Types and types of screws

By the type of thread, self-tapping screws are: with a universal thread, with a rare thread pitch and frequent. Self-tapping screws with a frequent thread pitch are intended for screwing into metal sheets. For example, if you need to hang a heavy painting on a drywall wall. Find with a powerful magnet the place where the profile is, to which the sheets are screwed, and screw the self-tapping screw into the profile through the drywall. If a self-tapping screw without a drill at the end, then a hole must first be drilled in the metal with a diameter equal to the inner diameter of the self-tapping thread.

For fastening sheets of roofing iron, there are special galvanized self-tapping screws of two sizes: 4.8 × 16 and 4.8 × 19 with a hex head. A type of self-tapping screws with a rare thread pitch are designed specifically for screwing into soft materials, such as plastic, plaster, asbestos, wooden planks and the like. Universal - designed for screwing into any materials. Of course, it is better to use specially designed ones, but they will reliably hold any.

| List of popular types of self-tapping screws, their purpose and sizes | ||||

|---|---|---|---|---|

| The appearance of the self-tapping screw | Self-tapping thread pitch | Scope of self-tapping screws | Self-tapping screw diameter, mm | A number of lengths of self-tapping screws, mm |

| Average | Universal self-tapping screws, designed for all types of fastening, are the most popular | 3,0; 3,5; 4,0; 4,5; 5,0; 6,0 | 12; 16; 20; 25; 30; 35: 40; 45; 50; 60; 70; 80; 90; 100: 120; 140; 160; 180; 200; 220 | |

| Frequent, two-way thread | Self-tapping screws for fastening to metal sheets up to 0.9 mm thick without a dowel, preliminary drilling of the hole is required. self-tapping screws come with a drill on the tip, but they are more expensive | |||

| Rare | Self-tapping screws for fastening to soft materials without a dowel - soft types of wood, plastic, gypsum, asbestos, and the like | 3,5; 4,0; 4,5; 5,0 | 16; 20; 25; 30; 35: 40; 45; 50; 55; 60; 70; 75; 90; 100: 125; 150 | |

| Medium, herringbone profile | Self-tapping screws for fastening to concrete or brick walls by driving into a dowel | 3,0; 3,5; 4,0; 4,5; 5,0; 6,0; 8,0 | 12; 16; 20; 25; 30; 35: 40; 45; 50; 60; 70; 80; 90; 100: 120; 140; 160; 180; 200 | |

| Asymmetric | Self-tapping screws for fastening elements of modern furniture made of wood, chipboard, plywood, etc. Pre-drilled hole with a diameter of 4.5 or 7 mm respectively | 5,0; 7,5 | 40; 50; 60; 70 | |

| Variable notched | Self-tapping screws for fastening to concrete or brick walls without a dowel (pins), screwed into a hole, 15 mm deep more than the screwed-in length of a self-tapping screw, with a diameter of 6 mm | 7,5 | 70; 90; 110: 130; 150; 180; 200 |

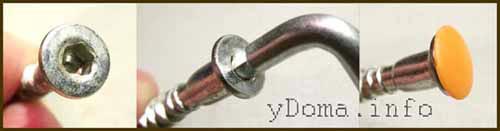

A separate line worth noting is a self-tapping screw - a confirmation specially created for the manufacture of furniture from wood and chipboard. The self-tapping screw of the confirmat type, with a clean surface and a large area of the lateral surface of the thread, allows you to obtain a high-strength and accurate connection of elements. The most popular standard size of the confirmat is 7 × 50. Before screwing the confirmation, drilling a hole with a diameter of 4.5 or 7 mm, respectively, is required. The confirmation head is made for a hex key.

To hide the head of a twisted self-tapping screw, the confirmat produces decorative plastic buttons - plugs of any color. The plug is tightly inserted with a protrusion into the hexagonal hole of the confirmation head and disguises it to match the color of the furniture.

