Which mounting hardware to choose for certain types of material

Modern manufacturers make furniture not only from chipboard, but also from other materials.

Thanks to a wide range of fittings, you can choose fasteners for any type of furniture

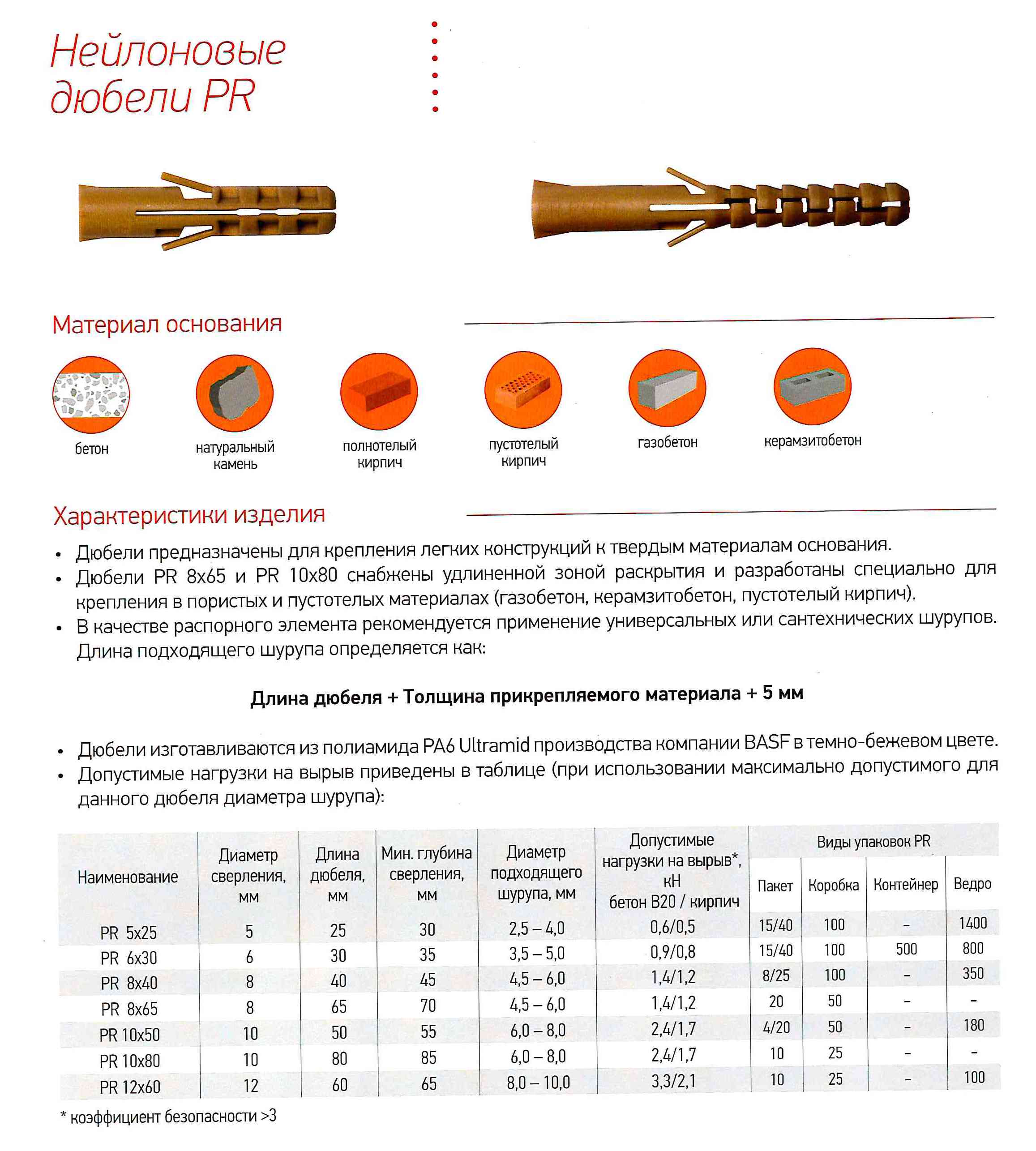

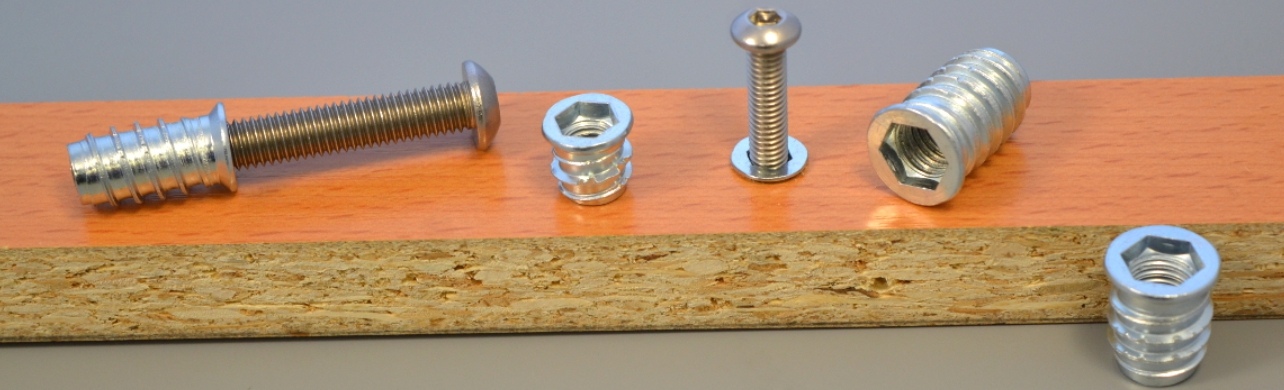

Table 6. The choice of fasteners based on the material of the furniture.

| Material | Description |

|---|---|

|

Glass |

Such fasteners are used as self-tapping screws (of the "quick installation" type), which are screwed into the wall. Usually it is a thin self-tapping screw with a plastic nozzle. Also, fasteners can have a special adhesive and a rubber gasket. They provide fixation of shelves, glass surfaces, while the furniture coating is not damaged. Glass doors on the curbstone can be installed using conventional furniture hinges. |

Metal |

Screw fasteners are ideal for connecting metal parts. They can be fixed to the stand using a screwdriver / drill. So that the furniture does not lose its aesthetic appearance, the head of the fasteners can be closed with a plug. |

Plastic and chipboard |

To fix such furniture, you can use any fasteners that are intended for chipboard. |

Fastening the dowel screw on various bases

Dowels are often produced with retaining collars that prevent them from being completely recessed into the wall. This can happen if the hole is too deep. They are used most often for outdoor work, when installing elements of a small mass such as cornices and ebb tides.

