Manufacturer's warranty obligations

If you come to buy ready-made furniture, you need to check if it is handicraft. Each company puts a shaped hologram on its products - it guarantees the quality of the products. If necessary, you can always clarify on it the master of the technical control department, the team that carries out the cutting and edge banding of the material, packaging.

In the event of a dispute or a warranty case, this will help restore the entire production process, it is enough just to present a photograph of the hologram.

A hologram is an insignia with a unique number that corresponds to a specific product

A hologram is an insignia with a unique number that corresponds to a specific product

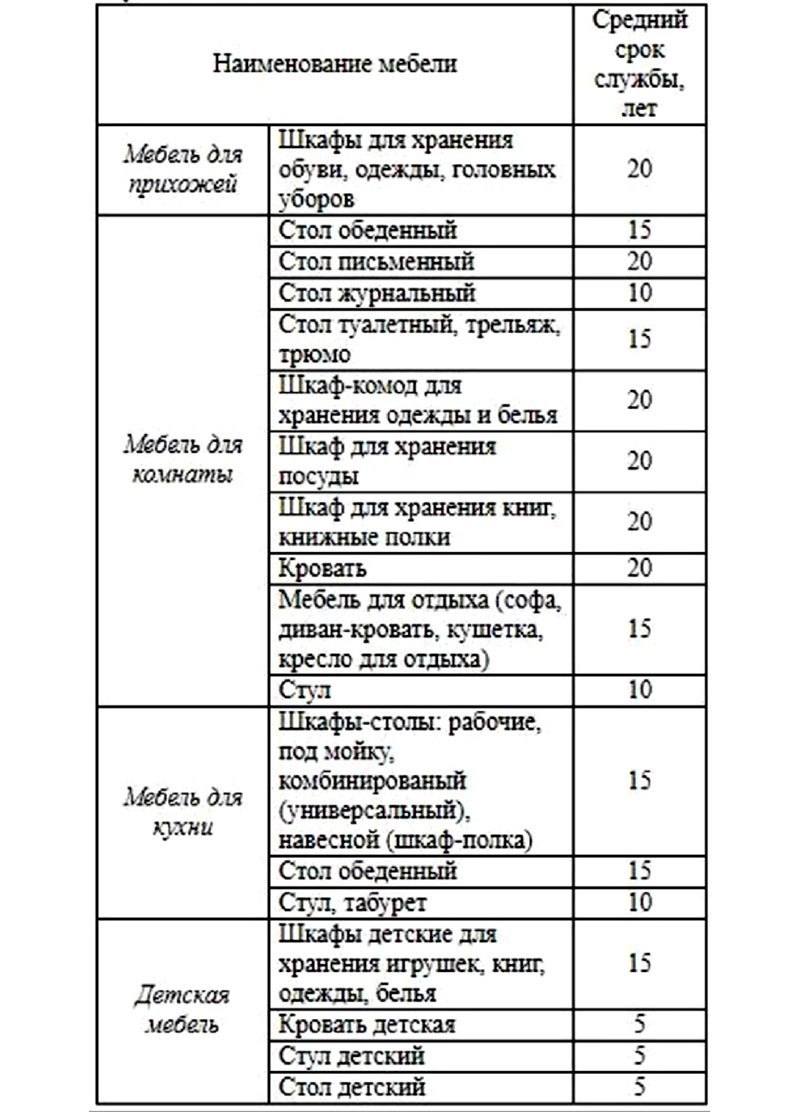

Another assessment is the manufacturer's warranty obligations. Verified companies provide not only a certain service life of products, but also provide a guarantee for fittings. Durability is a direct indicator of the quality of furniture, the lower it is, the worse the quality of the materials used. In addition, many companies provide after-sales service for the manufactured models, which means that they are responsible to the consumer for the result of their work.

Average life of furniture

Average life of furniture

What's better?

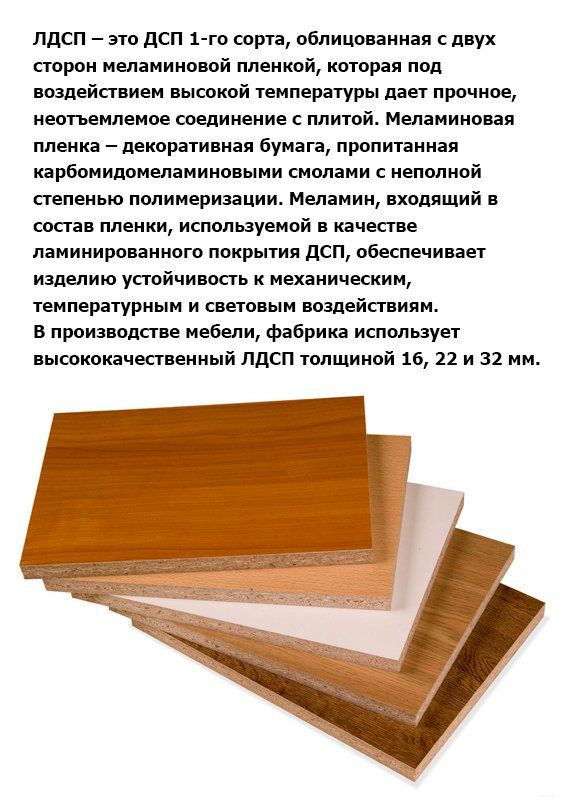

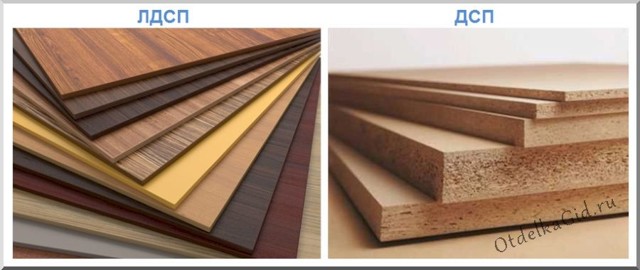

The cost of finished furniture products depends on what material is used for their production. Therefore, in budget class furniture, inexpensive chipboard panels are used, which can be covered only on one side with a moisture protection film. In addition, for the production of furniture, it is also important whether the material from which it is made emits formaldehyde. For example, a higher quality laminated chipboard material will be used for a bed, since its protective layer does not allow a vapor of a harmful component to come out.