It should be noted and self-tapping screws for concrete, which are screwed without a dowel, directly into the drilled hole. When screwing into porous material and with cavities with a perforator, it is not allowed to drill holes. to make it easier to screw, a little of any machine oil should be injected into the hole before screwing. They are used for fastening "forever". I do not use them, since it is difficult to tighten, and unscrewing is even more difficult.

There are also self-tapping screws, which have a herringbone thread profile. They are hammered into the hole simultaneously with the dowel with a hammer and are also designed to be fastened "forever".Their use is justified, for example, when attaching a baguette for a stretch ceiling or when installing frames of plastic windows. Their advantage is quick installation.

Classification of mesites by wood by color

Manufacturers produce many types of fasteners used to work with wooden blanks. The main characteristic feature of such products is the wide thread. However, there are self-tapping screws with fine threads, and most often they are used to work with hardwood.

Depending on the color, hardware are:

- Black, used primarily for rough work. This is mainly due to the fact that these products have a rather low resistance to corrosion processes, and at high ambient humidity, rust forms rather quickly on them;

- Yellow and white. Products of this group are plated with brass or zinc, which contributes to an increase in the service life of the fasteners. Both options are quite expensive.

Rules for choosing the length of the self-tapping screw

When choosing hardware for working with wooden parts, you must follow a simple rule. The self-tapping screw must enter the main workpiece to a depth of 1/3 of the thickness of the attached part. If two wooden blanks are additionally fixed with corner elements, in this case, the hardware should go to a depth of up to 1/4 of the part to be attached.

Based on this, certain conclusions can be drawn:

- Self-tapping screws up to 35 mm long are ideal for fastening plasterboard structures to a wooden base, and in addition, they are perfect for working with wooden frame cladding and OSB;

- The hardware, the length of which is 51 mm, is ideal for working on a two-layer sheathing of a wooden frame with gypsum plasterboards. It is recommended to carry out such an operation in those places where there is increased permeability;

- If hardware is used with a length of 75 mm or more, then you must first drill a small hole in the wooden base. Otherwise, microcracks may appear and the fibers will be damaged;

- If there is a need to use self-tapping screws with a length of 100 mm or more, then additional difficulties may arise. And therefore, to avoid them, it is enough to drop a little machine oil into the pre-drilled hole.

The Stroy Plus company directly cooperates with leading manufacturers of fasteners, and therefore guarantees that all products presented in the catalog fully comply with the requirements of GOST. By contacting us, you will get the opportunity to purchase self-tapping screws at affordable prices. And if in the process of work you have any questions, our managers are ready to give you recommendations. Call us, or write, and we will help you not only save money, but also save your time.

This is only half the battle. To complete the task of fastening, you need to wrap more screws, directly into the drilled hole or into the dowels.

Self-tapping screw - a type of fastener, which is a rod with a sharp thread and a head designed to transmit torque when screwing with simultaneous threading in the connected elements.

The range of self-tapping screws for wall mounting tends to endlessness. The task of selecting hardware (from the phrase "metal products") for fixing to the wall seems impossible. But if you put everything on the shelves, it becomes clear which self-tapping screw is required for each specific case.

Self-tapping screws are made of brass, carbon and stainless steel (the metal contains more than 13% chromium). The most widely used self-tapping screws are made of carbon steel with a protective coating. They are the cheapest.

Carbon steel self-tapping screws are available with the following protective coatings. Oxidized, black - for mounting in rooms with normal humidity.Galvanized silver color - for indoor and outdoor use. Galvanized, yellow - for indoor and outdoor use. They have a golden decorative appearance. Looks good on gold-plated door locks and hinges.

How to prepare for installation?

Installing hinges is a simple job and does not require much effort and time, but provided that a person has all the necessary tools at hand, and also has certain work skills. For beginners in this regard, the task of installing the hinge can be very difficult. You can't just screw it on.

