Annealing process.

The annealing process itself consists in heating the washers to a temperature of 550-600 degrees Celsius. As a result, the oxide film that appears on the products during their manufacture is destroyed.

After slowly cooling the washer, it is necessary to remove the scale from its surface. To do this, manufacturers use one of two methods:

- tumbling - mechanical cleaning of the surface;

- passivation is a technological procedure that leads to the formation of special compounds on the metal surface that prevent further corrosion.

The tumbling method is less costly and simple. It does not require sophisticated equipment and technologies to use it. But at present it is used only by small companies with a small production volume. Large manufacturers abandoned it due to the fact that, with the above advantages, it also has significant disadvantages.

During the tumbling process, the washer may deform. The number of such washers that have lost their shape in the total volume of products is quite large - up to 15%. In this case, not only the appearance of the washer deteriorates, but also its physical characteristics. By and large, such products can no longer be considered annealed, since the features of copper are such that when an element made of this material is bent by more than 30%, it becomes harder. The hardness of deformed washers reaches 55-58 HB, while the standard hardness of annealed parts should not exceed 45 HB.

Another significant disadvantage of tumbling is that during this procedure, the oxide film from the surface of the copper part is completely removed. And such a coating also plays an important role in terms of protecting the part from corrosion. As a result, an unprotected product is exposed to humid air, which is why its presentation is lost in just a couple of weeks.

All these shortcomings allow us to conclude that tumbling, as a method of removing scale from a copper product, does not justify itself. Therefore, most manufacturers choose passivation as the main way of giving products a presentation, that is, transferring the surface of the washer to an inactive state. As a result, the products are pleasing with their appearance even after a long time after leaving the production site.

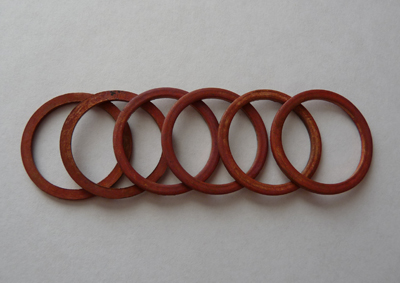

Description and purpose

The use of various sealing elements is practiced to improve the reliability and stability of screw connections. The choice of material for the washer is determined by what impacts the connection will experience. A copper washer is best suited where there are elevated temperatures and pressures in constant mode or intermittently. Therefore, it is widely used in the engineering industry when assembling mechanisms designed for high pressure. First of all, we are talking about fuel and hydraulic equipment.

The attractiveness of copper washers for a backing on a chainsaw and for a car drain plug is also associated with:

- high chemical resistance of their material in an aggressive environment;

- excellent corrosion resistance;

- preservation of sealing functions under the action of elevated temperatures, as well as with significant fluctuations in the thermal regime;

- vibration resistance;

- strength and stability of basic properties under significant pressure.

Such fasteners can also be used in automotive mechanisms, all parts of which are constantly heated, while still being moistened. This high level of responsibility means that these washers meet very demanding requirements. Compliance with the GOST specified for a specific type of product is of key importance. Compliance information can be found on the original packaging of the kit and on the accompanying quality certificate.The achievement of the required properties depends primarily on the characteristics of the feedstock.

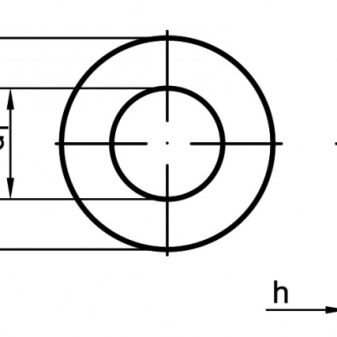

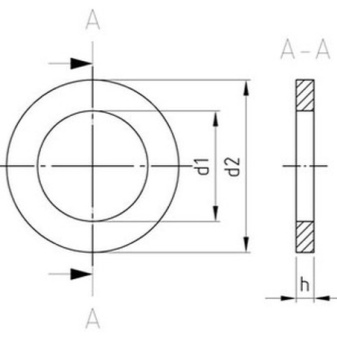

The way the washers look is clearly described in GOST 18123-82. According to this standard, there should be no deviations from the smooth shape on the surface. No burrs or cracks are allowed. Washers with signs of corrosion or with metal drips also do not comply with the standards. Roughness of more than 3.2 microns also makes it possible not to accept the product.

The control process implies, first of all, a visual check. If necessary, an accurate study is carried out through a magnifying glass. Roughness is assessed by indicator standards in accordance with GOST 9378-75 or using specialized measuring devices.

