Applications

Glazing is not the only application of the material, which is transparent and colored, and has the desired characteristics. Plexiglass can be used:

- for the creation of billboards, exhibition exhibits, decorative finishing of residential and public premises;

- a variety of colors and high operational qualities allow it to be used for the manufacture of items of home furniture, attributes required in trade establishments and cafes;

- a sheet of acrylic plastic is often used to obtain cladding details for building facades;

- a variety of household and decorative containers, ecosystems for growing plants and keeping fish, illuminated floors, roofs, shades for lighting devices, bathtubs are made of synthetic glass;

- plexiglass is relevant for making jewelry - excellent amber is obtained from it, almost indistinguishable from the real one;

- in the field of ophthalmology, the product is used to create lenses that replace the lens of the eye when it becomes cloudy, in dentistry - for the manufacture of fillings and implants.

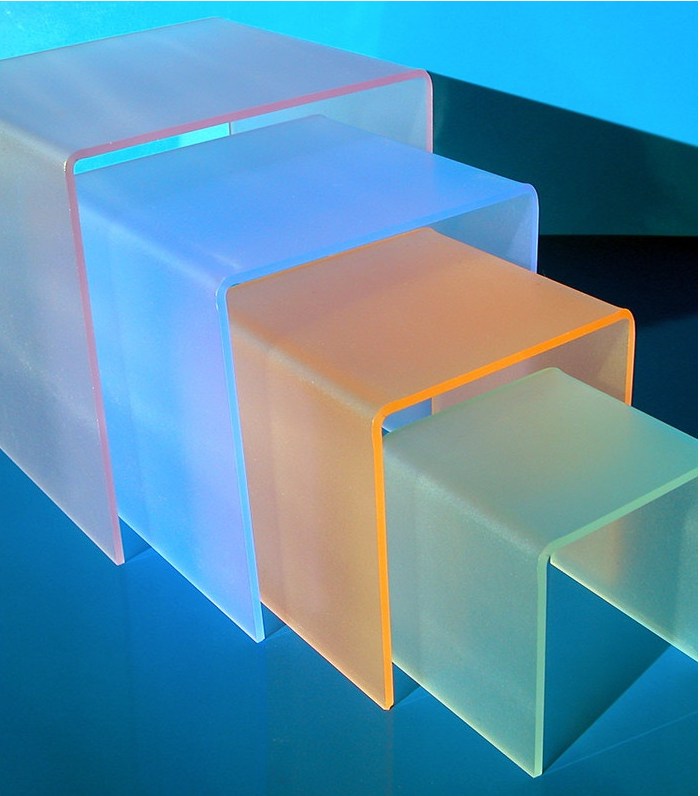

Decor elements from these products are voluminous and bright, can be decorated with engraving, gilding and silver due to the ease of processing. In the interior, plexiglass materials are used for the construction of original interior and zonal partitions and walls, from which spectacular shelves and racks, door and wall stained-glass windows and panels, steps of internal stairs are created. Transparent interior accessories are no less attractive, their area of application is facade decorations, glazing of furniture, decoration of shop windows, floor coverings.

Billets made of molded and extruded acrylics of various sizes are used by designers in their bold experiments to create an extraordinary style in apartments and private houses. Plastic products help to customize windows, create interesting mosaics in the kitchen and bathroom space, use plexiglass for the manufacture of countertops from painted materials with a textured surface. Molded plastic glass allows you to decorate residential houses and city buildings, create a spectacular home interior and make it unique.

For how to quickly and accurately cut plexiglass, see the next video.

Types of plexiglass

Many, choosing acrylic or such material as plexiglass, ask themselves the question - what is the difference, which is better? In fact, the difference is not significant. There are commonly used terms that mean the same material, namely this:

- Polymethyl methacrylate.

- Organic glass or as it is often called - plexiglass The material is very similar to silicate glass, but has many times better characteristics.

- Acrylic glass or acrylic. The material is manufactured using organic components.

- Plexiglass is one of the varieties of plexiglass.

Choosing plexiglass or acrylic, you make a choice, in fact, between the same materials, but you should focus on the purpose and conditions of use of the finished product, since there are varieties of plexiglass with different parameters.