The cost of budget furniture made of chipboard is also influenced by the type of material. There are several types of chipboard.

- I grade - sawdust of fine standard fraction without foreign inclusions is used as raw material for the manufacture of the panel. The finished chipboard turns out to be perfectly flat, smooth, it has no chips or cracks. The first grade of chipboard is subject to mandatory additional decoration with foil or veneer, and this is done on both sides of the chipboard.

- Grade II - made from high-quality sawdust raw materials of different fractions, let's say a minimum percentage of impurities. The finished board may have minor damage in the form of chips or scratches. For grade II chipboard, decorative cladding may not be used.

- III grade - made from sawdust of various wood species, may include a small percentage of foreign inclusions. The material is not exposed to decorative cladding, since this grade is not used in furniture production. Particleboard III grade can only be used for construction purposes.

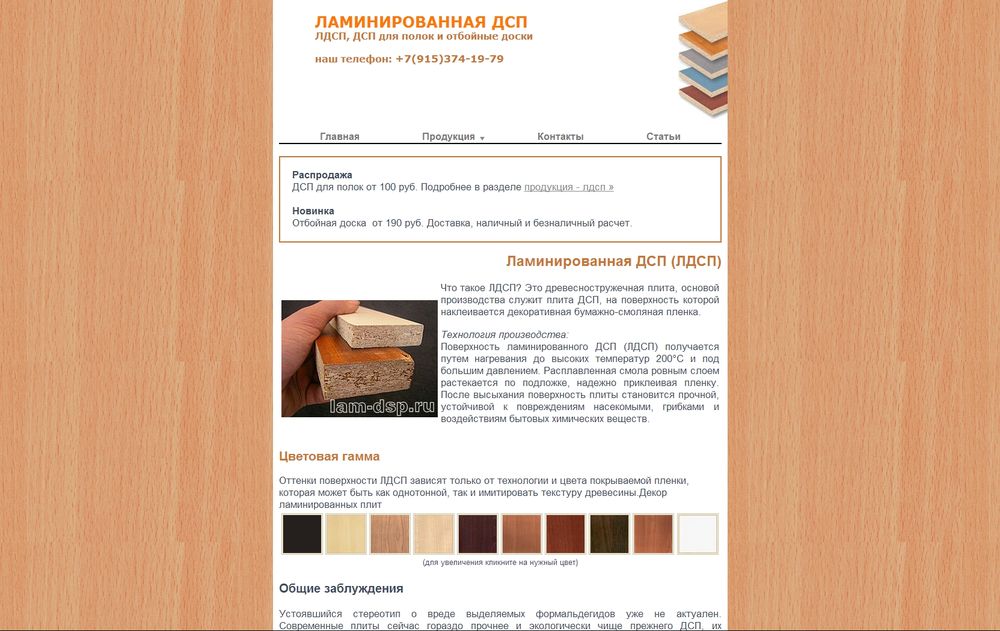

By the type of protective coating, chipboards are divided into such main types as:

- without cladding - this material is called rough; it applies only when performing construction work;

- laminated - chipboard has a durable varnish coating or melamine film treatment;

- veneered - chipboard has an external finish with natural wood veneer.

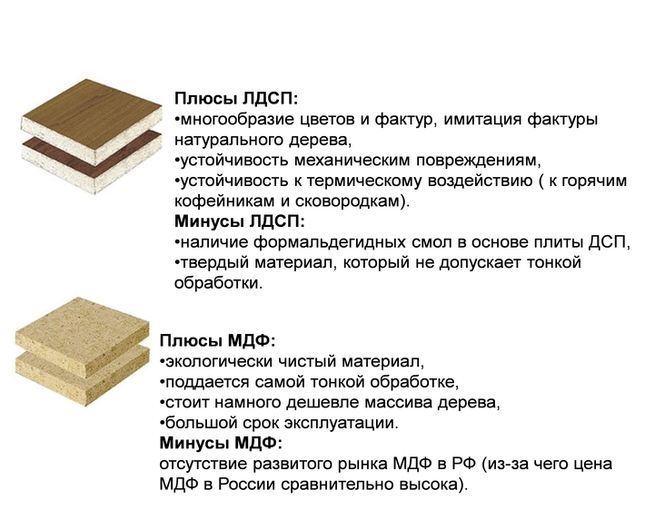

Unlike chipboard, chipboard materials have a wider variety. Lamination of the board can be done in various colors, as well as create an imitation of any texture. Furniture products made of laminated chipboard can harmoniously integrate into almost any interior composition.They look solid and elegant, while having a small, quite affordable cost. In some types of laminated chipboard material, a fire-resistant film containing carbon or HLP class material, which is resistant to fire, can be used as a laminating layer.

Chipboards of the laminated type, despite the mass of their advantages, are prone to the formation of chips and cracks. Most often this occurs from heavy objects falling onto the surface of the plate or under the influence of a mechanical factor. It is no longer possible to eliminate such a defect in furniture later. Due to this property of the material, it is not subjected to various treatments by milling, therefore, it is impossible to obtain a relief surface, smooth bevels or rounding of a chipboard panel.

When a chip or crack appears, the surface of the chipboard loses its safety, since formaldehyde begins to release outward, therefore, the quality of the laminating layer and its stability play a very important role for this type of chipboard.

