Main characteristics and features of the coating

The results and characteristics of the paint composition may differ from manufacturer to manufacturer, but for the most part hammer paints have similar characteristics:

- For the binder, an alkyd resin is used in the composition.

- The density of the substance is 1 kg / l.

- Indicators of the remainder of the coating on the surface - 47%.

- Drying time parameters - at least two hours.

- If you need to apply several layers, then each subsequent one is applied 5 hours after the previous one.

- Shelf life in a container is 2 years, subject to all storage rules.

- Gloss level indicators - 66.

- Withstands the influence of temperature up to + 80 ° С.

- For one coat, use a liter of hammer paint per 10 m2.

Among the main advantages of the paints in question, there are several of the most attractive:

- it is not required to clean the entire surface from rust before use;

- the coating tolerates vibration and many atmospheric phenomena;

- paint helps to protect metal from rust;

- re-painting of the metal structure may not be required for 10 years;

- the paint does not contain toxic elements that adversely affect human health;

- the coating does not have a strong and pungent unpleasant odor, which contributes to the use of the substance even in poorly ventilated rooms;

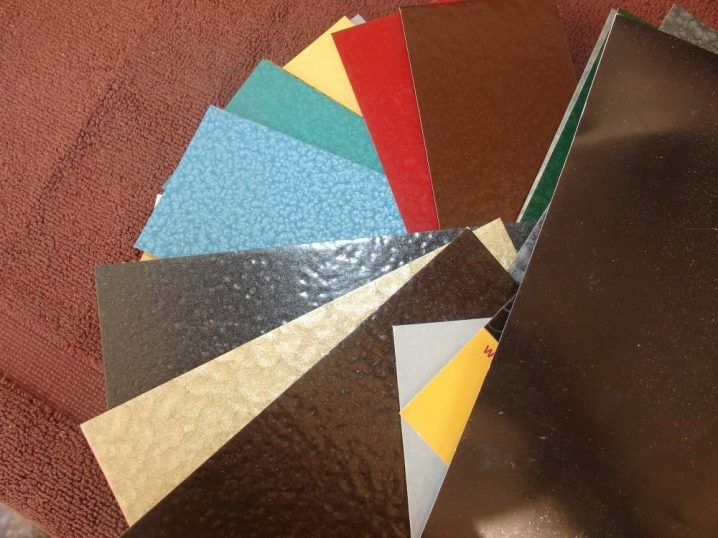

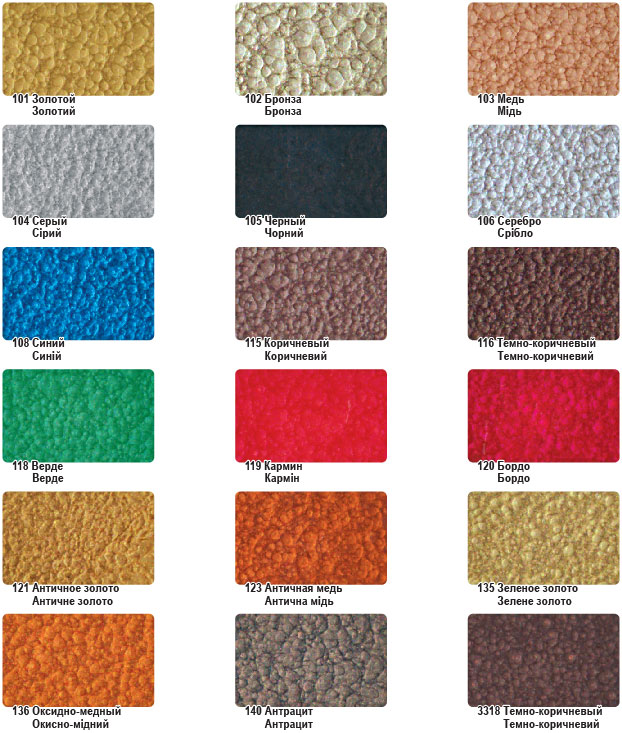

- the coating has a wide variety of shades, which makes a very rich choice;

- paint does not fade for a long time;

- dirt and dust do not adhere to such a coating.