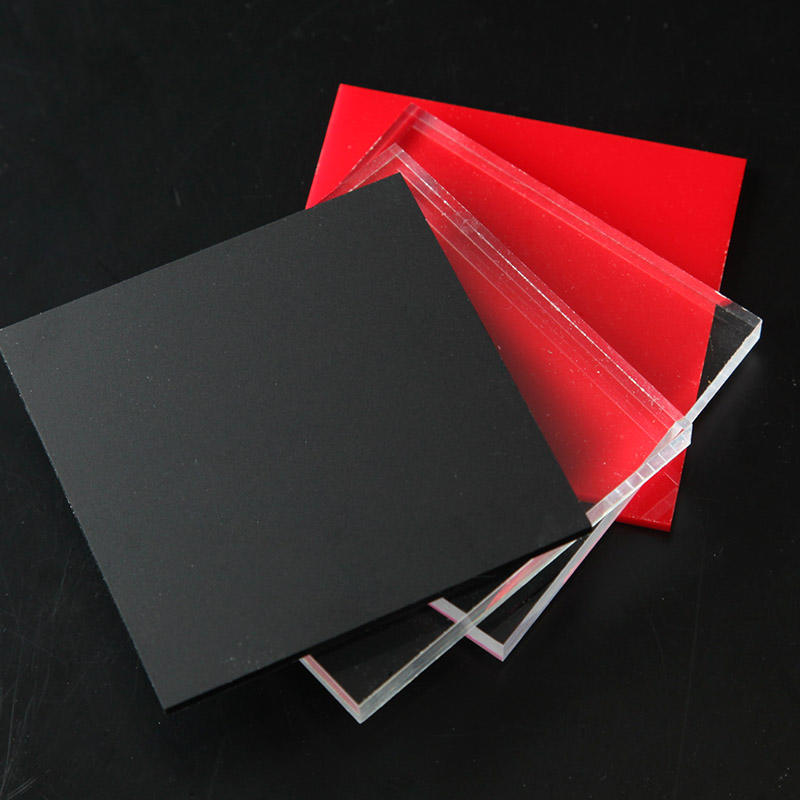

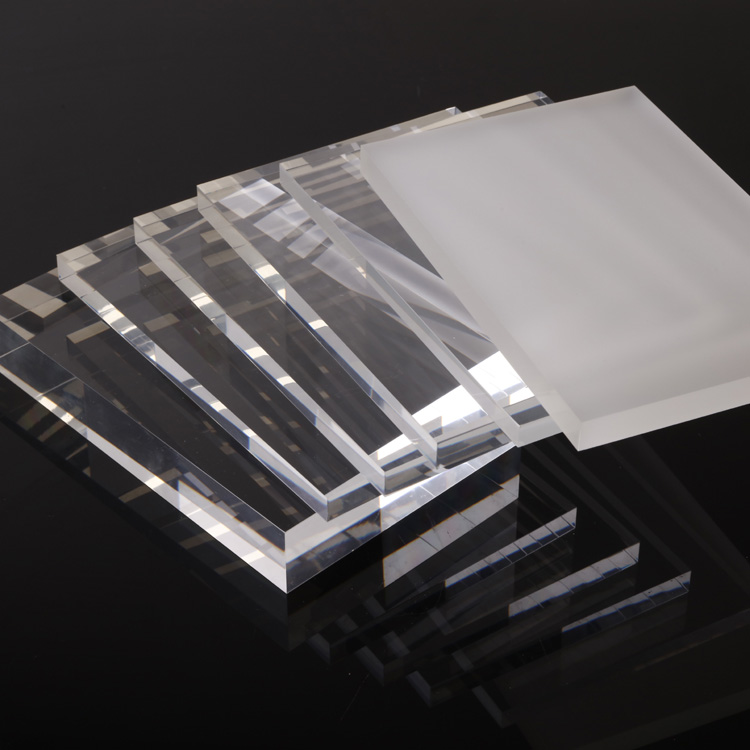

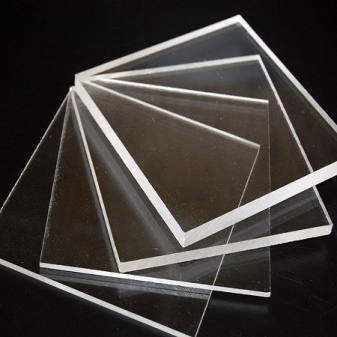

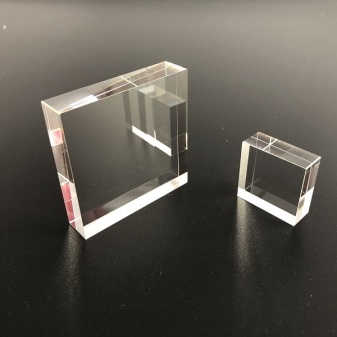

Acrylic glass is manufactured using two main technologies, namely:

- Extrusion method;

- Casting method.

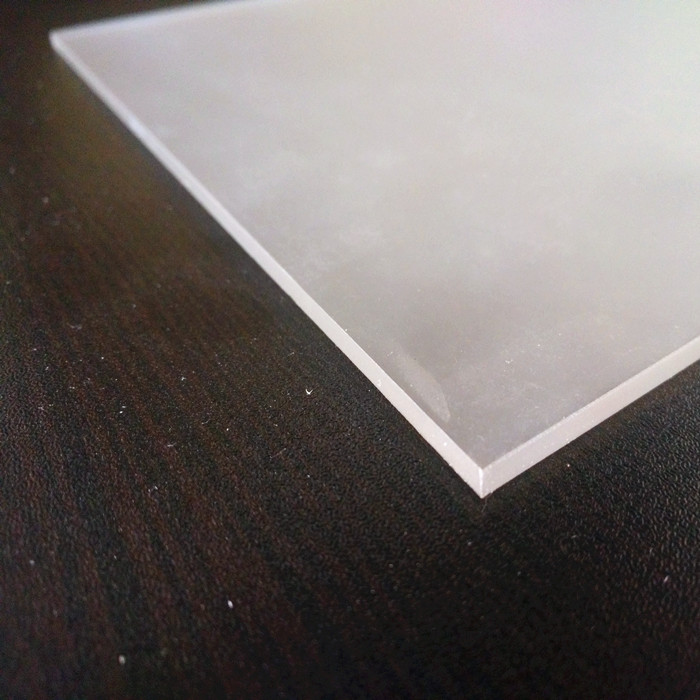

When manufactured according to the first technology, the material is less durable than when using the second method.

When manufactured according to the first technology, the material is less durable than when using the second method.

In this case, fewer colors are available, but the size of the finished sheet can be much larger.Also, the master, due to certain manipulations, has the ability to make a finished plexiglass sheet of the required thickness, in the range from 1.5 to 24 mm, but the cast plexiglass can be of greater thickness. Cast acrylic is less amenable to processing, especially when it comes to gluing, this should certainly be taken into account when working with this material at home.

