniture;

- sculptural compositions;

- decorative dyes.

The beautiful, durable material has found its way into residential and public buildings. Now not only metal is processed with it. Blacksmith paints work well on wood, glass and hard plastics.

It is useless to paint factory products without removing the grease from them. So, new sheet steel or rolled products require cleaning with white spirit or acetone. For better adhesion on the sheets, you need to walk with coarse-grained sandpaper.

Is it possible to make blacksmith's enamel at home?

The high price of paint has led to the search for alternative methods of enamel preparation. Enterprising craftsmen use home-made paint. Using their experience, you can make quite a good substance. For the procedure, you will need:

- base - UVL-1 varnish 96.8%;

- aluminum shavings: up to 6%;

- soot: up to 0.5%;

- silicone oil;

- mixing containers;

- drill attachment or separate mixer for mixing ingredients;

- rubber gloves.

Aluminum shavings for hammer paint

Due to the presence of soot in the composition, a specific shade and characteristic relief are created. The hammer effect is due to the inclusion of aluminum shavings. Silicone oil is useful for the formation of solid particles, which make up the texture.

Manufacturing features

Enamels with oil components should be mixed in a warm room. It is preferable to use a dedicated camera. All components should be combined with the exception of silicone oil, which is added at the end of cooking.

Initially, the mixture is stirred with any long tool, even a stick will do. After premixing, use a mixer. The final preparation of the mixture can be determined by the absence of floating chips, the substance should become homogeneous.

Hammer paint on cars can now be diluted with multi-colored enamels, if a color solution is required. The amount of foreign enamel should be no more than 30%. Only at the end are hammer enamels for metal diluted with silicone oil, usually 5-8 drops are added.

Surface preparation for applying hammer enamel

Hammer paint can be painted directly over rust or an old layer of any other coating (except for oil, bitumen-containing and powder paints). But the surface must still be prepared before applying it:

- New metal products are washed from the factory grease (2-3 rinses with white spirit or solvent and one wiping with acetone). When no traces of grease remain on the metal, it is treated with sandpaper or a wire brush to increase adhesion.

Wire brushing Old paintwork surfaces are cleaned of loose pieces of paint. Then washed with water and washing powder, rinsed and dried thoroughly.

Wire brushing Old paintwork surfaces are cleaned of loose pieces of paint. Then washed with water and washing powder, rinsed and dried thoroughly.

Attention! Heavily rusted metal is cleaned of loose and flaking rust. Blacksmith paint adheres securely only to firmly adhering rust

Aluminum, galvanized products, stainless steel and non-ferrous metal products are coated with a special primer for non-ferrous metals.

Primer treatment

Primer treatment

Wooden surfaces are treated with water-based acrylic primer. Without it, the coloring composition will be absorbed into the wood, and the pebbled effect will not work.

Additional Information: Rust enamel primer with hammer effect

Important! Despite the fact that before processing the surface with Hammerite hammer paint for metal, it does not need preliminary preparation, experts assure that in the case of advance application of the primer, the protection of the metal surface will be even more reliable. Remembering the disadvantages of hammer paint, you can mention the high price

A kilogram of such a mixture costs more than one thousand rubles. In addition, old layers can only be removed from the surface with the use of considerable effort and strong solvents.

Remembering the disadvantages of hammer paint, you can mention the high price. A kilogram of such a mixture costs more than one thousand rubles. In addition, old layers can only be removed from the surface with the use of considerable effort and strong solvents.

If you need a reliable metal coating that will give the surface an interesting texture and at the same time protect it from external negative influences, opt for hammer enamel. Its feature is also the fact that the paint can be applied directly to rust without preliminary preparation of the metal, it is as easy to use as possible.

The material is successfully used for the treatment of clean, rusty or early painted steel structures, cast iron, or other non-ferrous metal products. Consumption varies within 120 g / m2. Drying to touch does not exceed half an hour, but it takes 4 hours to completely dry.

Price - 650 rubles / kg.

I stuffed all the wiring along the way into a plastic split corrugation. Primer enamel for rust black composition? All door hinges are locks, etc. that adjoins the body - smeared with bituminous sealant.

The fenders from the inside and the sidewalls of the engine compartment under the fenders were painted with Kuzbass varnish (BT-577). The footrest was also tinted with Kuzbass. Inside the edge of the fenders I covered it up with vibra so as not to scratch the body pillars when mounting the fenders.

Hammer effect paint has excellent strength and durability. Previously, hammer enamel was used to paint construction equipment and fittings. It provides protection from moisture and other external natural influences, is resistant to temperature fluctuations (no matter how strong and sharp its jumps are), and is also practically not subject to destruction due to mechanical influences.

