How to drill a hole for the confirmation

The confirmation is screwed into a previously prepared hole, so the question of how to drill such a hole is quite relevant. This will require the following tools and materials:

- screwdriver or electric drill;

- a bit of the appropriate size;

- drill for confirmation;

- a measuring tool, which can be used as a ruler (or construction tape);

- pencil;

- awl.

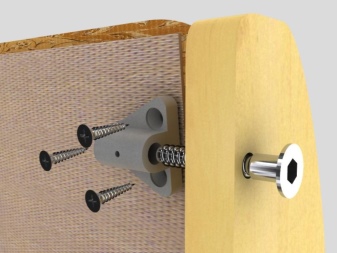

To facilitate marking and maintaining a strictly perpendicular position of the drill, use a template for drilling holes for confirmation

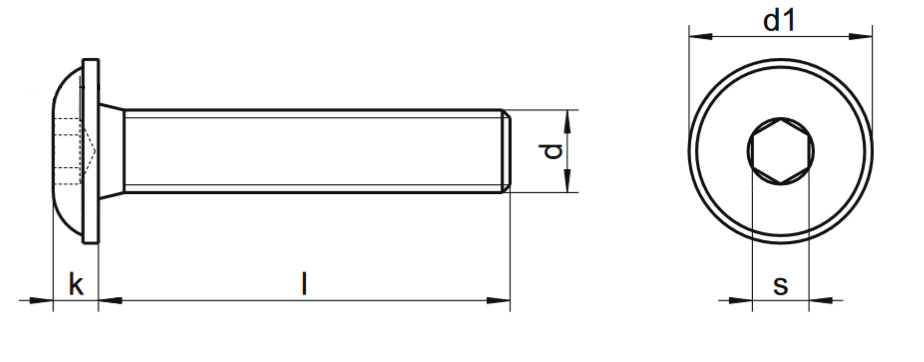

Hole dimensions for Euro screws

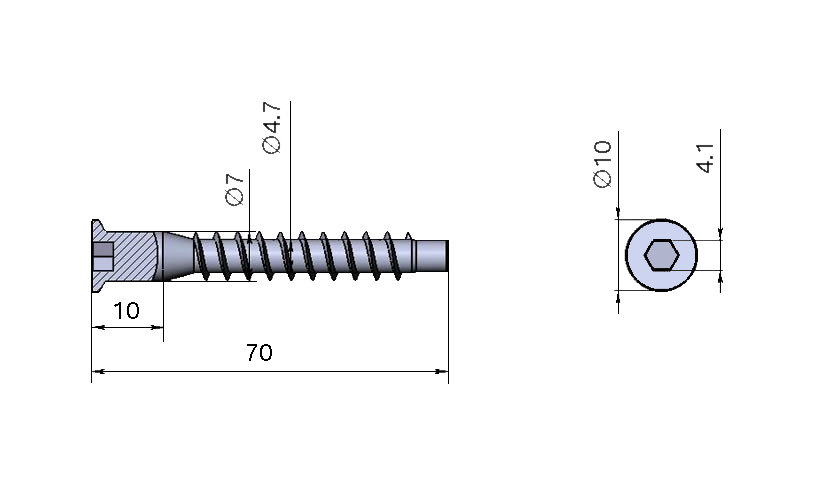

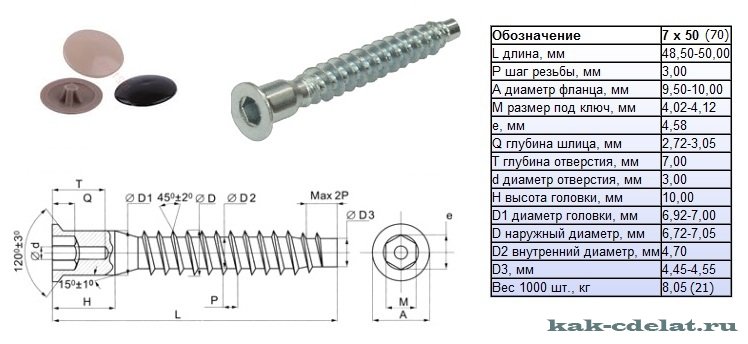

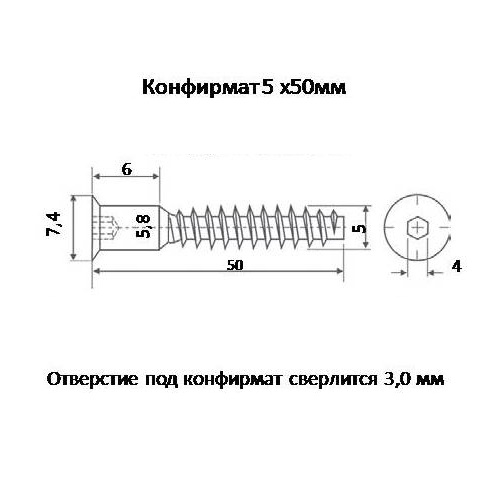