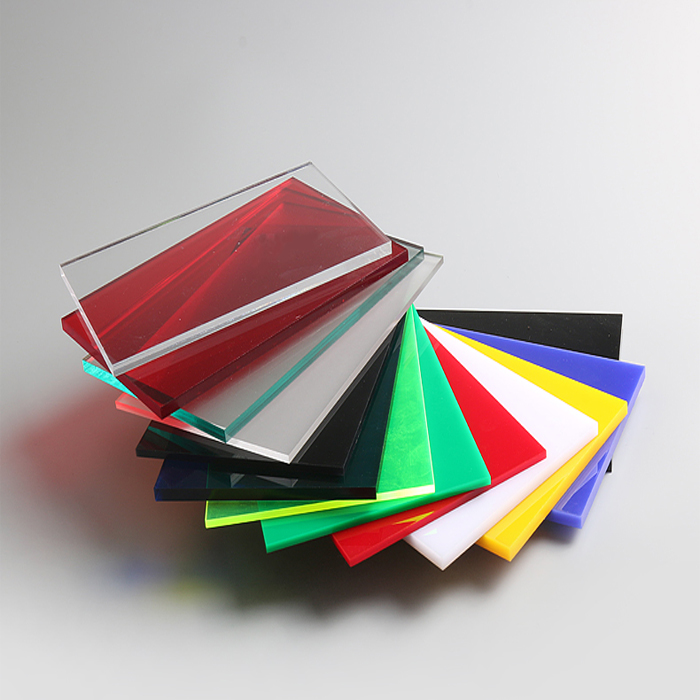

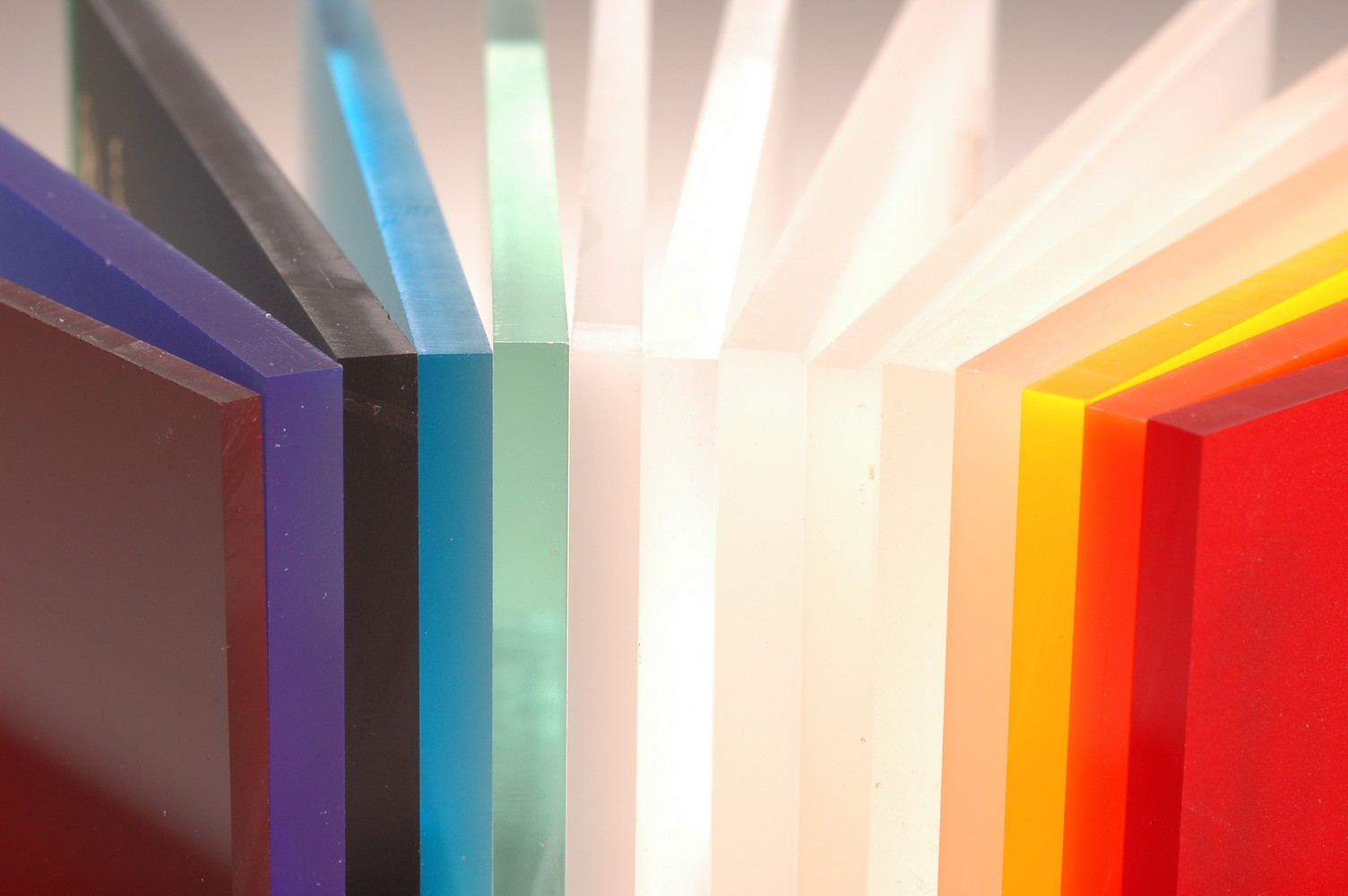

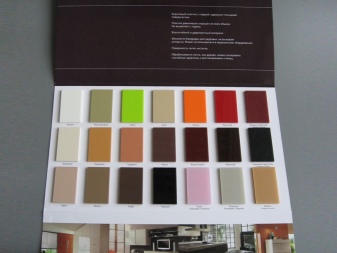

There are many varieties of acrylic on the market, this opens up wide opportunities for designers who increasingly use this material in their projects. The following varieties can be distinguished:

- Grandsilk. This material is made with a surface that imitates "metallic". You can find about 40 varieties of color schemes. Most often used in furniture production.

- Kamellit and Shine Glass. This type of plexiglass is made with a glossy surface. Of the features, it is worth highlighting a high degree of resistance to water. The material can be easily polished. It does not lose its color saturation over the years. It is most often used in the manufacture of kitchen furniture.