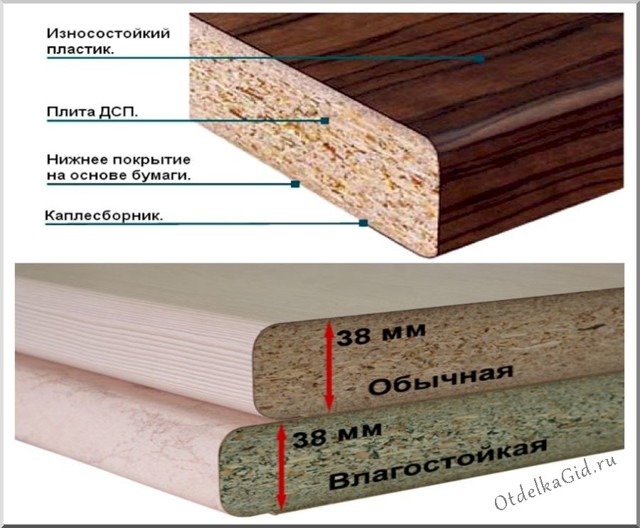

For the manufacture of countertops or kitchen sets, chipboard material is not used, since only the laminated surface of chipboard is able to withstand frequent and prolonged contact with water without prejudice to its appearance. Although prolonged wetting is undesirable even for laminated boards, such an effect from the edges of the material is especially dangerous.

To make low-cost, but high-quality and beautiful furniture, modern manufacturers use both woodworking products - chipboard and laminated chipboard, moreover, ordinary chipboard is used to create the supporting frame of furniture, while the front part is performed using laminated board. Furniture products made from a combination of materials can be used both for home use and in office premises.

See the next video for the differences in materials.

What is the difference and what is common between OSB and chipboard

First, definitions.

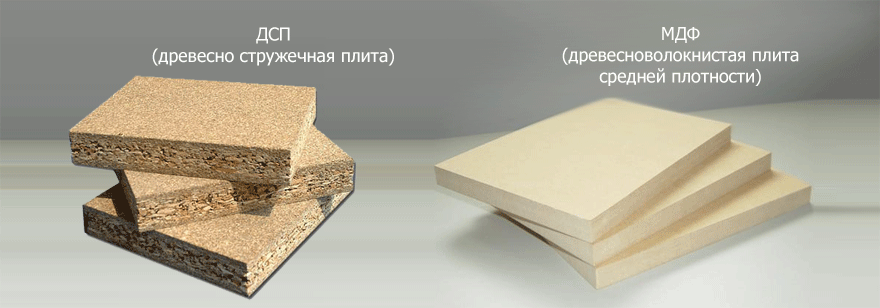

Chipboard is a particle board made by pressing from wood shavings of any shape.

OSB is a wood board, for the manufacture of which chips of a special shape are used, which are oriented in certain directions before forming the board. The slab consists of three layers. In the outer layers, the chips are oriented in one direction in the plane of the plate, and in the middle layer - perpendicular to the outer layers in the same plane.

The OSB name is derived from the transliteration of the English name - Oriented Strand wood construction Boards (OSB). Along with them, the Russian-language term and the corresponding abbreviation are used - Oriented Strand Board (OSB).

Both materials being compared are composites based on wood waste. They are manufactured in the form of sheets or slabs of various thicknesses and sizes. In both cases, the boards are formed from wood chips using formaldehyde resins. This is where the main similarities between them end.

The main difference between OSB and chipboard can be seen from the above definition. This is the special shape and orientation of the chips.

Assortment of materials

Chipboard is produced with a thickness of 1 mm and more, with a step of 1 mm. The most commonly used slabs are 10, 16 and 18 mm thick. These are furniture standards. The most popular sheet formats are 2750x1830, 1830x2440, 2800x2070 mm. But there are a lot of options, starting from 1800 in length and 1200 in width.

OSB has a thickness of 6 to 40 mm in 1 mm increments. The most commonly used formats are 2500x1250 and 2400x1220 mm, although there may be a variety of options. The minimum size defined by the standard is 1200 mm. In addition to ordinary rectangular sheets with a flat edge, grooved plates are produced, which are convenient to use as cladding. When they are joined, the profiled edges form a lock that aligns adjacent panels in one plane.

According to its physical and technical parameters, each of the materials is divided into grades or types.

Chipboard:

- type P1 - for general use;

- type P2 - for dry indoor conditions, including for the manufacture of furniture.

OSB:

- OSB-1 - boards for unloaded elements used in dry conditions;

- OSB-2 - boards for load bearing parts for dry conditions;

- OSB-3 - boards for loaded products in wet conditions;

- OSB-4 - for wet conditions with increased loads.

Security

The technology for the production of board materials implies that the content of harmful substances in MDF is less than in chipboard. We are talking about volatile substances, which are harmful to humans, released by resins (used as binders), which gradually (during long-term operation) "evaporate" and accumulate in the air if there is no sufficient ventilation of the room. All these substances do not cause instant damage to the human body and have a harmful effect only with prolonged contact with them (in other words, if you decide to lie down for a long time on a chipboard or MDF plate, then you will not die from poisoning by the substances they release, but from thirst, hunger or from old age).

However, the manufacturers nevertheless established a certain gradation:

- MDF - with strict adherence to the technology and the implementation of high-quality cladding of the surfaces of the structure, it is considered the least dangerous in terms of the release of harmful substances into the ambient air. In the production of MDF, the main binder is lignin, which is released during the heating of wood. Therefore, high-quality MDF is environmentally friendly;

- Chipboard class E1 - takes the second place in terms of safety for the human body (but also only with the appropriate facing of surfaces);

- Particleboard of class E2 - emits the largest amount of harmful substances, is prohibited for production in foreign countries, and in Russia - is prohibited for the production of furniture and products used inside public and residential premises (GOST 10632-2007).

The difficulty in determining the harm actually caused by these materials lies in the fact that the information recorded in the certificates does not always correspond to reality (and sometimes certificates are attached to the materials not "native", that is, drawn up based on the results of tests carried out, but "purchased"). In addition, not all manufacturers (especially Russian ones) follow the recommended process technology for the production of MDF and chipboard, trying to save money when using lower quality resins.

Array or chipboard? Pros and cons of materials

Solid wood, chipboard, MDF, fiberboard - what do these terms mean, and how not to get confused by an uneducated buyer? What is the furniture around us made of - wardrobes, dressers, cabinets, furniture for the kitchen, bathroom and bedroom?