Material grades

The official marking of the copper washer always indicates the presence of powder coatings. P29 class products are galvanized and passivated. P34 mark means that the product is only passivated. In cases where the standard provides for more than one accuracy class, its designations are placed at the very beginning of the brand. The composition of the marking includes:

- type of execution;

- section of the thread;

- part thickness;

- chemical brand;

- conditional index;

- the thickness of the coating used;

- applied standard.

There are such basic standards:

GOST 10450-78 (small products)

The copper-aluminum washer has a special brand - SHAM. There are differences in diameter. Other brands:

DIN 125 (basic)

How to properly anneal

It is worth firing copper washers under the nozzles if only to relieve internal stresses that inevitably appear during material processing in production

But it is very important to follow this procedure clearly. The process is carried out when heated to 700 degrees

Then the parts are smoothly cooled in a natural way at normal temperature until they cool down to +25 degrees Celsius.

Heat treatment is carried out using a welding torch. The flame is kindled in it using oxygen and acetylene supplied from different cylinders. Another important nuance - gloves and glasses are required. There should be a fire extinguisher near the place of work. Having connected the hoses to the cylinders, it is necessary to open the acetylene valve on the burner by 50%. After firing up the gas, wait until an orange-red flame appears.

Thereafter, the oxygen valve is opened until a blue flame appears. At this moment, the washers are burned. The fire is directed at the puck and directed along the surface, achieving a cherry red glow. Thereafter, immediately close both gas valves. Then, as already mentioned, you will have to leave the products to cool.

Requirements for copper washers.

Mechanisms that use copper washers are among the most critical parts of technology. It is not surprising that the highest requirements are imposed on any component in this case. The most important thing is the compliance of the copper washer with GOST, developed for this type of product.

This parameter must be noted on the packaging of fasteners. In addition, all products that meet quality standards must have a certificate confirming this.

When it comes to the performance of a copper washer, much depends on the quality of the raw materials used for its manufacture - that is, copper sheets. All the outstanding properties inherent in this material, copper products show only if the amount of impurities in the raw material is minimized. That is why the grade of copper is of great importance.

Requirements for the appearance of washers are regulated by GOST 18123-82 developed back in the days of the USSR. The surface of the products should be as smooth as possible, without burrs, cracks or chips, as well as without traces of corrosion or metal drips. The maximum element roughness (Ra) is 3.2 microns.

When carrying out control measures in production, the conformity of the appearance to all requirements is checked visually. In this case, a magnifying glass can act as an additional means of verification.To determine the degree of roughness of products, special samples are used, made in accordance with GOST 9378-75, as well as measuring instruments.

In some cases, the copper washers may be powder coated. This treatment improves the corrosion resistance of the fasteners. The thickness and quality of such a coating is also regulated by state standards - GOST 9.302-79.

As a rule, large manufacturers of copper fasteners, having an established production process, do not save on quality control of all their products, carrying it out at every stage of production, starting from the choice of raw materials. Therefore, the more popular the name of the manufacturer, the greater the guarantee of high quality products.

Features of production and marking of copper washers.

One of the important stages in the production of copper washers is the heat treatment of the workpieces, that is, annealing. In the process of annealing, copper products are heated to a high temperature (650-700 degrees C), and then slowly cooled. Such heat treatment makes it possible to increase the plasticity of copper, which means that damage to the copper element is excluded, for example, with a sharp change in the temperature regime in the area of operation of the product.

Note! Copper may harden with prolonged storage. Before installing a washer that has been in a warehouse or garage for a long time, it must be additionally annealed

You can do this yourself. To do this, you need to warm up the washer to the desired temperature (you can determine this by the red tint that appears on the copper), and then leave it to cool at room temperature.

The presence of a powder coating on the washer is noted in the product labeling. For example, the alphanumeric designation P29 shows that the washer went through the galvanizing and passivation processes, and P34 - only passivation.

Also, other features of the washers are indicated in the product labeling in the following order:

- execution option;

- fastener thread diameter;

- product thickness;

- conventional designation of the material;

- material grade;

- type of coverage;

- coating thickness;

- GOST.

In addition, in the event that the state standard provides for various accuracy classes for a given type of product, then the letter designation of this parameter is indicated at the very beginning of the marking before the version of the element.

Copper washers UGMK-OTSM

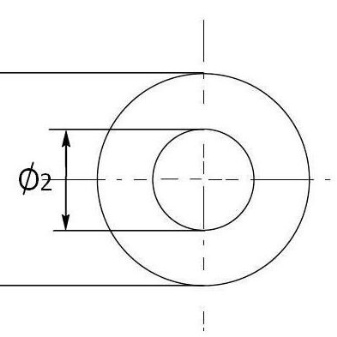

Washers UGMK-OCM are made of copper GOST 1173. Manufactured in Kirov at the Kirov OCM plant. The outer diameter of the products is 12-56 mm, the inner diameter is 6-33 mm. Washer thickness 0.3-5mm. The cold stamping workshop produces thousands of products every month. A reliable element of fasteners produced by the Kirov plant has long established itself on the market.

