Repair and fastening clamps: the main differences

Fasteners and repair connectors are completely different products. Each of them performs a specific function, respectively, has its own distinctive properties. The repair clamp is a multifunctional clamp that is designed to troubleshoot the following types of problems in pipeline systems:

- longitudinal and transverse cracks;

- violation of tightness in connecting parts (fittings);

- fistulas in pipes formed due to stray currents.

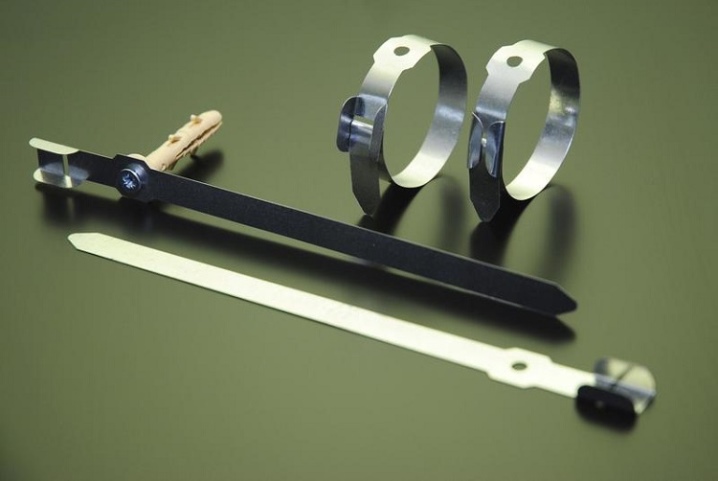

Basically, for repairs, they use classic models of clamps in the form of metal plates with bent ends. It is in these places that the nuts and bolts for the screed are installed. A rubber gasket is not included with such devices, so it must be selected individually.

Some clamps have comfortable handles for fastening

Some clamps have comfortable handles for fastening

Repair clamps enjoy advantages over fastening clamps. They are distinguished by simple and quick installation, are suitable for eliminating almost any malfunction, and do not require draining water for work.

Types of crimping metal pipe clamps

The type of crimped metal products determines their purpose and design features. They can be classified as follows:

- spiral - for fixing it is necessary to turn clockwise or counterclockwise, used on water supply networks made of reinforced plastic pipes;

- power clamp is a metal tape equipped with a tightening structure, can be used for fixing and repairing pipelines of various geometric shapes (circle, square) and for various purposes;

- reinforced fasteners - used for various types of hoses and hoses, it is a metal lock connected to a metal tape;

Clamp type "reinforced fasteners"

- wire fastening - made in the form of several rings of wire, connected by a mechanism for tightening them;

- a worm clamp is a metal strip with cuts (track) applied on its surface, equipped with a screw for tightening the strip;

- pipe clamp - made in the form of two half rings, one of which is equipped with an element for fastening to building structures and screws for fastening them;

- spring clamp - used in hot water supply and heating networks, it is a metal strip with applied holes, twisted under a certain diameter;

- with a rubber seal - can be equipped with various types of clamps discussed above, which provides strong fastening and tightness for models used for repair purposes.

Worm-type clamp

Clamps of the "reinforced fastener" type are also called power hinge devices, which is due to their design and the principle of operation of the fastening element. Worm gear models can be referred to as band metal clamps, which is also related to their design. Wire products can be referred to as spiral, therefore, when choosing a model, you must be guided by these names. All types of clamps can be produced in a reinforced design, which is expressed in the dimensions of the materials used (thickness and diameter), as well as the design of the tightening mechanisms.

Spring clamp, self-clamping

Repair clamps for pipelines: operating rules and appearance

To eliminate the dangerous consequences of accidents on pipelines, repair type clamps are used.For example, in the event of a breakthrough in the water supply or heating system, it is enough to simply fix the place of the problem without relieving the pressure. This repair method can be temporary or permanent.