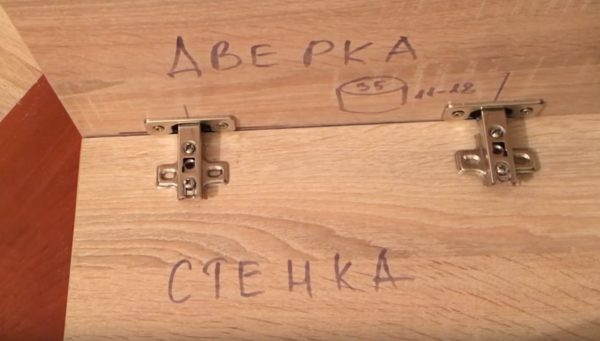

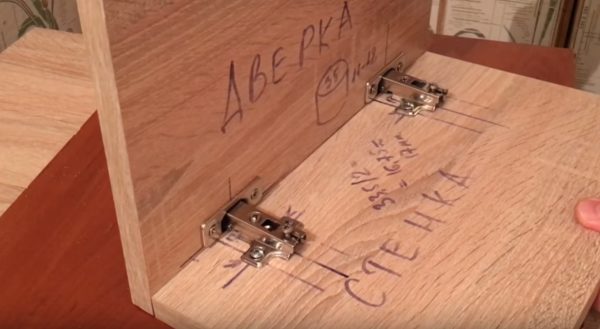

So, the most important tool that you need is a Forstner drill. It has a special working part with the same diameter as the hinge bowl (35 or 26 mm). With this drill, special holes need to be made in a clearly marked place. The hinge bowl will be embedded in it, and the structure will be fastened due to screws screwed into special ears.

Forstner drill

Forstner drill price

Forstner drill

Also, to install the hinges, you will need:

- screwdriver;

- ruler and square;

- simple pencil;

- drill with various attachments;

- level;

- screws and screws.

Cordless screwdriver

2.

The process of deformation of wood under the influence of force when tightening a self-tapping screw is very complex. Wood is a heterogeneous material and the strength of the wood is highly dependent on the point of application of the load, the presence of knots, the type of wood, etc. The minimum strength of wood is in the places of abutment of the fibers, therefore, the tip of the self-tapping screw usually falls between the wood fibers, and it is almost impossible to tighten the self-tapping screw, as well as to drill a hole in the wood with an accuracy of tenths of a millimeter. Fortunately, there is usually no such need. For domestic purposes, an error of 0.5-1.5 mm is quite normal.

Fastener Categories

If half a century ago the main elements for assembling the component parts of furniture were wooden dowels, and the installation of various specimens at the site of operation was carried out using nails or screws, today the range of accessories for connecting individual parts and elements of furniture has expanded significantly.

Modern fasteners and fittings can be divided into several categories, including both highly specialized products and universal fittings:

- threaded furniture fasteners represent a classic combination of two parts - a screw-nut, which are sometimes supplemented with washers to reduce specific loads;

- Confirmation (Euro screw) is a screw fastener, the thread of which is similar to screws or self-tapping screws, which allows you to significantly speed up the assembly process;

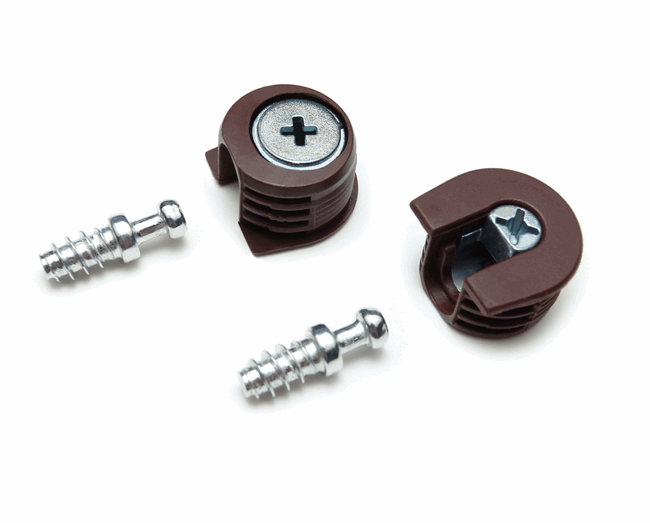

- eccentric ties are used to speed up the adjustment and in cases where it is required to avoid the visibility of individual fastening elements;

