DF brand products - composition, types, standard sizes and applications

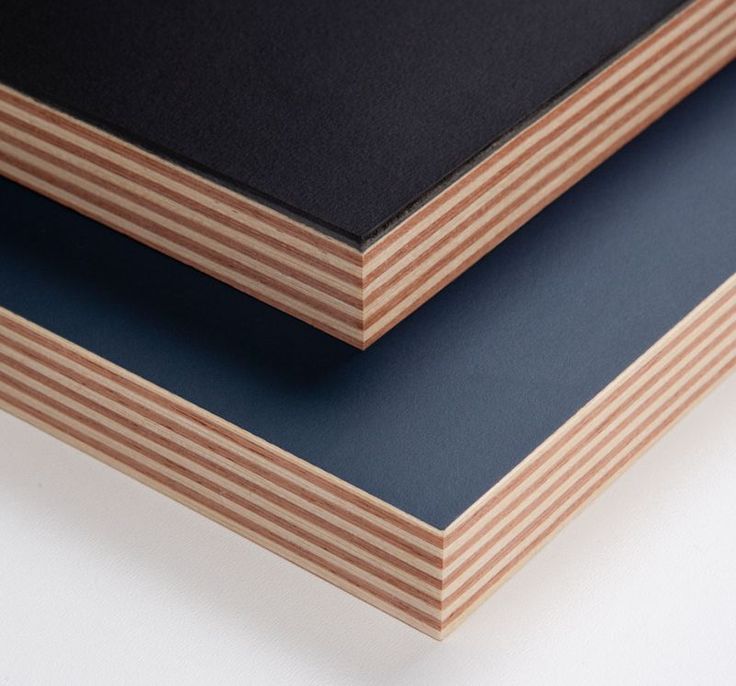

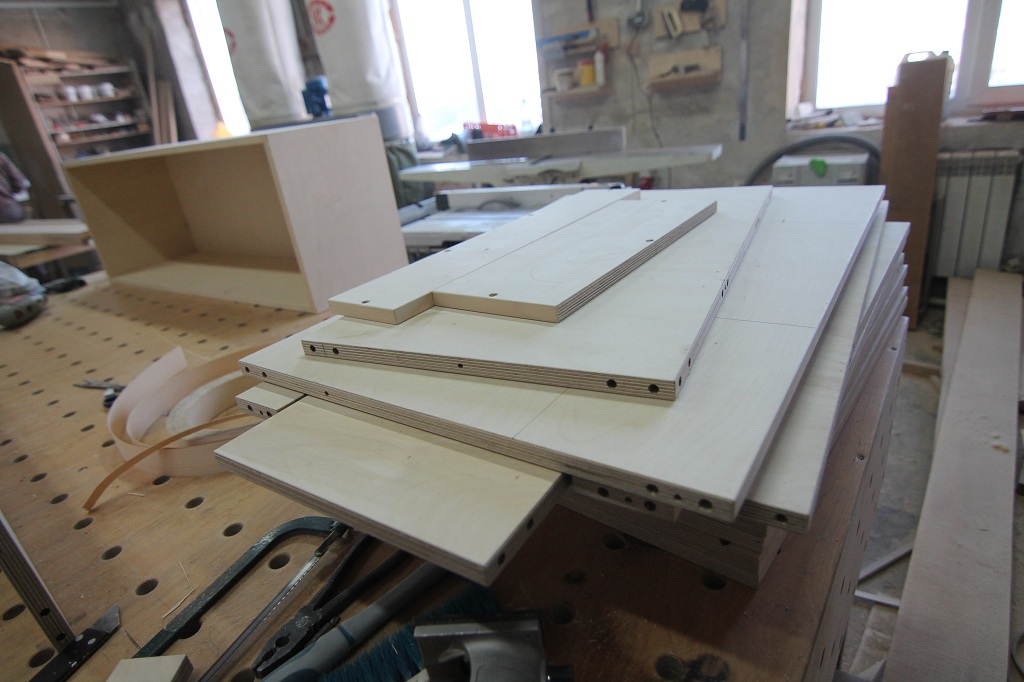

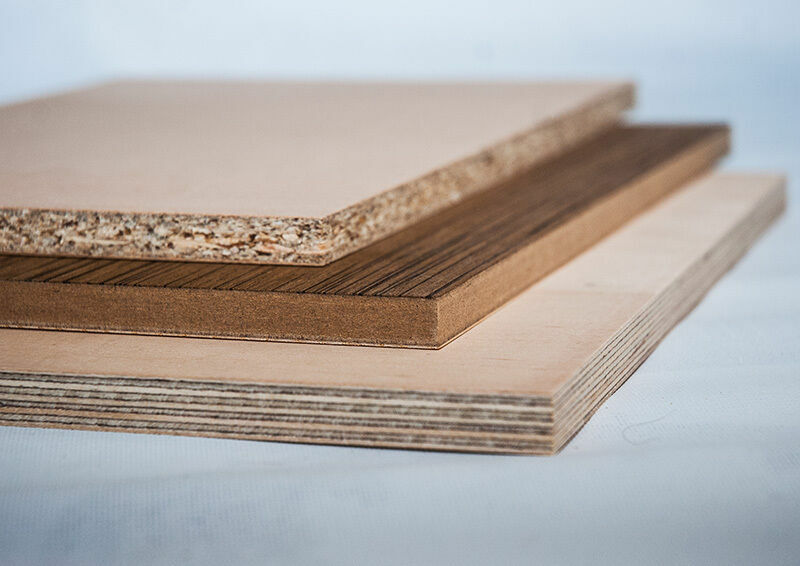

Inexpensive rotary cut veneer (coniferous and birch) is used as the basis for decorative plywood. Just as in the case of ordinary plywood, several layers of veneer are glued together and then pressed on special equipment.  Facing wood-laminated boards of various shades

Facing wood-laminated boards of various shades

The outer layer of DF, as a rule, is made of noble tree species: alder, linden, oak, beech, cherry and even exotic Aformsia (although the price for such a material is quite high). A cheaper version of the face layer is decorative paper impregnated with special resins, or colored polymer film.

Varieties of decorative plywood

From GOST 14614-79 it follows that decorative wood-laminated boards are divided into groups according to the following factors:

-

By the number of veneered sides:

- one-sided;

- double-sided.

