What is sand filtration?

There is always free space between individual grains of sand. Therefore, if you pour some water on the sand, then it will seep between the grains of sand and stop only when it hits a flat and hard surface. By measuring the rate at which water passes through the sand layer, you can determine the value of the filtration coefficient. For measurement, the metric unit "meters per day" is used, which shows what distance in meters the water will pass in 24 hours through different types of sand - quarry, seeded, river, etc. sometimes a unit of measurement is added, for example, sand kf 3 m per day.

Types of sand and their area of use

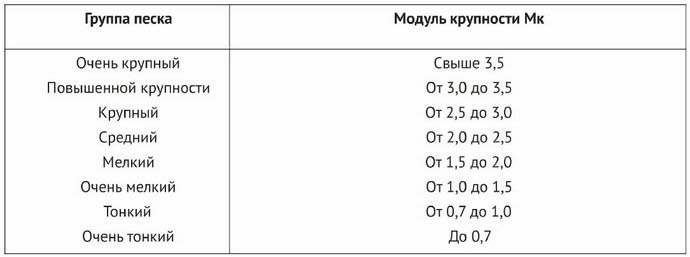

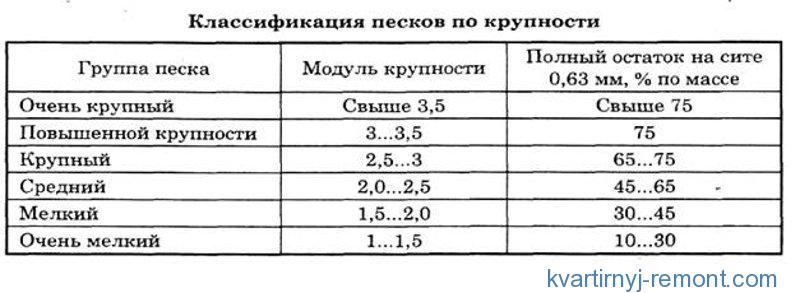

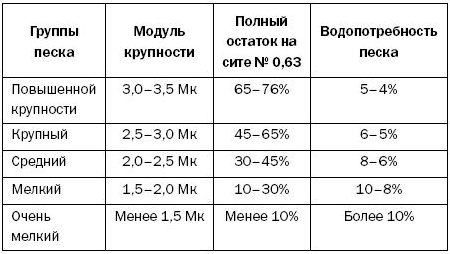

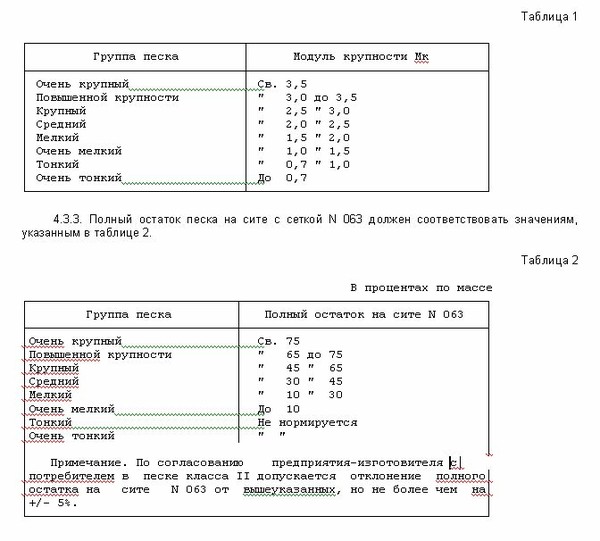

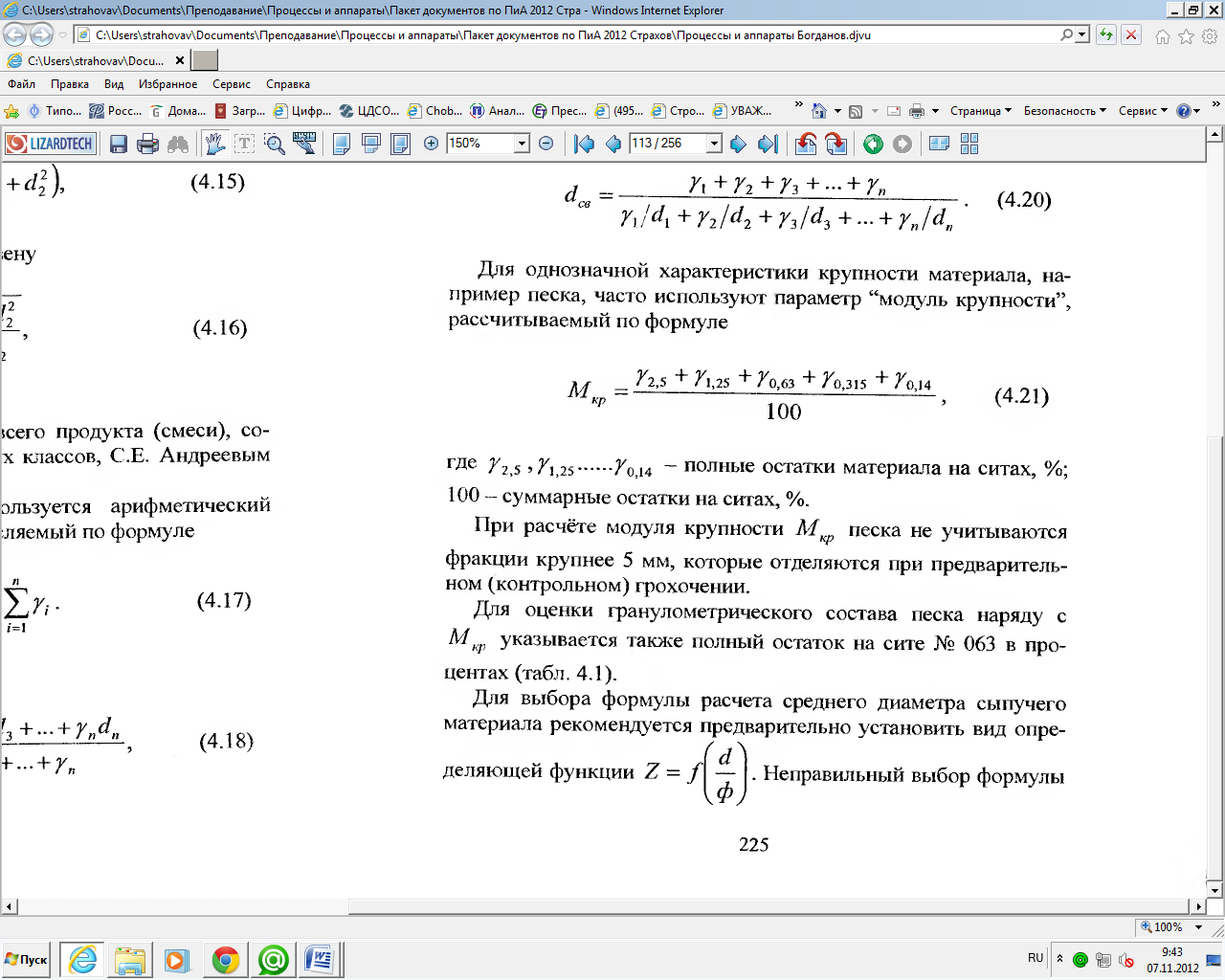

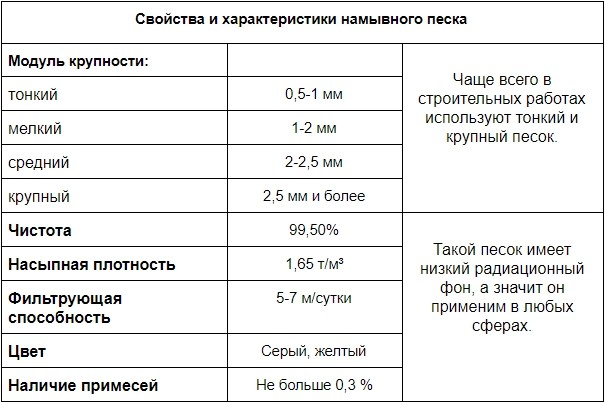

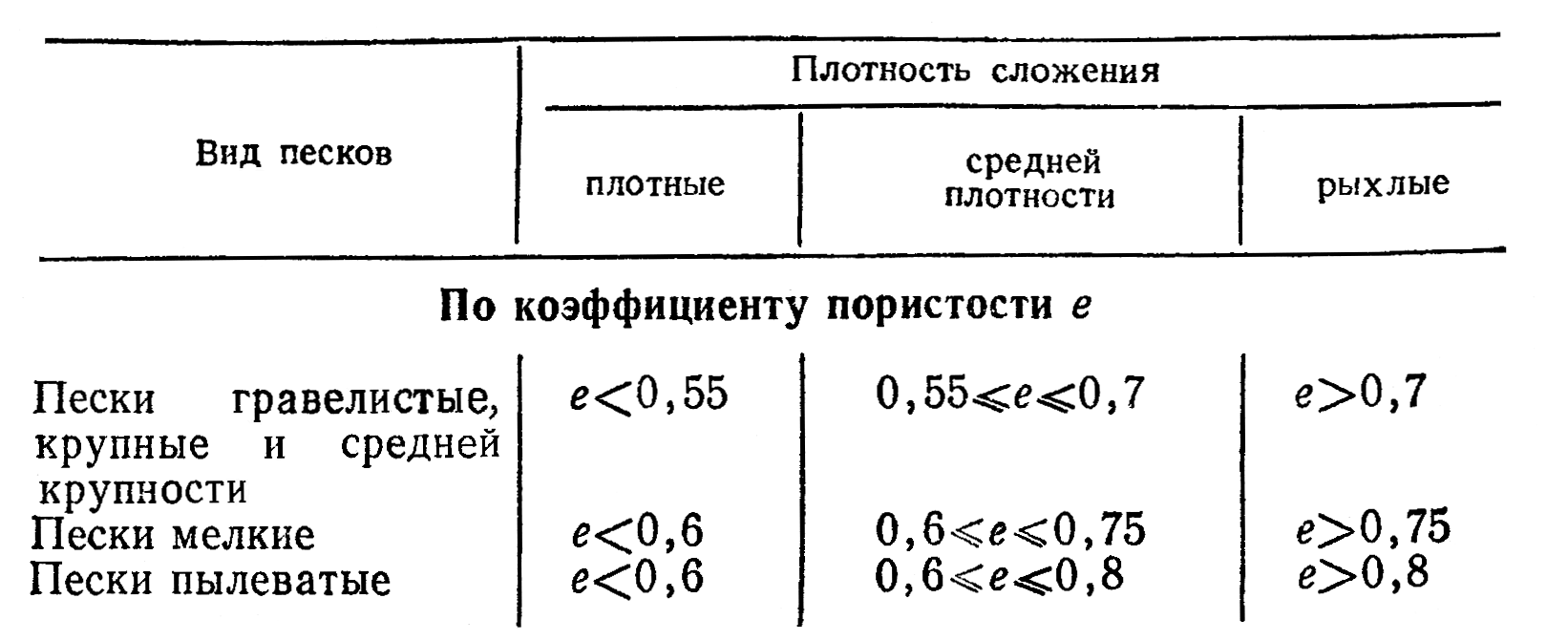

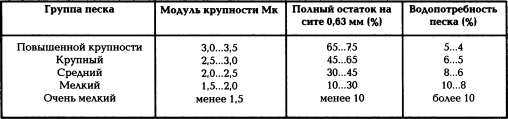

After determining the grain composition according to the table, the type to which the sand belongs is found:

- Coarseness module 3 and higher - coarse grain size. It is used for the preparation of high-grade concrete mortar, the production of tiles and curbs for sidewalks, rings for a well.

- For medium grain size, the characteristic sand size is 2.0-2.5. It is used for the production of B15 class concrete.

- Coarseness 1.5-2.0 corresponds to the fine fraction of sand. This type of material is suitable for the construction of bridges (including their parts located under water), the manufacture of bricks and mortar.

- Granularity 1.0-1.5 characterizes a very fine fraction of sand used for the manufacture of finely dispersed substances.

The use of sand of different fractions depends on its characteristics. A solution prepared using this material will be more durable and reliable if the modulus is larger. And at the same time, less water is required to mix the composition.

At the same time, we can say that the higher the granularity, the worse the plasticity of the prepared solution and its viscosity. If such sand is used, for example, for floor screed as part of a cement mortar, then it will be worse to fill the space between the particles of crushed stone or gravel

Therefore, it is very important to choose the right sand grain size depending on the purpose of its use.

CF calculation

Given the constant demand for sand for the organization of any construction work - both in industrial and in individual construction and repair - the characteristics of this building material should be such as to provide the highest possible quality, strength, filtration (CF) and other parameters.