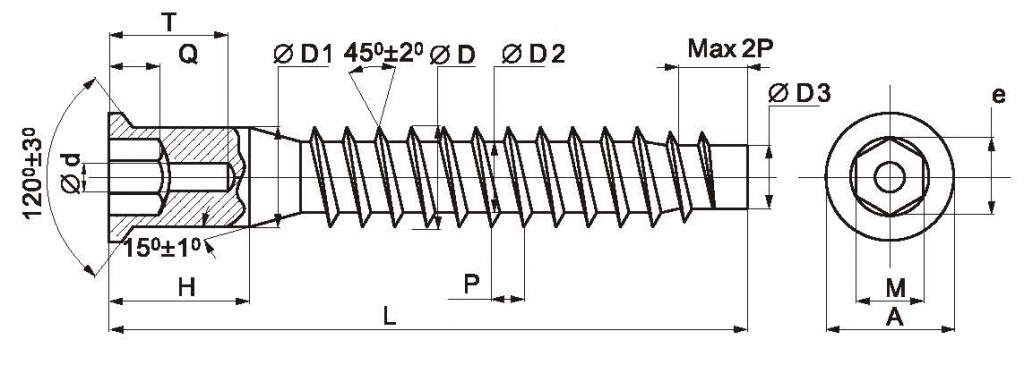

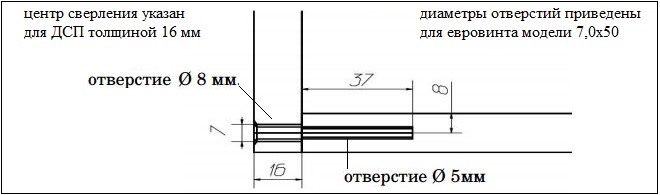

For the assembly of furniture, Euroscrews are usually used, the dimensions of which are 6.4x50 mm. To make holes for such a confirmation, the outer thread diameter of which is 6.4 mm, and the cross-sectional dimension of the screw body is 4.4 mm, a drill with a diameter of 4.5–5 mm is used. The holes for this type of confirmation must be drilled to a depth of at least 50 mm. If the hole diameter is greater than the specified value, then the Euro screw simply will not hold, if less, it can break the furniture element into which it is screwed.

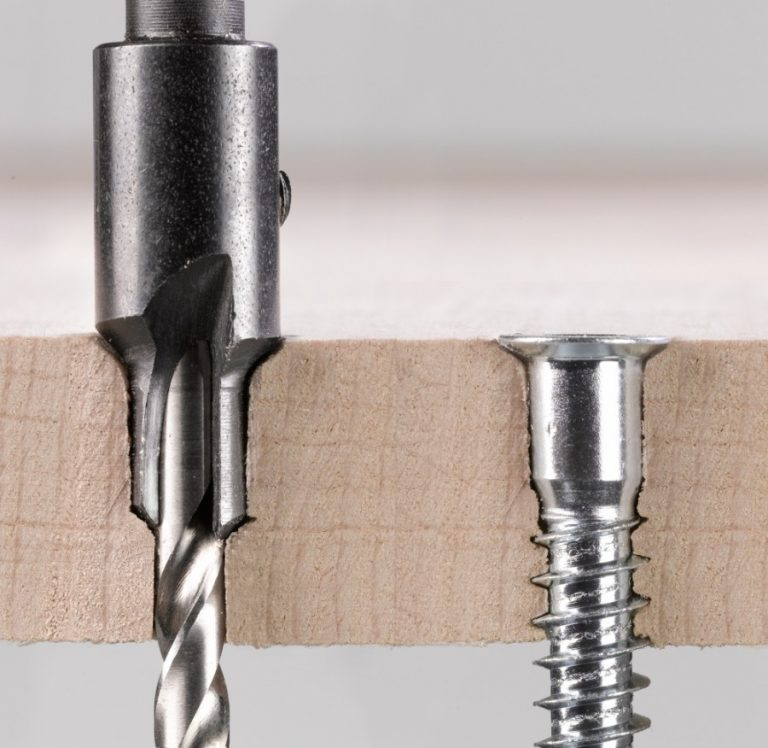

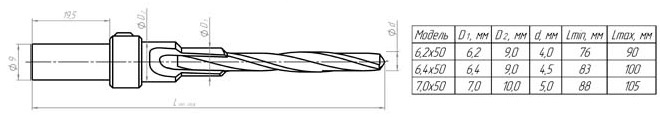

The stepped drill is selected based on the dimensions of a specific model of Euro screw

