Panel structure

Metal panels for the facade, depending on the material of production, have their own structural features.

Steel panels have a fairly simple structure, represented by a sheet of metal and a coating.

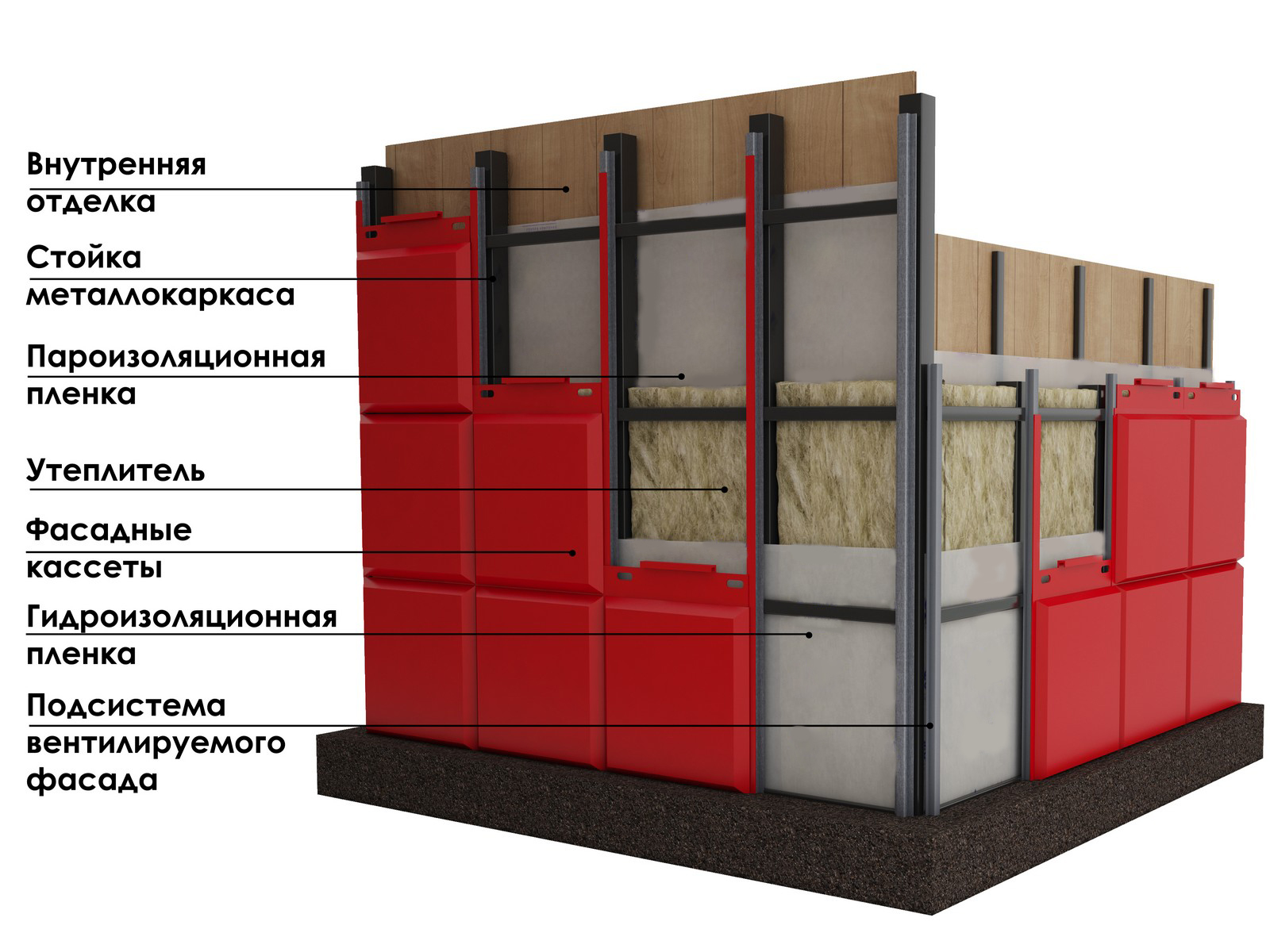

Figure 4. Scheme of the structure of a metal panel for the facade

Figure 4. Scheme of the structure of a metal panel for the facade

The structure of aluminum panels is somewhat different.