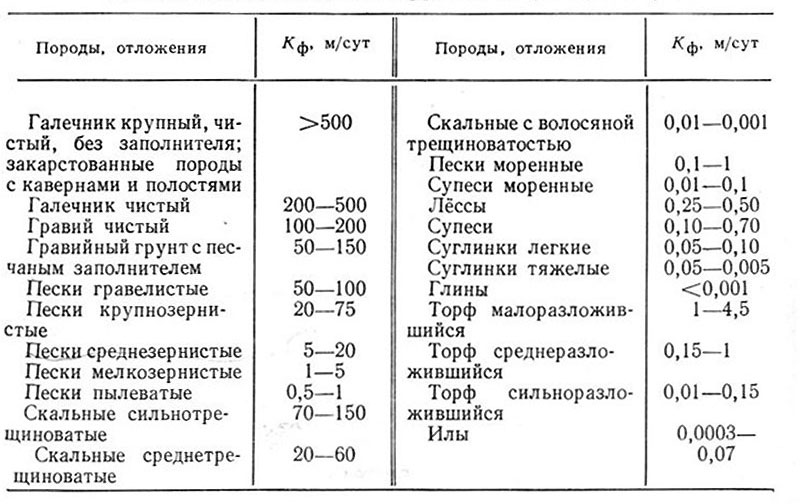

Approximate values of KF of sand

Approximate values of KF of sand

CF is determined using the following set of tools:

- KF-00M device, which consists of the following components:

- A filtration tube (tube) with a height of more than 100 mm and a diameter of 5.65 cm. The tube has a bottom with perforations for the passage of liquid.

- Steel mesh sleeve for liquid filtration.

- Glass tank.

- Electronic balance.

- Chronometer or stopwatch.

More details about the experiment on measuring the CF of sand:

Dry sand, which must be examined, is poured into the test tube of the KF-00M device, and a mesh with holes is attached to the bottom of the test tube. The device is placed on a horizontal surface, the sand in the test tube should be tamped tightly. To do this, it is covered with small portions, and each portion is rammed separately. Make three or more servings in total.

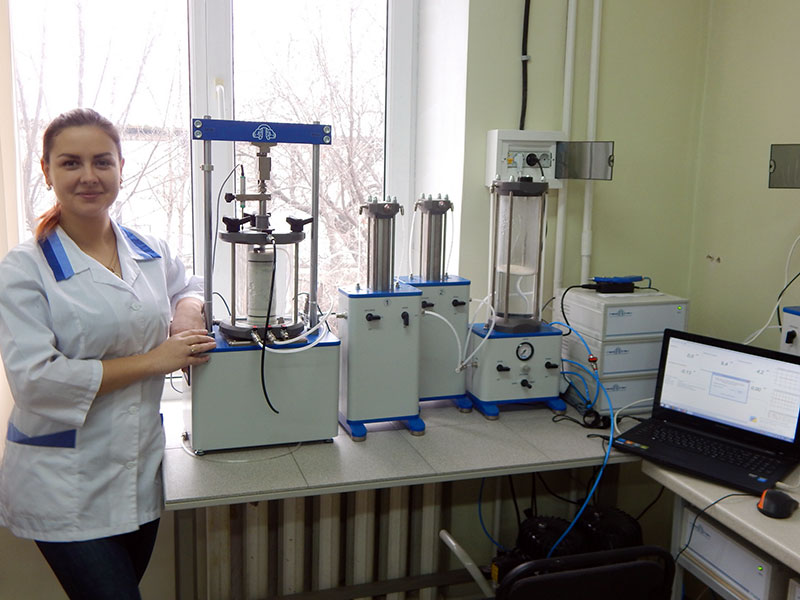

Apparatus for determining water absorption in the laboratory

Apparatus for determining water absorption in the laboratory

The distance from the top edge of the tube to the beginning of the sand level must be measured, and if it is more than 100 mm, the sand is tamped additionally.To investigate the CF unit, they begin by pouring water into the test tube so that it is 0.5 cm above zero.As soon as the liquid begins to flow through the perforated bottom, the time is measured with a chronometer to the 50 mm mark - water should descend to it. Add liquid to the test tube with water four times, 5 mm each. The result of the measurements will be the arithmetic average of all measurements taken.

| Soil water permeability | Site slope (in thousandths) | Irrigation furrow length (m) | Flow rate per furrow (liters per second) |

| Weak | Large (0.005-0.01) Medium (0.001-0.005) Small (≤ 0.001) | 120-150

100-120 80-100 |

0,1-0,3

0,2-0,4 0,3-0,5 |

| Average | Large (0.005-0.01) Medium (0.001-0.005) Small (≤ 0.001) | 100-120

80-100 60-80 |

0,3-0,5

0,4-0,6 0,6-0,8 |

| High | Large (0.005-0.01) Medium (0.001-0.005) Small (≤ 0.001) | 80-100

60-80 40-60 |

0,6-0,8

0,7-0,9 1,0-1,2 |

At the end of the research, the difference between the density index of dry pit sand and its limiting density should not be more than 0.02 g / cm3. For laying the roadbed, they take river, sea or quarry washed sand, since these sands have improved quality parameters, and the washed building material also has better cleaning. Due to the quality of washing, asphalt based on such sand will be stronger, and the duration of its operation will be longer. Sand extracted from the bottom of the sea is not used as often in construction and repair work as river sand, because its cost is higher. Sand with clay admixtures in construction is used much less often than other bulk materials, but if it is cleaned (washed and dried), then the scope of its use can not be limited due to the small CF.

Extraction of sea sand

Extraction of sea sand

Dirty sand mined in a quarry has a low filtration coefficient according to GOST - no more than 0.5-0.7 m / day. When it is washed, clay and other impurities are washed out, and large foreign grains (stone, granite or crushed stone) remain. To obtain a higher quality of such sand, it must not only be dried, but also sieved, after which it can be safely used to obtain high-quality solutions or mixtures. The CF for such sands turns out to be high - ≤ 20 m3 / day, since all extraneous fractions and impurities are removed from it by washing and sieving.