Solid wood

Furniture made of solid wood gives a solid and noble look to the room. Often these are exclusive custom-made furniture.

+ naturalness and environmental friendliness of the material;

— natural wood is prone to darkening, sensitive to dampness and temperature extremes;

— expensive and not always affordable option.

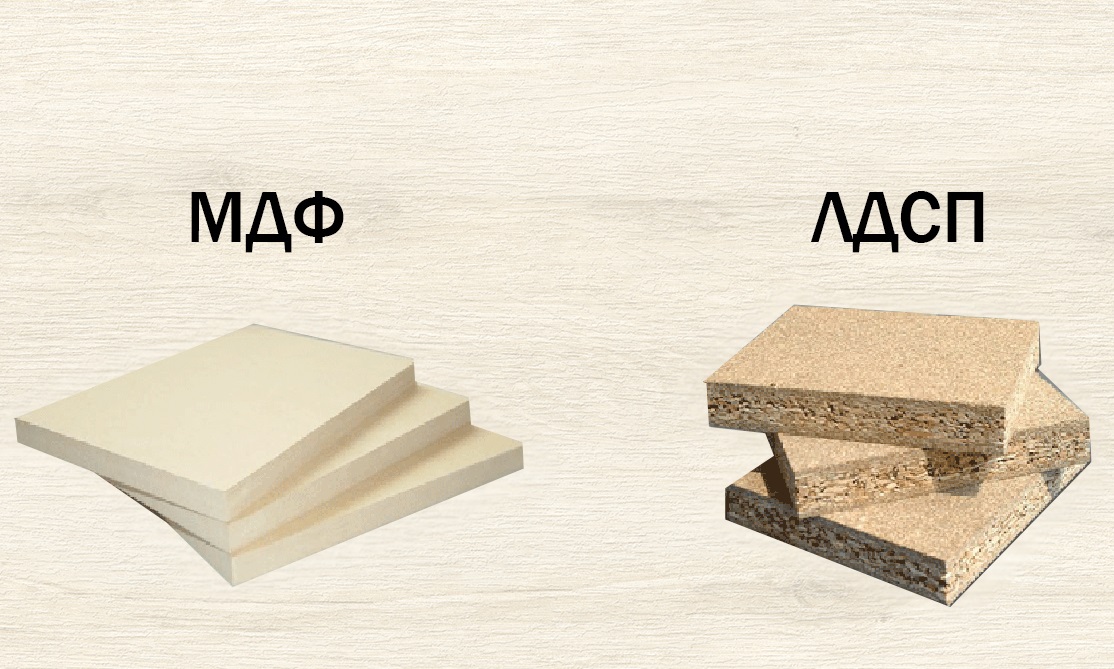

A cheaper analogue is furniture made of wood-based panels. MDF, chipboard, laminated chipboard, fiberboard are materials based on wood, but in the form of shavings, fibers and sawdust. Most often it is woodworking waste, as well as raw materials obtained in the process of sanitary felling of trees.

A classic option in the production of furniture is considered: the front part is made of MDF, the body is made of laminated chipboard, the back wall is made of fiberboard.