The only drawback is that old paint is very difficult to remove from the painted surface. In some cases, even a strong solvent does not help.

Application area

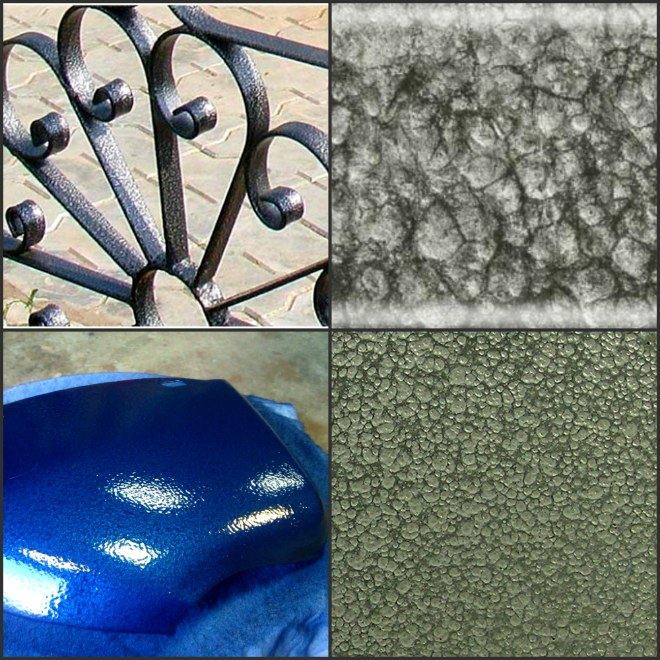

Hammer effect coating is a widely used material for painting a wide variety of metal surfaces. It looks especially gorgeous on forged products. In addition, paint with a hammer effect is used:

- For painting machinery, as well as various equipment.

- Metal pipes.

- Coloring of the main units in structures of different types.

- Glass surfaces.

- Fences and fences made of appropriate material.

On the street, this coating is very often used specifically for painting fences and other metal structures. They will be able to stand for a huge amount of time and not change their appearance.

Surface preparation

In order for the surface to last as long as possible with a new coating, it must be properly prepared. First of all, the surface is preliminarily wiped with acetone. It is easy to use a thin sheet of plain paper to test readiness. If you run it over the surface and there are no traces left, the product is ready for painting.

In order to better prepare the surface for painting, it is advisable to process it with an iron brush. After such stripping, the adhesion of the surfaces is improved.

The next step is to treat the surface to be painted with a primer. She will create a special film on which the paint will adhere to an even and durable layer.

Advantages and disadvantages

Hammer effect enamel is in demand in various areas related to repair and production. Its popularity is due to a number of functional advantages over classic paints.

- Resistant to weathering. Hammer paint forms a waterproof layer that is immune to the effects of ultraviolet radiation and temperature extremes.

- Durability and long service life.The composition confidently withstands mechanical force - scuffs and scratches do not appear on the painted surface, and its appearance remains in perfect condition for several years. This is especially true for metals subject to intensive use. For example, from which gates or doors are made.

- Resistant to high temperatures. Ordinary enamel with a hammer effect retains its properties even when heated to 80 C. Also, there are special modifications that are resistant to fires and can withstand higher temperatures. This ensures increased durability of the painted structures in extreme situations.

- Tightness. The use of hammer enamel for metal prevents corrosion by isolating the painted surface from oxygen. This factor is important for high-quality rust work - it localizes the damaged areas, preventing their enlargement.

- High polymerization rate. Compared to how long regular enamel dries, hammer paint is a true sprinter. Within three hours after application, it loses its tack, which significantly speeds up the processing of large structures.