The drill, with which the holes for the confirmation are made, must be equipped with a special working head. On the one hand, it prepares an enlarged hole for the screw neck, on the other hand, it countersinks the place where its head will be placed. A conventional drill can be used to place the confirmation, but in this case it is necessary to prepare places for the neck of the fastener and its head.

Drilling location marking

The reliability and quality of the connection made using confirmations largely depend on the accuracy of the marking of future holes for them. On the element that will be superimposed on the end of another element of the furniture structure, two types of markings are made:

- drilling depth (5–10 cm);

- the center of the future hole (if the thickness of the part to be joined is 16 mm, it should be at a distance of 8 mm from the edge of the plate).

Drilling pattern for Euro screws

To mark the drilling points as accurately as possible, you can use the following simple technique: in the superimposed part, after preliminary marking, a through hole is made through which, by attaching the first part to the second, a rotating drill marks the location of the second hole for the euroscrew.

Making holes

In order to make the holes for the placement of confirmations as efficiently as possible, it is advisable to follow the recommendations below.

- Before drilling the part, it is necessary to put a piece of unnecessary chipboard under it: this will avoid the appearance of chips at the exit of the hole being created.

- The formation of places for the neck and head of the confirmat in an already made hole can be done by holding the workpiece on the weight.

- When drilling both in the layer of the part and in its end face, the drill is placed strictly perpendicularly. This will allow you to get a high-quality result and not damage the part.

- When drilling two parts at the same time, they must be securely fixed in the desired position, for which you can use clamps and other clamping devices. This is the most accurate and fastest way to create confirmation holes.

- When drilling holes for dowels, it is advisable to equip the used tool with a depth stop, which will allow not to spoil the workpieces by drilling them through.

Peculiarities

Furniture fasteners are designed to connect furniture elements. The use of this product helps to reduce production costs, because more complicated types of clamps (thorn-groove or the so-called dovetail) will cost more. Furniture screws will also allow you to forget about the glue fastening of furniture parts. This means that the closet or bed can be disassembled, for example, for moving, but when fixed with glue, this is virtually impossible.

But screw fastening, if it suddenly remains unclaimed for its first purpose, can be useful in solving other problems. And it's not even about homemade shelves on the wall, where such fasteners are logical. In construction, in the country, in the garage, furniture screws can also be useful.

Installation rules

For many who first encounter confirmations, a natural question arises regarding which holes to drill for the used Euro screw and how this procedure is generally performed.

Problems with how to drill holes, if you have already worked with a drill and imagine the principle of its operation, should not arise.

Before installing the confirmation in the furniture case, it is required to make the appropriate markings. To apply it, you will need a jig or a template. With their help, you can significantly speed up work, as well as achieve a high level of accuracy. If you are doing simple markup, you will not need a conductor (template).

For the correct installation of the confirmation, it is recommended to find out in advance about the material of the furniture itself, as well as about the design features of the euro screw. A total of 3 holes are needed:

A drill of the corresponding diameter is used for each hole. It is the time it takes to create several holes that make you spend much more time assembling furniture.

But there is a solution. It is presented in the form of a special drill, which is intended specifically for confirms. Finding it in Leroy Merlin or in any other furniture accessories store will not be difficult. The peculiarity of the special drill is that it allows you to prepare 3 different holes at once in one go. This is due to the design of the drill itself.

Drilling and installation

Step by step we will consider the procedure for drilling a hole with the subsequent installation of a confirmation in it.

To assemble furniture using Euro screws, you need to prepare special holes. The process involves the following actions:

- First, a hole is drilled for the screed (confirmation). Drills with a diameter of 4 to 7 millimeters are often used here;

- Due to a stepped cutter or just a special drill for a confirmation, it is possible to significantly facilitate the procedure;

- The cutter is fixed to the drill. This makes it possible to correctly form a hole in two components at the same time;

- For the threaded part of the confirmation, the diameter should be 5 millimeters, and the diameter of the hole for the head itself is already 7 millimeters;

- On the first furniture element, a through-type hole is made, since the smooth part of the special head and the hat itself will be located there;

- In the second part, a blind hole is made, where the internal thread is formed by drilling the threaded part of the Euro screw in the end part;

- To ensure the most accurate connection, furniture elements can be fixed using machines, furniture vices and other devices. This prevents possible shifts.