- traditional dowels and corners, which have long been used to connect individual furniture panels, have also not lost their popularity.

mebelnye-ugolki

mebelnye-ugolki

mebelnyj-jekscentrik

mebelnyj-jekscentrik

konfirmat

konfirmat

rezbovoy-mebelnyiy-krepezh

rezbovoy-mebelnyiy-krepezh

The most common types of furniture fasteners

Consider the most common groups of connecting and fastening accessories for furniture, the features of its installation and operation.

Pan head or decorative head screws and head or square head bolts are the main examples used to tie individual panels of frame furniture. Thanks to the fixing bar or square head, the bolt (screw) is fixed in the hole of the chipboard, which prevents it from turning. Due to this design feature, the assembler has the ability to tighten the nut without additional fixing of the screw.

Universal screws with a countersunk or semi-countersunk head have slots of various shapes (cross, with an internal hexagon, straight slot, and others) and are intended for fastening individual assembly parts inside furniture structures. They are used to:

- installation of facades, back walls,

- fastening guides to drawers;

- installation of mounting angles;

- fastening of any furniture fittings, from roller supports, to locks and drawer handles;

- production of combined parts - for example, tabletops made of two sheets of MDF boards.

On a note!

When applying universal screws are used or screwdrivers with replaceable bits or screwdriver sets with replaceable tips.

Confirmates (Euro screws) in modern furniture production are the most demanded type of fastening and fixing devices. This type is used for fastening any parts made of chipboard or MDF panels.

Before screwing in the euro screws, holes are pre-drilled in the details using a special confirmation drill, the diameter of which depends on the diameter of the fixing element. To screw this type of fastener, either a screwdriver with special bits or screwdrivers with seed tips are used. The type of bit or bit depends on the type of slot.

Eccentrics are other fittings bearing the somewhat exotic name of rasteks and minifixes that allow you to connect and pull panels at right angles to each other. Despite the obvious advantages of this category of fasteners, their main disadvantages are:

- the need for additional milling of furniture panels, for the installation of individual fasteners;

- relatively high cost.

- high accuracy of marking and the complexity of installing individual fasteners;

On a note!

To install the individual parts of the minifix, three different types of woodworking tools will be required - one end mill and two drills of different diameters.

Furniture corners have established themselves as a reliable, easy-to-install element. Today they can be made either from metal or from special, high-strength plastic. In the industrial production of cabinet furniture, the color of the plastic of the corner is matched to the color of the furniture.

Modern furniture dowels are made of wood, plastic or metal. Their main advantages are low cost and ease of joining furniture parts together. To increase the reliability of the connection, there is a groove on the surface of the dowels.

Other types of hinges

So, all kinds of loops can be classified in different ways. So, different types are distinguished by design, by purpose, by the method of fixation and imposition. In general, there are several dozen types of furniture hinges, some are more common, some are less, but almost all are used in various options for furniture designs. In addition to the four-hinged ones, we will consider several more hinge variations that may be encountered by furniture assemblers or people who have bought new interior items and decided to assemble them on their own.

Card loop

Card loops are considered the oldest. Their progenitor is a forged hinge with a long escutcheon. Outwardly, they resemble a regular door hinge, only slightly smaller in size. The structure consists of two metal strips connected in parallel with a thin rod acting as a hinge. Now they are rarely used, but they are indispensable in the manufacture of furniture in the "retro" style.

Butterfly door hinges

Pendulum hinges or bar hinges make it possible to open the door 180 degrees. It turns out something similar to how the doors open at the entrance to the saloon in old westerns.