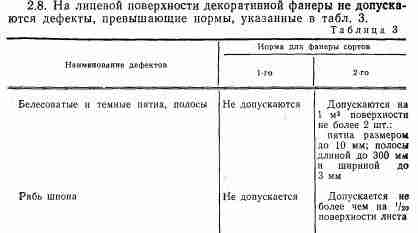

Instructions telling about what defects should not be on the front side of the DF

Instructions telling about what defects should not be on the front side of the DFContinuation of the previous table

-

By facing material:

- DF-1 - plywood sheets covered with a transparent polymer film, through which the natural veneer texture remains visible. The fixation of the protective and decorative layer is carried out with urea-melamine-formaldehyde resins;

- DF-2 - plywood faced with paper or film, completely hiding the natural pattern of veneer and imitating the texture of noble wood species. To fix the facing layer, again, urea-melamine-formaldehyde resins are used;

- DF-3 - here a transparent film with increased moisture resistance, glued to the base with melamine-formaldehyde resins, acts as a decorative layer;

- DF-4 - plywood sheets covered with a transparent film of increased moisture resistance + paper that hides the veneer and imitates the texture of valuable wood. The adhesive is melamine-formaldehyde resins.

In addition to the main varieties of this material, I would like to talk about two more interesting modifications of it:

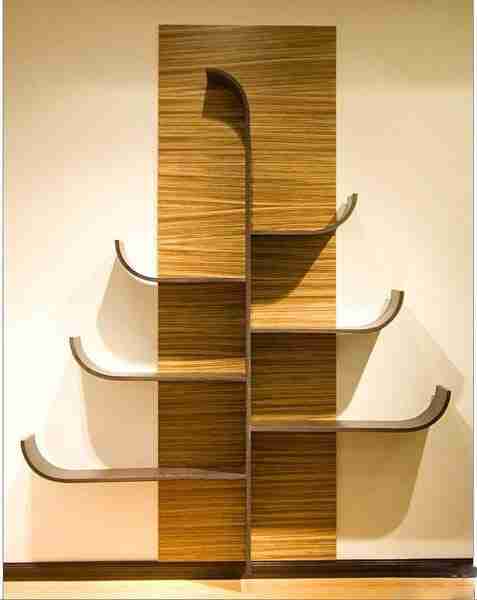

- Flexible plywood (thickness - from 4 to 15 mm, maximum bending radius - from 5 to 15 cm). Very cost-effective and convenient sheets for making bent rounded structures with your own hands: arches, columns, furniture facades, doors, semicircular walls and much more. This plywood decor allows you to create truly exclusive interiors!

Flexible wood laminate

Flexible wood laminate

Flexible plywood sheets have a three-layer structure: a main layer of extra strong mahogany wood and two layers of rotary cut veneer. All elements are hot glued together using thermosetting plastic glue.  In the photo - an exclusive rack, the trunk and shelves of which are made of flexible plywood

In the photo - an exclusive rack, the trunk and shelves of which are made of flexible plywood

- Ultra lightweight plywood. This modification is made from tropical wood species, which have a rather low specific gravity. Seiba veneer is most often used as a basis (inner layers), and falcatta and other light tropical species are used for external cladding.

Ceiba tree

Ceiba tree

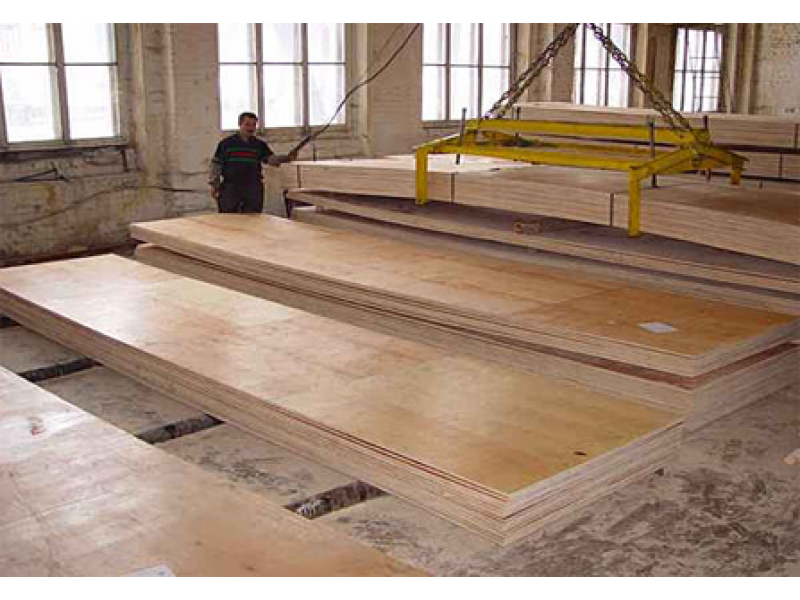

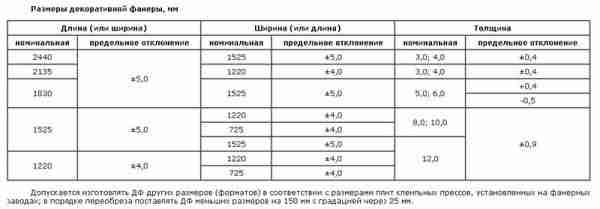

Standard sizes of facing plywood

Since the considered type of plywood is used exclusively indoors, there is no need to produce large-format DF sheets. As you can see in the table below, the largest standard dimensions for decorative plywood sheets are 2440x1525 mm.  DF standard sizes

DF standard sizes

Applications

Where is the use of decorative plywood acceptable?

As a rule, this material is used in various indoor construction works:

Sheathing of surfaces - walls, ceilings, floors.If ordinary plywood has an unpresentable appearance and therefore is suitable only for rough work, then decorative sheets are a worthy alternative to panels made of natural wood.

Stunning plywood ceiling - mesmerizing!

Stunning plywood ceiling - mesmerizing!

Interior decoration of train carriages, ship cabins, passenger transport salons. DF qualities such as high wear resistance, resistance to mechanical damage and durability make it an exceptional material in this particular area.

Interior decoration of transport

Interior decoration of transport

- Manufacturing of furniture from plywood - in particular, kitchen facades, doors, countertops, counters and so on.

- Creation of all kinds of decor for the interior.