Order the product on the website. The sales manager will contact you to clarify the details of the order.

Our company also offers cable lugs.

| Product code | Product name | Application area |

| Washers for automobiles: material - copper, GOST 1173 | ||

| 10 x 14 x 1.5 | 312482-P; 852205 fuel lines | |

| 6327 | 10 x 16 x 1.0 | KAMAZ, fuel system |

| 6302 | 10 x 16 x 1.5 | 1/02844/60-KAMAZ, regulator cover); fuel pump; fine fuel filter; |

| 11 x 19 x 1.0 | 201-1117120, YaMZ | |

| 6395 | 11 x 19 x 1.5 | 201-1117120, YaMZ |

| 6355 | 11 x 50 x 3.5 | |

| 6354 | 11 x 50 x 4.0 | |

| 6309 | 11 x 50 x 5.0 | ST142-3708771 KAMAZ starter pin disc |

| 6357 | 12 x 18 x 0.8 | |

| 6315 | 12 x 18 x 1.0 | KAMAZ, fuel system |

| 6332 | 12 x 18 x 1.5 | 1/02984 / 60KAMAZ, fuel. system, brake system |

| 6367 | 12 x 23 x 0.3 | 312472-P |

| 6306 | 12 x 32 x 2.5 | contact of the starter solenoid relay for the car "Volga" |

| 6384 | 12.5 x 20.5 x 1.5 | 312310 |

| 6379 | 14 x 19 x 1.0 | 312326, 852206 |

| 6380 | 14 x 19 x 1.5 | 312326, 852206 |

| 6316 | 14 x 20 x 1.0 | KAMAZ, fuel system |

| 6330 | 14 x 20 x 1.5 | 1/02800/60-KAMAZ, fuel and oil cleaning filter; engine power supply system; installation of an electric valve |