They also produce high-quality polyamide products without collars, a through hole in the dowel, and the upper part without spacers. Due to this constructive solution, the process of screwing in the screw is facilitated, and at the same time the expansion force increases, which means that the structure can withstand more weight.

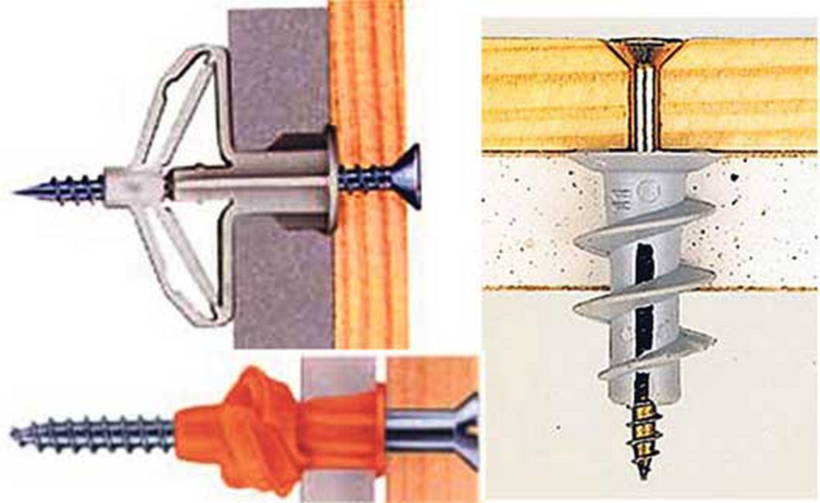

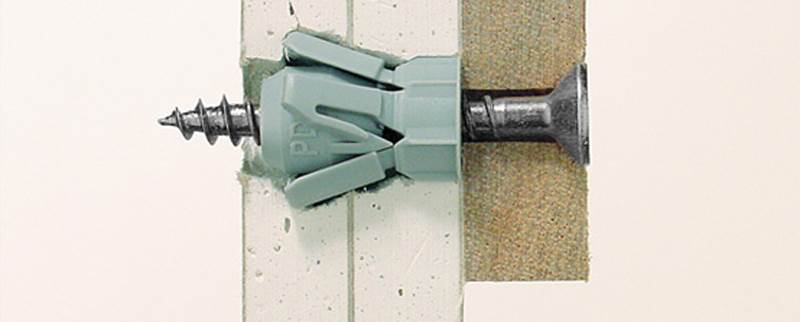

When installing in foam concrete and drywall, both metal and plastic dowels are used, and metal products do not need to be pre-drilled with a drill - their nose is made as a feather drill, and the spacer part also performs a threaded function. Thus, metal dowels are screwed into drywall or foam concrete with a screwdriver.

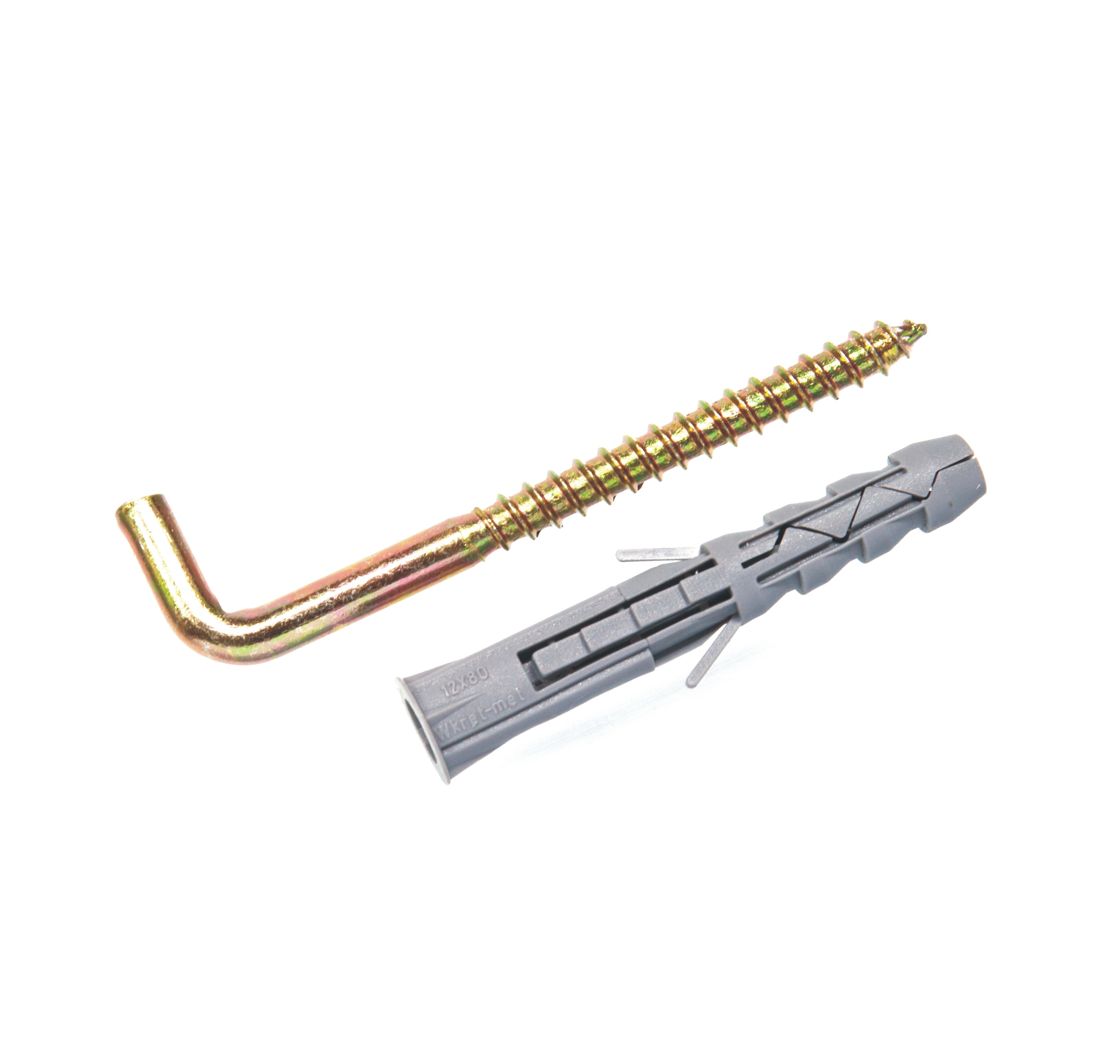

The mounting dowel-nail is used for mounting skirting boards, battens, fixing windows in openings before using mounting foam.

When installing TVs, air conditioners, hoods, you can safely use standard dowel screws without additional calculations, since they are already designed for the mass of household appliances. The limitation here is more in what kind of base is used - if it is concrete or brick, then there are no problems.