Withstands the highest loads and strong impacts.After painting, it is almost impossible to get rid of the old layer, and therefore it has gained great popularity among the owners of equipment that often works in extreme conditions.

Hammer enamel technology

In order for the formed coating to last as long as possible and possess the declared properties, it is necessary to carefully observe the technology of applying the composition. We offer you to get acquainted with the technological features and requirements for the performance of work.

Consumption calculation

Compositions offered by manufacturers have different consumption. For an accurate calculation of the required amount, you should carefully study the manufacturer's recommendations. In this case, be sure to take into account:

- temperature and humidity conditions;

- method of application;

- surface condition.

Preparation of the base for applying the composition

Before starting work, you should:

- remove loose rust and old paintwork residues from the surface. To do this, use a metal brush or a drill with an appropriate attachment. It is possible to use liquid washes;

- degrease the cleaned surface with a solvent;

- inspect the surface to ensure there is no loose rust.

Application technique

Various tools and equipment can be used to apply the composition. The requirements for the paint itself and the application technique depend on this. We invite you to get acquainted with the existing options.

Brush, roller and spray can

If the area to be treated is relatively small, you can use a natural bristle brush. The use of synthetic bristles is undesirable, as they can dissolve under the influence of organic components contained in hammer paint.

The coloring composition is applied without adding a solvent in 2-3 layers. The thickness of each should be minimal. Before applying the next one, let the previous one dry for 2-4 hours, depending on the manufacturer's recommendations.

Base coloring starts from corners and edges. After that, the paint is applied to the mating surfaces.

In more detail, the application technique is presented in the following video:

If the base area is larger, a roller should be used. The best option would be a tool with a pile length of 4-11 cm. The composition should be evenly distributed over the base. For this, 1 part of the solvent is added to 9-10 parts of the paint. To form a high-quality coating, 3-4 layers of the coloring composition should be applied, since in a diluted state the hammer texture is formed much worse.

If you decide to use an aerosol can, shake the container thoroughly before applying the composition. The nozzle is positioned at a distance of 15-20 cm from the base. A total of 4 coats should be applied, giving each one sufficient time to dry.

Pneumatic spray gun and airless spray gun

If the treatment area is large enough, it is better to use special equipment, which should be configured in accordance with the manufacturer's recommendations. The composition is pre-diluted with a solvent in a ratio of 8: 1 to 2: 1, depending on the manufacturer's recommendations.

In the absence of this device, it is necessary to ensure such a viscosity of the solution at which the hammer paint will not drip from the wooden spatula, but drain at a rate of 1 drop / sec. Additional filtration will ensure optimum uniformity.

In order for the coating to be of high quality, 3-4 layers should be formed, applied at the recommended time interval.