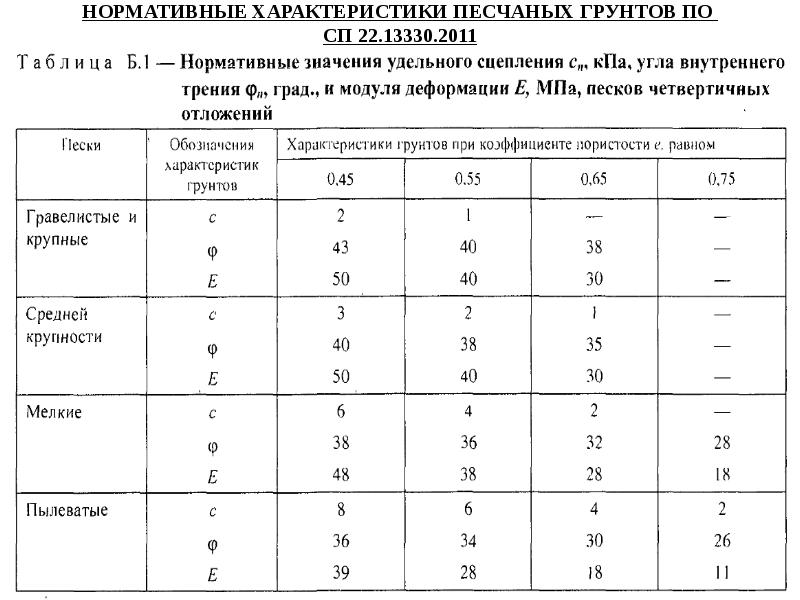

Table: soil filtration coefficient according to GOST

| Soil type | Approximate CF, m / day |

| Pebbles | ≥ 200 |

| Gravel | 100-200 |

| Coarse soil with sandy filler | 100-150 |

| Gravel sands | 50-100 |

| Coarse sand | 25-75 |

| Medium coarse sand | 10-25 |

| Fine sand | 2-10 |

| Dusty sand | 0,1-2 |

| Sandy loam soil | 0,1-0,7 |

| Loamy soil | 0,005-0,4 |

| Clay soil | ≤ 0,005 |

| Weakly decomposed peat bog | 1-4 |

| Moderately decomposed peat bog | 0,15-1 |

| Highly decomposed peat bog | 0,01-0,15 |

Extraction of sea sand

Extraction of sea sand

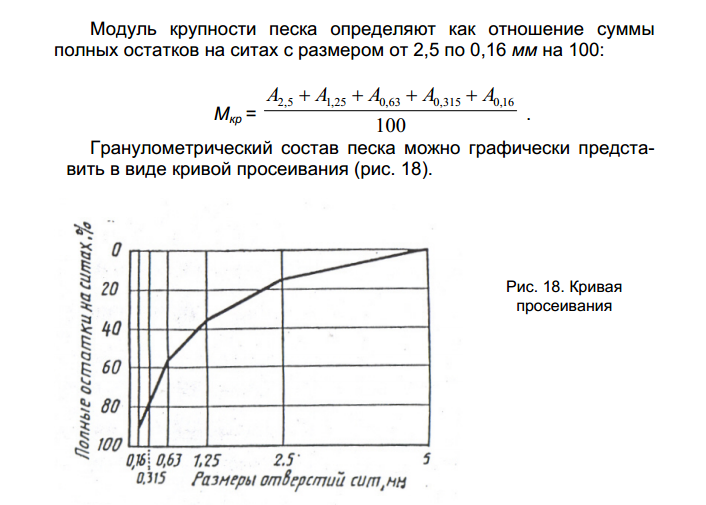

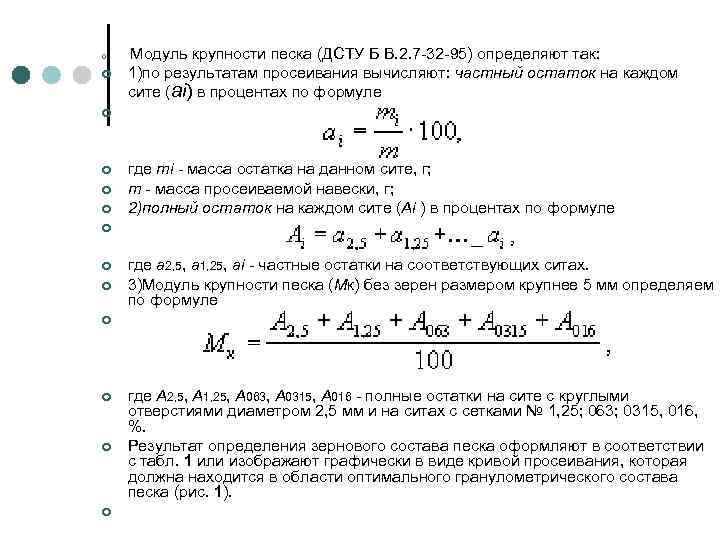

How is the sand size modulus determined?