When drilling, try to use a drill or screwdriver that can rotate at the highest adjustable speed possible. This will ensure the creation of the most accurate, even and quality holes.

It is difficult to imagine the assembly of modern cabinet furniture without the use of confirmations.This is the most modern type of hardware that allows you to significantly speed up and simplify the furniture assembly process.

The use of confirmations allows you to abandon corners, screws and other fasteners that do not have the most attractive appearance, and are also inferior to the Euro screw in terms of reliability.

Confirmation is not just a whim or a fashion. This is a truly versatile and effective solution in furniture production. And we are in many ways lucky that now we have the opportunity to assemble furniture with the help of such fasteners.

What do you think about confirmations and have you had to work with them? Who assembled ready-made furniture and used such fasteners? And who had to make the holes for the confirmation himself? Share your experience and your opinion.

Thank you all for your attention! Subscribe, leave comments and ask relevant questions!

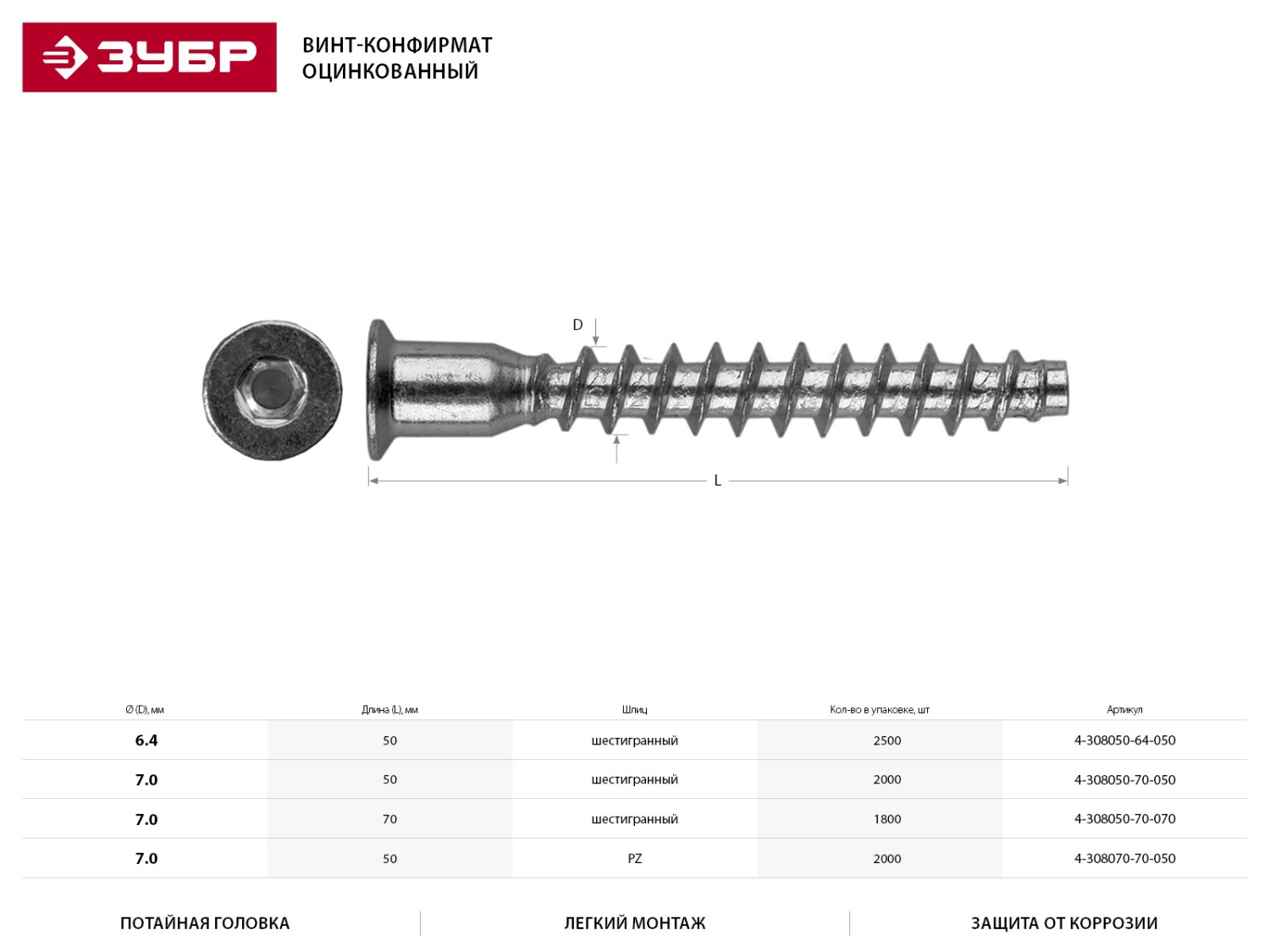

Used coatings

Furniture fittings are used in the vast majority of cases indoors, which protects it from the harmful effects of the environment. However, all metal elements made of corroded steel are subject to a special treatment:

- Galvanizing gives metal fasteners higher functional and decorative qualities. In most cases, this is a white, matte finish, less often with a golden tint;

- Electroplated brass plating. In contrast to zinc plating, this coating provides a more attractive appearance, which is achieved by adding copper to the coating alloy.

The above technologies for applying zinc and copper alloys to fasteners are designed to ensure higher performance and decorative qualities. Screw elements made of aluminum are almost never covered with protective compounds, which is due to the properties of the material from which they are made.