The repair clamp can be composed of several sections

The repair clamp can be composed of several sections

Technical data for repair anchors

From a technical point of view, a stainless steel or galvanized pipe clamp is a bracket with a rubber insert, which gives the connection a tightness. However, these attachment models are intended solely for damage in straight pipe runs. Broken structures at bends or branches cannot be repaired in this way.

Pipeline repair tools must have the following characteristics:

- the presence of bolt clamps;

- the presence of rubber sealants of different thicknesses;

- the possibility of spacers of crimp parts between themselves;

- durable metal that does not lend itself to deformation.

What are the types of repair clamps

Depending on the complexity of the work on fastening the pipelines, it is necessary to choose the model of the repair clamp. Let's deal with the existing varieties:

- unilateral. Most often, this is a U-shaped model of fasteners, which has one half-shaft with threads at the ends and a bridge, which subsequently fixes the pipe with bolts. However, this version of the device is convenient only to prevent various leaks;

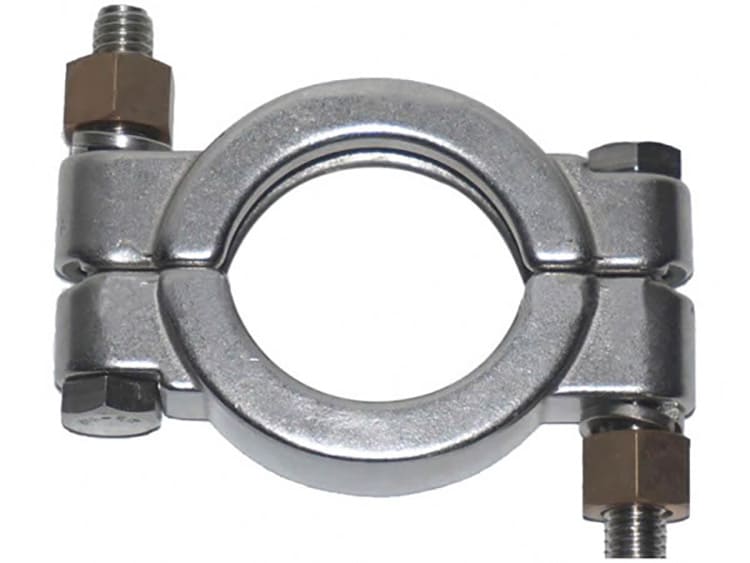

- double-sided is a structure that has two metal semicircles, which are connected to each other with bolts, which on this structure can be from 2 to 4 pieces;

- multi-part. Such a clamp is a more complex type of fastening. Typically, this option is designed to fix several pipelines at the same time.

Power fasteners can taper towards the attachment point

Power fasteners can taper towards the attachment point

Peculiarities

Metal pipe clamps are ubiquitous. With their help you can:

- securely fix the pipe to the wall or supporting beam;

- quickly eliminate the leak through the crack in the pipe wall;

- to give tightness to joints and fittings;

- fix a rubber or reinforced hose to the fitting;

- fix plumbing hoses and corrugations;

- remove fistulas in pipes that have formed due to stray currents;

- and even mechanically fasten some parts.

However, their direct purpose is to ensure the stable operation of pipelines. Therefore, they are widely used in various fields, such as:

- household and communal;

- hydraulic structures;

- engineering industry;

- motorcycle and automobile construction;

- energy;

- gas facilities;

- design and various crafts.

These fasteners must be reliable and durable. And also - to meet quality standards. Therefore, they are manufactured according to the requirements of GOST 24137-80.

This document states:

- limiting pipe diameters for which the clamp is designed;

- thread diameter (the fastening nut is selected according to it);

- the length of the thread (the thickness of the support depends on it, to which the pipe can be attached);

- product weight (also an important parameter, especially for transport);

- manufacturing precision;

- links to other documents (which define storage conditions, labeling, etc.).

What are the metal clamps for high pressure hoses

Crimp metal reinforced clamps are equally important for main pipelines and flexible hose lines. For such systems, either worm-type clamps or power ones are provided.

Hose clamps have a large clamping ratio

Hose clamps have a large clamping ratio

Worm Gear Hose Clamps

The worm-type fastening is a ring with a bolt and serifs, which are applied to the inner edge of the clamp. This helps the fixture to hold the connection more tightly.