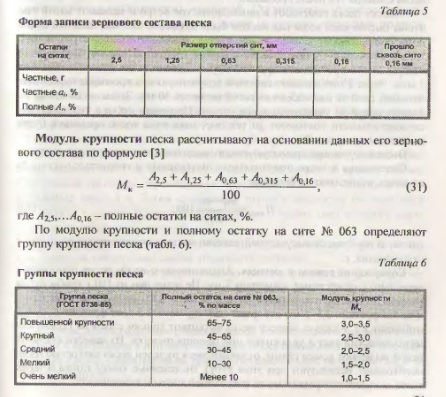

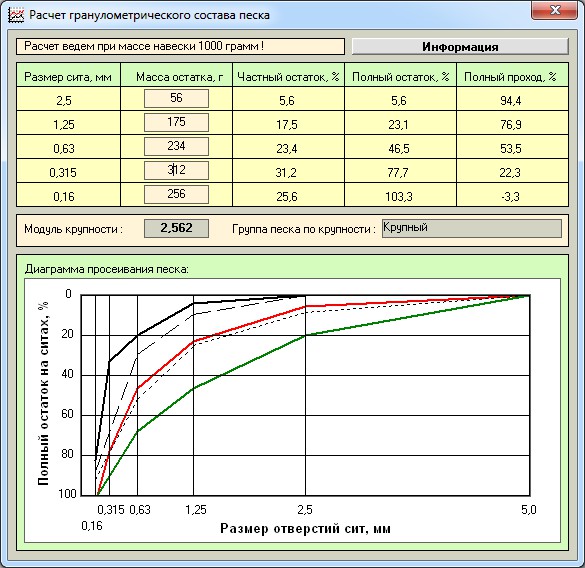

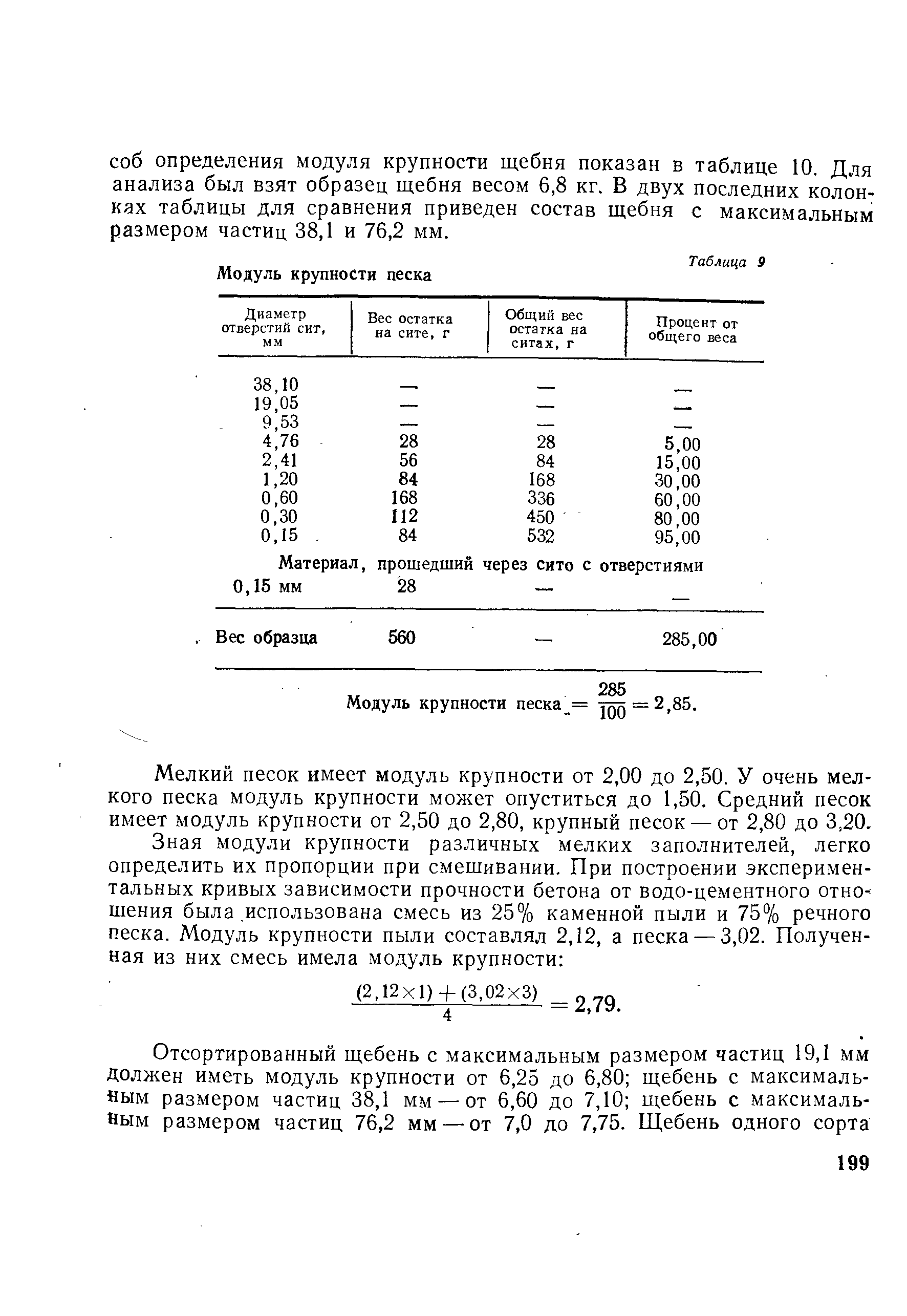

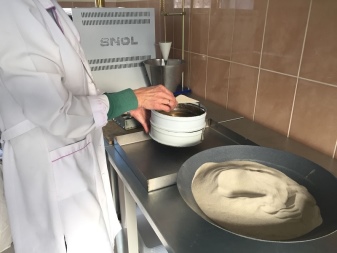

To calculate the modulus of sand fineness, a sample weighing 2 kg is taken and dried to an optimal state. Then the sand is sieved through sieves with a diameter of 10 and 5 mm. Within one minute, the sieve should not let more than 1 gram of the sample weighed through.

After sifting is complete, the sieve must be shaken over a white sheet of paper. If, at the same time, there are practically no sand grains on the paper, then sieving is considered complete. Further, to check the composition of sand without gravel, 1000 grams are taken from the sifted material and sieved through several sieves with a hole diameter from the maximum - 2.5 mm to the minimum - 0.14 mm.

How to calculate the bulk density of sand?