Here is such an unusual Christmas tree

Here is such an unusual Christmas tree

Plywood Processing Tips

Shaping plywood sheets

To make your furniture for a veranda, hall or kitchen made of plywood beautiful and even, certain rules for processing the material should be observed. They are quite simple and do not require any special processing tools.

So one of the most important processing elements is the cutting process. Glued veneer is cut, depending on its thickness, up to 1.5 mm using a knife. If the thickness is up to 6 mm, the cutting is carried out using a jigsaw, with a larger thickness, a circular saw is used. Perform cutting as shown in the photo.

The instruction advises to cut sheets of veneered plywood only along the grain, otherwise the veneer may delaminate during the sawing process. If you need to cut across the grain, you must first make loosening cuts along the cut line. This can be done with an ordinary locksmith's knife. Laser cutting of plywood is also a worthy alternative to a knife.

The process of bending glued veneer, although quite simple, will require a lot of time and perseverance. To do this, the sheets of building material should be wetted. It should be wetted enough and after soaking the building material with water, proceed to bending. Having been bent to the required or intermediate parameters, it should be fixed and allowed to dry for at least 12 hours. And although the process is quite long, it is worth it, because kitchen or toy furniture made of bent plywood looks very original.

Fastening plywood sheets

Fastening the plywood with nails or screws is possible only after pre-drilling them. The holes must match the size of the connector. If your building material is made of soft wood, then a soft pad should be put on the screws or nails. It will protect the plywood sheet from punching and cracking. It is optimal to use this type of fastening no closer than 12 - 15 mm from the edge of the sheet.

Fastening is carried out only after preliminary drilling

The process of gluing plywood requires preliminary processing. So it is necessary to grind the surface, for this it is better to use abrasive paper No. 80 - 100. Then sweep away the resulting dust and apply an adhesive on both surfaces. We squeeze the surfaces to be glued and leave them under load until the glue is completely dry.

Care rules

Colored film faced plywood is a popular material for garden furniture or home furnishings. Proper care is an indispensable condition for its long service life.

Optimal maintenance of structures consists of:

- it is best to regularly wipe dust from products;

- different liquids or dirt are removed promptly;

- it is not allowed that the sun's rays constantly fall on them, therefore if items are intended for outdoor use, then it is advisable to install them under a canopy;

- exposure of laminated furniture plywood to constantly high humidity is not allowed, since the material swells and loses its shape from water;

- it is undesirable to use any abrasive agents for cleaning;

- it is not recommended to use hard brushes.

Thus, the usual care is provided for plywood, as it is also used for various wooden furniture.

Views

This material can be used to make a really large number of different items. These include:

- country furniture made of plywood - is considered the most common and often purchased. It can be represented by different loungers, chairs, tables and other similar structures that provide the comfort of using a summer cottage for a good rest. An important point in the purchase or creation of such products is their competent processing with special protective equipment that prevents possible rotting under the influence of high humidity. It is advisable to store such furniture structures indoors in winter and rainy seasons. Many items are made from plywood for summer cottages, so it is possible to choose a complete set in which all parts will perfectly match each other;

- kitchen furniture made of laminated plywood - usually facades or full-fledged headsets, dining tables or even bar counters are made of the material. Although high humidity is always established in the kitchen, if you choose really high-quality furniture, and also treat it with special protective equipment, then it will last a long time, retaining its unsurpassed attractiveness;

- transformer furniture - it is usually purchased for a bedroom or living room, and can also be used in the country. Its main advantages include the fact that it performs several functions at the same time, therefore it is considered multifunctional and convenient for constant use.

For giving

For giving

Furniture transformer

Furniture transformer

For kitchen

For kitchen

Some items are not only made of plywood. This includes wicker furniture, the frame of which is formed using plywood sheets. Additionally, other materials can be combined to obtain unusual furniture.

The most popular plywood kitchen furniture made using this material are:

- kitchen sets, and often they combine several different materials, but the most popular is the use of plastic and wood;

- a variety of bedside tables and dressers, unlearning good roominess;

- stools and chairs, reinforced with various additional elements, therefore can withstand even significant loads;

- children's kits, moreover, photos of such full-fledged structures are below, and they can be used for sleep, study or play;

- numerous shelves with an original shape and various sizes;

- rocking chairs in which plywood is combined with a wicker structure.

The types of plywood are numerous, so if you plan to independently create interior items, then before making furniture, you should correctly choose a material that has high strength and other necessary parameters.