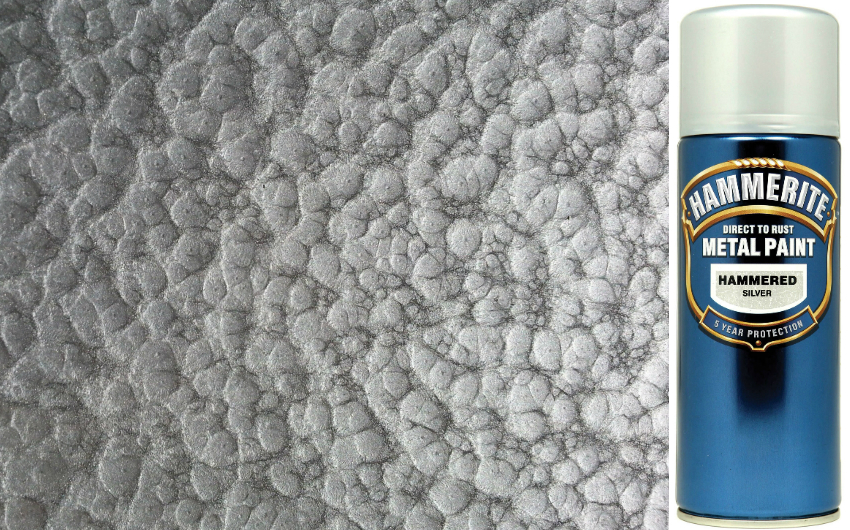

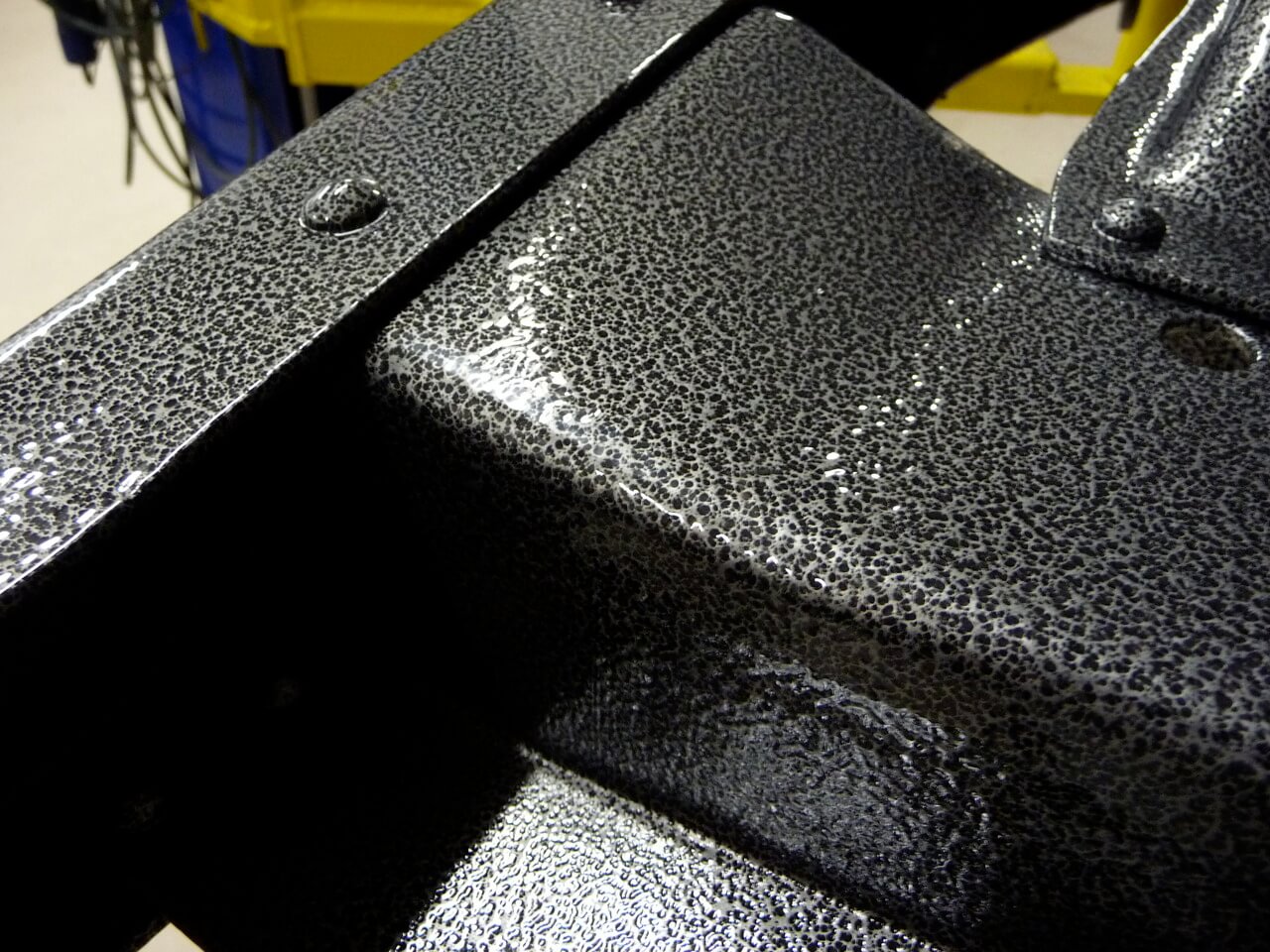

- Photo of the surface on which the hammer paint is applied for metal

If you still doubt the advisability of using hammer paint, we suggest looking at the following photos and assessing the presentability of the coating being formed:

1 out of 6

Types and features of hammer paint

Now the industry produces different types of hammer paint, so you can buy:

1. alkyd-styrene enamel, withstand temperatures up to 130 degrees in both directions from zero, dissolving only in xylene and suitable for any type of work, for example - ML-165;

2. epoxy enamel for external work "2 in 1", intended mainly for construction vehicles and street metal objects - lamps, gates and so on, it is applied to rust and perfectly masks chips, is resistant to all weather conditions, dissolves with solvents No. 648 and No. 667, example - EP-1323 ME;

3. nitro enamel intended for "home" use, that is, suitable for pieces of furniture and fragments of interior interiors, with a pronounced decorative effect and lower technical properties in heat resistance, resistance to precipitation and other external influences, is dissolved by common solvents for enamels, for example - NC -221;

4. hammer paint hammerite - English enamel, with very high technical and decorative properties, as well as full versatility in use and the absence of a strong specific odor.

In addition, the paint is divided into ordinary in cans and sprayed aerosols in cans.

Hammer paint has various forms of release, which allows the consumer to choose the most convenient method of application

How to paint hammer paint correctly?