Bar loop

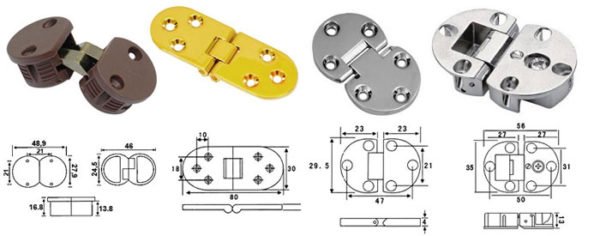

The mezzanine hinge structures are designed to hold horizontally oriented doors that will open upwards. The hinges have a spring mechanism and also allow the door to be fixed when open. They resemble the usual overhead buttonhole variations.

Top hinge MK01

Lombard designs are used for so-called hinged doors. They will be mounted from both ends of the cabinet, do not require a cut-in, but a small milling (up to 2 mm) may be required. Then the sash can be opened 180 degrees. This is the ideal folding table hinge.

Hinge for folding elements

The secretary designs are similar to the card ones described above, they have an axial hinge and plates.They make it possible to open the facade downwards and keep it in a horizontal position. They can be accompanied by a special bracket that provides a supporting function. They are usually installed in those cabinets where a bar is provided.

Secretary hinges

Blind hinges, otherwise called adit hinges, are used for doors on the side of the cabinet that is adjacent to the wall. They can be used to attach the door to the bezel.

Slit hinges

Heel products are extremely rarely used, because they are designed only for light doors. But on the other hand, they can be installed on facades with any type of opening. Installation is carried out at the bottom and top of the sash.

Furniture heel hinges

There are special hinges for glass doors. They also come in different types, but their advantage is that they can withstand a significant load, moreover, they look very beautiful.

Glass hinge

And relatively recently, hinges with 8 hinges, eight-hinges, appeared on sale. To install them, you do not need to resort to milling or cutting. This is an improved variation of the conventional 4-pivot hinge. True, it is more difficult to put them, and therefore, despite the absence of the need to carry out any preparation, such loops are rarely used.

8-hinge hinge

Size table of self-tapping screws for plywood, furniture board, fiberboard, chipboard, MDF, OSB

| L length, mm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D diameter, mm | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 70 | 80 | 90 | 100 |

| 4 | + | + | + | + | + | + | + | + | |||

| 4,5 | + | + | + | + | + | + | + | + | + | ||

| 5 | + | + | + | + | + | + | + | + | + | + | + |

Taking into account the peculiarities of the operation of wood-based materials, a table is presented below that allows you to select the required size of a self-tapping screw.

Recommendations for choosing the size of self-tapping screws for fixing wood-based materials

| Plate thickness, mm | Plate material | Self-tapping screw length, mm | Self-tapping screw diameter, mm |