Plywood selection

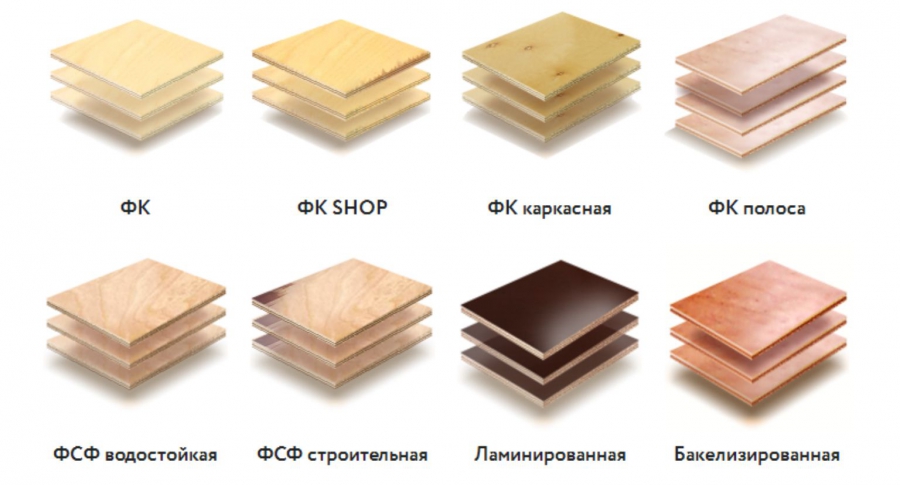

Differences in adhesive mixtures used for gluing

Plywood furniture

Plywood furniture

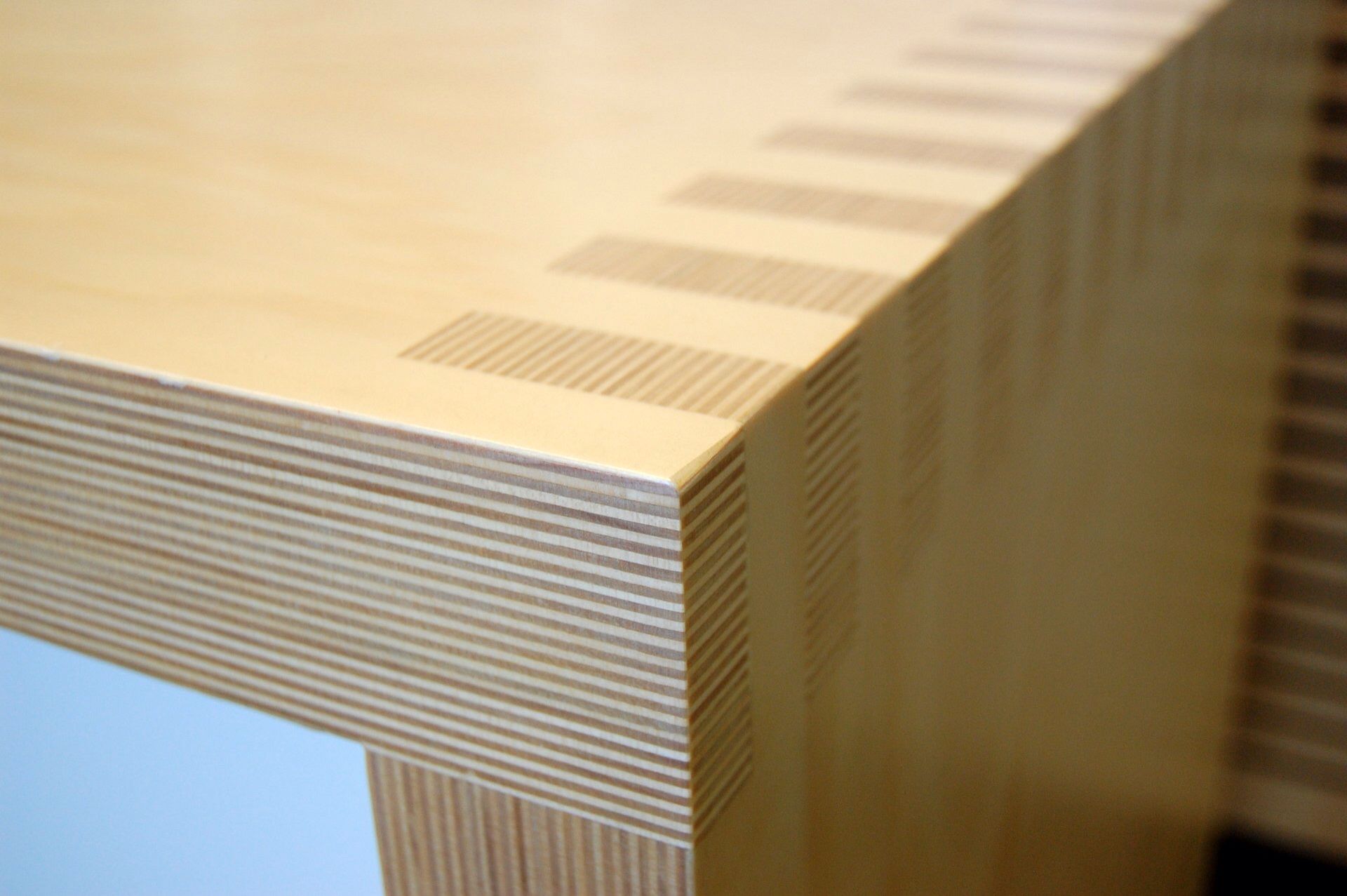

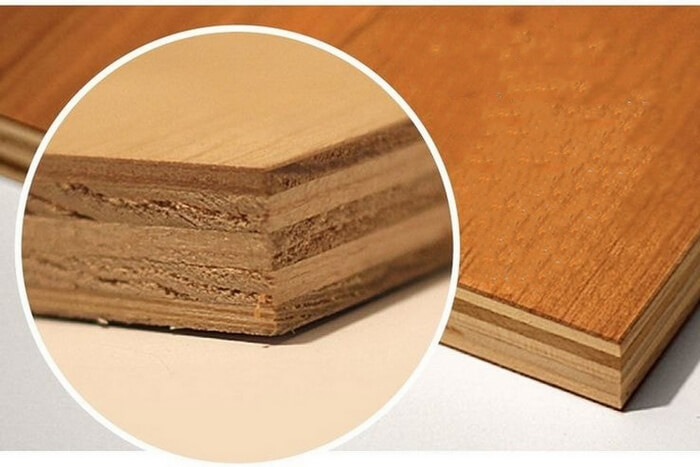

For the manufacture of furniture products from plywood, it is very important to choose the right material. Plywood is obtained by gluing veneer sheets, usually the number of glued sheets is odd - 3, 5, 7

But the material gets its main properties depending on the glue used.

- FC - in this type, plywood is glued with urea glue. It is also called moisture resistant, but the properties are not the best and we recommend using it only in the manufacture of furniture products in dry rooms.

- FSF - this type is called plywood with increased moisture resistance. In its manufacture, phenolic resins are used, which act as an adhesive. Homemade plywood furniture of this type can be used in wet rooms and even outdoors.

- FOF - film faced plywood. For its manufacture, a building material of the FSF type is usually used, which is covered with a laminating film.Such building material has a wider color gamut, but its properties are practically indistinguishable from the type of FSF.

Plywood thickness can be from 3mm to 40mm

- BV - this type is made by gluing veneer with water-soluble bakelite glue. When moisture gets on this material, plywood exfoliates, so it is poorly suited for the manufacture of furniture products. But it has a fairly high density, about 1200 kg / m3.

- FBA - for this type, albuminocasein glue is used, which, unfortunately, has extremely low moisture resistant properties, therefore the use of this building material for the manufacture of furniture is very limited.

- FB, BS, FBS - Bakelite glue or varnish is used for the manufacture of these types of veneer. The properties of these species are practically the same and differ in the same high density as in the BV species, but their main advantage is moisture resistance. It is thanks to this property that such building material is actively used in shipbuilding.

Differences in surface structure

According to the quality of surface grinding and the number of knots, according to GOST 1996, there are five main types.