But in the case of a drywall or foam concrete bulkhead, everything can end in disaster - it will not withstand a large mass and collapse.

For massive chandeliers or stretch ceilings, it is recommended to use specialized corrugated long, thick dowels with reinforced spacers.

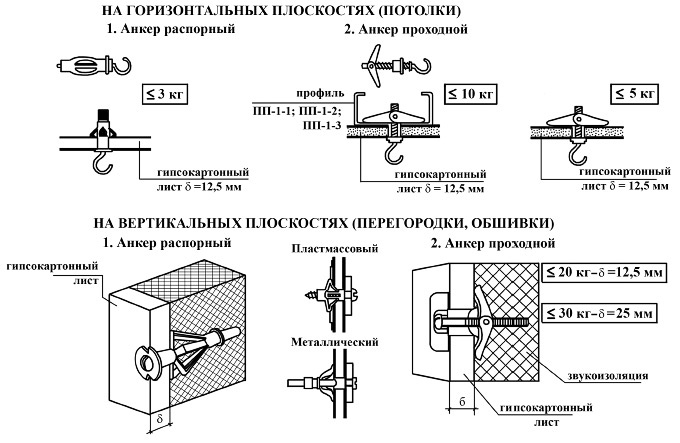

For particularly massive objects, anchor dowels are used, consisting of two parts - a sleeve with slots and a spacer. The spacer element is screwed into the sleeve, expanding its collets, while firmly fixing itself in the supporting structure.

It is not recommended to use the anchor in such bases as foam or aerated concrete and shell rock, as they can burst when the anchor is struck.

What is it and what is it for?

Dowel fastening is a way of mounting various objects or structures to solid solid surfaces - this is its purpose. It works great on concrete, brick or stone surfaces, and can also be applied to drywall and ceramics.Externally, the dowel-nail looks like a device that combines 2 components: a dowel structure made of plastic and a screw. The construct of certain varieties of the dowel frame has a limiter made in the form of a cuff, which is necessary so that when the dowel is driven into the wall, the device does not sink into the prepared hole. The limiter can be of various modifications - round, in the form of a cylinder or a countersunk type.

It is possible to install dowel fasteners inside the wall using a hammer, while the installation process is simple and does not take much time. This mounting option is used for mounting drywall systems, for installing a plinth or cable channel, hanging shelves, cabinets and much more. The dowel-nail performs reliable fastening only in solid monolithic structures; it is inappropriate to use it for aerated concrete or hollow bricks.

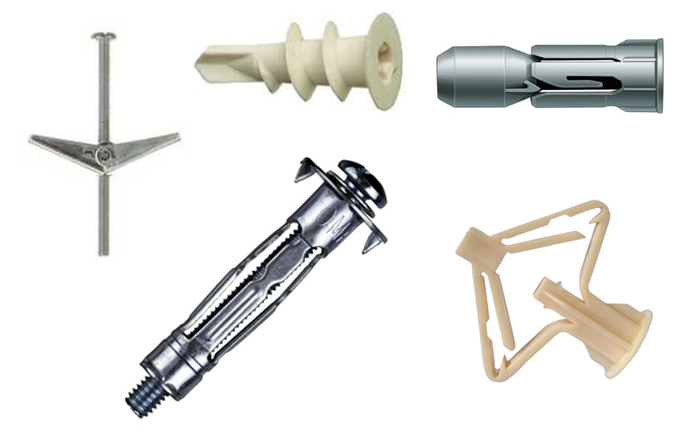

Views

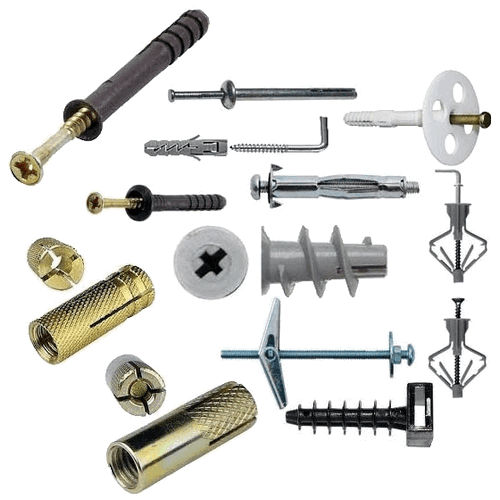

There are different types of dowels suitable for furniture. Usually they are selected based on the diameter of the fastener, the type of wall surface to which the product is attached. That is, for a 5 mm self-tapping screw, you will need an insert made of plastic or metal with the same thread parameters. For quick installation, metal and plastic elements screwed into the walls are used. The dowel is a bit similar to them in terms of functionality - a wooden dowel for furniture, which also provides a reliable connection.

The most suitable for attaching furnishings to the wall are several options for dowels.

- Universal polypropylene. They are used to create fastenings in walls made of solid bricks, concrete with a solid, non-cellular structure.

- Nylon with arches. They have an enlarged spacer surface and are made of durable elastic material. In the construction of porous walls, holes are drilled under them, corresponding in length and diameter. Fixation of fasteners is carried out by screwing in a screw or self-tapping screw, its arcuate parts expand, securely holding the sleeve in the wall.

- Plastic spacer with antennae. It is used for installation in solid brick, concrete, stone walls. The design has locking tongues that prevent the dowel from turning around its axis, wedging teeth.