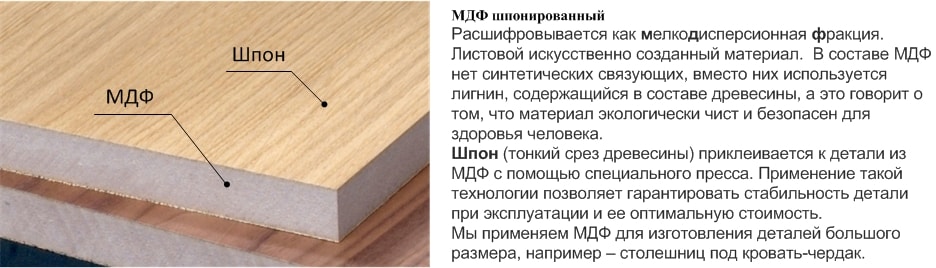

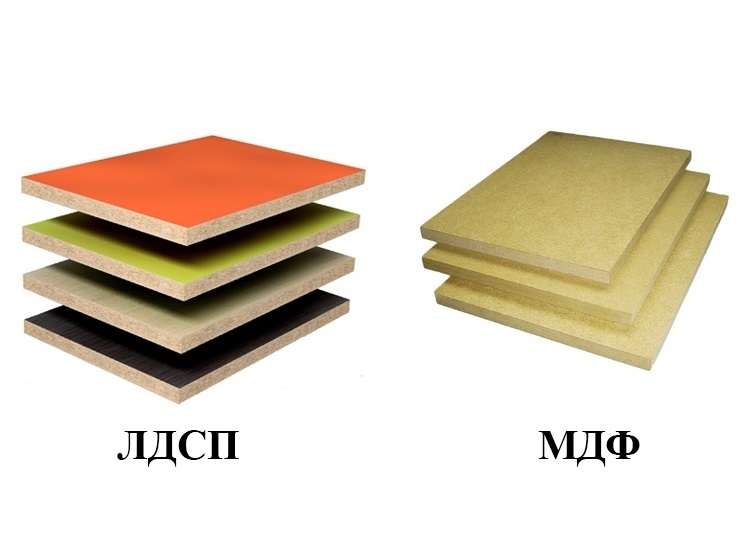

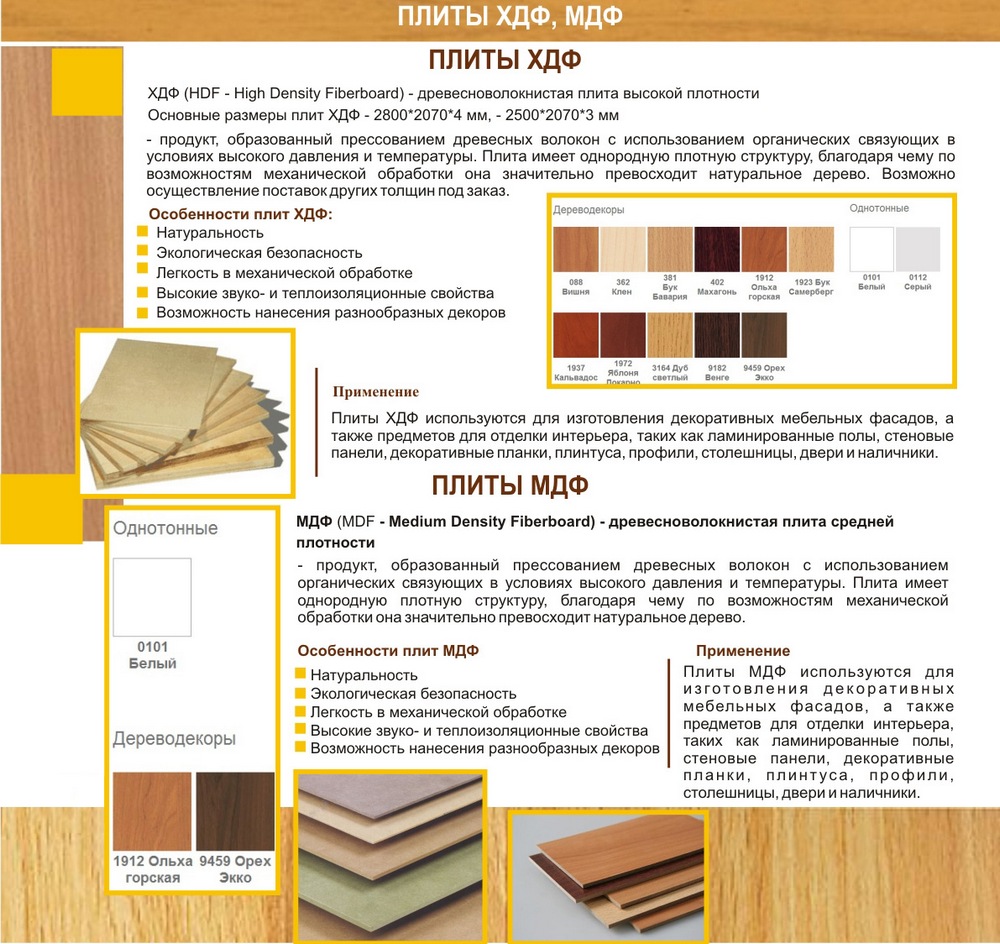

Medium Density Fiberboard (from English Medium Density Fibreboard - MDF - MDF ). In the production of MDF, the raw materials are crushed into practically dust and mixed with organic or non-toxic resins. It is a material that is easy to process, which is very much appreciated in the manufacture of furniture that requires elegance and subtlety of lines.

+ the density of the board, which almost corresponds to the density of natural wood, holds screws and other fasteners well;

+ the ability to produce bent furniture elements

+ the plate is immune to microorganisms, mold and mildew.

— reacts painfully to temperatures above 70 degrees Celsius: it swells, warps, and the decorative coating bubbles and peels off, which is why it is not recommended to place furniture made of MDF near heating devices;

— furniture made entirely of MDF is quite expensive, therefore such plates are most often used only in the production of facades.

Chipboard and chipboard

Chipboard (official abbreviation is Particleboard , in common parlance chipboard) is made by hot pressing of large shavings mixed with a binder - synthetic resin. Particleboard was manufactured back in the 1930s by the German inventor Max Himmelheber, and in 1951 he received a patent for his invention. "Ideal tree" - so then called chipboard for the homogeneity of the structure and the absence of defects inherent in wood (knots and cracks).