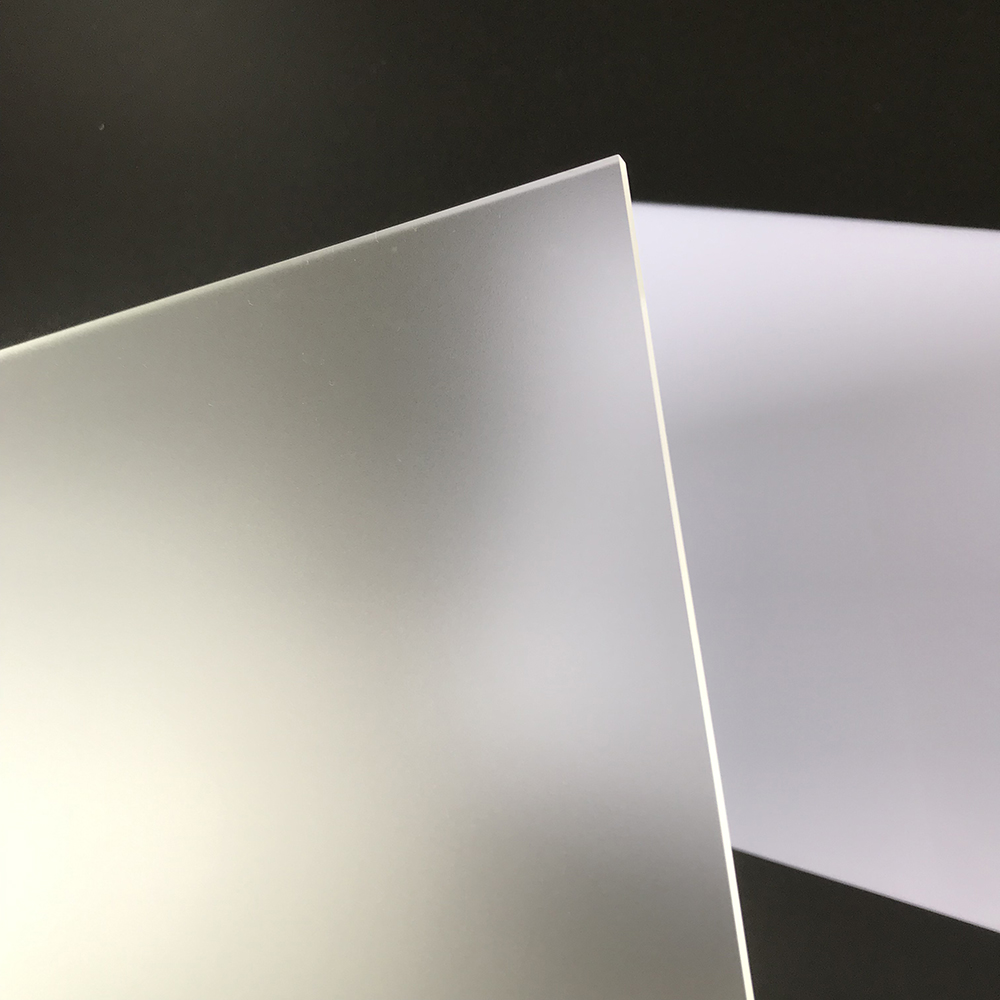

- Satin Glass. A type of acrylic with a matte surface. When used, no touch marks or scratches remain on the surface. It is most often used in furniture production, in the manufacture of chairs, interior partitions. Decor elements made from this material are very popular.

- Element Glass. This is one of the most unusual types of acrylic. The difference lies in the fact that various materials are "fused" into the base, they can be of both natural and artificial origin. These are shells, dried twigs, pebbles, or even cloth. The scope of this plexiglass is quite diverse, because the material is unusual and just looks gorgeous.

- Plexiglas SDP. A kind of honeycomb plexiglass. Consists of two layers. Of the characteristics, it is worth noting increased shock resistance, as well as resistance to weathering, therefore, it is an excellent choice for outdoor use.

- Frizzz. This is a very interesting and beautiful kind of acrylic.

The material is matte and has a velvety texture. Of the characteristics - increased resistance to scratches, dirt. Scope of use - window dressing, office furniture production, light cubes. - Plexiglas with fluorescent effect. This material is made transparent, but in different colors. Its ends emit a "glow" under the influence of ultraviolet rays. As a rule, this material is used in the manufacture of shop windows, as well as art installations.

Plexiglas processing

This material belongs to high quality types of plastic. It is good for both indoor and outdoor use. The modern market offers a wide selection of plexiglass with various operational features. It is worth noting that it is easy to process, which means that, if you wish, you can independently make various products from it. You can learn more about acrylic processing by going to the appropriate section on our website.

What is included?

Plexiglass is an environmentally friendly product based on polymethyl methacrylate. Its other name is acrylic, and it belongs to the type of artificial organic plastics. The basis of the material is thermoplastic acrylic resins, more precisely, one or more derivatives of a carboxylic monobasic acid. These are components that transmit light well.

The chemical formula of acrylic is the same as that of plexiglass - (C5O2H8) n, but in addition it contains many additives that impart special properties to the thermoplastic structure, such as hardness, flexibility, resistance to mechanical stress and damage, as well as pigments necessary for obtaining a specific color.