It consists of paint coating, primer, chrome coating, zinc coating, aluminum sheet, anti-corrosion coating.

! Aluminum has excellent adhesion, due to which the resistance of the paintwork to external influences increases. You just need to choose panels painted with PVDF varnish, which provides reliable protection against aggressive environments.

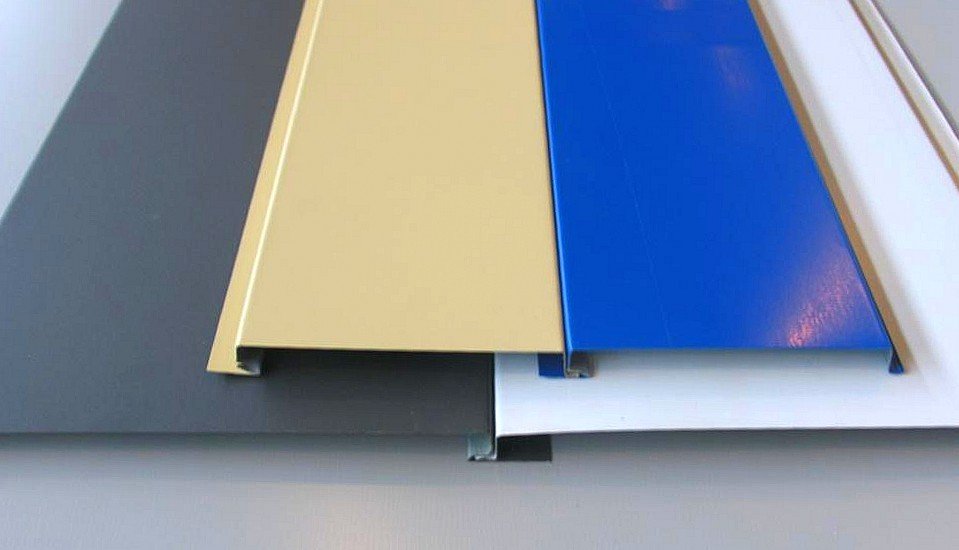

Figure 5. Structure of aluminum panels

Figure 5. Structure of aluminum panels

The central layer can have a different composition. For example, this is the structure of Alcotek panels. The manufacturer uses an innovative composite that the company has developed itself.

Before buying, please note - the anti-corrosion coating may be different!

Steel sheets are usually galvanized. There are various options for aluminum cassettes. So the most common and at the same time cheap coating - polyester provides weak protection from fading. Pural is more reliable in this respect, but it increases the price of facing. An alternative option is plastisol. It is not afraid of acids and alkalis, it is used to create a variety of textures.

Leading manufacturers of aluminum facade panels

Currently, the greatest demand is for composite aluminum materials from the following manufacturers:

"Alcotek"

The products of the production association "Alcotek" have long been in deserved demand among domestic developers. High quality of manufactured composite panels and a wide range of colors allow using AKP "Alcotek" for the implementation of any design solutions.

Facing slabs "Alcotek" are produced in widths of 1.22 and 1.5 m. The length of the panels is determined by the customer's requirements and can be from 2 to 8 m. The following modifications are currently in greatest demand: AlcoteK B2, AlcoteK, AlcoteK FR, AlcoteK FR Plus.

"Alukobond"

The company has been operating in the Russian market for over 15 years, and during this time has managed to take a leading position in the production of composite aluminum materials. Most often, AKP "Alukobond" is used for the installation of ventilated facades of varying complexity. In addition, the material has found the widest application in the manufacture of advertising structures and small architectural forms. A wide range of colors and textures allows using the AKP "Alukobond" not only for outdoor work, but also for interior decoration.

"Buildx"

Composite materials from the "Buildx" company are widely used in decorative cladding of facades, installation of advertising structures, as well as in interior decoration of residential and office premises. Long service life and high wear resistance of products are provided by a special protective and decorative PVDF coating. A large selection of textures and colors allows you to choose a material that ideally matches the overall architectural concept or design solution.

With standard widths of 1220 and 1500 mm, the length of the slab can vary from 2000 to 6000 mm, according to the client's requirements. Depending on the purpose, the thickness of the cassette can be 3 or 4 mm.