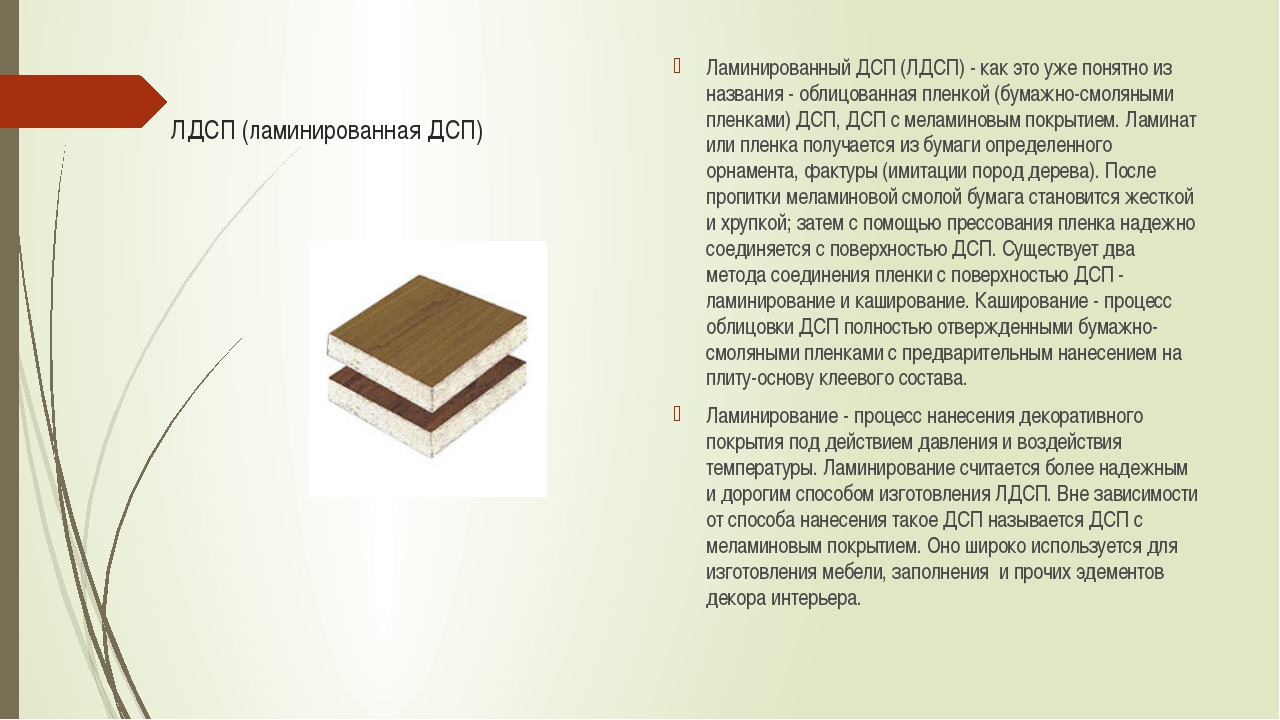

The most common material for the production of cabinet furniture - laminated particle board - or LDSP , in common parlance chipboard. This is chipboard, on which decor is glued on both sides, imitating the texture of wood of various species.

+ products made of laminated chipboard are resistant to moisture due to the laminating coating, in contrast to the analogue of solid wood described above. Furniture products made of laminated chipboard are as convenient as possible during operation: they can be easily cleaned and washed with usual detergents. Although, of course, it is better to refuse abrasive preparations, they can ruin the surface;

+ low price with a large number of colors;

— the material is not suitable for creating bent furniture elements;

— the main negative characteristic of chipboard is the presence of formaldehyde resins in the composition, which, at high concentrations, have a negative effect on human health. That is why it is necessary to ensure that there are as few uncoated chipboard sections as possible in the finished product.

Since 1986, an international scale has been in effect, which determines the emission class of wood-based board materials. It regulates the content of free formaldehyde in the products of manufacturing firms. The following international classification has been adopted: formaldehyde-free board of emission class E0.5 is used in the production of special furniture, for example, medical and children's furniture. Furniture made from chipboard with emission class Е1, approved by all Western countries, Ukraine and Russia for use in residential premises ... Particleboard with E2 emission class is prohibited from use in residential premises by the ministries of health of all European countries. EZ - wood-based panels, suitable only for use in construction.

Fibreboard and DVPO

Fiberboard or Fiberboard, in common parlance - hardboard. In composition, it is similar to MDF, but less in density and thickness, and does not have a decorative finish. The use of such a plate in the manufacture of furniture allows you to make products more affordable.

Refined fibreboard or DVPO. Slab, one side of which is painted with a solid color or imitates wood. The scope of application of such a plate in the manufacture of furniture is limited: the back walls of cabinets, the bottoms of drawers and other parts that do not imply a large load.

What salt and chipboard have in common

What happens if you combine two poisons, forming a new substance? That's right: a new substance with unique properties. A striking confirmation of this is kitchen table salt, ordinary sodium chloride.

Chlorine is a toxic asphyxiant gas. Pure sodium is flammable, and as a result of its violent reaction with water, a caustic alkali is formed. But the combination of these two substances - sodium chloride - plays an important role in human life.So important that people consume on average up to five kilograms of salt per year. At the same time, no one even thinks to compare it with chlorine or sodium - the properties are not the same.

Now let's get back to formaldehyde resins. This is also a completely new substance, which is made from poisonous, flammable and carcinogenic phenol and formaldehyde. Correctly cured resin is an absolutely harmless substance. The only danger is unreacted formaldehyde residues.

It should be borne in mind that most of this carcinogen escapes even during the production of plates that undergo high-temperature processing. Further, these products undergo certification, as a result of which the emission class (amount of emission) of formaldehyde is determined.

Well, the final stage in the processing of furniture chipboard and MDF is lamination - coating with melamine film or special varnishes, which almost completely exclude the interaction of the board with the environment. That is, even those formaldehyde residues that are allowed by the standards are clogged inside the stove and practically do not evaporate into the atmosphere (the exception is the open ends of the furniture). But what happens if the coating is damaged?

What is the best choice?

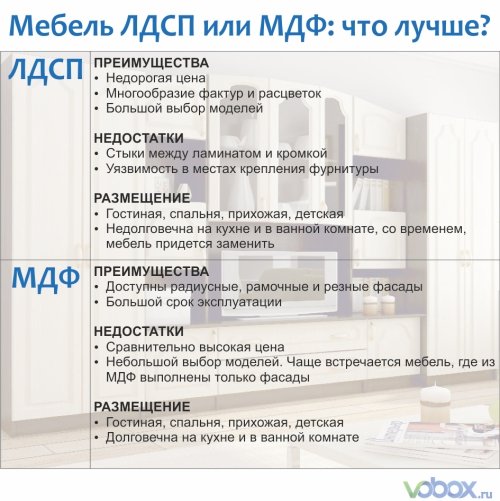

For furniture manufacturers, laminated chipboard and MDF are in almost the same demand. However, when choosing products from a particular material, one must take into account the upcoming operating conditions (expected power loads, humidity, temperature effects).

For kitchen

Modern kitchens can be made from particle board or wood fiber panels. Furniture made of laminated chipboard is considered to be of poor quality. Under the influence of moisture, it will quickly lose its visual appeal. Fine grain kitchens are more reliable, stronger and more durable, but they are too expensive.

To make the headset cheaper, it is recommended to purchase a combination product. It is best if the facades, vanity units and sliding doors are made of MDF.

For bathroom

MDF and laminated chipboard are wood-based boards from which budget furniture is made. For this reason, they are often used in the manufacture of products. bathroom... However, neither MDF nor chipboard panels are suitable for use in the bathroom. Too difficult conditions are noted in this room - excessive humidity, temperature drops, regular exposure to water. Even a moisture-resistant fine-grain stove in such conditions can soon lose its flawless appearance.