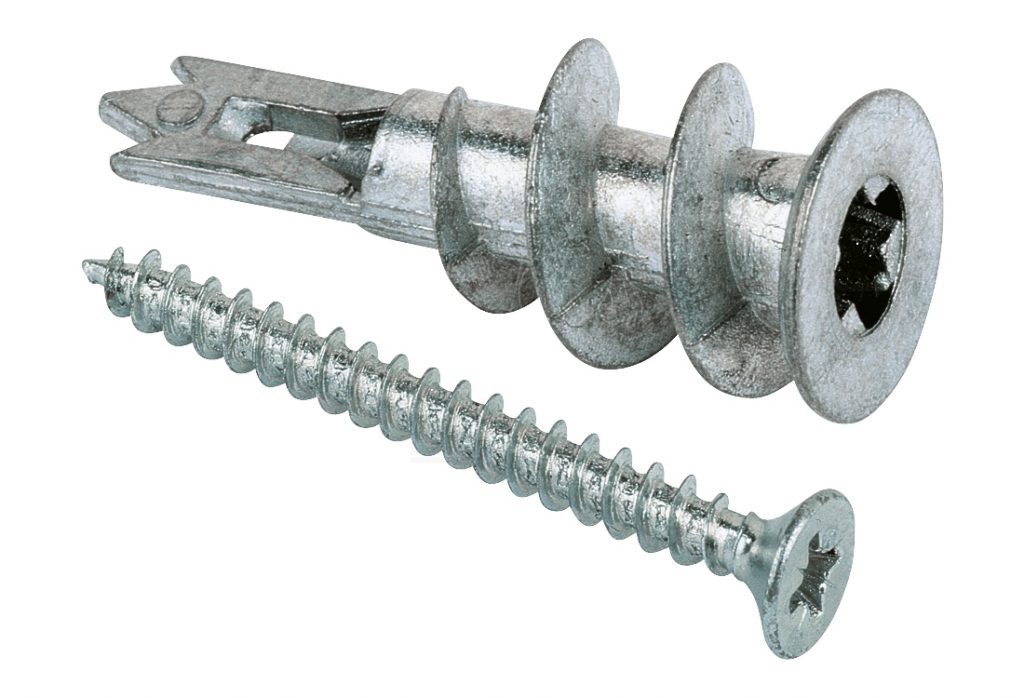

- MOLLY steel. The most popular standard sizes of the metal butterfly dowel are M6, M8, M10. It is used in hollow structures made of plasterboard, bricks. After installation, the middle of the product opens up, preventing the dowel from reversing in the hole.

- Steel mortise or dowel-nail. It is wrapped in drywall without first placing a sleeve.

- "Butterfly" plastic. Similar to MOLLY, used for hanging lightweight furniture structures. Can be used for attaching light shelves to internal hollow partitions made of plywood, plasterboard.

- Anchor. Made of steel. It is installed by push-in method into brick and concrete solid walls. It is used when hanging heavy furniture.

These are the main types of dowels used in attaching various furnishings to the surface of the walls.

Rules for installing and hanging cabinets

Before you hang the cabinet, you must:

- carefully align the walls;

- finish laying electrical wiring, installing sockets, switches;

- complete wall decoration - plastering, wallpapering, installation of drywall;

- collect the tool;

- determine the height of the headset;

- markup with a pencil, chalk.

For work you will need:

- electric or hand drill;

- puncher, if the wall is concrete;

- level, better than water;

- tape measure for measuring distance;

- screwdriver with a set of nozzles;

- hammer and punch;

- clamps, if the boxes will be hung with a solid set;

- wrenches if anchors are used.

On a concrete wall

For hanging on a concrete base, anchor bolts are used, which guarantee reliable fixation. The mounting strips can be attached to screws that are screwed into the plugs, the holes for them are punched with a puncher. You can use a corner to fix the cabinet to the wall.

The appearance of small chips indicates the poor quality of the concrete. It is better to reinforce such walls with a 20 x 30 mm wooden lath.

On a foam block wall

It is necessary to fasten furniture to cellular material with air bubbles with special fasteners. Dowels, anchors, nails will not hold, but can destroy the wall when the load increases. Fasteners that can be held in the hollow material are called chemical anchors. They are an adhesive mass. They also hold dowels made of plastic, nylon, metal.

Installation of fasteners in foam blocks is performed as follows:

- mark the wall;

- drill holes corresponding to the dimensions of the fasteners;

- inserts a dowel into a hole previously cleaned of crumbs;

- tighten the screw.

Drilling holes with a punch is not worth it: the material will crumble strongly.

Features of fixing cabinets on a plasterboard wall

Mounting strips are attached to the surface of a drywall sheet with special self-tapping screws or anchor bolts, on which furniture with adjusting fittings will subsequently be hung. This method is not suitable if cabinets are planned for heavy kitchen utensils and appliances. For attaching weighty kitchen cabinets to the wall, decorative cables or tubes are used.

Installation features

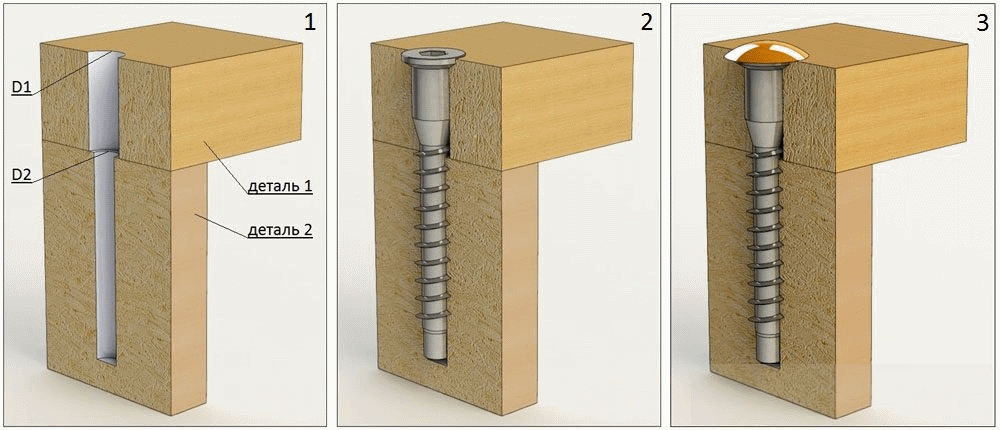

To drive a dowel into, it is not necessary to invite craftsmen. You can do everything yourself. You will need such tools and materials: the dowel itself of a certain design, a sharp nail, an electric drill and a victorious drill (you can use a puncher), electrical tape, a small hammer.

The main stages of fastening:

- The installation site is determined after careful planning.

- With a hacksaw, nail or something else, make a small indentation in the marked place.

- A drill is selected for an electric drill of the appropriate diameter - it must exactly fit the size of the screw and the required hole for it. The dowels must be inserted into the hole with force in order to be securely fixed inside. On the drill, it is advisable to make a mark with a piece of electrical tape along the depth of the hole with a small margin to limit drilling. The drill should be strictly perpendicular to the surface. A hole is made.

- You need to remove dust, debris, crumbs from the hole - it is better to do this with a vacuum cleaner, but you can use anything you like.

- Next, a plastic or metal dowel for concrete is carefully mounted into the hole, hammered with a hammer with strong precise movements to the maximum stop, a screw is screwed into it (if screws are included in the construction kit).