Galvanized

Galvanized

Brass

Brass

Scope of application

As the name suggests, the main purpose of this fastener is furniture production. Naturally, the application is not limited to this, and screw fastening is used in many sectors of the national economy, as well as for solving everyday problems. Depending on the size and design, the following options for using this fastener can be distinguished:

- Connection of laminated chipboard panels during the assembly of cabinet furniture;

- Assembly of frames in the process of making beds, sofas, armchairs and other upholstered furniture;

- Interfacing of solid wood parts in joinery and construction.

Some types of screws have a rather narrow scope. For example, shelf supports with a lock are designed exclusively for holding shelves. At the same time, no wardrobe or bedside table can do without such fasteners as the confirmat. And the use of bolts, in addition to their main purpose, is common in areas that are quite far from the furniture industry.

Applications

Countertops and sectional walls, cabinet and sofa parts, tables, dressers and children's complexes - this is the main area of demand for furniture screws. They are made primarily for assembling furniture, for holding hinges and fittings, for attaching handles and the like.

Such fasteners allow:

- connect chipboard sheets;

- collect furniture frames;

- fix bulky wood elements.

There are fasteners that cannot do more than one task. So, it is unlikely that shelf holders can be used somewhere else (well, except that the creative of the master will find another area of application for them).

Since today the uniqueization of the interior design of housing, the simplicity of solutions, the introduction of vintage elements, Soviet samples and homemade furniture into the interior are actively developed and supported, screws will help bring these ideas to a reasonable embodiment.