|---|---|---|---|

| OSB (OSB) | |||

| 3 | pine, spruce | 30 | 4 — 4,5 |

| 6 | pine, spruce | 40 | 4 — 4,5 |

| 9 | pine, spruce | 45 | 4 — 4,5 |

| 12 | pine, spruce | 50 | 4 — 4,5 |

| 15 | pine, spruce | 55 | 4 — 4,5 |

| 18 | pine, spruce | 60 | 4 — 4,5 |

| Plywood FC, FSF, FBV, FBV-1, FBS, FBS-1A and FBS-1 | |||

| 3 | birch, pine, spruce | 30 | 4,5 |

| 6 | birch, pine, spruce | 35 | 4,5 |

| 9 | birch, pine, spruce | 40 | 4,5 |

| 12 | birch, pine, spruce | 45 | 4,5 |

| 15 | birch, pine, spruce | 50 | 4,5 |

| 18 | birch, pine, spruce | 60 | 4,5 |

| 21 | birch, pine, spruce | 70 | 4,5 |

| 24 | birch, pine, spruce | 80 | 5,0 |

| 27 | birch, pine, spruce | 70 | 5,0 |

| 30 | birch, pine, spruce | 90 | 5,0 |

| 36 | birch, pine, spruce | 100 | 5,0 |

| 40 | birch, pine, spruce | 100 | 5,0 |

| MDF, fiberboard, chipboard, furniture board | |||

| 3 | wood chips, shavings, cellulose | 30 | 4,5 |

| 6 | wood chips, shavings, cellulose | 35 | 4,5 |

| 9 | wood chips, shavings, cellulose | 40 | 4,5 |

| 12 | wood chips, shavings, cellulose | 45 | 4,5 |

| 15 | wood chips, shavings, cellulose | 50 | 4,5 |

| 18 | wood chips, shavings, cellulose | 60 | 5,0 |

| 21 | wood chips, shavings, cellulose | 70 | 5,0 |

| 24 | wood chips, shavings, cellulose | 80 | 5,0 |

| 27 | wood chips, shavings, cellulose | 80 | 5,0 |

| 30 | wood chips, shavings, cellulose | 90 | 5,0 |

| 36 | wood chips, shavings, cellulose | 100 | 5,0 |

| 40 | wood chips, shavings, cellulose | 100 | 5,0 |

When choosing self-tapping screws for plywood, OSB, chipboard, it should be borne in mind that the dimensions of the finishing material slab may vary depending on the ambient humidity, therefore the most loaded points of fixing wood-based materials are points located along the perimeter of the slab.

The number of attachment points (number of screws) is determined by the size and thickness of the slab and in most cases is at least 20 per square meter, provided the correct size of the screw is selected. In the middle of the slab, a lower density of the location of the attachment points is allowed than along the perimeter.

Self-tapping screws for plywood, OSB, chipboard and board materials

When laying between the boards, it is necessary to leave an expansion gap, which excludes their contact even when they swell.

Virtually all board materials have a density equal to or higher than that of the base. When the dimensions of the slab are changed under the influence of moisture, the fasteners (self-tapping screws) loosen to a greater extent in the base and to a lesser extent in the slab.

Therefore, when fixing board materials that do not have a transverse arrangement of layers (chipboard, fiberboard, MDF, solid wood furniture board), it is necessary to use plates of the smallest dimensions. For an open method of fastening, it is necessary to choose self-tapping screws with a threadless part equal to or greater than the thickness of the plate.

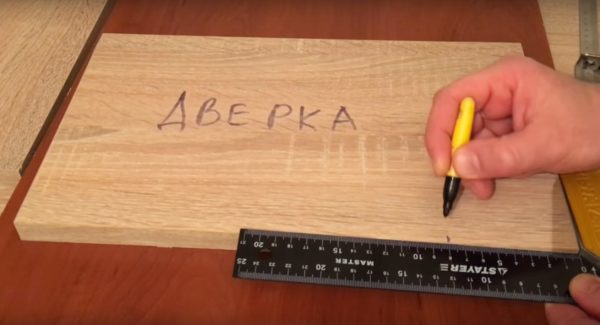

detailed instructions

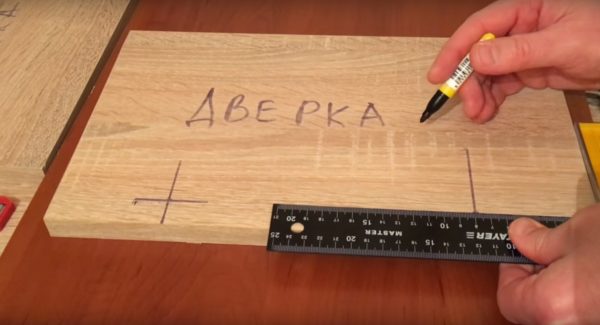

Step 1. From the upper and lower edges of the door, you need to retreat about 7-12 cm. In this case, in the instructions, the indentation is made at a distance of 8 cm. It is required to draw two lines strictly perpendicular to the edge of the door.

Indent 8 cm

Lines are drawn perpendicular to the edge

Step 2. Further from the edge of the door to the center of the place where the hole will be drilled, you need to make an indent of 22 mm. This is the standard distance. And you also need to draw lines through the marked point, perpendicular to the one drawn earlier.