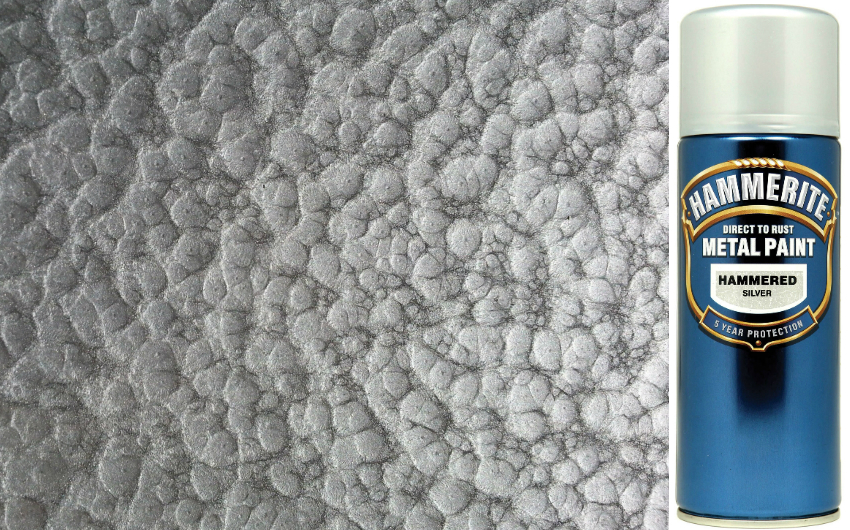

In addition to the functional advantages, you can also highlight the visual effect. Hammer paint combines gloss and relief that are pleasing both visually and tactilely.

Speaking about the shortcomings, we can rather note a number of features associated with the use of hammer enamel

It is important to take them into account in advance in order to avoid possible difficulties.

Difficult to remove. The composition of the enamel acquires special strength when it dries, which can become a problem if you need to clean the surface. Both scraping and the use of solvents do not give quick results and will require a lot of effort.

The need for a solid surface paint to protect against corrosion

It is important to apply hammer paint to the entire area of the structure, otherwise rust from unpainted areas can penetrate under the enamel layer, leading to its gradual destruction.

The complexity of painting work. Smooth painting with hammer paint with a spray gun will require a stable pressure in the region of 4-6 atmospheres, otherwise the formation of drips, unpainted areas and "spitting"

For a high-quality result, it is recommended to use a professional technique.

Price. The peculiarities of the paint determine its price - the spread in the market ranges from 500 to 1200 rubles, depending on the manufacturer's brand.

Varieties

Hammer effect paint is divided into the following types:

- Nitroenamel "NTs-221" is considered the cheapest, as it plays the role of only a decorative coating. Therefore, it is used for interior work. She is afraid of high humidity and corrodes.

- Hammer enamel "ML-165" has an alkyd-styrene base. Withstands the highest temperatures, up to +130 degrees. Possesses a high degree of adhesion to any material. Used for outdoor and indoor use. It can even be painted over rust.

- Epoxy enamel "EP-1323" performs the function of a dye and a primer at the same time. Possesses thermal and anti-corrosion properties. Designed for cars, gates, art forging, etc.

- Enamel "Hammerite" is considered the most expensive. Manufacturer - Great Britain. When painting with it, a primer is additionally carried out. After drying, a film forms that protects the metal from oxidation. It is made from silicone additives, alkyd resins. Feature - it is undesirable to paint with a paint sprayer. Used everywhere, even on top of rust.

Advantages

Among the pluses of hammer paint:

- high degree of resistance to temperature extremes;

- anti-corrosion;

- the ability to apply directly to rust;

- quick drying, especially if spray paint;

- moisture resistance;

- reliable protection against rusting for 8 years;

- coating strength;

- no toxic fumes after drying;

- harmless to the body even when used indoors;

- a large selection of colors;

- unusual decorative effect;

- repelling dust and dirt;

- water-repellent properties;

- smoothing irregularities on the surface;

- in the presence of chips, it is not necessary to remove the entire layer of paint, it is enough to cover it with enamel at the site of the defect;

- immunity to vibration, therefore, hammer paint is used for cars;

- lack of unpleasant odors;

- the possibility of staining with different tools.

disadvantages

There are also disadvantages, but there are not many of them:

- high consumption and high cost;

- cannot be removed with solvent or tools with an abrasive surface;

- difficulty when applying with a spray gun.

Advantages and disadvantages

In search of high-quality and attractive paint, each consumer seeks to find the ideal option that will delight him with its wear resistance and durability. The original hammer mix meets these requirements.