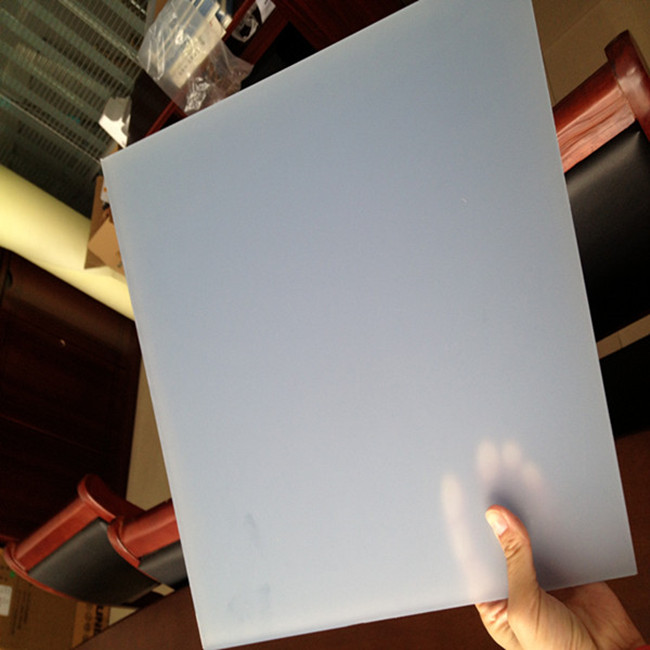

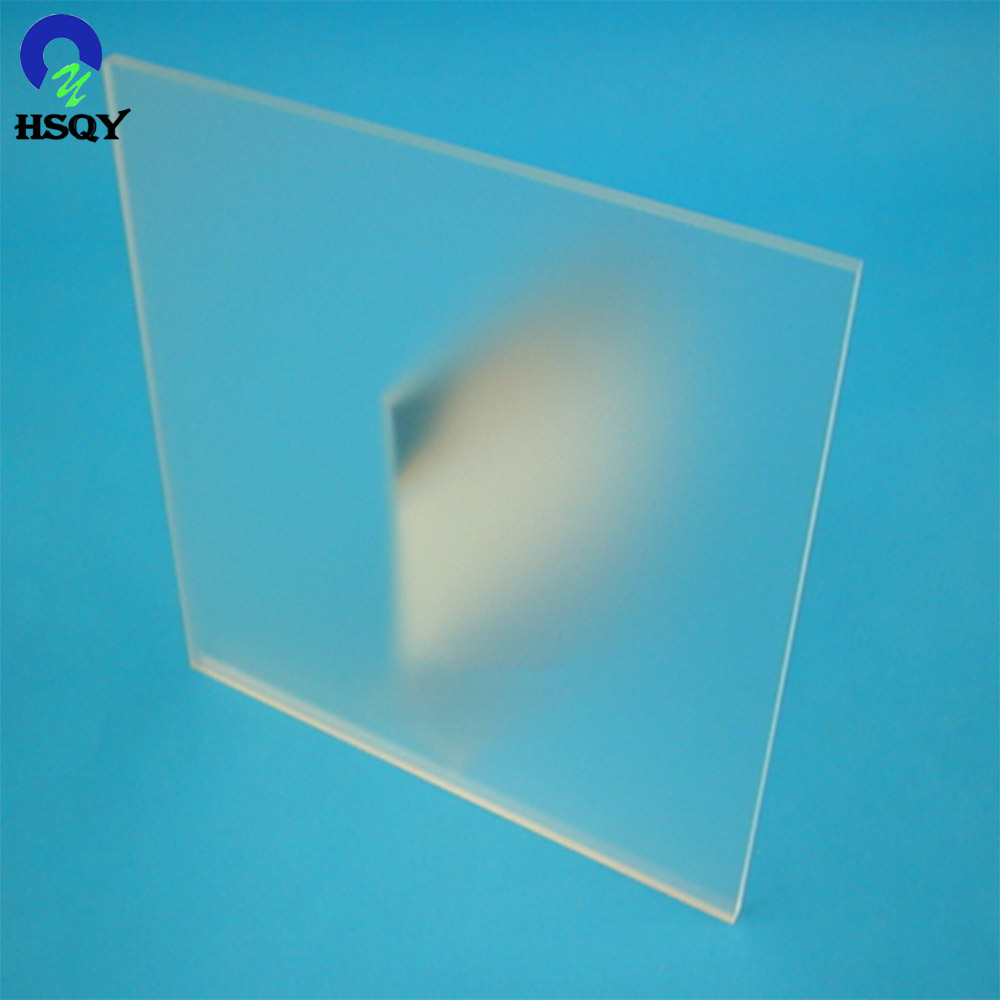

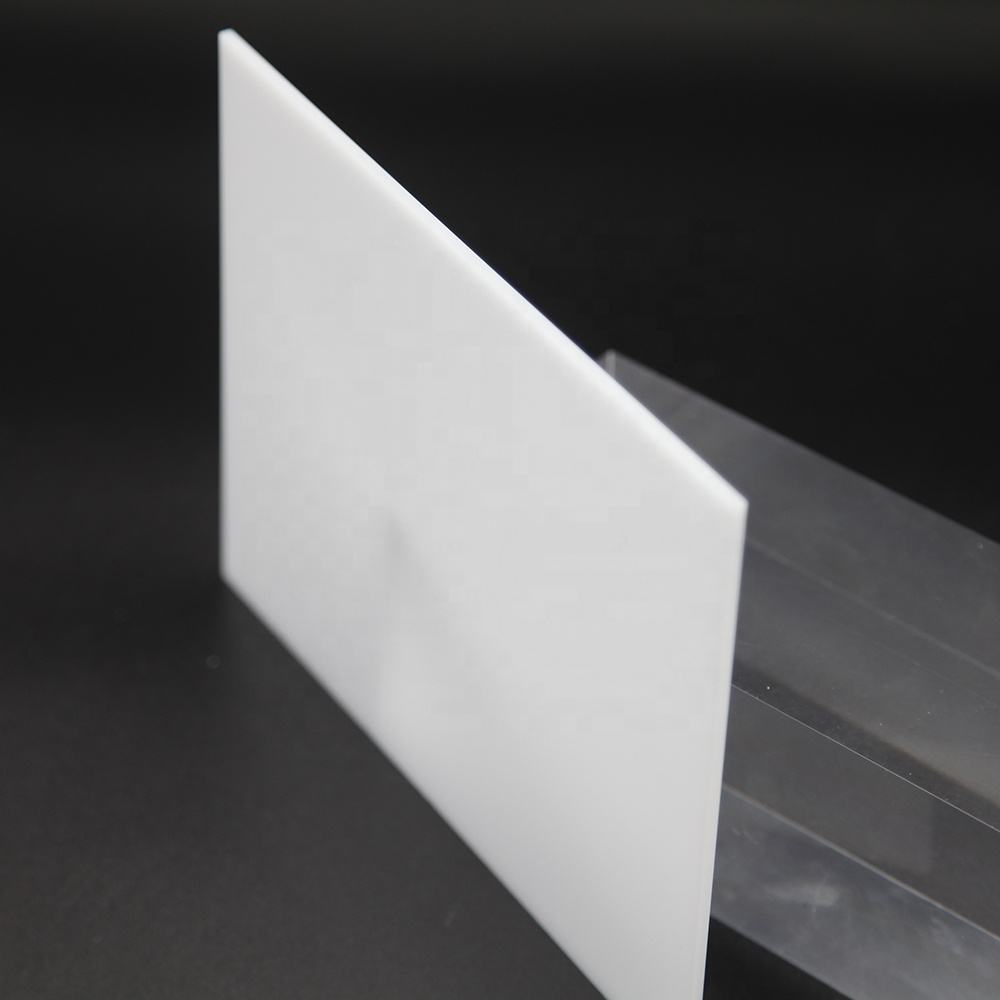

Application of matte plexiglass

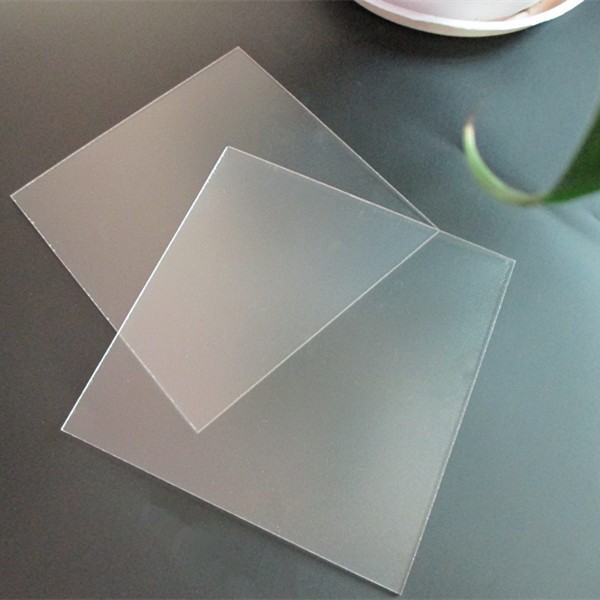

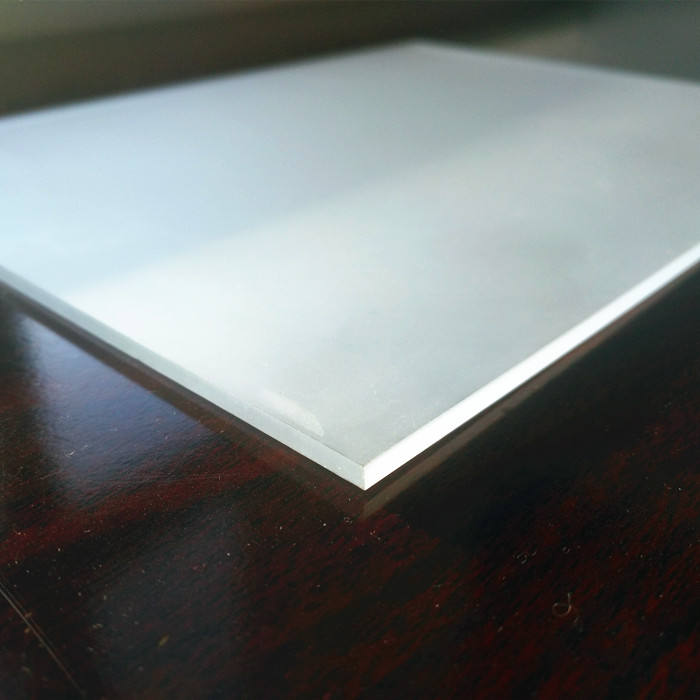

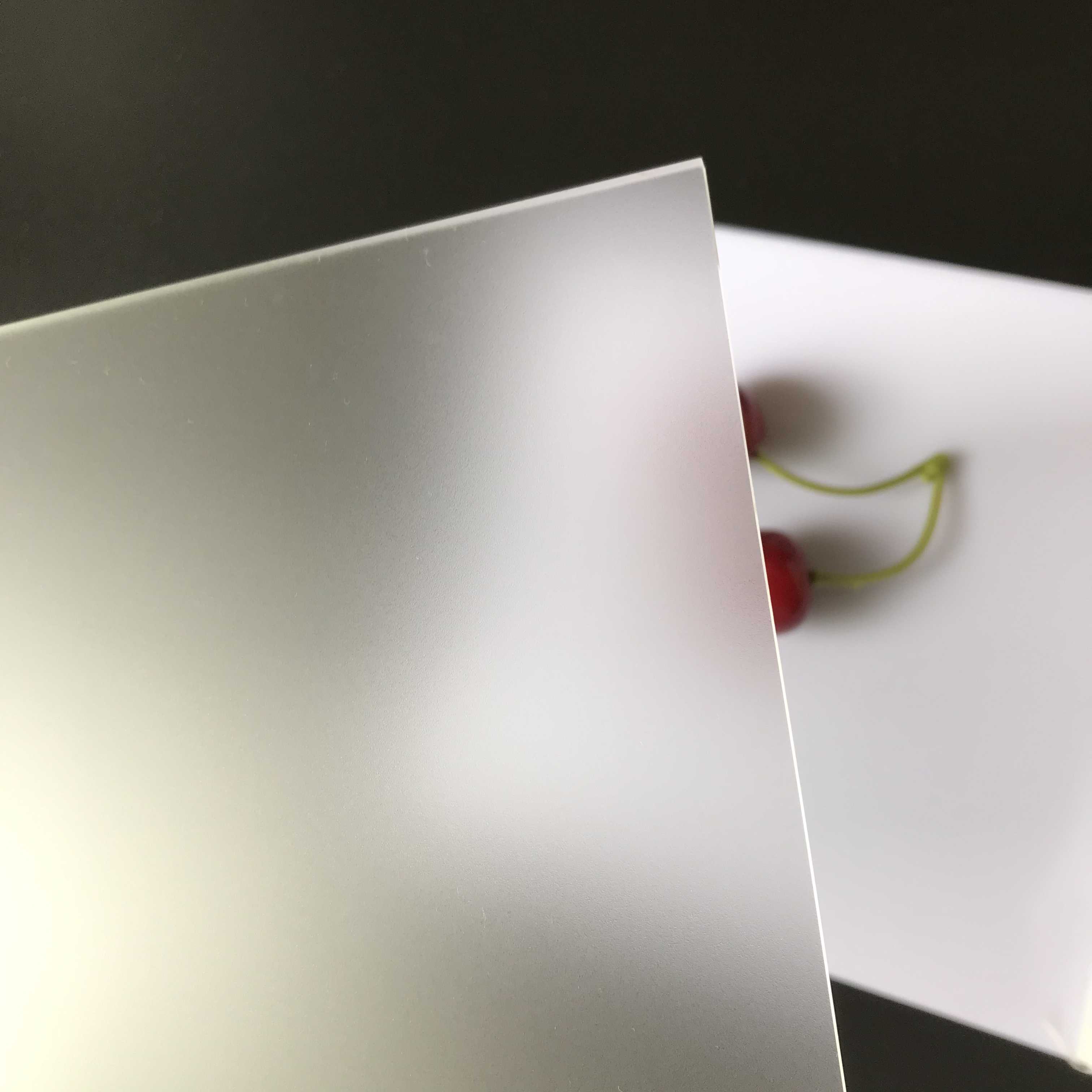

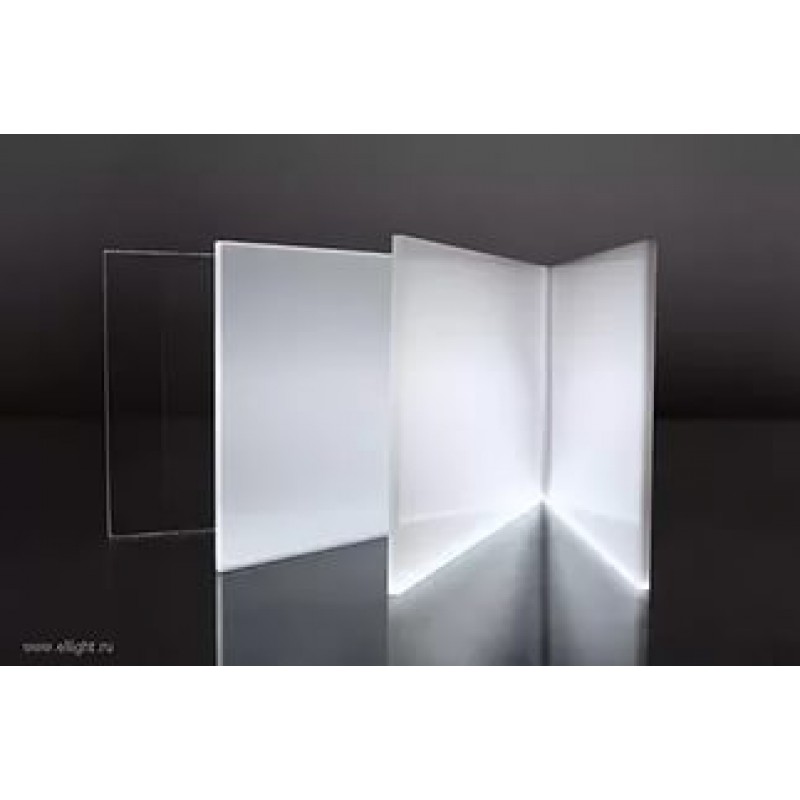

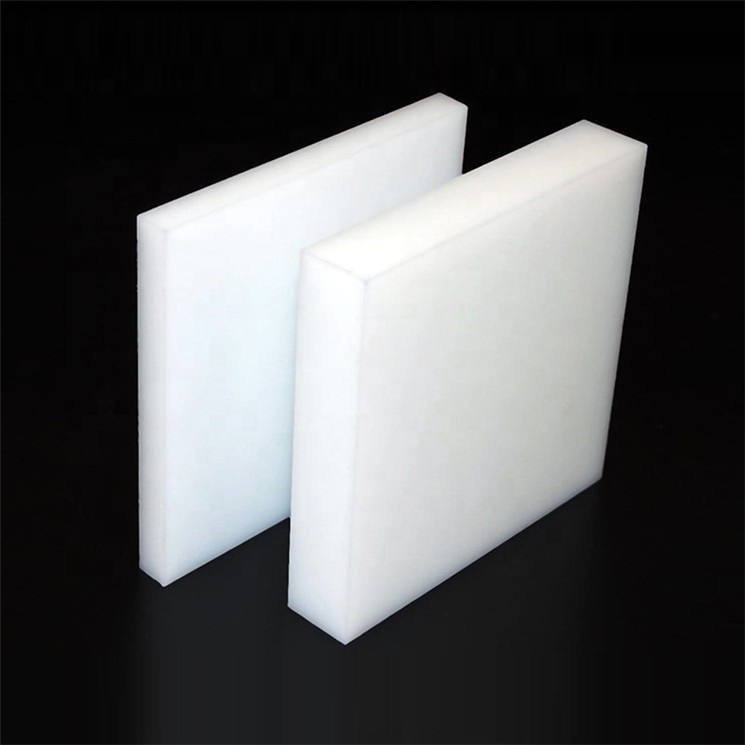

Matt acrylic is a fairly durable material that has demanded decorative properties.The light that passes through it is evenly scattered, due to which it becomes even, without a pronounced source.

Matte white acrylic is widely used for the manufacture of various information light installations, such as road signs, light boxes, advertising signs. Its surface is well suited for screen printing or self-adhesive applications with the necessary information and drawings.

Frosted plexiglass of various colors can be used as details for the decoration of premises, designs of sliding wardrobes, colored inserts in the doors of furniture and shower cabins.

Colored acrylic is used for luminous elements of outdoor and indoor installations. Unlike matte plexiglass, it is less commonly used as a basis for drawing. Colored acrylic figures of complex shapes can be part of appliqués or act as independent objects, such as three-dimensional symbols and letters. Stained glass windows and mosaics made of colored plexiglass with natural or artificial lighting are widespread.

Frosted acrylic glass is great for making fluorescent lamp shades, bedside lamp shades and other lighting fixtures. The light from a lamp with a frosted plexiglass screen is always even, pleasing to the eye and does not show any dazzling effect.

Comparison with other materials

Most often, plexiglass is compared to plexiglass. What's the difference? In fact, the choice is made between the same products that have an organic basis, however, there are different types of this material, and their parameters have significant differences.