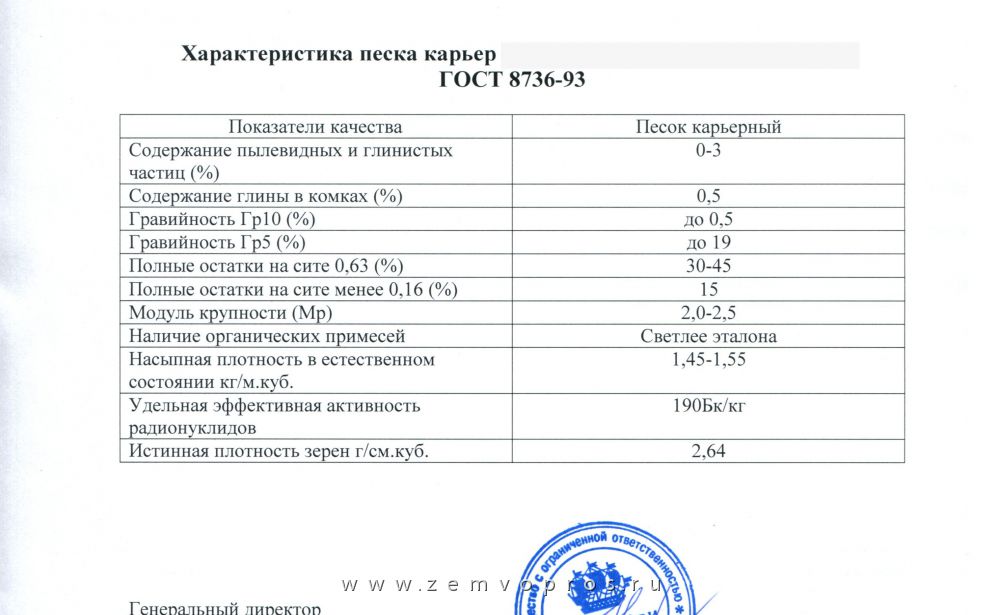

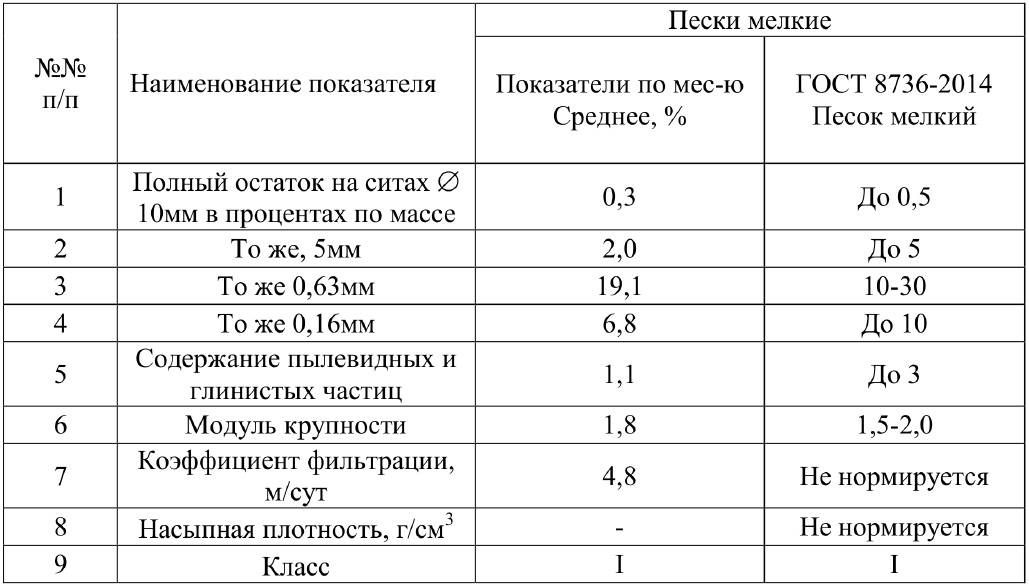

Sand classes in accordance with GOST.

To carry out such measurement calculations, the sand is initially sieved with a sieve (0.5 cm). Then they fill a measuring vessel (1 l). Further, the sand should be freely poured into it from about 0.1 m in such a way that a cone forms below the edge of the vessel. Then, using a ruler, the upper part of the cone is removed, that is, to the edges. Separately, it is necessary to weigh the container with and without the substance. The following formula is used to calculate the density factor: (empty weight - full weight) / container volume.

Here it is immediately worth stipulating that such calculations are made only with those measuring containers that initially have a certain shape and size, since this significantly affects the results. To make this issue easier to solve, there is GOST.

The average density of substances is influenced not only by moisture, but also by the presence of voids. The less space between the granules, the higher this characteristic.

The average density indicator for each type of sand is different: quartz dolly in a loose state has an indicator of 1500-1550 kg / m³, while if it is compacted, the characteristic will increase to 1600-1700 kg / m³. If it is planned to mix frost-resistant concrete, then one of its components will be sand with an increased average density coefficient.

The use of sand in parts of the road structure

River sand for road construction is selected based on the design features of the structure. The road consists of several parts, in which a layer of sand is used, therefore the calculation is made on the basis of the project documentation separately.

Sand filling is necessary:

- in the sand and gravel cushion of the roadbed, which creates conditions for depreciation and partial drainage;

- in some cases, an additional layer of sand is used, which compensates for high mechanical loads during temperature changes and removes moisture to the lower layers of the cake;

- sand is poured into the side drainage ditches, with its help a part of the shoulder is formed, which should receive and drain water flowing from the surface of the canvas;

- sand is used to create an asphalt-concrete base and coating, while it can be used in combination with fine gravel, with inclusions of river pebbles.

Based on the ability of sand to pass water (filtration coefficient), its density when backfilling without tamping (bulk density), normal moisture content at the time of backfilling (within 10%), size modulus, it is possible to calculate the need for procurement and delivery of sand during the construction process.

Size modulus and sand purity

Separately, it is worth dwelling on the sand size module for the road - this indicator determines most of the properties of the cushion and drainage. In the overwhelming majority of cases, sand of river origin is used with grain sizes in the range of 1.7 - 2.2 mm, which meets the criteria of “average size”. Smaller fractions are suitable for the manufacture of concrete solutions, the larger ones are sent to fill large foundations for structures. Grade 2 sand meets the basic requirements for road construction.

A very important parameter remains the purity of the material, the absence of clay inclusions, since when saturated with water, sand contaminated with clay can significantly change its properties, which will lead to deformation of the loaded part of the roadway.

Technical requirements

Manufacturing is carried out in accordance with the standards of technical documentation, which are agreed with the company and the norms of technical legislation.

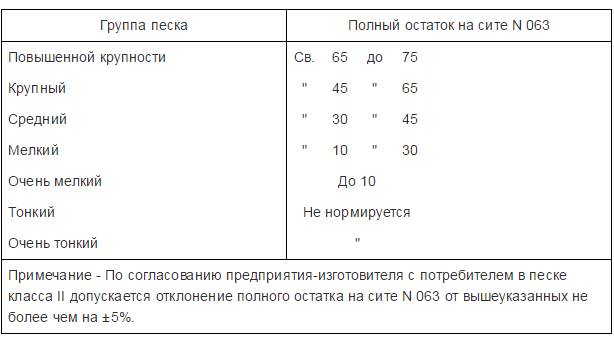

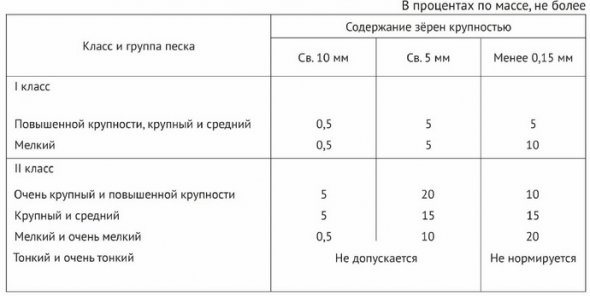

According to the grain composition, 2 categories are divided:

- Class I - high quality material, the fraction ranges from large to small;

- Grade II - sand, which is of somewhat inferior quality, but has a greater variety of fraction, down to the finest. At the same time, the thickness of the grain is also determined, the class includes thin and very thin.

