Care Tips

If you do not take care of the material made of natural wood, over time, during operation, it can gradually lose its attractive appearance and protective properties. The processing of pine material consists in cleaning the surface of the products, and in order to extend the service life, the surface of the wood must be covered with a protective compound.

Compliance with some rules will help keep the product presentable.

- Painting the furniture board with a colorless varnish will help eliminate small irregularities in the material and hide the flaws in the sheet. This treatment protects the surface of the wood board from moisture.

- Clean the outside of the product with a soft cloth, or use a vacuum cleaner to collect dust. This condition is explained by the fact that during wet cleaning the dirt is absorbed into the pores of the wood, and over time it acquires a grayish tint.

- Even if the wooden surface is covered with a layer of varnish, water ingress on the wood is undesirable. Wipe the area with a dry cloth as soon as possible.

- To perform hygienic treatment of the surface of the furniture board, do not use brushes with stiff bristles and aggressive detergents.

- Pine furniture is not recommended to be installed in direct sunlight.

- If the furniture is accidentally stained with ink stains, you can remove them with a school eraser, but before using it, treat the contaminated area with a dry bar of soap, and then clean it with an eraser.

For information on how to properly glue wide furniture boards, see the next video.

Classes

The cost of finished pine slabs depends on their classification by grade. Determination of the grade is carried out by assessing the quality of the surface of the material. Material marking is done with letters written with a fraction. For example, the notation A / C will mean that one side of the shield is of grade A, and the other side corresponds to grade C.

Pine furniture panels can be of several classes.

C

This grade allows the presence of surface chips and cracks in the material, as well as a high content of large knots. Furniture boards of this quality are used as blanks that will be veneered or laminated. Grade C material is used for construction needs or the construction of frames that will not be visible to prying eyes.

B

The furniture board is made from connected lamella bars, which are not specially selected for color shades and texture uniformity. On the surface there may be small flaws in the form of small cracks. Knots are present in the material, but their number is small. The material is used in the manufacture of furniture frame structures. The strength and reliability of the material provides it with a long service life.

A

The trim material is selected according to the color shade and texture. There should be no significant flaws and cracks on the surface of the shield. Knots can be present only in small numbers, their size should be minimal. The material is used to create external furniture structures and external parts.