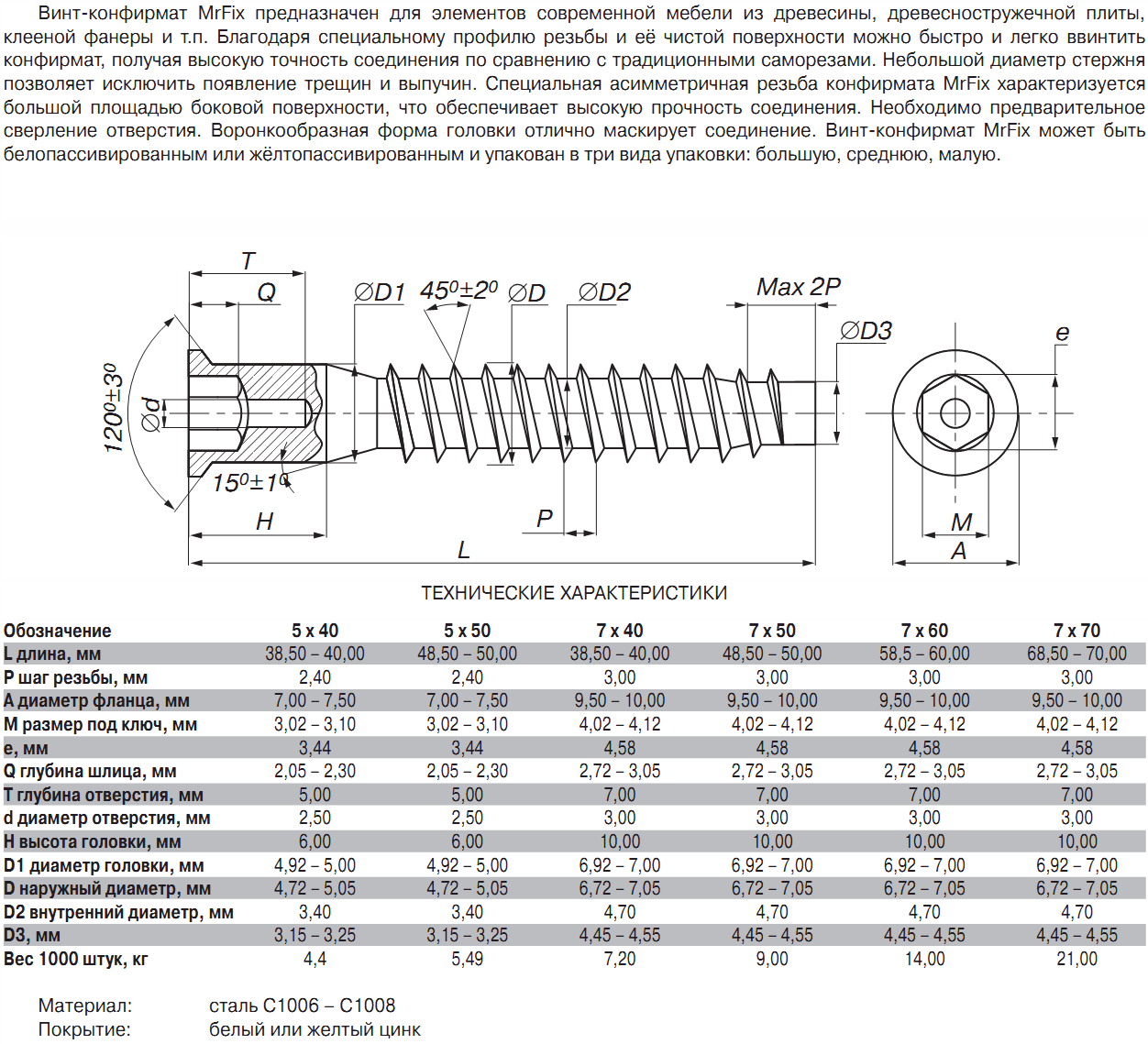

Dimensions (edit)

It is easier in this sense, when choosing screws, to be guided by the table.There are such columns as M4, M5, M6, M8, M6x30, various parameters like 8x35 and others. M is an indicator of the thread, then in the table there are the minimum and maximum values for this indicator, as well as the nominal dimensions.

If you don't feel like looking at the table, here are a couple of examples:

- the conical coupler is universal in its dimensions - 44 mm length and 6 mm diameter;

- the thickness of the confirmation is 5, 6.3 and 7 mm, and the length is from 40 to 70 mm;

- the length of the screw tie is 34 mm, the barrel diameter is 10 mm, the diameter of the screw part is 8 mm;

- furniture fixtures with a square-shaped headrest reach a maximum length of 150 mm, a diameter of 6 or 8 mm.

In building markets, furniture fasteners are sold in a separate block, where all options and sizes are divided into sections. A consultant will help you navigate the range.

Shelf supports

There are a huge number of types of shelf supports. However, they can be divided into two groups: chipboard shelf supports and glass shelf supports. In turn, each of these groups can be divided into two types: shelf supports with and without fixation.

The shelf support for laminated chipboard consists of 2 parts: a rod and a shelf support.

Increase

Fig. 14.

The screw is installed into the wall of the cabinet, and the shelf support into the body of the shelf. To mount the shelf support, it is necessary to drill holes in the shelf and in the cabinet wall. For most shelf supports, the hole sizes are standardized, they are shown in the figure below. However, when installing the shelf support, you should carefully look at the instructions so that there is no error.

Increase

Fig. 15.

It should be noted that the shelf supports for laminated chipboard are available with or without fixation. The fixed shelf support has an eccentric mechanism, thanks to which the shelf will be firmly connected to the cabinet wall. A shelf holder with fixation has one more advantage, shelf supports of this type play the role of additional reinforcement of the furniture structure.

Increase

Fig. 16.

Glass shelf supports have a simpler design. They are fixed only to the cabinet walls with a self-tapping screw.

Increase

Fig. 17.

Shelf supports for glass without fixing are a rod or corner. Shelf supports with fixing have a special screw with which the glass is firmly fixed and cannot accidentally fall out.

Increase

Fig. 18.