"Goldstar"

AKP "Goldstar" are produced by the production association "Aluminstroy".The innovative production technology and the use of the latest equipment have made it possible to organize the production of composite panels that meet all existing quality and fire safety standards. The model range of the company includes several series, the most popular among which are: "Chameleon", "Pearl", "Classic" and "Quartz".

The standard slab length is 4000 mm, however, if required, slabs of any length in the range from 1850 to 6000 mm can be produced.

"Kraspan"

Another Russian manufacturer of composite materials, the quality of which is not inferior to foreign counterparts. The main features of Kraspan aluminum composite panels are high fire resistance and strength. The plasticity of the products allows the cladding of facades with a complex configuration, including radius elements. A variety of colors and textures makes it possible to bring to life the most original design developments.

In addition to facing slabs, the Kraspan Company produces elements of load-bearing systems for the installation of ventilated facades and the construction of various building structures.

"Grossbond"

ACP "Grossbond" belongs to the class of universal finishing materials. The main area of application of Grossbond composite boards is facade cladding, in addition, the material is actively used in the creation of interiors, the manufacture of signs, signs, billboards and special furniture.

Panels "Grossbond" fully meet all fire safety requirements, which is confirmed by the presence of appropriate certificates. In addition to composite materials, the company produces elements of subsystems from structural galvanized steel and aluminum alloys.

The rapid development of construction technologies makes it possible to significantly speed up the process of construction and installation work. The use of aluminum composite panels not only makes it possible to produce cladding or advertising structures in the shortest possible time, but also ensures a long service life and high aesthetic characteristics of the facade.

Installation instructions

To

perform facade decoration on any object, you should adhere to the correct

sequence of works.

Required tools

For

markup you need to take a level, tape measure and marker. A grinder is also useful,

drill, scissors and a hacksaw for cutting metal. You also need to prepare dobras,

accessories for mounting the frame and fixing all elements.

Preparatory work

Implemented

cleaning the facade from debris, foreign objects are removed from the entire surface of the building

(roller shutters, window sills, cornices, gutters). Existing defects (traces

corrosion, pits, cracks) must be repaired. For a wooden facade it is used

antiseptic impregnation.

Markup

Perforator

holes are drilled to install the profile in areas that have been

marked with a marker. The distance between the marks depends on the pitch of the lathing.

To determine the required amount of material, the facade area is measured and the size of the openings of doors and windows is subtracted from the obtained value. Additional details are also considered, the number of which depends on the parameters of the corners, the perimeter of the existing doors and metal-plastic windows.

Lathing

Lathing

created from metal or wooden slats. The best choice for the frame is

durable, reliable metal profile. Its dimensions must exceed the thickness of the insulation

(if insulation is used). Brackets are suitable for attaching the lathing.

After fixing the frame from the metal profile, the insulation is laid from the bottom up, which must be dry. It is covered with a waterproofing film, after which the panels are attached.

Mounting

Procedure

begins with fixing the additional parts (initial, corner, final plank), after

what is the facing of the wall near the openings.When using a finishing strip

the installation of the elements is carried out in the reverse order. Along the perimeter and on

a seal is attached to the corners.

On

the next step starts attaching other planks from the bottom of the left area

walls. The parts are connected to each other with screws or built-in locks. Can

mount locks with additional screws. Once the cladding is ready,

removed elements (shutters, slopes, gutters, cornices and

NS.).

V

in general, the setting steps for different materials are performed in a similar way

principle. This is an inexpensive solution for a summer residence or cottage, and the result obtained is

will remain for years.

Methods for applying perforation to aluminum sheet

For the manufacture of facade panels-screens, for decorating the facade over translucent glazing or for decorating opaque surfaces, as well as for creating media facades, aluminum panels with through-slots in the form of ornaments are used. Moreover, any shapes are possible, the only limitation is that the area of the cuts should be no more than 55% of the total surface area, otherwise the aluminum panels do not withstand wind loads, bend and break.

Cutting is carried out in a solid sheet by different methods depending on the batch size:

- Small batches - cut out with a cutter of a special cutting plotter, according to the same principle as volumetric letters;

- For single piece aluminum sheet for small batches, laser cutting can be used, giving excellent accuracy and repeatability of the ornament. The disadvantage of this method is its high cost;

- For the manufacture of large quantities over 1000 sq. M. you can use a punching press.