Basically, the discrepancies in the properties of the material are associated with the methods of its manufacture. Products created by extrusion are less durable than injection molded. But do not forget that there are other varieties with their own specific characteristics.

- Shine material has a shiny surface and can be polished. And also it has a high level of moisture resistance.

- Honeycomb plexiglas Plexiglas SDP - two-layer. It is used for outdoor decoration due to its high impact resistance and immunity to external influences.

- Most plastics are vulnerable to damage, but SatinGlass acrylic is not susceptible to scratches.

- There are materials that are distinguished by a smooth, velvety texture, the presence of a fluorescent effect and a metallic sheen.

It is no longer a question of differences, but of the purpose of the choice and the conformity of a particular material to it. As for comparing plexiglass with ordinary quartz glass, even here it is impossible to talk about which products are better and which are worse. Crystal clear glass, familiar to you, is UV resistant, hermetic and strong material. However, even with such a minus as fragility, it is not always possible to replace it with acrylic or something else.

In turn, the polymer does not break, leaving debris, but it is also not without its drawbacks. Some of its types are destroyed under the influence of the sun, household cleaning products are capable of melting. On the other hand, despite all the advantages of quartz products, acrylic is gradually taking the leading position, and, of course, this is due to its flexibility, strength, durability, ease of processing and low price.

Acrylic glass suspended ceilings

The use of matte plexiglass for the ceiling has become relatively recent. A wide selection of types of material allows you to achieve uniqueness and artistic expression in the design of this part of the interior of the premises. As a rule, to create a cozy atmosphere in a living room, matte acrylic in soothing colors with dim backlighting is included in the construction of a suspended ceiling. Office ceilings are usually milky-colored plexiglass panels with sufficient lighting to ensure normal working conditions.