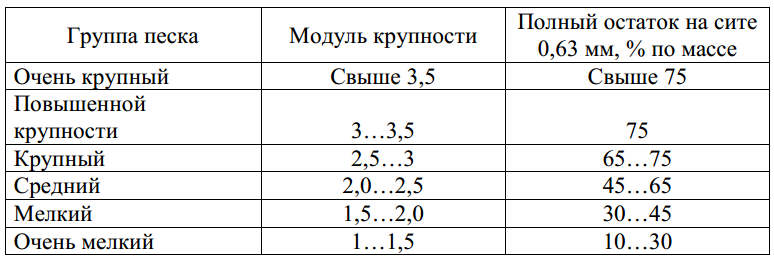

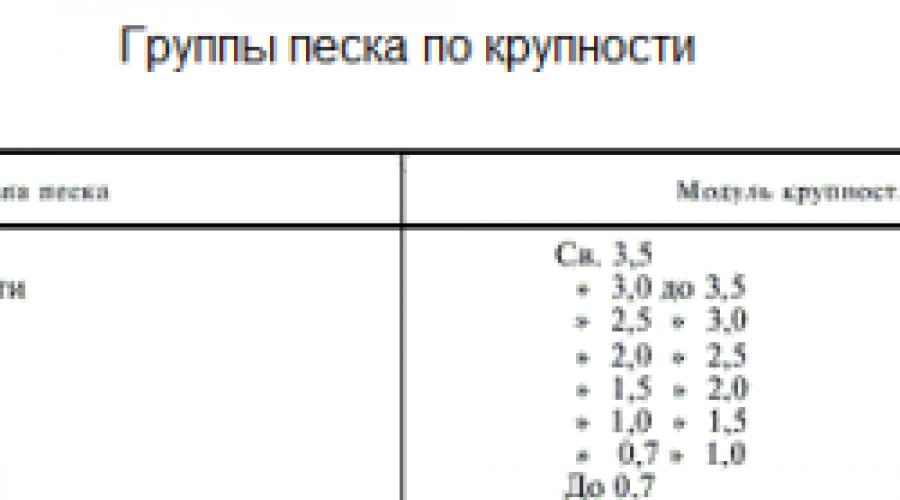

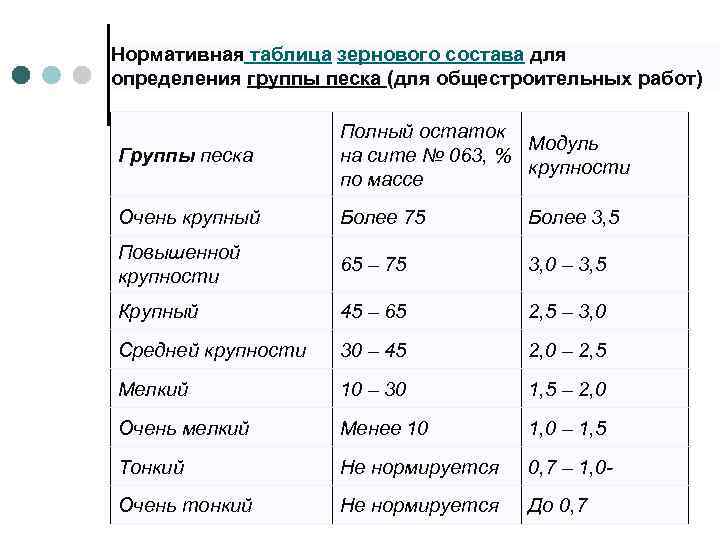

Size module

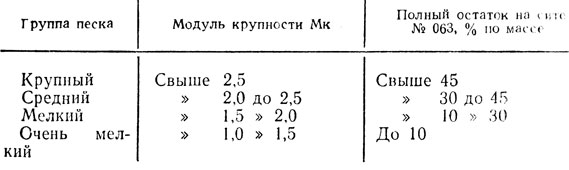

The document regulates the difference in sand by the size modulus (Mc), it also regulates the residual amounts of residues after filtering, it can take the following indicators:

| Material type | Size module | Residual parts on a sieve N 063 |

| Very big | More than 3.5 | Over 75 |

| Oversized | 3 to 3.5 | 65 to 75 |

| Big | 2.5 to 3 | 45 to 65 |

| Average | 2 to 2.5 | 30 to 45 |

| Small | 1.5 to 2 | 10 to 30 |

| Very small | 1 to 1.5 | Less than 10 |

| Thin | 0.7 to 1 | No norms |

| Very thin | Less than 0.7 | No norms |

A preliminary agreement with the manufacturer may indicate that deviations from the normative data are permissible in class II sand, but within 5%.

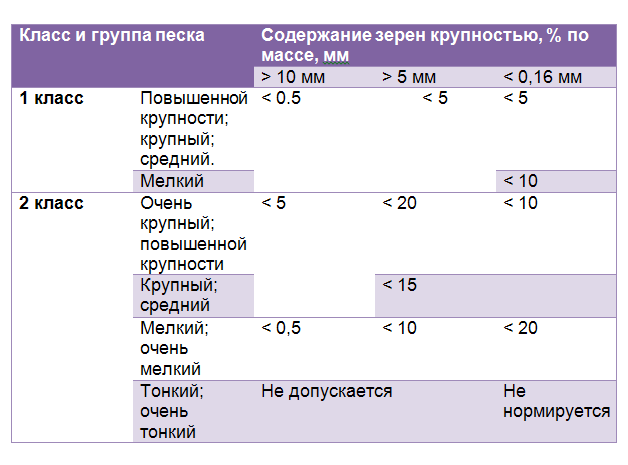

Also, the document determines the number of large grains and small, dusty ones. So, in order to comply with the standard you need:

| Classification | More than 10 mm | More than 5 mm | Less than 0.16mm |

| Class I | |||

| Very large - medium grained | 0,5 | 5 | 5 |

| Small | 0,5 | 5 | 10 |

| Class II | |||

| Very large - large size | 5 | 20 | 10 |

| Large - Medium | 5 | 15 | 15 |

| Small - very small | 0,5 | 10 | 20 |

| Slim and very thin | – | – | – |

Determination of the coefficient of dusty sand, medium size, etc. - test of the method

Determination of the filtration coefficient of quarry, quartz sand is carried out with the help of special experience using the simplest objects. This test measures the depth to which water percolates through a layer of sand in 24 hours.

According to GOST 8736, this method should be carried out using the following tools:

- KF-00M device;

- laboratory scales;

Laboratory balance

electric thermometer;

Electric thermometer

stopwatch.