Design options

Metal profile panels differ in surface relief. The following options are distinguished:

- corrugated. With angular sharp protrusions or soft waves;

- smooth. Standard products, differing in shade, can repeat the Scandinavian-style wood pattern, compose a large picture or create a mirror effect;

- with decorative ribs. Different distance between the ribs allows you to visually expand or increase the height of the facade;

- perforated. They can differ in patterns (individual, geometric options), let the light emanating from the object pass through, creating a unique glow. Their use allows you to embody design ideas.

The decoration of public and industrial buildings is often done with cassette panels. They are produced in cassette or linear form. Cassettes are three-dimensional square-shaped products made of steel or aluminum with polymer spraying, with bends at the edges. Linear panels are distinguished by their long length, allowing installation with little or no gaps. They are similar to cassettes, but have a three-dimensional or perforated surface.

Wide

assortment of building materials, often the facades are finished with sandwich panels,

made of several materials. Simple designs consist of two

layers of cladding and filler.

Design

In addition to differences in the material from which the facade panels are made, they can differ in surface relief.

- Smooth. Conventional steel panels that differ only in color. They can repeat a wood pattern, make up one large picture from fragments or become glossy, creating a mirror effect.

- Corrugated. Curved by soft wave or hard angular protrusions.

- Perforated. They come in various patterns: from geometric to individual ornaments, made to order. In the dark, such panels let the light emanating from the building pass through and create a whimsical picture, embodying all kinds of designers' ideas.

- With additional decorative ribs. Depending on the distance between such ribs, you can visually expand the facade or make it higher.

When decorating industrial and public premises, cassette panels are used, as a rule.

Such panels are of several types.

- Cassettes are volumetric panels consisting of aluminum sheet or steel with polymer spraying. Such a cassette has a bend at the edges and is manufactured not only in factories, but also directly at construction sites due to the simplicity of the design. Most often they have a square shape and a smooth surface.

- Linear - elongated panels for exterior and interior decoration. Due to this design, the facade is mounted with a minimum number of gaps at the joints or no gaps at all. Linear designs are similar to long cassettes, but can have a perforated or 3D surface.

With all the variety of materials, most of the facades are cladding with sandwich panels made of several layers of different materials. The simplest products have three layers: two facing (metal, wood board or other materials) and one filler layer (most often it is insulation).

Maintenance of metal panels

Front metal panels are not demanding on storage and transportation conditions. They demonstrate their best performance throughout the entire period of operation.

However, there are nuances that should be taken into account.

The panels must not be thrown or dragged. Do not place heavy objects on them. All this can lead to the loss of a part of the protective layer and the appearance of defects.

If the installation of the cladding is postponed, it is better to store the panels indoors without access to sunlight at a temperature of -5 to + 15 C.

The protective film must be removed immediately before installing the boards.

To clean the facade of dirt, it is enough to water it with a hose 1-2 times a year.

If any panel is damaged during operation, it can be replaced with a new one without large-scale alterations.

Manufacturers overview

The production of metal panels can be both manual (directly at the facility) and professional (at large factories). Products from foreign suppliers are presented by various companies, among which there are several brands that have received the best reviews: Finnish metal panels of the Ruukki brand (in the construction market for more than 50 years), American siding from Alcoa, made mainly of aluminum, as well as a British-Dutch brand Corus Group.

Among domestic manufacturers, one can name Grand Line facade panels. The products of Lipetsk Roll Forming Equipment Plant and INSI holding are widely represented on the market. The products of the SeverStal plant also received positive assessments from buyers. The main difference between Russian manufacturers is that, with the same quality, domestic products have a lower price than foreign ones. This difference is due to the lack of transportation costs.

Features of steel panels

Modern steel panels enable owners to solve any problem of facing the external walls of various houses. An important advantage of such products is their low weight, due to which they do not create a strong load on the foundations, and therefore can be used to decorate not only new, but also old buildings.