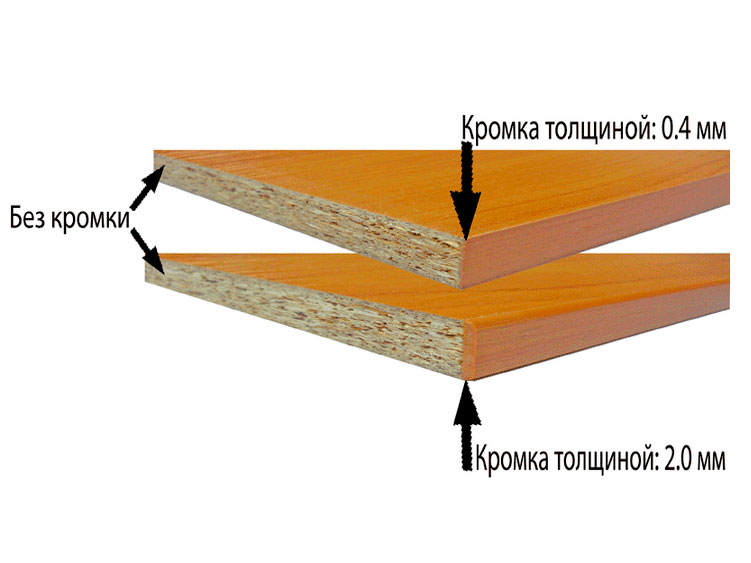

If there is no other choice, experts recommend opting for MDF furniture. At the same time, it is worth giving preference to high-quality products with processed edges and ends. Products with a thin melamine tape are not suitable for the bathroom - during use, cracks are easily formed on it, through which moisture penetrates. Getting under the protective film, it leads to deformation of the furniture.

Conscientious manufacturers in the production of quality furniture use a thick and durable PVC sheath, which is difficult to damage

If the budget is limited, you can take a closer look at the chipboard models, but in this case you need to pay attention to the labeling. Bathroom products should be made of chipboard with increased moisture resistance

Such materials are marked "B". They are made using paraffin wax.

For the nursery

When equipping a nursery, it is best to opt for furniture made from safe MDF material. Chests of drawers, wardrobes, shelves, desks, beds or sofas are made from it. Due to the evaporation of formaldehyde, furniture made of chipboard can cause allergies, dizziness and other health problems in a child. It is not recommended to purchase furniture made of particle board for children under the age of 7.

For bedroom

In this room, a person spends a lot of time at night, therefore, when choosing furniture, it is worth first of all taking into account its safety for health.MDF products are more environmentally friendly, which is why they are preferable. However, to save the budget, many people prefer chipboard furniture. In this case, you need to look at the quality certificate of the slabs. They can have 2 classes - E1 and E2.

Furniture with an E1 class is considered safer due to the lower formaldehyde content.

For the living room and hallway

In these rooms, wardrobes, tables, slides and furniture for relaxation made of MDF or chipboard are often installed. If there is no need to save money, you can furnish the corridor and living room with furniture made from MDF panels.

How to choose the right chipboard?

Today there is a considerable number of chipboards for various purposes. Their differences are in thickness, composition, wear resistance, density. Such features are associated with the use in various areas of plate production. There is a stereotype about the density of the slab. It is believed that the denser it is, the better. But it is not so. The advantage of these boards is in the budget raw materials (low-grade wood). It includes "thin gauges", slabs, slats. The main thing is that these materials meet the following standards.

- Chip fractions should not be small.

- The cross section of the shavings should be square, and the shape of the petal. If these requirements are violated, the physical and chemical properties of the finished slab will deteriorate (bending and resistance will suffer).

Chipboard has a wide range of colors, which is widely used in the production of cabinet furniture.

Often consumers ask questions: what kind of material is this for a bed - MDF? What is the difference between MDF and laminated chipboard for furniture? Let's consider these nuances in more detail.

The film is paper impregnated with melamine resins, so the term “melamine board” is often used.

- low price;

- does not dry out, does not exfoliate, does not grow moldy;

- thanks to chemical additives, bugs do not live in the stove;

- service life is more than 10 years.

- affordable price for middle-income consumers;

- strength;

- moisture resistance;

- includes all of the above advantages of chipboard.

Chipboard can be washed and cleaned - it is moisture resistant.

The choice of material depends on what you plan to make. Chipboard can be used in the manufacture of furniture intended for office, home, shop, supermarket. It is better to choose MDF for children's furniture.

He is also not afraid of high temperatures.

The production of fibreboard allows us to manufacture products at affordable prices for various interiors. Thanks to MDF and laminated chipboard furniture, every house will be filled with coziness, warmth and comfort.

Its advantage, in addition to all of the above, is its excellent ability to imitate various textures, most often - imitation of wood texture.

Pay attention to the formaldehyde standards in cabinet furniture

MDF and chipboard: what is the difference

Particleboard (chipboard) contains compressed shavings and sawdust impregnated with formaldehyde resins. Depending on the grade, chipboard has different quality characteristics: from loose material with a density of 300 kg / m 3 to a more durable and expensive 600 kg / m 3, which is used in the manufacture of furniture.

Modern production makes it possible to minimize the harmful effect of the binder resin and improve the appearance of the board with the help of coating with melamine film - lamination. Hence the name "chipboard". The film has good aesthetic properties and does not allow formaldehyde to evaporate.

Manufacturing of MDF board is carried out according to the improved technology of chipboard production - by drying wood fiber and hot pressing. Medium density fibreboard (MDF) contains only the smallest sawdust compressed to a homogeneous state. Unlike chipboard, which must be carefully sanded before being coated with a film,

MDF immediately has a smooth and even surface. Such a board is more dense and durable, resistant to drilling and moisture in comparison with laminated chipboard.It is also better suited for deep milling and deformation when creating curved furniture fronts. In addition, the MDF board has significantly higher environmental properties due to the fact that mainly natural resins, lignin and paraffin are used as impregnation of sawdust. Formaldehyde is also present, but in a much smaller amount.

For greater clarity of the differences between the two materials, you can compare the structure of chipboard with heterogeneous raw materials passed through a blender, and MDF with a product from a meat grinder. The density of the MDF board varies from 600 to 800 kg / m 3, which in conditions of increased moisture allows the material to surpass even natural wood in some characteristics.