| 6393 | 14 x 20 x 1.7 steel | |

| 6352 | 14 x 20 x 2.0 | |

| 6348 | 14 x 20 x 3.0 | |

| 6378 | 14 x 56 x 2.0 | |

| 6353 | 14 x 56 x 3.0 | |

| 6308 | 14 x 56 x 3.5 | RS25 3708030 Starter pin disc MAZ |

| 6320 | 16 x 22 x 1.0 | KAMAZ, fuel system |

| 6329 | 16 x 22 x 1.5 | 1/02570/60-KAMAZ low pressure fuel pump 312327-P |

| 6358 | 17.5 x 21.5 x 0.3 | |

| 6321 | 18 x 24 x 1.0 | MAZ, fuel system |

| 6331 | 18 x 24 x 1.5 | 1/02599/60 KAMAZ, MAZ, fuel system |

| 6323 | 19 x 28 x 6 | eccentric car "PAZ" |

| 6342 | 20 x 26 x 1.0 | KAMAZ, fuel system |

| 6343 | 20 x 26 x 1.5 | 1/02574/60 KAMAZ, fuel system |

| 6377 | 22 x 26 x 1.0 | 309793-P, 312382-P pressure regulator washer |

| 6376 | 22 x 26 x 1.5 | 309793-P, pressure regulator washer |

| 6314 | 22 x 28 x 1.0 | KAMAZ, fuel system |

| 6328 | 22 x 28 x 1.5 | 1/02795/60 KAMAZ, fuel system; |

| 6339 | 24 x 32 x 1.0 | KAMAZ, fuel system |

| 6340 | 24 x 32 x 1.5 | 1/02645/60 KAMAZ, fuel system |

| 6337 | 26 x 32 x 1.0 | KAMAZ, fuel system |

| 6338 | 26 x 32 x 1.5 | 1/02578/60 KAMAZ, fuel system |

| 6341 | 28 x 34 x 1.0 | KAMAZ, fuel system |

| 6336 | 28 x 34 x 1.5 | 1/03033 / 60KAMAZ, fuel system |

| 6347 | 28 x 34 x 2.0 | 870625 |

| 6346 | 30 x 37.5 x 2.0 | |

| 6385 | 33 x 38.5 x 1.5 | for clutch master cylinder plug |

| 39 x 47 x 1.5 | For KAMAZ crankcase | |

| 6382 | 39 x 48 x 2.0 | |

| 6366 | 6 x 12 x 1.0 | KAMAZ, sealing; 312652 |

| 6368 | 6 x 12 x 1.5 | KAMAZ, sealing |

| 6361 | 8 x 12 x 1.0 | KAMAZ, MAZ sealing, oil tube |

| 6356 | 8 x 12 x 1.5 | KAMAZ, MAZ oil pipe; 852204, 312353 |

| 6300 | 8 x 18 x 1.5 | |

| 6344 | 9 x 15 x 0.7 | 870638 KAMAZ, MAZ injector |

| 6383 | 9.7 x 17.5 x 1.5 | 6T2-2022-1 |

| 6304 | Ring No. 1- 89x98x0.3 | cylinder liner gasket for vehicles "Moskvich" |

| 6305 | Ring number 2 - 100x110x0.3 | 66-1002024 cylinder liner gasket GAZ-53, 24 |

| 6318 | Cam 16x24x4.5 (brass) | eccentric car "UAZ", "Volga" |

| 6317 | Cam 19x28x6 (brass) | eccentric car "Gazelle" |

| 6349 | Starter jumper | ST 142-3708091 ST142B solenoid relay housing KAMAZ |

| 6303 | Plate 18x25x2.5 hole 8 | contact of the starter solenoid relay for the car "VAZ" |

| 6307 | Plate 18x28x2.7 hole 10 | contact of the starter solenoid relay "Belarus" |

How copper sealing washers are made.

The entire manufacturing process, which the sealing copper washers go through, is regulated by the norms laid down in state standards. In this case, copper of the M1M brand is used as a raw material, the composition of which corresponds to GOST 495-92. The requirements of this standard state that the material must be extremely pure, that is, contain no more than 0.1% of various impurities. In addition, the requirements for the physical properties of raw materials are also spelled out in it. For example, it should exhibit tensile strength at the level of 200-260 MPA, and also have a relative elongation of at least 36%.

One of the production stages is washer annealing. This process allows you to maximally balance the structure of the metal, that is, to remove the internal stress resulting from recrystallization. After carrying out this thermal process, copper becomes less solid, which leads to an increase in its ductility and toughness. As a result, the use of a sealing washer made of such a material makes it possible to achieve complete sealing of the connection without undue pressure on the thread of the fasteners.

Copper sealing washer production

To obtain the washers, a cold-rolled sheet of the M2 grade is used. In the process of stamping, blanks are obtained, which are subsequently processed by tumbling. The operation is required in order to remove chips and burrs. Copper sealing washers are available in a wide variety of diameters, not just standard sizes. If the batch is large, then wholesale prices work. Copper washers are more flexible than carbon steel or stainless steel. During operation, the engine, for example, experiences various temperature differences

In doing so, it is important that the parts retain the required flexibility. The copper sealing washer is perfect for this task.

In almost any unit today there is such an element as a copper washer. Washers are used in ordinary cars, in agricultural machines, as well as in special construction equipment. They are irreplaceable in many components of assemblies and mechanisms.

Copper parts are highly resistant to corrosive processes. The temperature regime of copper is about 300 degrees Celsius. Aluminum has a design temperature range of 200 degrees. Due to their corrosion resistance, copper washers are widely used in mechanisms that operate in aggressive environments.

For the manufacture of copper washers, special state regulations are provided, the technological process is strictly regulated.First of all, the purity of the rental should be maximum. The presence of impurities in the range of 0.1% is possible. As for the relative elongation index, it should not be less than 36%.

One of the most important technological operations is the firing of copper products. Firing allows you to make the structure of the metal homogeneous, thanks to firing, it is possible to get rid of internal stress. After the firing process, the toughness and flexibility of the copper increase, while the hardness of the metal decreases. After firing, the copper washer can be used as a sealed element. The firing process involves heating the copper piece to 600 degrees Celsius. After such heat treatment, the oxide film is destroyed, it is formed in the process of manufacturing the blanks. The scale is removed by passivation. Making copper washers requires special equipment.

Overall assessment of the article: Posted by: 2020.06.08

Copper Washers for Automotive

Copper washers are designed to work where other material will fail. Copper does not oxidize, is resistant to corrosion, does not deform at high temperatures and temperature extremes, and withstands vibration. Therefore, copper washers are used in the automotive industry. The fuel and braking system, clutch control cylinder, crankcase and other parts of automotive technology are constantly influenced by moisture and pressure.

Basically, copper washers are used as spare parts for fuel equipment and when assembling, repairing gearboxes of agricultural machinery, trucks, and special equipment.

When assembling cars of the KAMAZ, VAZ, MAZ and other brands, copper washers are irreplaceable. The specific purpose determines the diameter and thickness of the product.