In addition, such coloring compositions have many other advantages that make them popular and in demand:

- Hammer paint is not afraid of temperature changes. Neither hot summer, nor frosty winter, nor rainy autumn will affect its appearance and performance.

- Hammer effect enamel can be applied to rusty surfaces. Moreover, for this it is not at all necessary to prepare the bases and treat them with a primer.

- Hammer mixes dry quickly enough.

- Such paints and varnishes are not afraid of dampness and moisture.

- Quality hammer paints protect metal substrates from rusting outdoors for up to 8 years. Not every enamel can boast of such a characteristic.

- Such enamel can be purchased for both interior and exterior finishing works.

- Hammer effect paint is not subject to mechanical damage. Due to this characteristic, it will be very difficult to leave a scratch or other damage on such a coating.

- Such a paint and varnish composition is safe for health. It does not emit hazardous substances either during application or after drying.

- It should be noted the decorative properties of such paint. It is presented in a very rich color palette. Over time, hammer mixes do not fade when exposed to sunlight.

- Hammer paint does not have an unpleasant odor.

- The dried hammer surface has an interesting ability - it repels water, dirt and dust. That is why the objects on which it is applied look well-groomed.

- Due to its characteristic texture, hammer paint is able to hide minor imperfections in the base. If there is a noticeable chip on it, then it can be painted over locally. In this case, the tinted area will not be noticeable.

As you can see, hammer paint has a considerable list of positive qualities.

However, it also has its weaknesses:

- Removing such paintwork from any surface is not an easy task. This requires the use of aggressive solvents and abrasive tools. However, even with such devices, it will be difficult to remove the paint layer.

- If you paint a metal base with hammer paint, then you need to make sure that no area remains unpainted. Otherwise, corrosion will quickly appear on the unfinished place, which will eventually spread to the coating itself.

- It is very difficult to apply such paint with a spray gun (or using a can, spray), since it is characterized by increased density and density.

- Many consumers consider the high cost of hammer paint as a disadvantage. Moreover, it is notable for its high consumption, so there is no need to talk about its availability.

How to paint a car

How to paint flat surfaces is understandable, but how to paint a car? First of all, you need to prepare tools and materials:

- directly hammer enamel;

- short-haired roller or spray;

- solvent # 647;

- enamel primer;

- abrasive material.

Attention! Prepare all the necessary items in advance, they should be nearby, as they may be needed at any moment. The enamel dries very quickly, so delays in working with it are excluded

Although blacksmith paint does not imply preliminary priming, experts still recommend doing this to achieve the highest quality painting.

Stages of staining:

- Clean parts and car from dirt and dust.

- Degrease the surfaces with special solutions.

- If there is heavy rust, get rid of it. To do this, you will need abrasive paper (sandpaper). Even if there is no rust, still use sandpaper, since the enamel adheres better to a rough surface, plus adhesion increases.

- A rust converter can be used to remove large areas of corrosion. If you bought Hammerite enamel, then don't worry about corrosion. Because the paint contains substances that envelop rust.

- Treat the surfaces with primer enamel, which must first be diluted.

- Now pour the paint into the building ditch, dip the roller into it. When it is soaked, roll it over the ribbed surface of the cuvette. Or prepare the spray gun for work.

- Further, you can paint large surfaces. After applying the first coat, wait 30 minutes and only then can you paint with the second coat.

Complete drying of the mixture is achieved after seven hours, but it is permissible to operate the machine only after three days.

You can cover the last coat with regular varnish. This will improve the decorative qualities of the painted surface.

Important! The glossy coating of the car must be removed - the paint does not adhere to such a surface, only matte.