- Grade E - elite plywood. For this type of building material, knots and cracks are not allowed. Ideal for the front side of furniture products, but the price of such plywood is higher.

- Grade 1 - allows cracks no more than 2 cm. Well suited for subsequent lamination and painting. It is used both for the front side and for interior decoration of products.

- Grade 2 - allows defects up to 20 cm, glue leakage up to 2% of the total area is possible. Making furniture from plywood with your own hands from such a building material is not the best option, in extreme cases, it can be used in areas hidden from the eyes.

Plywood grades other than E grade

- Grade 3 - allows cracks and other defects up to 30 cm, glue leakage up to 5% of the total density is also possible. It is better not to use such plywood in the manufacture of furniture products.

- Grade 4 - the lowest quality building material, it can have defects up to 60 cm or more. This type includes everything that has not reached the 3rd grade. It is impossible to use such building material for the manufacture of furniture products.

Postforming table top: a classic of the genre of the right size

You need a very small piece of furniture worktop in order to significantly save on buying a dining table for the kitchen. It's about how to make a table from a tabletop with your own hands. The classic kitchen table (photo 3) practically does not differ from the furniture bought in the furniture showroom - except perhaps in the size of the countertop, which is ideal for your kitchen.

We need the following materials and tools:

Markup. In accordance with the drawing, parts A and B are absolutely identical along the contour, the only difference is in the depth of the assembly grooves. Therefore, it is better to make one template (from Whatman paper), and use it to make markings on plywood

Pay attention to the highlighted in red: the groove stops should be on the same line, and their width (as well as the height of the puzzle protrusions at the top of the parts) should be equal to the thickness of the plywood. Sawing and processing of parts

Attention and accuracy are important here: the strength and stability of the product depend on them. Grinding, toning and varnishing should be carried out on all parts of the parts, including the ends. Assembly. With a high-quality performance of the previous stages, the assembly will not take much time: we connect parts A and B (into the groove), we put part B on top of the puzzle protrusions. If the fasteners of the underframe protrude somewhat above the plane of the tabletop, they must be leveled (with a grinder). We cover the details with a finishing layer of varnish - the table is ready!

How good is plywood as a material for children's furniture? Are there any subtleties in material processing in this case? In this article we will try to study the problem from different angles; it also provides some helpful tips and ideas.

The scope of the material in the nursery is not limited to chairs and beds. In the photo - a children's playhouse made of plywood.

DIY plywood table: opportunities and limitations

Plywood is a soft and pliable material for processing.Not differing in special strength characteristics and durability, multilayer plywood may well become the raw material for the manufacture of tables that do not experience heavy loads (both folding and folding). In some cases, even children's tables are made from it: plywood in this case can be used as a surface for various childish crafts.

The undoubted advantage of the plywood table will be its originality, which can be seen in the photo. And homemade, for example, you can decorate with carved shelves, also made with your own hands from plywood.

In order to ensure satisfactory strength of the countertop, it is better to use sheet material for its manufacture. A table made of a sheet of plywood turns out to be stronger than the same one, but made from scraps of this material, even if carefully connected to each other using wood glue that is resistant to water and moisture. In many cases, the finished product is subsequently varnished or stained. The exception is kitchens, which are often used to cut food.

Materials and tools required for manufacturing

The best for this kind of handicrafts is considered to be premium Sh2 plywood (ground from both surfaces). In this case, there are practically no surface defects in the material. Depending on the purpose, the water resistance class of the material is also selected:

- FSF plywood is suitable for both outdoor and indoor products, so it can be used to make a folding table for summer cottages or for playing table tennis.

- Plywood FC is suitable for use only inside - therefore, it is quite possible to make a writing or computer table from it with your own hands.

If we proceed from the wood material, then it is most advisable to choose birch plywood for making the table, which is easy and well processed, and also has sufficient strength. The thickness of the material must be at least 20 mm.

You will also need:

- A template with which the contours of the legs and countertops are transferred from the drawing to the plywood sheet (for small tables, for example, coffee tables, two wide and stable legs are usually provided). A sheet of drawing paper or cardboard is often used as a template.

- Portable sander for surface finishing of countertops.

- Jigsaw.

- Electric drill for drilling technological and fixing holes.

- Hacksaw with fine teeth of the saw blade.

- Fasteners (screws, screws or bolts with anti-corrosion coating).

Manufacturing sequence

The quality of the finished product largely depends on the correctness and accuracy of the template made according to the drawing of the product. In the case of using plywood scraps connected to each other during the manufacture of the table, all subsequent operations are performed only after the semi-finished product is fully ready. In this case, excess glue should be removed immediately so that they do not spoil the appearance of the finished product. Since a jigsaw is used to cut out individual elements of the future table, its capabilities should be correlated with the dimensions of the parts being cut.

You will have to work especially hard on the countertop: it should have a perfectly symmetrical appearance with allowances for subsequent grinding and removal of sharp corners. In particular, after grinding, the surface of the countertop should be free of burrs, tears and other surface defects. If in the future the surface is supposed to be decorated, then it is better to use not paints, but colorless waterproof varnishes, under which the beautiful texture of the original material will be clearly visible.

If the table will be in unfavorable external conditions (for example, it can be exposed to aggressive chemical environments), then the best option would be to make the table from laminated plywood - in this case, the surface layer of the starting material will have a higher operational resistance. For example, it makes sense to make homemade kitchen tables from laminated plywood, and in some cases even writing and computer tables.

Drawings of plywood tables in various types and designs can be seen in the photo.You can see a photo of plywood tables, as well as a corresponding training video, which shows the sequence and procedure for making a plywood table.