Bottom distance - 2.2 cm

Perpendicular lines are drawn

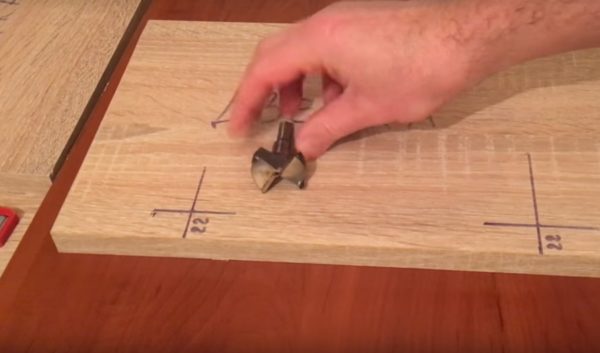

Step 3. Next, you need to take a special drill with a standard diameter - 35 mm.

Take a drill with a diameter of 35 mm

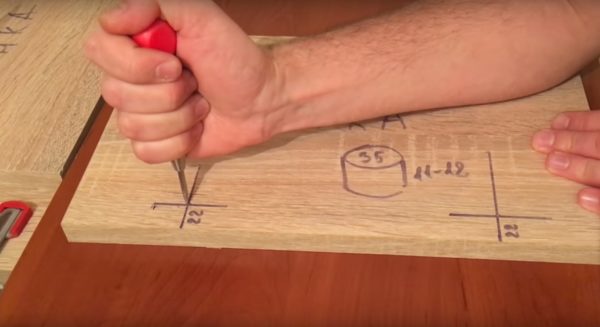

Step 4. To make drilling easier, and the drill was clearly positioned, at the intersection of the lines on the marking, you need to make small notches with an awl.

With an awl, notches are made

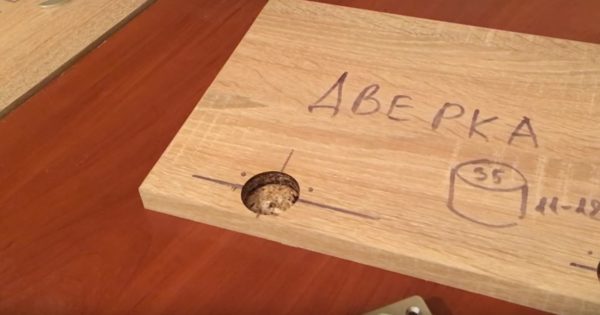

Step 5. Now you can drill the holes. You can do this with a drill, or you can use a special router.

You can start drilling holes

Prices for a linear range of milling cutters

Fraser

Result of work

Step 6. Once the holes have been drilled, you can try on the bowl of the hinge, and also, aligning the holes for the screws on the ears of the bowl along the line drawn earlier, mark where drilling will be made, but with a thin drill. Moreover, the points will turn out not on the line itself, but slightly to the side, the ears are aligned along the line.

Fitting a loop bowl

Marked for future holes

Step 7. Now, at the designated points with the help of an awl, you need to make recesses for positioning the drill.

Recesses are made to position the drill

Step 8. Next, you need to drill holes for self-tapping screws 4x16 mm in size.

Holes are drilled

Step 9. It is necessary to reattach the canopy to the door, placing the bowl in the hole, and screw it to the facade with self-tapping screws.

Fastening with self-tapping screws

Step 10. Now you can attach the door to the cabinet wall. This is done this way - first you need to attach the door to the wall, choosing the position in which it should stand.

Now you can attach the door

Step 11. When applying the markings, you need to make sure that the upper hinge screw, which will be attached to the wall, is in a position close to the door itself.

You need to carefully apply the markup

Step 12

Further, it is important, after simple measurements, to set aside 17 mm from the center line on which this part of the canopy lay

From the center line, you need to postpone 17 mm

Step 13. After that, the door must be reattached and marked with a marker through the holes in the hinge, aligning them with the lines drawn at a distance of 17 mm.

Markers are made through the holes in the loop

Step 14. Now you need to drill holes for euro screws with a drill.

Holes for Euro screws are drilled

Step 15. Next, you need to screw part of the hinge to the wall.