The popularity of such facings is also largely due to their wide variety. The market presents facade panels made of galvanized steel coated with polyester of various colors and textures; modern products made in the form of imitation of surfaces of various natural materials - stone, wood and brick - are in significant demand.

Dignity

Currently, steel products for ventilated facades are considered one of the most reliable and durable cladding options.They have a huge number of advantages, this is attractiveness, good technical characteristics, and a fairly low cost, especially when comparing the price with other cladding products.

Among the main advantages of such finishing materials, it is customary to highlight their following characteristics:

- creation of reliable protection for building structures and insulation material from any negative external environmental influences;

- keeping the dew point at a level due to which the walls of the building always remain dry, do not freeze in the winter months and do not undergo excessive heating in the summer;

- do not prevent moisture evaporation from the surface of external walls and heat-insulating material;

- low weight, thanks to which such cladding can be used on any, even old buildings;

- simple installation, which does not include "wet" works, due to which the installation of the finishing material can be carried out at any time of the year and under various weather conditions;

- providing protection against noise from the street;

- there are no deformations due to the expansion of materials that occur during seasonal temperature changes;

- affordable price;

- the service life declared by the manufacturers is from 30 years or more;

- panels do not burn and do not spread fire.

Dimensions and characteristics of aluminum composite panels

The ACP manufacturing technology allows setting up the production of panels of any size, in accordance with the wishes of the customer, however, there are also standard dimensions. Let's consider the main performance characteristics and dimensions of composite panels using the model range of the Aluminstroy company as an example.

Overall dimensions of AKP "Aluminstroy"

|

Options |

Dimensions, mm |

||||

|

Goldstar A2 |

Goldstar S1 |

Goldstar FR |

Goldstar FR1 |

Goldstar FP |

|

|

Width |

1220 |

1220 / 1500 |

|||

|

Thickness - panels - aluminum base |

4 0,4 |

4 0,4 |

4 0,4 |

4 0,5 |

4 0,4 |

|

Standard length |

3250 |

||||

|

Length range |

1700 — 6000 |

Operational properties of AKP "Aluminstroy"

|

Options |

Dimensions, mm |

||||

|

Goldstar A2 |

Goldstar S1 |

Goldstar FR |

Goldstar FR1 |

Goldstar FP |

|

|

AKP weight, kg / m2 |

7,16 |

7,7 |

7,2 |

7,4 |

6,6 |

|

Specific weight, kg / m3 |

1795 |

1905 |

1780 |

1830 |

1680 |

|

Minimum tensile strength, MPa |

37 |

33 |

33 |

33 |

33 |

|

Minimum flexural strength, MPa |

125 |

85 |

85 |

85 |

85 |

|

Tensile elongation,% |

6,5 |

3,5 |

3,5 |

3,5 |

3,5 |

|

Permissible bending load, MPa |

43 |

68 |

69 |

50 |

50 |

|

Panel delamination load, N / mm |

3,1 |

5,6 |

5,6 |

5,6 |

5,6 |

|

Flexural modulus, MPa |

2.9x104 |

1.5x104 |

2.1x104 |

1.8x104 |

1.8x104 |

|

Working temperature range, С |

from - 55 to + 85 |

Fire-technical properties of AKP "Aluminstroy"

|

Options |

Dimensions, mm |

||||

|

Goldstar A2 |

Goldstar S1 |

Goldstar FR |

Goldstar FR1 |

Goldstar FP |

|

|

Flammability class |

G 1 |

||||

|

Flammability class |

IN 1 |

||||

|

Smoke generation group |

D 1 |

D 2 |

|||

|

Toxicity class |

T 1 |

T 2 |

|||

|

Structural fire hazard class |

K 0 |

||||

|

Minimum calorific value, MJ / kg |

4,2 |

10,6 |

10,7 |

10,7 |

24,5 |

Applications of Aluminum Composite Panels

In modern construction and design, AKM is widely used for:

- decorative cladding and ventilated facades;

- installation of entrance groups of supermarkets, office centers and administrative buildings;

- production of outdoor advertising elements: signboards, signs, lightboxes, pillons, etc .;

- decoration of interiors and decoration of premises;

- production of elements of interior advertising, exhibition stands, racks and other structures;

- solving problems related to the industrial design of industrial and office premises;

- manufacture of cold rooms and industrial refrigeration equipment;

- production of specialized equipment: boxes, cabins, refrigerated cars and car freezers;

- creation of small architectural forms such as pavilions, kiosks, signs, steles, etc .;

- manufacturing of special furniture operating in high humidity conditions in a wide temperature range;

- erection of partitions and installation of suspension systems.