Care of laminated chipboard or MDF furniture

There are several general conditions for the care of furniture made of MDF or chipboard.

- Prolonged exposure to high temperatures is undesirable: at 75 degrees and above, the coating may peel off.

- Another factor is sunlight, which can also change the appearance of the slab. The film on laminated chipboard is more susceptible to fading, although MDF can change color somewhat with constant exposure to sunlight.

- You also need to be careful about long-term interaction with water. If the joints of the coating are not airtight, when water gets inside the slab, the sawdust will swell, and the slab itself will lose its appearance and properties. However, this is an extreme case. Under normal living conditions, with short-term exposure to water, which is inevitable in the kitchen, the stove can retain its original appearance for a long time. MDF manufacturers claim that fiberboard can withstand even a small flood.

Chipboard or MDF: which is better

The common plus of both materials in comparison with natural wood is resistance to pests and fungal infection.

Advantages and disadvantages of MDF:

Chipboard and MDF: combining materials

The best option for a wallet, not at the expense of quality and durability, is to choose furniture with a combination of materials.

Chipboard will perfectly fulfill its functions as a basis for the kitchen body, and MDF, thanks to the variety of films for covering and the possibility of decoration, will make beautiful facades that fit perfectly into the interior of the kitchen. So you shouldn't choose which is better for the kitchen: MDF or chipboard? The answer lies in the correct combination of both materials and their rational purpose.

For example, laminated chipboard, in addition to being used in the furniture body, can be used as an inexpensive but durable and reliable tabletop of various thicknesses: from 25 to 38 mm. The slab is covered with multilayer plastic using the Postforming technology. Such a plate is resistant to moisture and mechanical damage, so it will last for many years without requiring special care.

High-quality laminated particle board in combination with MDF can be used in the production of other furniture, including wardrobes, beds, furniture groups for a children's room. If the joints and joints of laminated chipboard are reliably protected, and the manufacturer has the appropriate certificates confirming the environmental friendliness of the material, then such furniture is safe to use and can deservedly take a place in the apartment.

Array or chipboard? Pros and cons of materials

Solid wood, chipboard, MDF, fiberboard - what do these terms mean, and how not to get confused by an uneducated buyer? What is the furniture around us made of - wardrobes, dressers, cabinets, furniture for the kitchen, bathroom and bedroom?

Solid wood

Furniture made of solid wood gives a solid and noble look to the room. Often these are exclusive custom-made furniture.

+ naturalness and environmental friendliness of the material;

— natural wood is prone to darkening, sensitive to dampness and temperature extremes;

— expensive and not always affordable option.

A cheaper analogue is furniture made of wood-based panels. MDF, chipboard, laminated chipboard, fiberboard are materials based on wood, but in the form of shavings, fibers and sawdust.Most often it is woodworking waste, as well as raw materials obtained in the process of sanitary felling of trees.

A classic option in the production of furniture is considered: the front part is made of MDF, the body is made of laminated chipboard, the back wall is made of fiberboard.

Medium Density Fiberboard (from English Medium Density Fibreboard - MDF - MDF ). In the production of MDF, the raw materials are crushed into practically dust and mixed with organic or non-toxic resins. It is a material that is easy to process, which is very much appreciated in the manufacture of furniture that requires elegance and subtlety of lines.

+ the density of the board, which almost corresponds to the density of natural wood, holds screws and other fasteners well;

+ the ability to produce bent furniture elements

+ the plate is immune to microorganisms, mold and mildew.

— reacts painfully to temperatures above 70 degrees Celsius: it swells, warps, and the decorative coating bubbles and peels off, which is why it is not recommended to place furniture made of MDF near heating devices;

— furniture made entirely of MDF is quite expensive, therefore such plates are most often used only in the production of facades.

Chipboard and chipboard

Chipboard (official abbreviation is Particleboard , in common parlance chipboard) is made by hot pressing of large shavings mixed with a binder - synthetic resin. Particleboard was manufactured back in the 1930s by the German inventor Max Himmelheber, and in 1951 he received a patent for his invention. "Ideal tree" - so then called chipboard for the homogeneity of the structure and the absence of defects inherent in wood (knots and cracks).

The most common material for the production of cabinet furniture - laminated particle board - or LDSP , in common parlance chipboard. This is chipboard, on which decor is glued on both sides, imitating the texture of wood of various species.

+ products made of laminated chipboard are resistant to moisture due to the laminating coating, in contrast to the analogue of solid wood described above. Furniture products made of laminated chipboard are as convenient as possible during operation: they can be easily cleaned and washed with usual detergents. Although, of course, it is better to refuse abrasive preparations, they can ruin the surface;

+ low price with a large number of colors;

— the material is not suitable for creating bent furniture elements;

— the main negative characteristic of chipboard is the presence of formaldehyde resins in the composition, which, at high concentrations, have a negative effect on human health. That is why it is necessary to ensure that there are as few uncoated chipboard sections as possible in the finished product.

Since 1986, an international scale has been in effect, which determines the emission class of wood-based board materials. It regulates the content of free formaldehyde in the products of manufacturing firms. The following international classification has been adopted: formaldehyde-free board of emission class E0.5 is used in the production of special furniture, for example, medical and children's furniture. Furniture made from chipboard with emission class Е1, approved by all Western countries, Ukraine and Russia for use in residential premises ... Particleboard with E2 emission class is prohibited from use in residential premises by the ministries of health of all European countries. EZ - wood-based panels, suitable only for use in construction.

Fibreboard and DVPO

Fiberboard or Fiberboard, in common parlance - hardboard. In composition, it is similar to MDF, but less in density and thickness, and does not have a decorative finish. The use of such a plate in the manufacture of furniture allows you to make products more affordable.

Refined fibreboard or DVPO. Slab, one side of which is painted with a solid color or imitates wood.The scope of application of such a plate in the manufacture of furniture is limited: the back walls of cabinets, the bottoms of drawers and other parts that do not imply a large load.