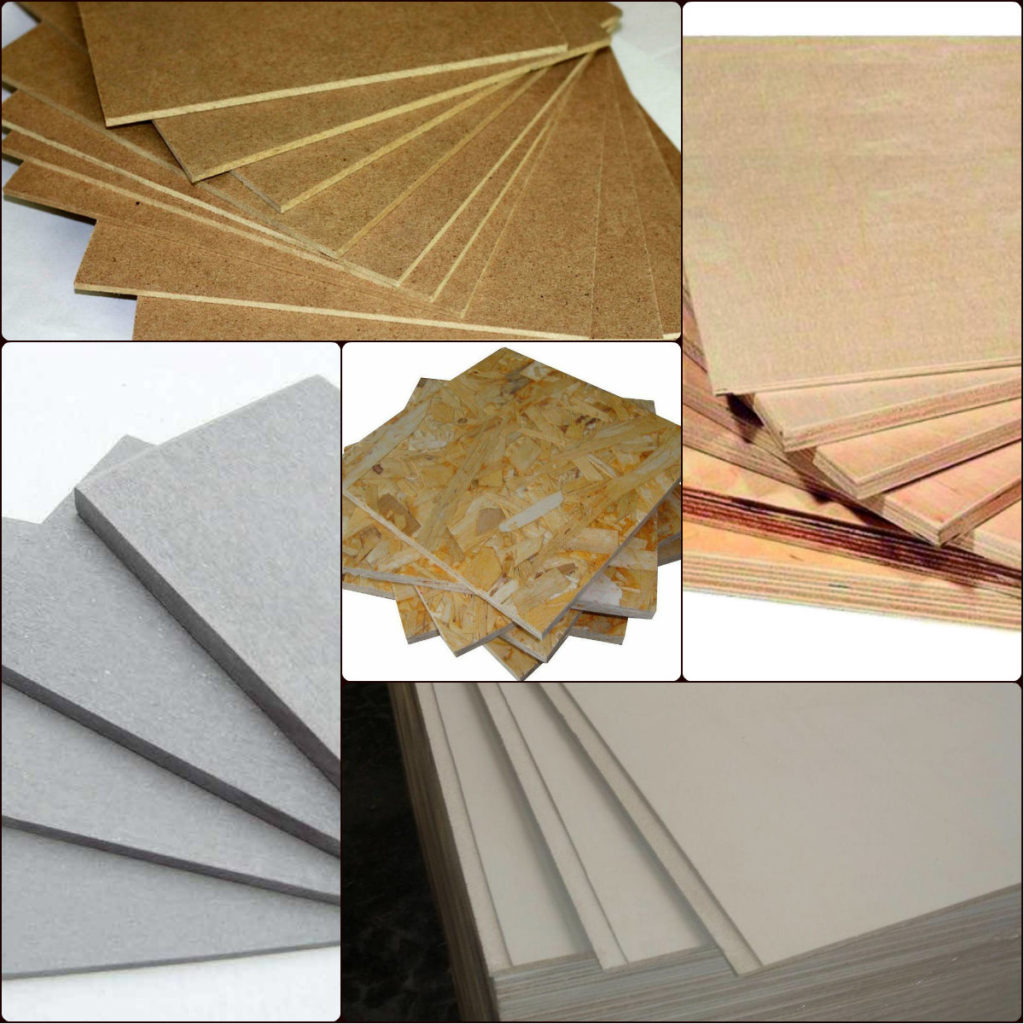

What is the difference between chipboard, MDF, plywood, furniture board, lumber, veneer?

A bit of reasoning about furniture materials: chipboard, MDF, plywood, furniture board, lumber, veneer.

The choice of furniture materials can seem daunting. And yet, when understanding the essence of the issue, the choice will always be elementary. About this video. Look, ask questions, comment ...

Today I want to reveal the following question: What is the difference between the materials used for the production of furniture? Today there are the following materials: chipboard, MDF, plywood, furniture board, lumber, veneer. Let's talk specifically about each of them.

Chipboard Is an abbreviation for the full name: chipboard. A modern composite material obtained by pressing wood particles (sawdust and shavings), formaldehyde resins are used as a binder. Interesting fact from Wikipedia: “Particleboards appeared in the 1940s in the United States (English Chipboard) for temporary furniture for American refugees. ” A pertinent explanation that once again reminds us why and for whom the chipboard furniture was originally invented.

Consider further the performance characteristics of the chipboard. One (and probably its only positive characteristic) is stability. Chipboard products retain their shape, color and size under normal room conditions. This is a dead material and, in comparison with wooden furniture, does not require adherence to the relative humidity of the air, unless it is completely flooded with water.

The next indicator directly affecting the lifespan of furniture is strength. Whoever had chipboard furniture (most likely each of us) knows how fragile this material is. Despite the external solidity, which is created by a thin layer of plastic (laminated chipboard), inside it consists of sawdust and shavings. And in terms of its density, chipboard may differ, which is immediately visible on the saw cut. Loose chipboard will not last you even a year: hinges will immediately fly out of it, shelves may break from the weight of books, chips appear, etc. Such furniture cannot be repaired, don't even hope! If you are lucky and you have purchased furniture from a higher quality dense chipboard, then it will serve you for a maximum of 10 years. But only under the condition of correct operation: do not hit on corners, do not scratch or water. If you want to disassemble and reassemble such furniture, then keep in mind that the third time you will not be able to screw in the screws.

But these are only the visible disadvantages of chipboard furniture. An environmental indicator is also important, which is hidden, but has a direct effect on the health of consumers. Binder resins are to blame for this, which emit formaldehyde, harmful to humans. The maximum permissible emission of harmful substances is determined by sanitary standards. But do all manufacturers comply with these requirements? Low-grade cheap slabs sometimes exceed the MPC up to 40 times. Boards of this class are no longer produced abroad (in Europe and the USA), and for the production of furniture it is allowed to use only super-safe boards of the "Super E" class. Especially dangerous for health is new furniture, from which active formaldehyde particles have not yet eroded.

Therefore, when buying, you should especially pay attention to the pasting of all, even invisible from the outside, the ends of the furniture. Take advantage of your sense of smell and sniff

Furniture made of chipboard with a high concentration of formaldehyde has a pungent unpleasant odor. But often, what is worth as a sample is not always what will be brought to your home.

What makes MDF different (Medium Density Fibreboard) from chipboard? It is classified as less toxic materials, because the boards are formed by dry pressing of fine wood chips at high pressure and temperature.Urea resins modified with melamine are used as a binder. This ensures very low formaldehyde emissions comparable to those of natural wood. Therefore, it is considered a more environmentally friendly material and is widely used in furniture production. The strength of MDF exceeds chipboard by about 2 times, slightly increasing the service life of the furniture. Unlike chipboard, MDF is a moisture resistant material, especially if it is coated with varnishes and enamel. It is practical to use such furniture in the bathroom, where the humidity is constantly high.