Painting with hammer paint does not require any special skills, tricks or tricks. Although the "blacksmithing" and undemanding, but some preparatory work is worth doing:

- if on the surface there is a layer of crumbling, swollen, crumbling old paint - oil, bitumen-containing or powder, then it must be cleaned off;

- new products must be degreased, completely cleaned of grease using any technical means, for example, white spirit, solvent and acetone;

- the surface must be freed from loose, falling rust and falling off layers of paint;

- for wooden surfaces or products, a primer is needed, water-based acrylic is ideal, this is necessary in order to obtain a decorative effect, without primer, the paint is simply absorbed into the wood;

- glass, plastic and other materials must be degreased and clean.

The technology and method of painting itself depends on which tool you plan to use:

The brush must be chosen carefully, checking before buying for convenience and for "shedding", that is, buy with stubble that does not come out. This tool is irreplaceable for complex surfaces, with details or hard-to-reach places.

The painting itself should be carried out as follows - two layers on horizontally located surfaces and three on verticals. This will provide maximum decorative effect.

Ideal for large and flat surfaces such as walls or countertops. It is necessary to purchase one made of velor or fur with a short medium-hard pile, the paint corrodes the foam rollers.

The paint is applied in two or three layers. Depending on where the work is going - horizontally or vertically.

3. Aerosol can

Good for painting defects, decorating complex artsy surfaces or individual elements, as well as when performing artistic images on cars.

It is applied in 3-4 layers from a distance of 15 to 25 cm. Anything that cannot be stained must be securely covered. The first layer dries from 2 to 5 minutes, the next from 20 to 30 minutes.

4. Pneumatic spray gun

Good for working on large areas with decorative elements, both protruding or convex, and sunken. Due to the fact that the spray gun will not be able to paint exactly any surface, a good additional reinforcing decorative effect is created. Coloring is carried out in 2-4 layers, be sure to thoroughly dry each of them.

Airless and pneumatic spray guns are not the best choice for this paint as the enamel is very heavy. The use of this tool will require dilution and a change in its density, which will inevitably lead to a loss of technical and decorative qualities.

The average material consumption, if hammer paint lays down on rust and other difficult surfaces, is from 100 to 150 grams per square meter.

Advantages and disadvantages

In search of high-quality and attractive paint, each consumer seeks to find the ideal option that will delight him with its wear resistance and durability. The original hammer mix meets these requirements.

In addition, such coloring compositions have many other advantages that make them popular and in demand:

- Hammer paint is not afraid of temperature changes. Neither hot summer, nor frosty winter, nor rainy autumn will affect its appearance and performance.

- Hammer effect enamel can be applied to rusty surfaces. Moreover, for this it is not at all necessary to prepare the bases and treat them with a primer.

- Hammer mixes dry quickly enough.

- Such paints and varnishes are not afraid of dampness and moisture.

- Quality hammer paints protect metal substrates from rusting outdoors for up to 8 years. Not every enamel can boast of such a characteristic.

- Such enamel can be purchased for both interior and exterior finishing works.

- Hammer effect paint is not subject to mechanical damage. Due to this characteristic, it will be very difficult to leave a scratch or other damage on such a coating.

- Such a paint and varnish composition is safe for health. It does not emit hazardous substances either during application or after drying.