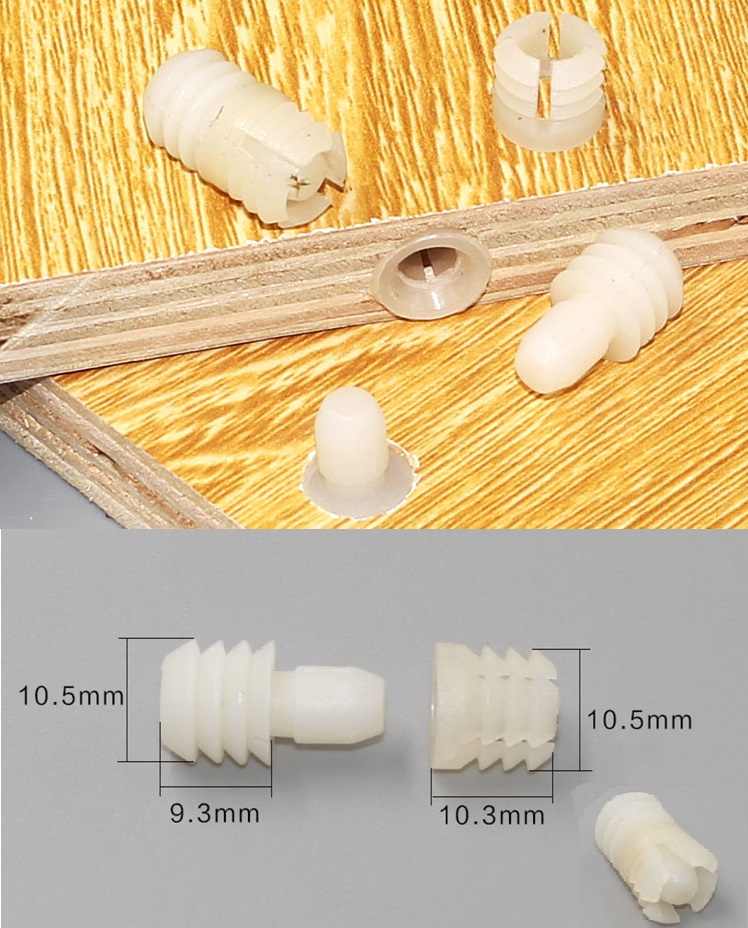

Types and features

The dowel fastening device is a bushing with four petals and a rough surface. When twisted or clogged, they begin to expand in the porous structure of aerated concrete. The teeth and incisors in such a device contribute to a secure fixation. They can be especially secured when the teeth move in a spiral and the tip of the screw does not protrude beyond the dowel.

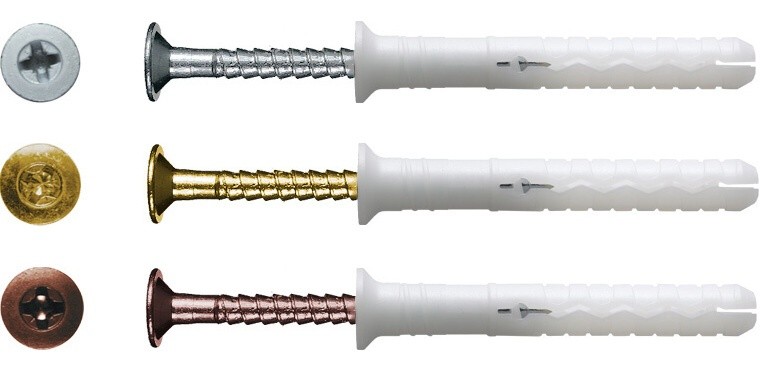

Fasteners, depending on the material used, can be:

- metal - stainless steel, galvanized, brass, aluminum, with the addition of an anti-corrosion compound;

- plastic (polyethylene, polypropylene, nylon).

The first type is considered the most reliable in operation. They are perfect for push-through and complex installations. However, such fasteners have a significant drawback - they begin to oxidize under prolonged exposure to moisture. Equip them with supporting elements to minimize the risk of cranking, falling through heavy hardware inside aerated concrete blocks.

Fasteners made of plastic are appreciated for their lightness, versatility and resistance to corrosion processes. Of all the varieties, nylon dowels are considered the best.

All these fasteners are divided into hammered and screwed in, depending on the installation method. They are suitable for installation without pre-drilling the blocks and are also threaded into a pre-drilled hole.

By the type of thread and fixing of the elements, the bushings can be standard with the same section length and a helical spiral. There are cone-shaped hardware, which diverge to the sides with blades when twisted. Some begin to expand when the structure is pulled apart.

A separate group includes chemical anchors. Their fixation occurs due to the polymerization of a special composition. They are very convenient to use, since it is enough just to put the capsule in the prepared place.

Metal dowels

These fasteners are fire resistant and are therefore often used in installations where there is a risk of fire. Metal dowels have a stopper collar, which is also called a "collar". At the moment of twisting, it prevents the sleeve from turning around its axis and prevents it from falling into the wall. Most often they are made from galvanized steel.

The metal dowel for aerated concrete is used when performing the following works:

- for the installation of equipment and furniture with an impressive weight;

- fixation of pipelines, including the most complex ones;

- fastening guides designed for the installation of sheets of gypsum board.

Plastic and nylon retainers

Such fasteners are good because they are not affected by corrosion processes. The plastic dowel for aerated concrete has special spiral ribs. This part of the part is responsible for maximum adhesion to the cellular structure of the material. The main advantage of plastic mounts is environmental friendliness. The advantages also include resistance to aggressive environmental influences.

They are distinguished by their low cost, which makes them irreplaceable and always in demand when working with aerated concrete. Despite all the positive characteristics, they are not suitable for use on the facade surface. Their significant disadvantage is poor resistance to sub-zero temperatures. In winter, during frosts, such a fastener can easily burst.

The nylon versions are also non-corrosive. However, they are more durable than plastic counterparts. They are often used when doing outdoor work. A nylon dowel for aerated concrete is considered much stronger and more durable. At cost, they are much more expensive, so they are rarely bought by consumers.

The high price is fully justified, since the characteristics of the clips allow them to be used for many jobs. For example, with their help, they make the installation of window and door openings. This is a great option for mounting mirrors and installing lighting fixtures, if you use fasteners with a diameter of less than 12 mm.

Chemical anchor

Often, massive objects have to be fixed on the aerated concrete surface. In this case, chemical anchors are used. Metal dowels, in comparison with anchor bolts, will not be able to withstand very heavy weight. They are sent to a prepared place using a special adhesive.