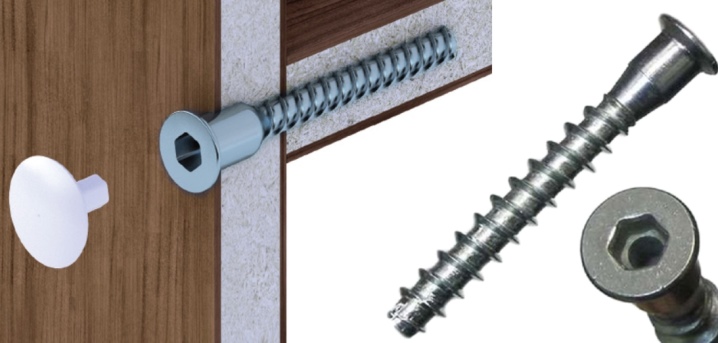

Confirmation

The most common type of fastener is the confirmation. It is also the easiest to use. With its help, it is easier and faster to assemble furniture than using other types of furniture screed. Especially if during assembly you have to drill holes for fasteners yourself. With the help of a confirmation, two parts are connected at an angle of 90 degrees.

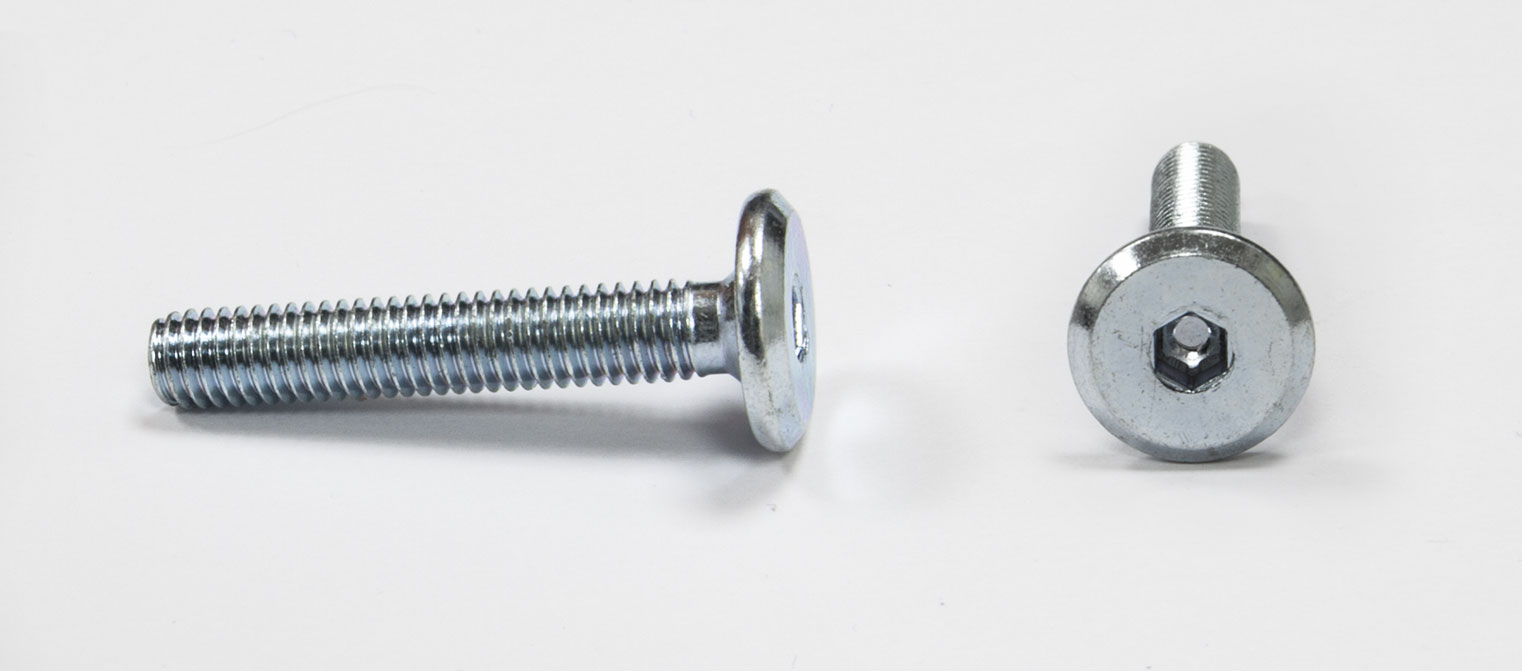

Increase

Fig. 1.

Fig. 1.

In order to pull off the two parts, you need to drill two holes. One is in one part, with a diameter equal to the diameter of the confirmation head, the other, at the end of the second part, of a smaller diameter equal to the diameter of the threaded part.