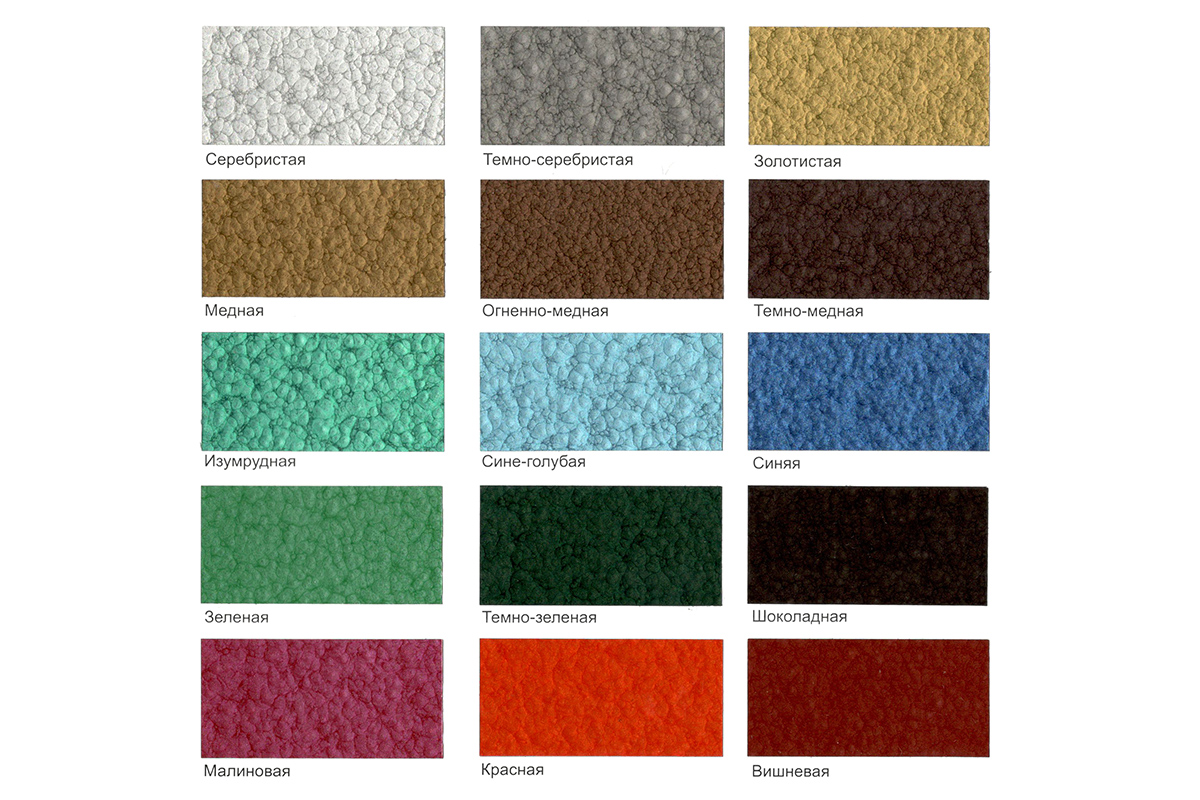

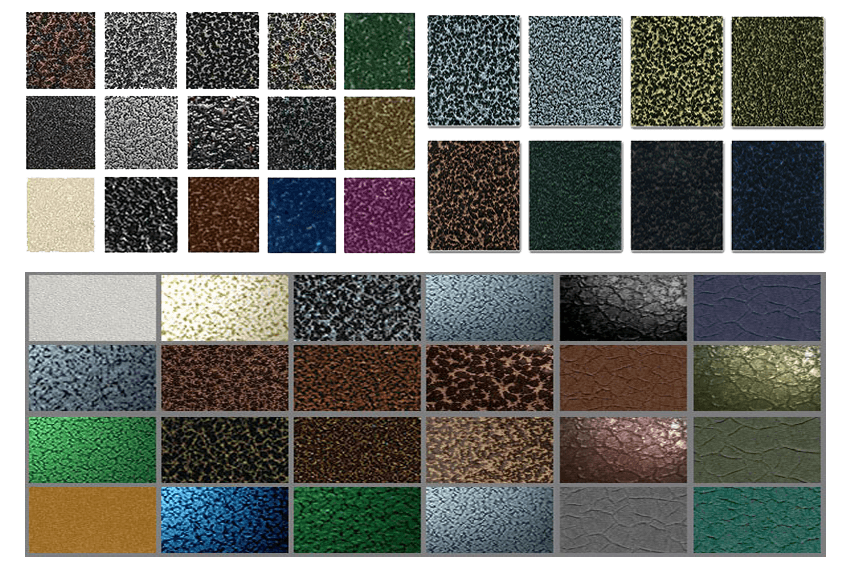

- It should be noted the decorative properties of such paint. It is presented in a very rich color palette. Over time, hammer mixes do not fade when exposed to sunlight.

- Hammer paint does not have an unpleasant odor.

- The dried hammer surface has an interesting ability - it repels water, dirt and dust. That is why the objects on which it is applied look well-groomed.

- Due to its characteristic texture, hammer paint is able to hide minor imperfections in the base. If there is a noticeable chip on it, then it can be painted over locally. In this case, the tinted area will not be noticeable.

As you can see, hammer paint has a considerable list of positive qualities.

However, it also has its weaknesses:

- Removing such paintwork from any surface is not an easy task. This requires the use of aggressive solvents and abrasive tools. However, even with such devices, it will be difficult to remove the paint layer.

- If you paint a metal base with hammer paint, then you need to make sure that no area remains unpainted. Otherwise, corrosion will quickly appear on the unfinished place, which will eventually spread to the coating itself.

- It is very difficult to apply such paint with a spray gun (or using a can, spray), since it is characterized by increased density and density.

- Many consumers consider the high cost of hammer paint as a disadvantage. Moreover, it is notable for its high consumption, so there is no need to talk about its availability.

Varieties

Hammer effect paint is divided into the following types:

- Nitroenamel "NTs-221" is considered the cheapest, as it plays the role of only a decorative coating. Therefore, it is used for interior work. She is afraid of high humidity and corrodes.