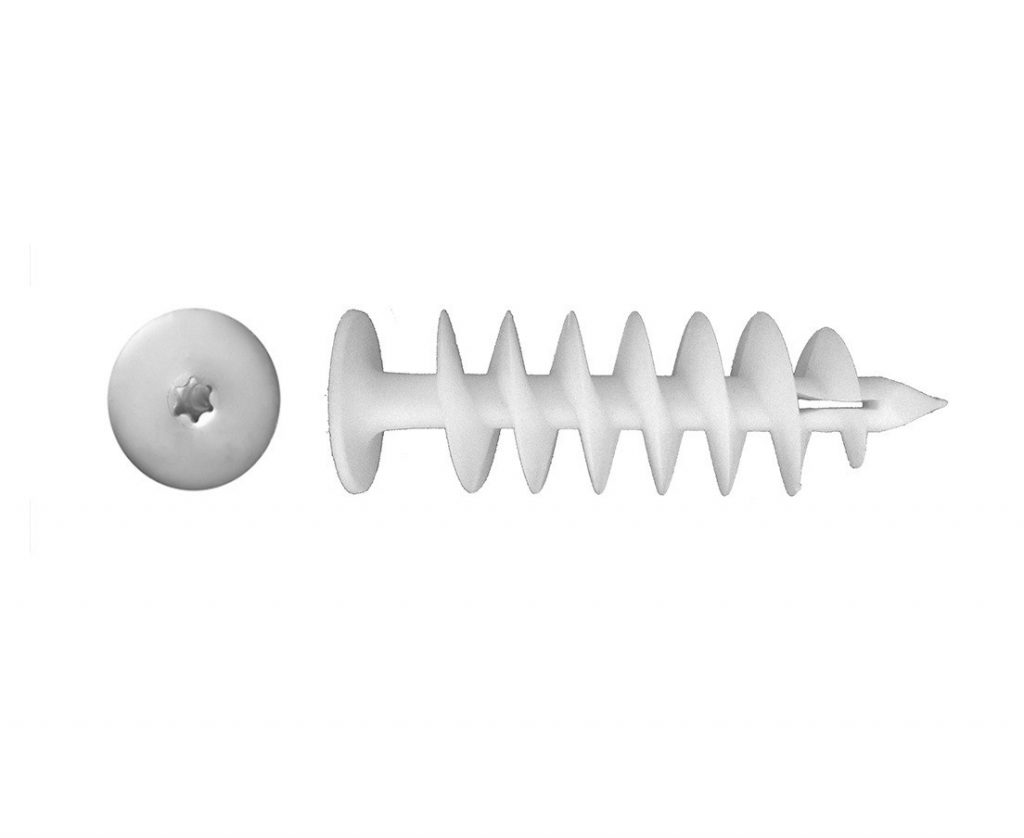

Types of dowel-nails

Builders have to use different tools depending on the conditions. For example, fastening an object to a concrete or plasterboard wall has a significant difference.

In some cases, the reinforced strength of the rod is important, in other places - thermal conductivity and moisture resistance. Even a simple seemingly driven dowel-nail has several varieties that differ not only in size and material, but also in the method of installation

Common types of dowel nails:

- Dowel-nail for manual installation.

- Dowel-nail for pistol - installation is carried out using an automatic device, which greatly accelerates the progress of work.He has no spacer part. The nail is made of the strongest steel (hardness 53-56 HRC, bending no more than 0.1 mm).

- Acoustic dowel-nail - in the manufacture of fasteners, not metal is used, but plastic and fiberglass, which prevents corrosion or the passage of cold. Consumables of this type are used for the installation of thermal insulation, sound insulation, cable ducts, decor.

- Dowel-nail "umbrella" - has a wide head and a long body, used for fixing thermal insulation.

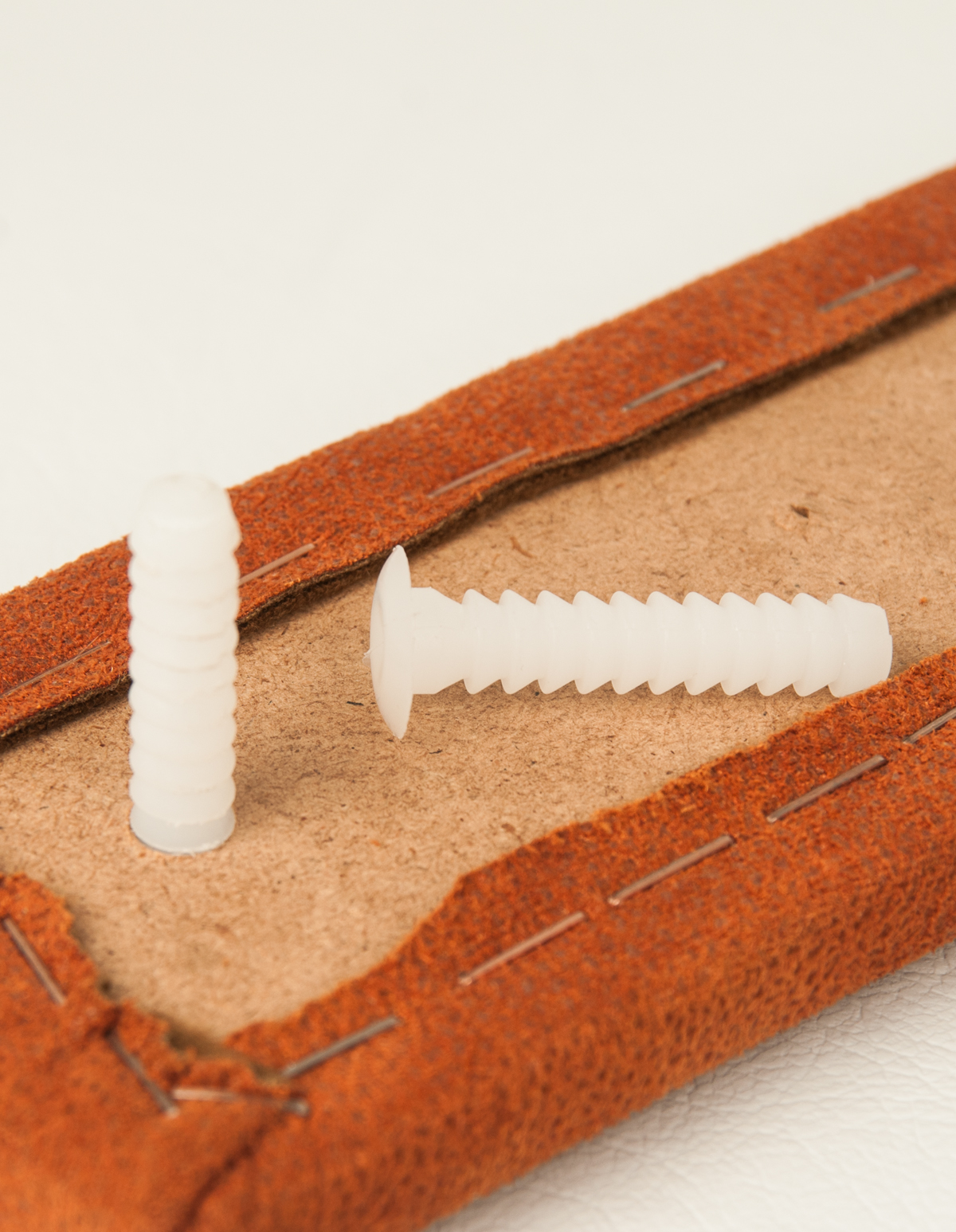

Plastic dowel nails

The plastic cup has a spacer and non-spacer surface. The plastic dowel-nail is equipped with a collar that prevents the fasteners from falling into the surface. The presence of toothed elements prevents the product from scrolling in the hole. We list the common types of plastic fasteners:

- Universal dowel - used together with wood and chipboard screws, screw-screws, suitable for hollow and solid materials.