Types and manufacturers of hammer enamel

Among the presented hammer paints, there are several proven brands that have their own characteristics:

-

ML 165, the composition contains a substance characterized by toxicity, has good heat resistance and a long service life. It should be applied on a fat-free base;

-

NTs 221, has a low price, is applicable only for interior work, it is not allowed to paint places of corrosion. Has good protective properties;

-

Delhi is distinguished by its ability to create a durable protective layer against rust. It is applied on stainless steel, galvanized, non-ferrous metal, cast iron;

-

Molotex, good rust protection properties, covers small surface flaws, the protective layer perfectly resists environmental influences;

-

Hammer Prestige paint, includes the properties of a primer, colorant and decorative coating. Low cost, anti-corrosion property, resistance;

-

Hammerite, the most popular and expensive paint, with the best item protection. Hamerite is applied directly to the corrosive lesion, there is no need to prepare the surface for a long time before application. The service life of the coating is up to 8 years.

Paint application recommendations

In application technology paints for metal hammerite there are some nuances. For example, despite the improved technical characteristics of the composition, it is not applied in rainy and even foggy weather, since the permissible percentage of humidity should not exceed 85.

The permissible moisture percentage should not exceed 85.

The permissible moisture percentage should not exceed 85.

Metal surface preparation

Depending on the condition of the coating, preliminary surface preparation is performed. For products with traces of noticeable corrosion, minor mechanical treatment with sandpaper or a wire brush is required. Then the base is washed, dried and degreased without coating with a primer.

Coatings with pronounced traces of rust and corrosion are treated with the previous method and primed. Previously painted surfaces are cleaned, washed, dried and degreased. Previously unpainted bases are degreased from factory grease and painted. For better adhesion to the paint, smooth surfaces are treated with sandpaper or a wire brush.

For products with traces of noticeable corrosion, minor mechanical treatment with sandpaper or a wire brush is required.

For products with traces of noticeable corrosion, minor mechanical treatment with sandpaper or a wire brush is required.

Preliminary processing

Surface treatment can be done both manually and mechanically using drills with a special nozzle or sandblasting machines. Hard-to-reach places in complex structures are handled only by hand.

For surfaces with old signs of destruction, priming is used. Experts recommend using the number 1 Rust Beater of the same name (Hammerite). Special solvents are used for degreasing. However, most of them only remove greasy stains. Additionally, you can degrease the surface with a weak 10% solution of acetic acid, which is washed off after processing, and the surface is well dried.

The priming step improves the adhesion of the materials. Each material has its own formulations. For example, for ferrous metals, corrosion protection is important, and for non-ferrous metals, an important point is good adhesion with paint.

Special solvents are used for degreasing.

Special solvents are used for degreasing.

Paint application

Hammerayt enamel on rust adheres well to metal 100 microns thick. This moment is taken into account regardless of the method of application.

The paint can be applied with a roller, brush, spray gun or using an aerosol paint bottle (available in the assortment).

-

The paint brush is suitable for medium-sized surfaces or for complex structures. Before use, the viscosity of the dye composition should be determined. When thickening, it is diluted with a solvent of the same brand "Brush Cleaner & Tinners" at the rate of 8 parts of paint - 2 parts of solvent.

-

The roller is used for painting surfaces with a larger area. Places of corners, folds, turns are processed only with a brush.

-

Aerosol cans are handy for painting small structures.

-

When using a spray gun, the main point is the viscosity of the paint. If there is an imbalance in the ratio of paint and solvent, the surface will be painted unevenly. A thick composition will not come out of the mechanism, and a highly diluted one will leave smudges and gaps.

The coating is applied in at least 2 layers, but not more than three. Wait at least three hours before applying the next layer. Premature staining can make the coating unstable and brittle.

Hammer paint for metal - how to paint?

Before performing work, the composition must be thoroughly stirred, and, if necessary, diluted with a solvent. Hammer paint for metal, black or any other, is applied with a roller, brush or using a spray gun. All work is carried out in goggles and rubberized gloves. Ordinary rags are not very suitable, because they quickly get wet, and paint is washed off the skin very poorly. In addition, it is necessary to take care of the protection of the respiratory tract, and a good respirator will help in this.

Hammer paint - surface preparation

As already mentioned, hammer paint for metal for rust does not require cleaning from corrosion, but if traces of old enamel, dirt and other materials remain on the product, then it is better to remove them, otherwise the layer of the new coating will not be smooth and beautiful. Preliminary surface preparation is of particular importance if the product is made of wood. Hammer paint will simply be absorbed into it, so the surface must first be primed, let the primer dry, and only then painted.