- Hammer enamel "ML-165" has an alkyd-styrene base. Withstands the highest temperatures, up to +130 degrees.Possesses a high degree of adhesion to any material. Used for outdoor and indoor use. It can even be painted over rust.

- Epoxy enamel "EP-1323" performs the function of a dye and a primer at the same time. Possesses thermal and anti-corrosion properties. Designed for cars, gates, art forging, etc.

- Enamel "Hammerite" is considered the most expensive. Manufacturer - Great Britain. When painting with it, a primer is additionally carried out. After drying, a film forms that protects the metal from oxidation. It is made from silicone additives, alkyd resins. Feature - it is undesirable to paint with a paint sprayer. Used everywhere, even on top of rust.

Advantages

Among the pluses of hammer paint:

- high degree of resistance to temperature extremes;

- anti-corrosion;

- the ability to apply directly to rust;

- quick drying, especially if spray paint;

- moisture resistance;

- reliable protection against rusting for 8 years;

- coating strength;

- no toxic fumes after drying;

- harmless to the body even when used indoors;

- a large selection of colors;

- unusual decorative effect;

- repelling dust and dirt;

- water-repellent properties;

- smoothing irregularities on the surface;

- in the presence of chips, it is not necessary to remove the entire layer of paint, it is enough to cover it with enamel at the site of the defect;

- immunity to vibration, therefore, hammer paint is used for cars;

- lack of unpleasant odors;

- the possibility of staining with different tools.

disadvantages

There are also disadvantages, but there are not many of them:

- high consumption and high cost;

- cannot be removed with solvent or tools with an abrasive surface;

- difficulty when applying with a spray gun.

What is hammer paint for metal?

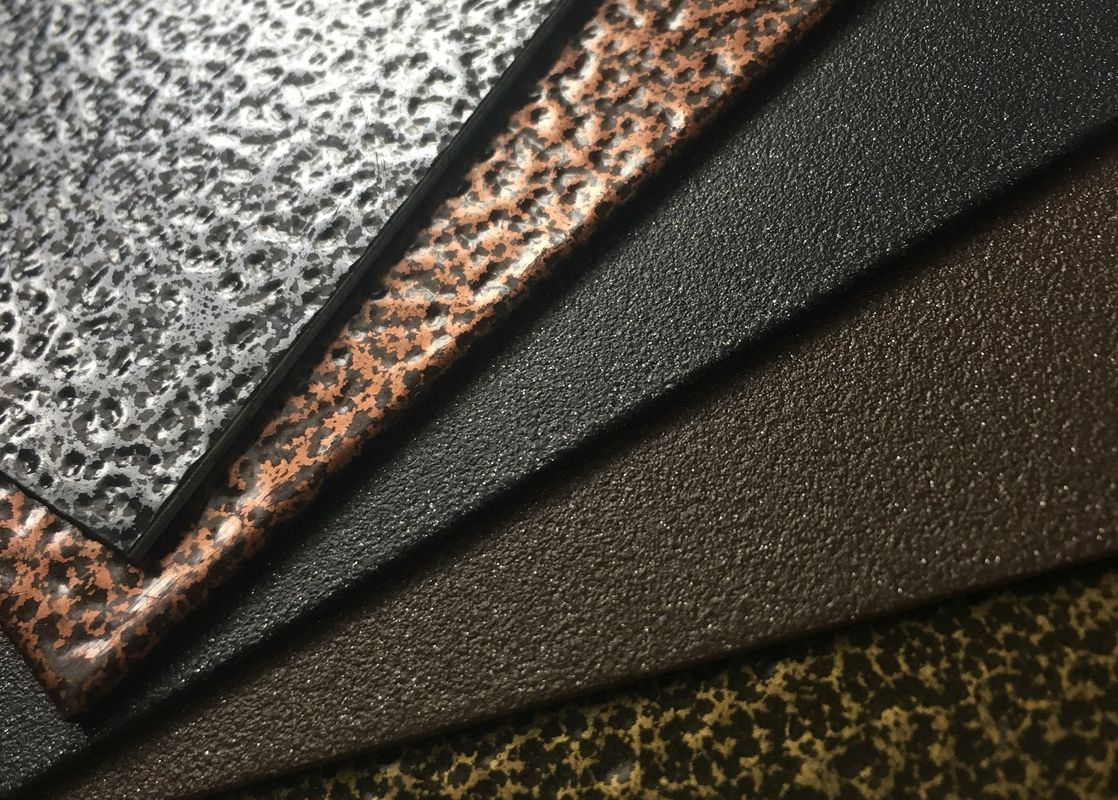

Recently, hammer enamel has become popular in landscape design, interior and exterior design. They say a lot about this tool, but they do not specify what hammer paint is, which is why there are many misconceptions. The key difference between the paint is its special texture, it cannot be confused with any other type, since after the surface hardens, it takes on an appearance similar to numerous hammer blows. Due to the specific effect, the substance acquired its name, sometimes it is also called blacksmith's.