Extra

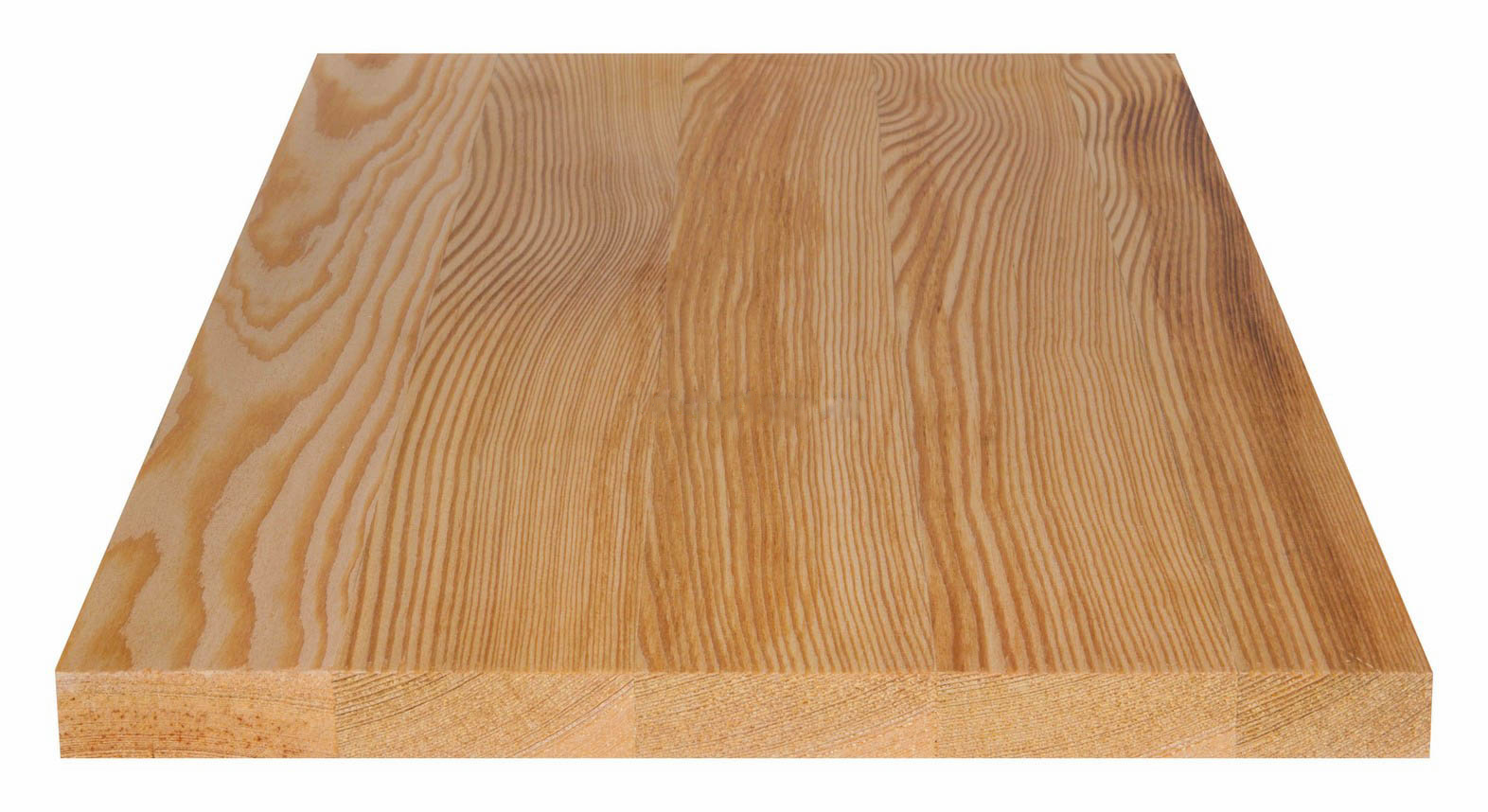

The material consists of a solid lamellar sheet, where the components are selected according to the texture pattern and color shades. Such furniture boards do not have any scratches, chips or cracks. As a rule, the composition of the web is selected without knots, it uses the best selected wood raw materials. Before being released for sale, the shield undergoes a long and careful finishing.The cost of the Extra class material is higher than all other analogues, the price can be compared with the species of valuable wood.

Usage

Since pine wood furniture board is highly environmentally friendly, there are no restrictions on its use. Pine is used for making shields for orthopedic beds, assembling cabinet frames, kitchen furniture, making dividing decorative interior partitions, creating flooring or wall cladding.

The coniferous material has a long service life, it has a beautiful wood grain texture, is not susceptible to moisture absorption and is resistant to mold. The pine panel can retain its properties for many years.

Despite the many positive performance characteristics, it is possible to extend the life of an Angara pine wood product for a much longer time. To do this, you must follow certain rules when using furniture products:

after purchase and delivery, the material needs to rest for 2-3 days to adapt to room temperature conditions;

before you go shopping, you need to calculate the amount of material required, its dimensional parameters and thickness according to the drawings, in order to avoid a large amount of waste;

for high-quality work, you will need good carpentry tools, which must be sharpened without fail, so as not to spoil the first-class material during work;

when assembling furniture, it is important to use high quality hardware and fasteners;

the use of a protective varnish coating helps to significantly extend the life of natural wood products;

the texture of pine wood has an attractive appearance, but if desired, it can be painted or used for decoration.

In some cases, plasterboard sheets are replaced with pine panels when decorating walls or ceilings. Often this finish can be seen in private homes. A pine board is also used for flooring instead of laminate or parquet boards. With the help of this material, door leaves and stair treads are made.