Illuminated acrylic ceilings can be an important and highly functional interior detail in rooms that do not have windows or other sources of natural light. Frosted organic glass evenly distributes light throughout the room, to some extent compensating for the lack of sunlight

For the same reason, it is good to arrange a plexiglass suspended ceiling in those rooms where a high degree of illumination is required, for example, in kitchens. The acrylic ceiling in the living room will surprise visiting friends and become an interesting subject for discussion.

Frosted organic glass evenly distributes light throughout the room, to some extent compensating for the lack of sunlight. For the same reason, it is good to arrange a plexiglass suspended ceiling in those rooms where a high degree of illumination is required, for example, in kitchens. The acrylic ceiling in the living room will surprise visiting friends and become an interesting subject for discussion.

The positive aspects of using plexiglass for ceilings are as follows:

- acrylic is an environmentally friendly material that does not emit toxic substances;

- the material does not absorb moisture and is biologically inert, does not support the growth of mold and mildew;

- plexiglass does not fade and even after years it looks presentable;

- acrylic sheets are a perfectly flat surface, behind which you can hide any flaws in floor structures and unsuccessful repairs;

- opaque plexiglass for the ceiling is convenient to install and does not require additional processing after installation;

- it washes well with plain water or water with the addition of a small amount of household chemicals;

- the material is easy to process;

- provides ample opportunities for creativity and experimentation in the design of complex surfaces.

What it is?