As a rule, drills with a diameter of 6 and 5 mm are used for this, respectively. However, there is a combo drill available for simultaneous drilling of holes. It is very convenient. There is no need to constantly rearrange the drills or use two drills at the same time.

Increase

Fig. 2.

Confirmate is a universal fastener, but it has some drawbacks and application features.

Confirmate should be applied simultaneously with the use of dowels. A dowel is a wooden rod with a diameter of 6-8 mm and a length of 20-30 mm (pictured below, next to the confirmation). The dowel acts as a guide and does not allow parts to move during tightening.

Increase

Fig. 3.

Despite the fact that furniture assembled with the use of Confiramate can be assembled or disassembled, furniture made of laminated chipboard does not tolerate this very well. As a rule, after one disassembly, the furniture screed already does not hold well.

Wrap the confirmat carefully. The best option by hand or with a screwdriver at low speed

Otherwise, the confirmation thread turns into a drill, which breaks the hole.

Increase

Fig. 4.

In order to drown the hat into the body of the piece of furniture, you should use a key and do it carefully, otherwise there is a possibility of thread breaking. Sometimes it is necessary to pre-make a ciconing

Confirmation refers to "visible" fasteners. Those. unlike other types of fasteners, it remains visible, so it is necessary to use special plugs or stickers to hide the fasteners.

Increase

Fig. 5.

Increase

Fig. 6.

Fig. 6.

Applications

The only and main purpose of hardware for furniture is to connect elements of a prefabricated structure. But hardware of smaller sizes is used to assemble decorative fittings for the purpose of fastening for the handle, and they also act as a tie for assembling and tightly connecting the body parts of furniture to each other.

Despite the fact that furniture screeds are inferior in metal strength to construction hardware, their fastening potential is quite high.

In modern furniture production, hardware is used for the following products:

- for the manufacture of sofas, kitchen cabinets, wardrobes and cupboards, countertops, dining tables, dressers and armchairs, beds and other items;

- to carry out restoration work in case of severe wear of furniture fittings and fasteners;

- for the construction of garden gazebos, awnings, as well as for the manufacture of wooden stairs located inside the house;

- in all other cases, when the assembly assumes the presence of a safe semicircular bolt head - in the manufacture of pointers, lightweight structures, in the manufacture of accessories, door locks, and so on.

When purchasing new furniture, few of us pay attention to what bolts the fasteners are made with.

But for those who are engaged in furniture production, it is very important to be able to understand what types of furniture fasteners exist, how to choose the right type and size

Usage

Due to the fact that the most common option for furniture screws is precisely the confirmat, on its example you can see how to tighten the screw correctly.

Let's consider the algorithm of work.

- To pull together 2 parts, you will have to drill two holes, respectively. One is in the first part, and it will be commensurate with the diameter of the screw head, the second is in the end part of the second part, and its diameter is commensurate with the threaded part.

- Usually drills of 5 and 6 mm are taken for this action. But you can also find a combination drill that can drill holes at once. This is more comfortable for the assembler, since there is no need to rearrange the drills.

- You need to wrap the confirmat delicately. It's great if you can do it manually or, if you still use a screwdriver, put it at low speed. Otherwise, the screw thread will turn into a drill that breaks the hole.

The following video talks about furniture joining.

Features and Benefits

In fact, the confirmations are the same screws, but they have a more massive working body. The thread has a wide threaded pitch, the head is longer, and a secret special design is hidden in the head.

Confirmates can use different splines, which allows different tools to be used. In one situation, you will need a bit for the confirmation, in another a regular curly screwdriver, in the third a hexagon or a tetrahedron. If we compare with other hardware, then here we have a round section and a straight cut.

The most practical option is the use of confirmations adapted for hexagons. They are the most reliable and easy to use. When the parts are connected together, you can use a hex bit, screwdriver or special wrench for additional tightening.

Compared to the same screwdriver fasteners, they cannot provide the same level of strength.Therefore, furniture connected by confirmations turns out to be more stable, does not loosen over time.

All confirmations can be used:

- for an array;

- Chipboard;

- for wood;

- plywood.

The Euro screw can be used to replace the traditional corners. This is due to the property of the confirmat to withstand bending loads. Therefore, confirmations have become widespread not only as fastening accessories, but also as frame-forming elements.

To mask the fasteners, plastic plugs or special stickers are used. They are made to match the color of the furniture itself or in a similar shade. This ensures the creation of a finished look for furniture products, since confirmations are invisible against the general background.