How to choose plywood for making furniture with your own hands

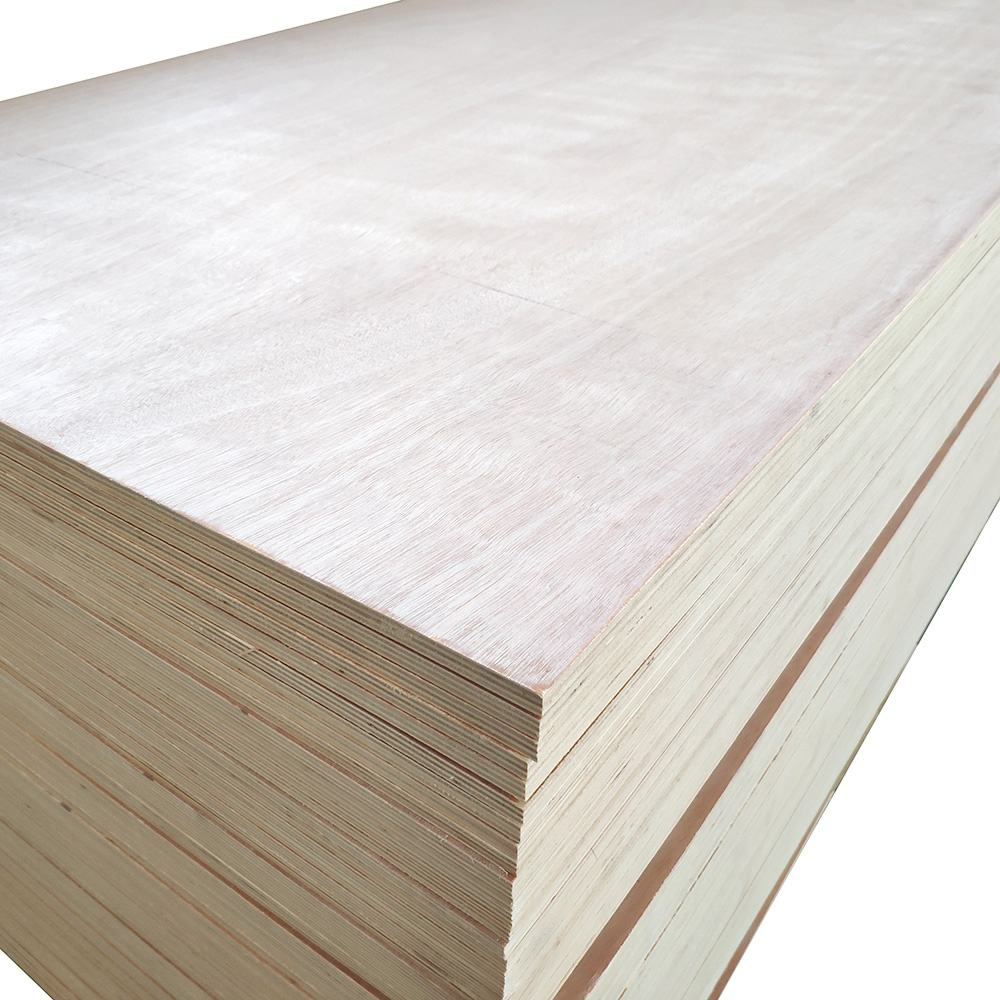

For the independent manufacture of furniture and other interior elements, plywood is most often used. This material has gained such popularity due to its functionality. Plywood does not require complex processing, it is characterized by a low weight, combined with strength and flexibility. In addition, the cost of glued wood panels is much lower than that of natural wood.

However, the plywood on the market varies greatly. To get really high quality, reliable and beautiful furniture, you need to use the appropriate material. In addition, different types of plywood are suitable for different purposes. For example, if you are planning to make garden furniture, you will need a waterproof FSF. Typical home furnishings are best made from 15mm birch plywood boards. For all sorts of interior designs - for example, podiums - more solid slabs will be required.

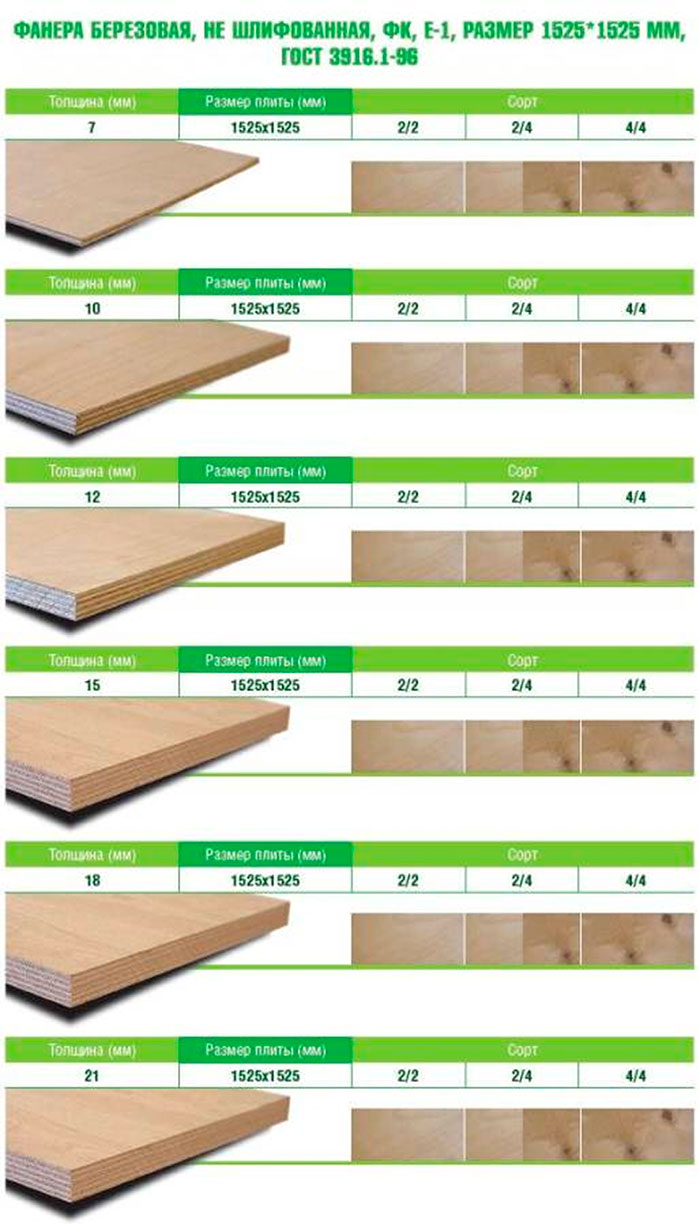

What plywood to choose for the floor

Choosing plywood on the floor you should pay attention to options:

plywood brand. As already noted, it is better to purchase FC brand plywood for residential premises. Its moisture resistance indicators are fully consistent with the operating conditions in residential premises;

plywood class (emission class). Only class E-1 is suitable for the floor;

grade of plywood for the floor. Plywood is divided into 4 grades. In this case, the sides of the sheet can have a different grade. This is marked as 1/1, 1/2, 2/2, etc. For the subfloor, plywood of 3 and 4 grades is suitable. For finishing - 1 or 2 grade;

moisture of plywood. A sheet with a moisture content of 12-15% is of high quality;

number of plywood layers. The thickness of the veneer in the plywood sheet ranges from 1.7 to 1.9 mm. Therefore, their number determines the thickness of the sheet. The more layers a sheet has, the more durable it is. However, the thickness of the plywood is chosen taking into account its purpose. So for the subfloor, plywood with a thickness of 12-18 mm is needed, for the final 10-12 mm. When using plywood in production - at least 25 mm

Please note that if the plywood will be laid in two layers, then the thickness of the sheet should be divided by two;

plywood sheet size. Allocate formatted and large-format plywood. The sizes regulated by GOST 3916.1-96 and 3916.2 are shown in the table;

The dimensions of plywood are more important for transportation and storage than for laying. After all, it is inconvenient to work with a large size, and any method of stacking involves adjusting the sheet to the desired size. The main thing is to number the selected sheets and not to confuse them during installation. By the way, professionals advise to stack the workpieces with an offset. The joining of four corners significantly reduces the surface quality;

plywood manufacturer. European or domestic manufacturers offer good quality material. But Chinese-made plywood raises complaints from users and often does not meet the declared characteristics.

Types of slabs

The existing options differ in technical parameters and production method.

Pressed plywood

This name means OSB panels that are made from shavings. The products are among the most popular building materials.

The manufacturing technology of this plywood has some nuances:

- Chips of different sizes are used for the layers, which ensures strength and reliability.

- The high pressure gives the pressed structure the desired stability.

- The chips are stacked in layers in different directions.

The high strength of OSB is largely due to the special weaving of the carpet from wood chips

The high strength of OSB is largely due to the special weaving of the carpet from wood chips

The material undergoes additional processing, which gives a moisture-resistant effect, but only products of the 3rd and 4th grade have such indicators. The latter category has improved characteristics, therefore it is used for outdoor work in aggressive environmental conditions.

Without serious protection in the open air, only 4 grade sheet can be used, the third grade needs to be equipped with a reinforced putty, and 1 and 2 are designed for indoor installation

Without serious protection in the open air, only 4 grade sheet can be used, the third grade needs to be equipped with a reinforced putty, and 1 and 2 are designed for indoor installation

Glued version

This is a fairly popular product made from veneer. Various compositions are used to connect the layers.

At the moment, there are the following varieties:

- FC. It is based on carbamide glue with phenolic additives. It stands out for its good resistance to moisture, but without direct contact, therefore the boards are used exclusively for internal cladding. To enhance the properties, parts can be processed at home with special primer and waterproofing mixtures.

- FSF. The veneer for obtaining such moisture-resistant panels is glued using phenol-formaldehyde resin. The structure of the products is preserved even in direct contact with liquid, so the material can be used for facade work.

- FBK. It is made by impregnation with bakelite varnish. The resulting products are distinguished by their increased strength and are suitable for use in difficult climatic conditions.

- FBS. Also called marine or Finnish plywood. It is produced using bakelite composition, but, unlike the previous version, alcohol-soluble glue is used. The material has excellent performance properties, includes varieties of FBS-1, FBS-A and FBS-1A. The surface of the products is completely waterproof, so even direct contact with sea water is allowed.

- FBV. The peculiarity of this material is that a water-soluble bakelite composition is used for gluing the veneer. The panels are quite strong, but do not have a water-repellent effect, therefore they are not recommended for use outdoors and in areas with constant high humidity. Includes a variety of FBV-1.

- FOB (FOB). This category includes decorative and laminated options. Due to the presence of cladding, the products perfectly cope with harmful external influences.

Only bakelite plywood glued with alcohol-soluble glue has high moisture resistance parameters, although FSF is declared as waterproof, it can only be mounted in technical unheated rooms, and FC sheets do not belong to moisture resistant at all

The FBS and FBV brands can be quickly distinguished, since they look different: the first variety is brown, the second is black.

Overview of varieties

Plywood furniture can be easily used in absolutely any room of your home. At the same time, you need to carefully choose this kind of product, first of all, taking into account the conditions in which you are going to operate the acquired structures. So, for some rooms, cabinet furniture is ideal, which perfectly tolerates high humidity, and for others, decorators do not recommend using laminated material.

Plywood is an excellent choice of material to create stylish office furniture. Original ideas of professional designers can become a unique decoration of any modern office.Many design studios offer customers interesting products made from high-quality plywood: sturdy tables, easy-to-use cabinets for storing papers, wide shelving shelves for storing documents, creative chairs for office workers, original armchairs and couches for visitors.

Plywood sheets are often used to make very interesting in appearance cots for children, compact computer transformer tables, low pedestals, walls, luxurious dressing tables, and comfortable chairs. For safe use, it is best that all corners of wooden furniture products intended for the nursery are rounded. In this case, the plywood sheet is covered with any desired color or retain its natural shades and texture, but it is still treated with a special stain or special varnish.

Garden and country furniture made of high-quality plywood is usually represented by light tables and comfortable sun loungers, other original designs that should provide the most comfortable rest and are characterized by increased moisture resistance. In the cold season, such furniture is brought into a warm room, therefore, many products in this series are often collapsible for ease of storage and movement.

Prefabricated pieces of DIY furniture will allow you to quickly transform an ordinary bedroom into an exquisite boudoir, and a living room into an original room, decorated in a loft or minimalist style.