Part of the hinge is screwed to the wall

Step 16. Then you can attach the door to the wall

It is important to get the front part of the hinge fixed on the door onto the screw located on the part of the hinge that is fixed to the wall. Also, under the hinge that is fixed on the door, there is a screw with a "heel", which is important to get into the groove located on the other side of the hinge part fixed to the wall

This part needs to hit the screw

The door is attached to the wall

It is important to do everything in accordance with the instructions.

Another photo of the process

Step 17. To prevent the hinges from disconnecting, the extreme screws need to be tightened a little. So far, you do not need to wrap them up to the end.

The outermost screws are tightened a little

Step 18. Now you need to adjust the door. To begin with, it is worth moving it away from the cabinet wall by about 1-2 mm, you do not need to fix it tightly to it. Once the clearance has been met, the screws can be tightened.

Door adjustment

Step 19. There is another screw that will help move the door to the left or right if necessary. In this case, it did not have to be regulated.

This screw in our example did not need adjustment.

Video - Fastening the hinges

It is important to remember that after a while the hinges will have to be adjusted again - the doors can sag under their own weight. So you still need to tighten the screws at first

Sometimes you should also lubricate the hinges - then they certainly will not begin to creak or rust over time. If the furniture is in a damp room, then the service life of the awnings is greatly reduced, and this is important to take into account.

Varieties

The more demanded and popular samples used in the production, assembly, installation of furniture pieces include:

Also in the furniture industry, a number of characteristic screws are used with blunt ends, large threads adapted for chipboard, specific heads. One of these products is a galvanized steel screw that allows you to attach chipboard sheets at an angle of 90 degrees.

Universal screw

The product is presented in the form of a rod in the form of a cylinder with various types of heads and external threads. Its main task is to fasten individual assembly elements inside furniture structures. The top of this screw can be of different shapes:

- a countersunk head of the product that, after twisting, completely sinks and does not protrude above the materials to be fastened, its scope is the installation of shelves, handles, hinges, guide rails for drawers;

- the semi-countersunk head, due to the smooth transition from the rod to the thread at the moment of twisting, goes into the material, as well as the counterpart;

- a semicircular head, the horizontal plane and the inner base of the surface of the semicircular head of which, during installation, additionally creates pressure on the fastened material, increasing the strength of the structural unit, thereby eliminating its deformation.

The presence of a special thread makes it possible to easily fix the screw even in the hardest types of wood. Hardware slots can be simple and cruciform. Products with a cross recess have a number of irrefutable advantages:

- a screwdriver or drill is instantly fixed in the head;

- only one screwdriver is useful;

- the installation process in hard-to-reach places is carried out without much effort.

When using universal screws, you must arm yourself with a screwdriver, screwdrivers with replaceable nozzles. For a high-quality connection of materials, in the process of screwing in the screws, drill holes, the diameter of which will be 70% of the thickness of the hardware, and also choose the right drill.

Confirmation

These products have another name - euro screws, which in modern furniture production are considered a more popular type of fastening and fixing devices, since they are among the most reliable, inexpensive furniture joints. Such products are resistant to mechanical stress and fracture.

Confirmate is used to connect structures made of materials such as wood, laminated chipboard, plywood, chipboard. In many cases, screws with dimensions of 5x50 mm and 7x50 mm are used. In addition to fastening parts, euro screws replace the usual corner, performing a body-forming function, while withstanding all bending loads. To make cabinet furniture look aesthetically pleasing, confirmations are supplemented with plugs made of plastic. They mask the visible part of the cap to match the color of the furniture product.

|

We will help you figure out the choice of milling cutters for the home. Review of power tools for work and home. |

Distinctive features of these fasteners are coarse thread, blunt tip, cylindrical head, hexagon slot. When assembling structures, furniture screws for a hexagon do not require special skills, specialized equipment.

The screw tie is performed using a hex bit, a screwdriver, a special key, a drill. Do not use products made with a Phillips screwdriver. This technology will not allow the connecting elements to be tightly tightened. As a result, the structure will become loose.