You can fix the fasteners with a Phillips screwdriver

You can fix the fasteners with a Phillips screwdriver

Power Clamps for High Pressure Hoses

Devices for fastening the power type in connections do an excellent job with their tasks, while there are several subspecies of them:

- strip and wire galvanized have a bolted connection as a clamp;

- reinforced hose clamps - have clamps on both sides;

- universal cast, equipped with two bolts.

Such clamps are equipped with fastening bolts and have massive spacers.

Such clamps are equipped with fastening bolts and have massive spacers.

All these types of clamps are made exclusively from stainless steel. All of them are equally easy to use and relatively cheap, so some stock of such fasteners on the farm will not hurt.

We recommend watching a video review of clamps, which tells about the purpose for which this or that type is used, which of them is better to buy.

Dear users, if you still have questions on the topic of the publication, be sure to ask them. Our team will be happy to answer them as soon as possible. If you have experience using this or that crimp - share it with us.

Nuances of operation

It is recommended to lubricate the screw connections with machine oil or silicone oil before installation. This will not only make the screws easier to tighten, but will also prevent further corrosion. Just keep in mind that industrial oil corrodes some types of rubber.

When mounting, always balance the applied force and the dimensions of the fastener. In addition, the spring clip may jump off and fly to the side when compressed. Be careful.

Make sure that no dirt or dust gets on the work surface. Not only will it scratch the pipe, but it can also lead to premature corrosion.

Tighten screw connections periodically, especially if the pipe is vibrated. If the tool is difficult to operate, buy a wing clamp instead of the screw. No tool is required to tighten it.

Do not allow the screws to become dirty with dust. This not only extends the service life, but also allows the clamp to be reused after removal. The clamp is in good condition without signs of corrosion and is designed for a minimum of 50 assembly-disassembly cycles.

And always follow safety precautions. And also do not skimp on fasteners, because most often the pipe breaks down precisely at the joints.

An overview of useful tools for working with clamps from China in the video below.

Dimensions and weight

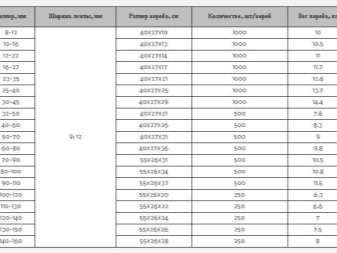

There are a large number of clamp models on the market, while the range of possible diameters for all designs is different.

- Worm gear. The smallest clamping diameter is 8 mm, the largest is 160 mm.

- Screw - 18-76 mm.

- Spring-loaded - 13-80 mm.

- Spiral - 38-500 mm.

At the same time, worm clamps have the largest adjustment range. This means that one and the same clamp can be used to secure a pipe both 110 mm and 200 mm in diameter. After installation, the excess part of the clamp is simply cut off. This is actively used by installers.

The sizes of all types of clamps change stepwise and are prescribed in GOST. It also indicates the width of the tape, weight and maximum load.

Standard sizes of worm gear clamps are shown in the table.

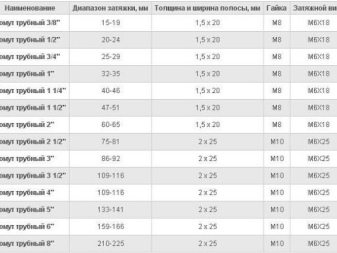

The diameter of the plumbing (pipe) clamps is usually indicated in inches (1 inch - 25.4 mm). This is convenient because the size of the pipes is also counted in inches.

For metal models with a hairpin, the number of standard sizes is slightly different.

It should be borne in mind that with an increase in diameter, the width and wall thickness always increase, especially in repair models

This is important when there is a lack of working space or a short pipe length.

The width of the fastening clamps is usually 20-25 mm.

The internal thread of the union nuts usually ranges from M6 to M10. It makes no sense to put large nuts, since the size of the clamp increases greatly.