- Expansion plug S - nylon fasteners have a double-sided spacer. The absence of a stubborn edge allows you to hide the dowel inside the plaster.

- Expansion plug M-S - Suitable for working with standard bolts or threaded rods.

- Dowel for aerated concrete GB - the presence of spiral ribs allows to provide the strongest fit in soft material.

- Dowels for mounting TV / TVV steps - have a good surface geometry to prevent squeaking, vibration. Fasteners of the TV brand have a small spacer for installation in a steel profile.

Metal dowel-nails

The use of a steel spacer sleeve increases the cost of the estimate, but allows an increase in the design load. A metal dowel-nail for a foam block, brick structures or concrete structures is installed in the same way as plastic fasteners. We list the advantages and disadvantages of such a product:

- High load-bearing capacity.

- Metal does not stretch over time.

- Galvanized or stainless steel sleeve is corrosion resistant.

- Large selection of fasteners.

- Simple installation.

- The cost of metal dowel-nails is higher.

- It should be borne in mind that steel fasteners can create more stress, so it is better to place them further from the edge.

Bolts, anchors or bars?

So that the fasteners are reliable, and the filled cabinet does not fall at the most unfortunate moment, the material for making the walls and furniture should be taken into account. Think carefully about the type of attachment.

How to fix and what fittings are most optimal for a brick, concrete, wooden wall?

For a wooden wall of a country house, fasteners using hardened alloy countersunk head screws will be optimal. The most effective installation is with self-tapping screws with a large pitch and two-start thread.

It is better to fasten the shelves to a concrete and brick base with dowels, plugs, metal bolts, plastic fasteners. You can strengthen the fittings in the holes after the drill with plaster mortar.

Molly's screws or butterflies will securely secure the hanging furniture to the plasterboard wall.

For open shelves with a small load, decor, lighting, you can use plastic butterfly dowels and drill dowels.

Hanging storage systems for dishes, products, appliances should be mounted on classic metal fittings. For example, you can buy ordinary dowels made of durable alloy or molly (butterfly dowel in metal version).

If it is impossible to reach the wall through the cladding, you can use wooden bookmark blocks. The thickness of the embedded beam must be equal to the thickness of the transverse frame. If these numbers do not match, the structure may deform. The adjustment of the thickness of the timber is performed according to the profile sample. As a fastening hardware, a metal butterfly screw is optimal.

The attachment of the attached object is made directly to the bar from the bars.To enhance the bearing capacity, use the greatest length of the plank: for example, across the width of the entire set of hinged furniture.

The most proven are two types of fasteners:

- mounting rail;

- classic bolts and screws.

Installation Recommendations

Of materials other than the dowel, you will need electrical tape and a sharp nail. As for the tools, you need to prepare:

- drill;

- hammer.

It is better to use a winder drill.

Sequencing:

We mark the place of the future hole on the wall with a marker, make a small depression with a nail.

We drill a hole. Previously, using electrical tape, mark the required depth on the drill. Keep the tool strictly perpendicular to the wall.

We clean the hole made, remove debris and dust.

We insert a dowel into it

This must be done all the way, and with the utmost care and caution, otherwise there is a risk of damaging the fasteners.

We screw a self-tapping screw or screw into the dowel. Here you can use a screwdriver or screwdriver - as it is more convenient for anyone.

Buying dowels, although it seems not so difficult, still requires a responsible approach.

It is necessary to remember the importance of the correct choice of the type and size of such fasteners, because the reliability of the fastening will depend on this. It will not be superfluous to consult with experienced craftsmen - they will gladly give you advice.

Types of dowels for drywall profiles

Dowels for profiles - fasteners used in the installation of guide profiles and hangers for the frame under the gypsum board.

Distinguish:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- Driva;

- Knauf-Hartmut;

- Fischer Pd ";

- umbrella;

- chemical anchors.

The main types of dowels used in the installation of the frame base

To understand which dowel should be used in a certain situation, all options are considered below.

Dowel-nail for drywall profile

The most common fasteners for mounting the GKL frame. According to the method of fastening, two types are distinguished: manual driving and with the help of an assembly gun.

The second type is a fastening element consisting of a nail and a washer. They are used for mounting heavy massive structures to a concrete base.

This type of fastener is not applicable to work with gypsum board

I mark the products by size. Dimensional specifications indicate the diameter of the base and the length of the nail. When working with a drywall profile, the best option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 is the length. They fix the guide profiles to the rough base, and also fix the direct suspensions.

Dowel-wedge

A wedge or anchor wedge is a reliable fastener. Dowel for fixing profiles on concrete and solid brick walls. Withstands heavy loads. Fastening is possible even at a small distance from the edge of the base. Anchor wedge is produced in sizes from 8/45 mm to 16/150 mm.

Fasteners are used for through and pre-assembly

Butterfly dowel

According to dimensional characteristics, there are:

- 8/28 mm. The smallest, suitable for attaching light objects. Self-tapping screws are not included. Must be purchased separately, size 3.5 x 35 mm.

- 10/50 mm. Self-tapping screws with a size of 3.5 x 55 mm. Withstands loads up to 24 kg. Suitable for fixing furniture shelves and cabinets.

- Metal dowel-butterfly. The second name is Molly. Suitable for use on walls made of hollow materials. Sizes range from 4/21 to 6/80.

Observing all the rules for fastening, "butterflies" serve as durability for a long time

You can find out more about the sizes and types of butterfly dowels on our website.

We advise you to watch a video about the process of attaching the "butterfly".

Driva

They produce two types of hardware: with and without a drill, from nylon, metal. For hanging heavy objects on a plasterboard surface, a galvanized part is used.

The shape is a conical cylinder. The thread pitch is large. Flat hat with cross recess.They are used for the installation of small-sized, lightweight structures. Sizes 12 x 38, 12 x 42, 14 x 38, 15 x 29.

Knauf-Hartmut

The fastener consists of:

- U-shaped profile;

- plastic antennae and bushings;

- screw with dimensions 5/60 mm.

Principle of operation:

- drill a hole in the wall;

- insert the profile plate into the hole using the guide antennae;

- break off the antennae;

- screw in the screw.

Withstands loads up to 55 kg.

Fastener for mounting heavy objects

"Fischer Pd"

Fastening device for working with drywall and profile. Plastic cylinder with sleeve and side blades. Principle of operation:

- drill a hole, the diameter is equal to the dimensions of the sleeve;

- insert a phisher;

- fix with a screw.