Hammer paint is one of the most durable compounds for metal processing

Hammer effect paint is made from acrylic, styrene alkyd and epoxy base. To create a special appearance, aluminum powder, silicone oils and fine glass are added to the composition. Due to the presence of special silicone oils in the composition, it is possible to stabilize the texture and provide protection from water.

After mixing all the ingredients, a liquid mixture with the highest adhesion is obtained. When the mixture hardens, a high-strength coating will appear, from which the density of the body increases. Sold paint in cans and cans.

Peculiarities

Today hammer paint is very popular as it has anti-corrosion properties. In addition, she is not afraid of negative external factors. Hammer paint is not afraid of rains and snowfalls, therefore it is often used for finishing the facades of buildings.

Under the influence of temperature changes, such wear-resistant paint does not crack and does not lose color saturation. That is why it is used not only to decorate certain bases, but also to protect them from various external influences.

The secret of this wear resistance lies in the composition of the hammer paint. It contains special polymer resins that adhere especially well to metal surfaces. Moreover, they protect them from corrosion and extend their service life.In addition to polymer resins, such a wear-resistant dye mixture contains acrylic and alkyd components.

In addition, hammer paints are often mixed with silicone oil, epoxy resins and complex fillers such as aluminum powder or fine glass. The listed components make the coating not only of high quality and durable, but also provide it with increased adhesion, so hammer paint can be applied to almost any surface without problems.

True, due to excessive density, it is unlikely that it will be possible to apply such paint with a spray gun. Initially, such dye mixtures were produced only in gray color. When they began to be used for decorating various substrates, manufacturers added pigments of different colors to their composition. Today in stores you can find reliable hammer paint of any shade.

Such paint looks very unusual on certain surfaces. It is not only distinguished by an interesting shine and unusual texture, but also forms small potholes, because of which it is very often confused with a powder mixture applied in special pressurized chambers. Real and high-quality hammer effect paint is sold in ordinary cans and does not need to be diluted, since it is initially ready for finishing work. Working with hammer paint is pretty easy. Even an inexperienced home craftsman can handle this without any problems.

Unfortunately, there are a lot of fake hammer paints in stores today, which are not of high quality. They often have branded stickers that are trusted by many consumers.

Subtleties of application

Hammer coating is quite simple to apply. However, it should be borne in mind that it is possible to finish surfaces with it only at temperatures from +10 to +25 degrees. At the same time, the humidity level should not exceed 83%.

When you paint this or that base with a similar composition, you should pay attention to the thickness of the applied layer. It should not exceed 100 microns.

This thickness is suitable for the proper formation of a high-quality anti-corrosion layer.

In order to distribute the coloring mixture over the base, you need to use the tools provided for this:

Brush. This method of applying the coloring composition is the most popular. Thus, it is possible to finish the bases of small size and uncomplicated configuration. As a rule, for a greater protective effect, it is recommended to apply 2-3 (maximum 4) coats of paint

Particular attention should be paid to edges and corners. If you are planning to carry out more serious decorative work, then you should stock up on a high-quality brush with natural bristles.

Roller

Hammer paint can also be applied using the popular roller tool. It is recommended to use this method of application if you plan to process sufficiently large and flat surfaces. Before application, forge paint must be thinned in proportions 9 to 1 using a special solvent. Then the resulting mixture should be carefully applied to the surface of the base. A roller with a short fur or woolen pile is ideal for this.

- Spray can. It is very convenient and simple to apply the coloring composition with an aerosol. Moreover, it takes very little time and effort. This processing option is most often used when there is a need to touch up minor defects on small surfaces. Substrates should be painted in accordance with the instructions, which, as a rule, are indicated on the spray can. Apply blacksmith paint with an aerosol in 3-4 thin layers. After applying the first layer, it should be kept for 2-3 minutes, and then the surface should be treated again. With each new layer, the interval between applications should be increased to 15-20 minutes.

- Pneumatic sprayer.A pneumatic sprayer is ideal for finishing larger and more impressive areas. However, for such devices it is necessary to select paints of a suitable consistency. In accordance with the instructions, hammer paint in powder is diluted in a ratio of 2 to 1. To achieve the proper decorative effect, experts recommend applying a "zero" layer to the base. It is a very thin coating that should be cured for 1-2 minutes. With the further formation of subsequent layers, the starting layer will become thicker.