How to dissolve hammer paint on metal?

When diluting such enamel, its type must be taken into account. Gray hammer paint for metal alkyd-styrene is diluted with xylene. It is a hydrocarbon recovered from the crude alcohol. Epoxy compositions for coloring cast iron and other iron alloys belong to single-composite enamels and are diluted with solvents No. 667 and No. 648. Indoor nitro enamels are enriched with aluminum powder as a pigment. Colloxylin and nitrocellulose based paints are diluted with solvent No. 646.

What is the best way to apply hammer paint to metal?

When painting, a variety of materials at hand are used. Hammer paint for metal for outdoor use and indoor product coating is applied with the following tools:

- brush;

- roller;

- spray gun.

They all have their advantages and disadvantages. Foam rollers are not suitable for working with hammer enamels, as they immediately become unusable. As for the brush, it should be made of high-quality bristles that do not fray. Well, for a spray gun or spray gun, it is required to observe the proportions of the coloring pigment and the solvent.

How is hammer paint applied to metal?

Those interested in how to apply hammer paint to metal should take into account the area of the surface to be treated, its type, the presence of curved and winding lines, joints, and the like. The roller is preferable for use on large, level surfaces where there are no curved configurations and hard-to-reach areas. In this case, it is recommended not to dip the tool in paint, but to pour the enamel on it in small portions. It is easy to get into the most intricate patterns of patterns with a brush, so it is advised to use it for products that are complex in design.

All the intended areas must be painted over in one cycle, then left to dry completely and only then apply the second and all subsequent layers. As you can see, working with such paint is easy and convenient. It dries quickly, provides the coating with strength and durability, and gives it an attractive appearance. Hammer paint is in demand and is sold in almost any specialty store.

Molotex semigloss hammer enamel

1 310 rub.

vendor code

Availability

Retail price

To order

Yes

RUB 1 310

Yes

RUB 1 310

Yes

RUB 1 310

Yes

RUB 7,340

Yes

RUB 7,340

Yes

RUB 7,340

Molotex is a protective and decorative hammer enamel for metal.

Suitable for use on clean or partially corroded surfaces (without prior priming) from:

- become;

- galvanized metal;

- aluminum alloys;

- copper alloys.

Protects products and structures from corrosion that are used indoors and outdoors in an industrial atmosphere, in various climatic regions.

It is used as an independent coating. To increase the service life of the coating, we recommend priming the metal in advance.

Enamel Molotex is a suspension of fillers, corrosion-resistant pigments and special ingredients in synthetic varnishes.

Hammer paint for rust combines three properties: anticorrosive primer, corrosion converter and decorative enamel.

The peculiarity of the paint and varnish material is that the resulting coating is similar in texture to a metal surface treated with hammer blows. This effect occurs due to special inclusions in the paint composition. Thanks to this feature, the paint perfectly hides the defects of the painted products.

Preparation

The metal surface must be cleaned of old peeling paint, loose rust, dirt, oils and dust. And dry.

For degreasing previously unpainted surfaces, we recommend using our OM-01S degreaser.

To improve adhesion, smooth and polished surfaces should be pre-sanded with a wire brush or emery paper.

Stir the enamel thoroughly until smooth.

Mode of application

Work should be carried out at temperatures from + 10 ° C to + 35 ° C.

Attention! To obtain a pronounced hammer effect, we do not recommend thinning the paint with solvents!

Apply in one or two coats with a roller, brush or pneumatic spray.

The working viscosity when spraying (t + 20 ± 0.5 ° C) according to a VZ-246 viscometer with a nozzle diameter of 4 mm should be from 40 to 70 s.

The recommended coating thickness is from 80 to 100 microns.

At a temperature of + 20 ° C, forge paint dries up in 5 hours.

Storage

Store Molotex in a tightly closed container away from heat and UV rays. Do not heat, keep away from fire.

The guaranteed shelf life is 12 months from the date of manufacture.

Nobody has written anything here yet, be the first!