The mount can carry up to 16 kg. Sizes - 10/28.

When fixing, the side blades should be open and pressed against the base from the back.

Umbrella

It got its name from the principle of operation. After fixing in the hole, the side blades unbend and the fastener looks like an open umbrella. This contributes to the distribution of the load, the ability to withstand heavy weight.

Chemical anchors

It is a cartridge with a capsule containing an adhesive liquid. Under mechanical stress, the capsule bursts, the glue enters the hole.

Due to its properties, it is a monolithic fastener that can withstand heavy loads

Mounting options

There are 2 methods for fixing kitchen cabinets. Installation is carried out:

- One line, that is, the location of the fastener is equidistant from the ceiling;

It is considered the most common type of accommodation. Thus, you can easily fix the cabinets yourself.

This method is used much less often, since its implementation is much more complicated than a linear fastening scheme.

The first method is popular because you can only use your own strength to fix kitchen cabinets without asking outside help.

The choice of option is due to the number, size and depth of the wall cabinets.

The second option for attaching fixation items is less common among ordinary people. This is because the roof of this furniture is used as an additional surface.

Any of the proposed variations is perfect for both a small area and a large one.

And all due to the fact that they do not have any effect on the fullness or compactness of the room.

When choosing a method, only the interior and design change.

Choice

The search for suitable dowels requires you to take into account the type of surface to which the furniture is to be attached. They are not installed on wooden walls. In other cases, you need to take into account the recommendations of specialists.

- Fastening to brick or concrete. Here it is worth considering simple metal or plastic dowels, wooden corks for nails. They will be enough if the load on the wall is not too great, it is planned to hang a shelf or a kitchen cabinet.

- Fastening to drywall. Here, special dowels are used that can provide reliable fastening. These can be products like "butterfly" or MOLLY.

- Fastening light shelves with a minimum amount of additional decor or lighting. For them, it will be enough to use dowels-drills or "butterflies" made of nylon.

- Heavy, heavily loaded shelves. Storage systems in the most critical areas of the kitchen, living area, workshop require the use of the most reliable metal fasteners. These can be MOLLY dowels or classic metal options.

- If there is cladding on the wall. If the base is hidden under the interior trim, it is necessary to use bookmark bars with a thickness equal to the same characteristic of the transverse frame. Here the best fasteners will be MOLLY.

Selection Tips

In order to choose the right dowel-nail, you need to understand what kind of load the fastener has to withstand, and what it will be intended for. Most often, dowel fasteners are used to work with concrete material in the form of a dense monolith. Consider the recommendations of experts for the selection of fasteners.

- If you need to hang kitchen cabinets or other items with a fairly large weight, then you need to stock up on a mount, the length of which will be at least 85 mm.

- When making fasteners for a plinth, for a cable channel, for insulating walls with one or another material, as well as for fixing structures located horizontally, the length of the dowel attachment is chosen from 30 mm, and its diameter is taken from 6 to 10 mm.

- For the installation of a suspended ceiling, as well as for PVC structures or the installation of lighting devices - in a word, for those products where the load comes from the lower part of the structure, dowel mounts are used, which have spacer antennae or notches applied to the working case.

- If you need to choose dowel fasteners for a ready-made hole in the material, you should remember that the size of the diameter of the hole and the dowel fastener must be equal. In the case when the hole diameter is larger than that of the dowel, high-quality and reliable fasteners will not work, since the dowel will loosen and come out over time.

- In walls made of foam concrete, dowel fastening can become a kind of softening cushioning material. In this case, it is necessary that such fasteners be tightly fixed in the material, and the weight load of the supported structure is evenly distributed over all fastening nodes, that is, over the rest of the dowels.

Some points to know

This type of special fastener has long been used in a variety of works, where fastening becomes a necessary process, according to technology. Below are a few important points to consider:

The two main parts that make up the element are the nail and the dowel itself. Such a connection allows without destruction to carry out the fastening of objects to such materials as concrete, brick, stone.

Other materials, which are classified as corpulent, with a high density, lend themselves to fastening. It is possible, among other things, to give the types of appropriate fasteners suitable for installation processes, where fiberboard, chipboard, drywall are used as the main materials for connecting to the bases.

As for the length, it varies from 30 millimeters. The longest specimens reach 160 millimeters in length. It is this kind of dowel-nail that is used for thermal insulation. The wide pressing cap has given rise to the fact that sometimes such a dowel is called a disc-shaped dowel.

Confirmation: nuances of application

Under this name, in reality, the simplest screws are hidden. Fasteners primarily differ from most others in the simplicity and availability of each installation, since absolute accuracy is not required from the assembler.

In order to fasten the furniture pipe, you only need a drill. For independent work, it is advisable to immediately purchase a hex key, since it is for it that there is a special hole in the cap.

To install this part, you will need to additionally drill two new holes. One of them should be in the element that will be fixed, and the second - right at the end of the part itself.

The ease of the assembly process of any furniture using a confirmation allows the master to independently drill holes, saving time.

You can further facilitate the repair process by using an additional drill designed for fasteners. But many craftsmen note that this device loosens quickly, so they get by with classic drills and, judging by the photo of furniture fasteners, everything goes fine.

1 What is a nail dowel?

A dowel-nail is understood as a special product used to perform fastening work. It consists of two elements - a special nail and a dowel itself, and is used for mounting objects to concrete, brick, stone, and other solid dense materials. There are also types of the described fasteners designed to work with chipboards and drywall.

The dowel-nail design is very simple. It is made in the form of a cylindrical rod, which consists of a spacer part (it expands during installation and allows reliable fastening) and a nail familiar to everyone. In some cases, the fastener of interest to us can be additionally equipped with a special cuff that acts as a limiter, which does not allow the fastener to sink into the hole made. The shape of the specified cuff is different, for example, cylindrical or hidden.

Also, modern industry produces a dowel-fastener with a thread applied to a nail and a slot, which is located on the head of the product. Such an element can be mounted with a screwdriver. It is quite simple to work with it, since the process of entering the nail into the dowel is facilitated by the presence of a “smoothed” thread in the product. We add that the top of the thread of this mounting fixture is directed towards the head. Externally, the dowel-thread is no different from the standard stop thread.

Most often, the dowel is made from polyethylene, polypropylene or polyamide. But already directly the dowel-nail is made from steel alloys with a zinc coating. In fairness, we note that there are many fasteners of the described type on the market without additional coverage. Standard diameters of dowels are 5, 6, 8 and 10 millimeters, and their length ranges from 30 to 160 millimeters.

Photo of an expansion dowel

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Wood grouse wood screw

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- What are wood screws

- How to choose a wall mount for your TV