- Airless spray. For large surfaces, airless spray can be used. For such design options, it is necessary to dilute the dye mixture in a ratio of 1: 9. In order for the mixture to acquire an optimal consistency, the spray bottle must be shaken well.

For details on how to paint metal with hammer paint, see the next video.

Hammer effect enamel manufacturers

Hammer enamel for metal, unlike other paints, is not available in powder form. This is due to the complex component structure of the material. The paint is available in the form of a ready-made mixture: in steel cans and plastic buckets, as well as in aerosol-type cans.

Hammerite

Let's start with the most popular and most expensive manufacturer. Hammerayt is the market leader in the hammer paint segment. If you want to know what hammer paint is, start with this brand. The company produces enamels of any texture, which are distinguished by consistently high quality, strength and durability.

This paint is widespread in the field of car restyling. You can read more about the use of Hammerayt paint for painting cars here.

In addition to the range of paints and varnishes, Hammerite has solved a regular problem for beginners - how to dilute hammer paint. The company produces its own brand of solvent that can be used to reduce the viscosity of the enamel. The paint is available in various volumes and packages - from 0.25 to 20 kg.

Dali

Dali is the second most popular brand. Enamels are used as a protective and decorative coating for metal structures. They have a high degree of resistance to external influences, guaranteeing the preservation of the quality of the coating for up to seven years. Reviews confirm that Dali paints easily adhere to both new and painted surfaces.

Hamerton

Hamerton is a decorative paint based on alkyd resins. It is suitable for galvanized steel structures as well as plastics, concrete and wood.

Prestige

The domestic manufacturer offers a wide range of color solutions, including unusual shades - silver red, chocolate and others. Hammer enamels "Prestige" are best suited for painting objects located indoors.

Alpina

Alpina paints are an inexpensive three-in-one enamel for protecting metal surfaces. This means that it simultaneously performs anti-corrosion, priming and decorative functions. Apply to clean or rusted iron.

Mister hammer

Enamel "Mister Hammer" is made on the basis of modified alkyd varnish and light-resistant pigments with the addition of a desiccant. It works well on rusted metal surfaces, extending their lifespan and restoring their attractive appearance.

Kalininskaya

Forging paints under the Kalininskie brand are the products of another Russian manufacturer focused on professional work with metal products. The company produces a limited palette, specializing mainly in three colors: dark copper, black and chocolate.

Where are they used?

Hammer paints have unique technical characteristics.

Today they are used in various sectors of the national economy:

- Industry. The composition is used for painting machines, structures and mechanisms. It is also the best choice for protecting the enclosures of various electrical systems (switchboards, etc.).

- Automotive industry. Many types of discs, bodies, and other metal parts of cars are covered with hammer paint. This allows them to extend their service life several times.

- Building sector. Here, with the help of this agent, metal structures are protected from corrosion.

- Painting forged fences to give them an aging effect, as well as to prevent the likelihood of corrosion processes.

- Metal furniture production. In most cases, hammer mortars are used to paint entrance doors, safes and other similar products.

- Advertising industry. The compounds perfectly protect metal structures, and are also used to create a decorative effect on various types of plastic or glass.

Views

Hammer paint is of several types:

- Nitroenamel (NTs-221). The most affordable. It is mainly used for interior finishing works, as it performs the function of only a decorative paint coating. Does not possess water-repellent and protective properties, is subject to corrosion.

- Hammer enamel (ML-165). It can withstand high heating temperatures (up to 130 degrees). Due to the styrene base in its composition, it has a high degree of adhesion to the metal surface. This compound can be applied over rust. Suitable for outdoor and indoor use.

- Epoxy enamel (EP-1323). It combines the functions of a surface priming and decorative painting. It is able to withstand high temperatures, has high anti-corrosion performance. It is most often used for painting gates, art forging parts, cars.

- Hammerite hammer enamel (produced in Great Britain) is one of the most expensive. After this dye composition dries, a film with high protective properties is formed on the metal. This coating completely protects the metal surface from oxidation.

Scope of use

- Forged products, cast iron decor items.

- Metal doors, fences, fences, gates.

- Auto and mechanisms - car parts, electrical panels, etc.

- Steel structures - such as weather vane, pipes, beams, support structures, fasteners.

- Furniture - wardrobes, safes, benches, etc.

- Decor items - frames, accessories, art forging, inventory and much more.

- Manufacturing equipment, specialized devices, racks, shelves.

Materials: can be painted on wood, metal, glass, tiles, plastic.

Important! Hammer painting involves applying the mixture to a horizontal surface. Therefore, before painting a metal door, remove it from its hinges and lay it on a plane.

Otherwise, the paint may drip. If this is not possible, you can purchase a quick-drying version.

Pay special attention to this!