Stopwatch

The KF-00M device is a structure consisting of:

- a filtration tube with a height of at least 10 cm and a diameter of 56.5 mm;

- perforated bottom with holes;

- coupling with brass meshes.

- measuring glass bottle.

The determination of the sand filtration coefficient, according to GOST, is as follows:

- the measuring tube of the device is filled with sandy material;

- the perforated bottom and brass mesh are attached to the filtration tube. You must first put on gauze soaked in water on the net. The device itself is installed on a table or any other flat surface;

- Pour sand into a measuring tube, and then tamp the material. Remember to fill in the sand in batches, so you can divide the total by three. Before loading the next batch, slightly loosen the top layer of sand in the tube with a knife or any other sharp object;

- then you need to measure the distance from the extreme point of the measuring tube and the surface of the sand in it. The sand level may not always be the same, therefore, it is better to measure it at several points, and then determine the average;

- if the distance turns out to be more than ten centimeters, then you need to tamp the sand a little more.

At this point, the preliminary stage of preparation for the test can be considered complete. Then you can go directly to the experiment itself, which allows you to determine the sand filtration coefficient:

- liquid must be poured into the measuring tube to a level of 5 mm above the zero mark;

- when water begins to seep through the perforated bottom, you need to time the time with a stopwatch.

These manipulations make it possible to determine the time interval for which the liquid falls below the level of 5 cm. This must be repeated at least four times, each time pouring water 5 millimeters higher.

Remember that it is strictly forbidden to allow the liquid in the tube to fall below the sand level. Otherwise, the whole experience will be useless.

GOST 25584 contains information on the specific coefficient of sand for each of the types of this material. In particular, the filtration coefficient of silty sand is from 0.1 to 2 meters per day. This is a very small figure, therefore, the scope of application of such a material is extremely limited.

The established GOST makes it possible to significantly simplify the determination of the scope of use of a particular type of sand. So, quarry sand has a low filtration rate, so it can only be used for plastering work, where these indicators are not particularly important.

For more information on determining the sand filtration coefficient, see the video:

How to determine the size?

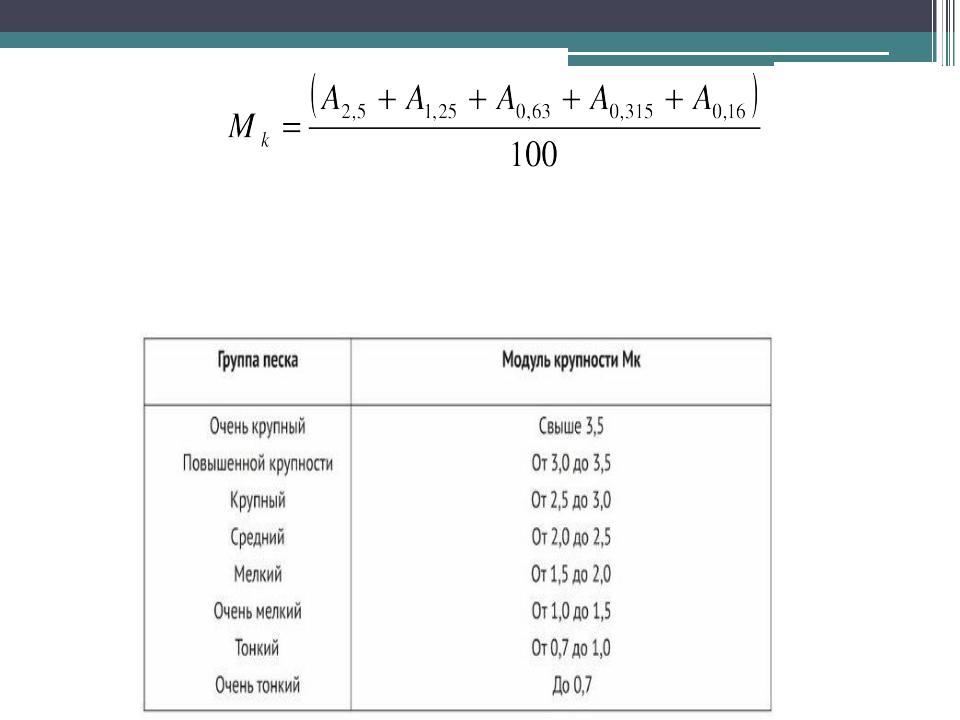

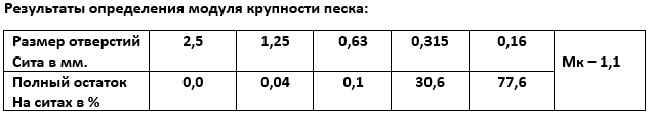

According to GOST 8736-2014, the module is measured using a special method.

- Grains larger than 5 mm are separated from a sample weighing 2 kg using sieves.According to the normative parameters of the state standard, the presence of gravel inclusions with dimensions of more than 10 mm in a volume of 0.5% is allowed in the sands, and inclusions from 5.0 to 10.0 mm - within 10.0%;

- Residues weighing 1 kg are alternately passed through sieves with meshes of 2.5–0.16 mm (5 sieves). Parts of the mass as a percentage of 1 kg remaining on the sieves are recorded in the table. The processing process ends when the grains of sand no longer pass through the cells.

- Calculation of Mk is carried out according to the formula Mk = (Q2.5 + Q1.25 + Q0.63 + Q0.315 + Q0.16) / 100, where Q is the parts remaining on 5 sieves as a percentage of the total mass.

The data of the results of the measurements made make it possible to build a graph of the sand screening curve, reflecting the granulometry and giving a picture in which concrete compositions it is optimal to use the material. So, if the curve on the graph is located between 2 lines built according to standard indicators, then the sand satisfies the preparation of the required concrete solution.

In the physical sense, the formula corresponds to the definition of the weighted average number of grains of a particular size per unit of bulk mass. The higher the level of presence of coarse-grained particles in the samples, the greater the value of Mk.

Nevertheless, this pattern is not always true. Experts note that 2 batches of fine substrate with particles of different sizes may have similar Mc values. It is for this reason that for a high-quality and more accurate description of bulk substances, in addition to Mk, they are guided by other parameters:

- the level of grain size distribution;

- the degree of presence of dusty elements;

- concentration level of clay-like elements;

- level of minor impurity inclusions;

- bulk density level;

- grain density indicators;

- the degree of content of biologically harmful inclusions;

- the degree of activity of radionuclide and other inclusions.

You can find out how the determination of the sand size modulus takes place in the video below.