Views

Metal panels are on average 0.55 mm thick. They are waterproof and fireproof.The impact resistance is 50 kg / cm, and the flexural strength is 118 MPa. The classification of panels is based either on their appearance or on the metal used. Depending on the appearance, the panels can imitate wood, stone or brickwork. Profiles can be corrugated, smooth, perforated or various embossing along the edge.

Cink Steel

Metal roofing companies also produce galvanized steel panels coated with polyester. Whether smooth, grooved or patterned, they all have a lock connection and are easy to install. The thickness of the galvanized metal is 0.5–0.7 mm, and the coating not only protects the material, but also allows you to give the product different colors and textures. Such material is the most versatile and is used for cladding any facades, from country and country houses to shopping pavilions and sports centers. The length of such panels can reach 5–6 meters and are ordered from the manufacturer. They can be mounted both horizontally and vertically. The panels are lightweight, durable and economical.

Unfortunately, due to their lightness, such structures are susceptible to deformation, as well as accumulate static electricity and require additional thermal insulation.

Stainless steel

Stainless steel is another popular material for facade cladding. Coated with a layer of oxide "stainless steel" does not require additional coating with various protective agents. With the right grade of steel, such panels are durable, lightweight and very easy to maintain, despite their rather high price. Like galvanized steel cladding, stainless steel requires thermal insulation and accumulates static electricity, but at the same time it is more resistant to corrosion.

Aluminum

Aluminum panels are also called composite panels. Their total thickness does not exceed 6 mm, and the length is 6 m. From above, the metal can be coated with an oxide film, which will protect the material and give it various shades. With the help of such a film, you can get a mirror effect, imitate a wooden or stone surface.

Composite multilayer aluminum panels, called "Alukobond", are distinguished as a separate type. Between the sheets of durable metal there is either a synthetic polymer or a foamed under high pressure polyethylene... Such material reliably protects the facade from moisture and mechanical damage, and also allows you to bring to life almost any design idea due to the fact that it easily bends and takes on the required shape.

Other types of metals

In addition to steel and aluminum, metal panels can also be made from other materials and alloys: brass, copper and even bronze. These panels are coated with a glossy or matte varnish and are installed using hidden fasteners. Inside, such structures are pasted over with a sound-absorbing material in order to exclude ringing during mechanical stress. They are durable and easy to install and remove. Such panels are used not only for cladding facades, but also for interior decoration.

Polymer coated

The basis of such panels is aluminum or galvanized steel, on which a protective polymer coating is applied on top. The thickness of such metal panels is about 0.56 mm. They are smooth, corrugated or perforated. Such panels are moisture and frost resistant, have good sound insulation, and are also easy to install. Before installation, it is necessary to pre-insulate the facade or use more expensive sandwich panels. In order for such a cladding to serve for a long time, it is necessary to correctly mount the battens made of wood or aluminum profiles.

Sintered metal

Such panels are steel sheets that are coated with glassy enamel. The enamel imparts high resistance to aggressive media, high rigidity and durability.Such structures are most often used in the construction of transport infrastructure: various tunnels, crossings and stations. However, today this material is increasingly used for cladding the facades of ordinary residential buildings. Their thickness is 200 mm, the material is non-combustible, withstands temperature drops from -60 degrees to +800. Products made from this material are easy to care for and serve for over 50 years.

Conclusion

Thus, high strength, light weight, corrosion resistance and

other external factors, a wide variety of colors, sizes and textures,

high sound insulation and fire safety, relatively low cost

make aluminum panels an excellent choice for cladding buildings.

With their help, the most daring in layout, original and

exquisite exterior designs in modern and techno style. It is perfectly

suitable for many urban objects: high-rise residential buildings, business centers,

shopping malls, company headquarters, medical and educational institutions, museum

and exhibition centers, galleries, restaurants, cafes, beauty salons, pharmacies,

gas stations, fitness centers, swimming pools, etc.