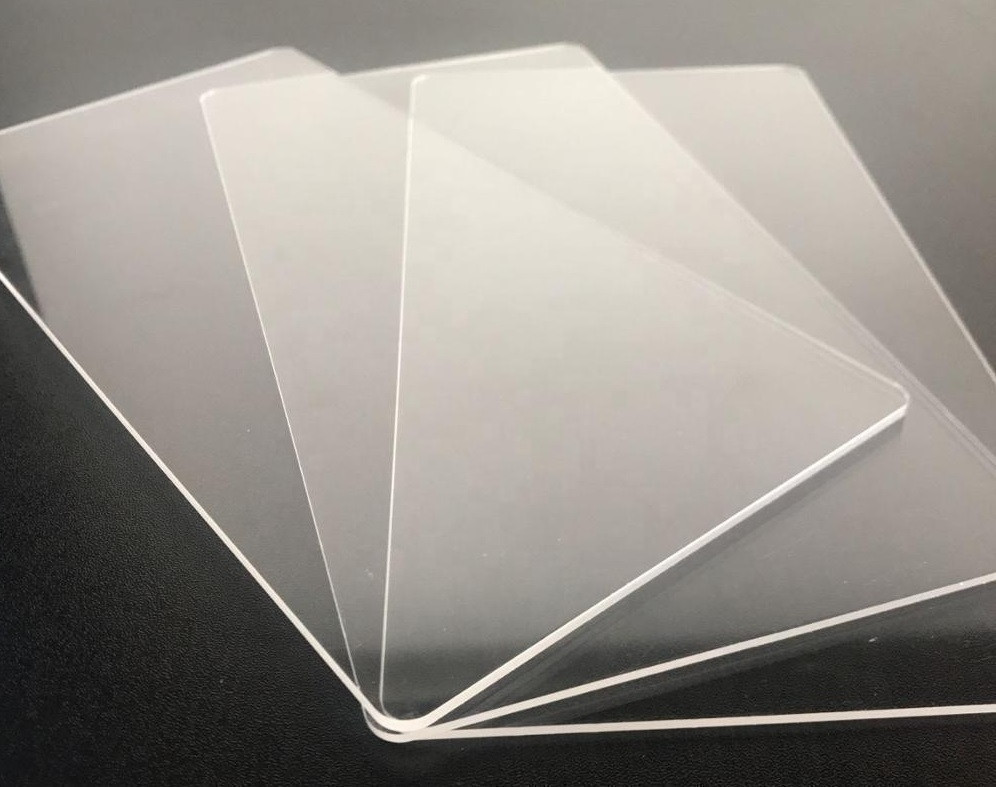

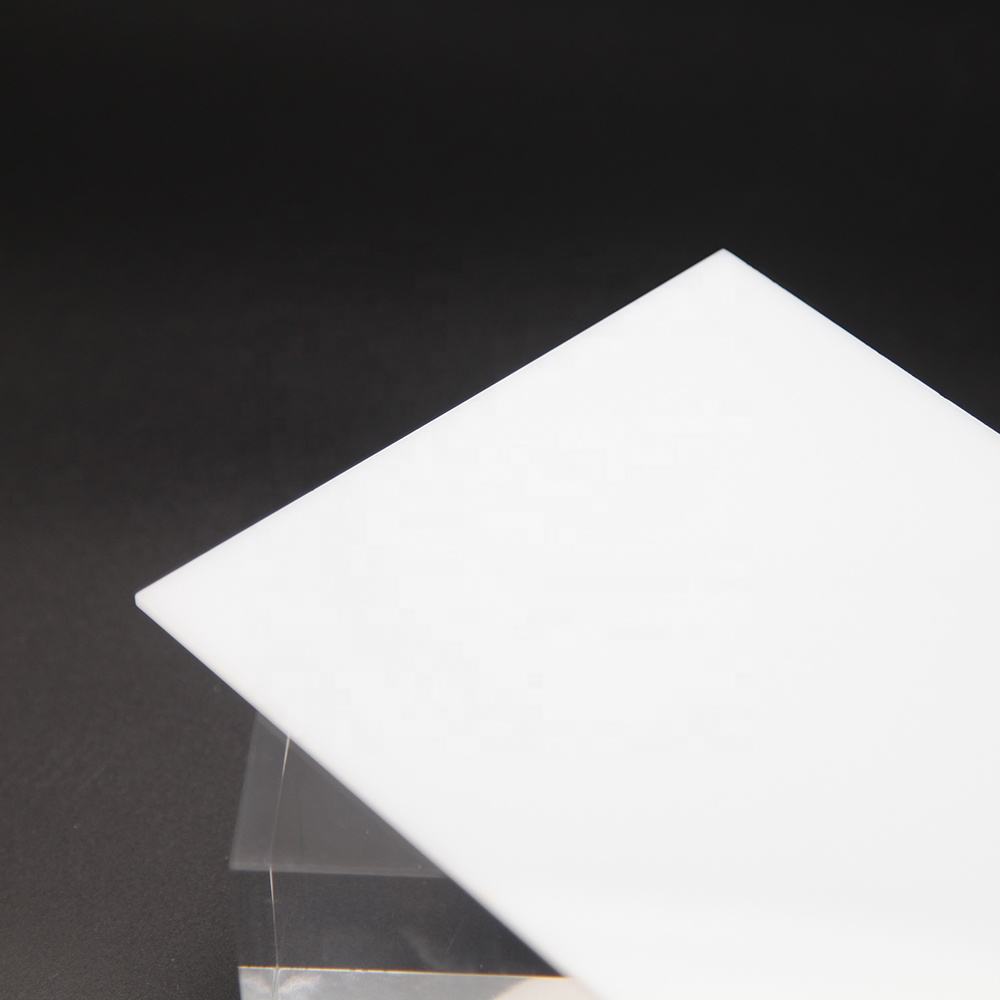

First of all, you need to decide what is matte plexiglass. Generally speaking, this material is a kind of ordinary organic glass. At the same time, a distinctive feature of the material is the fact that it has rather limited capabilities in relation to light transmission. So, depending on the specific category, the light transmittance of glass can vary from 25% to 75%. It is interesting. Popularly, frosted plexiglass is also called frosted plexiglass, acrylic glass or just acrylic

This is important to keep in mind when purchasing material on the construction market.

At its core, frosted organic glass is a sheet (usually white). The material is smooth to the touch. Also, with the naked eye, you can notice the fact that matte plexiglass has a shiny surface (and this characteristic of the material is characteristic of both the front and back sides).