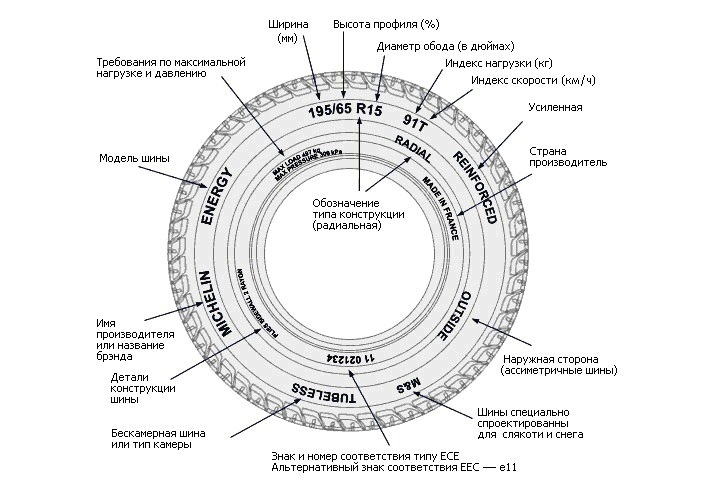

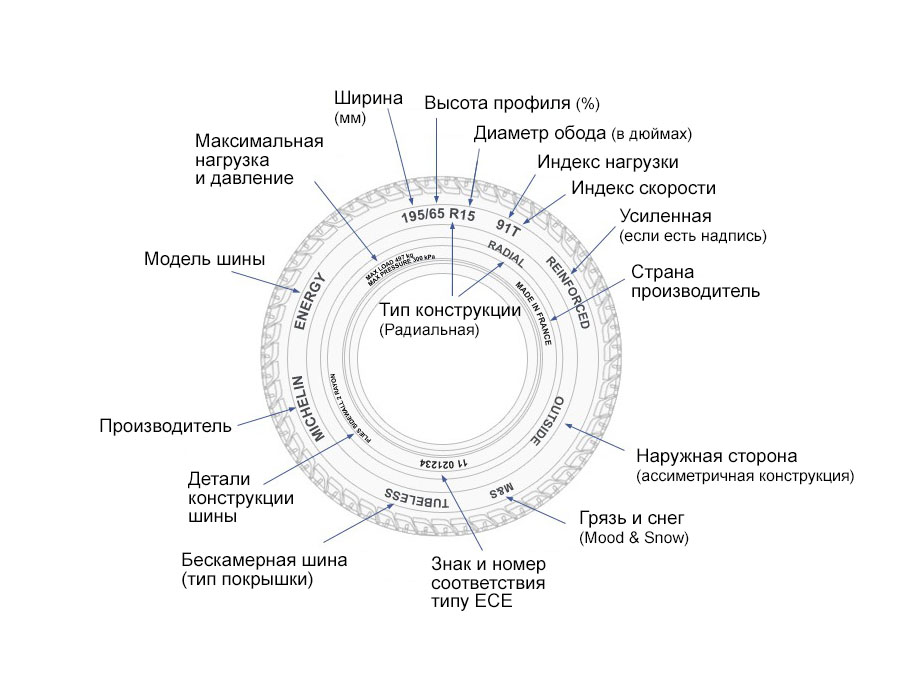

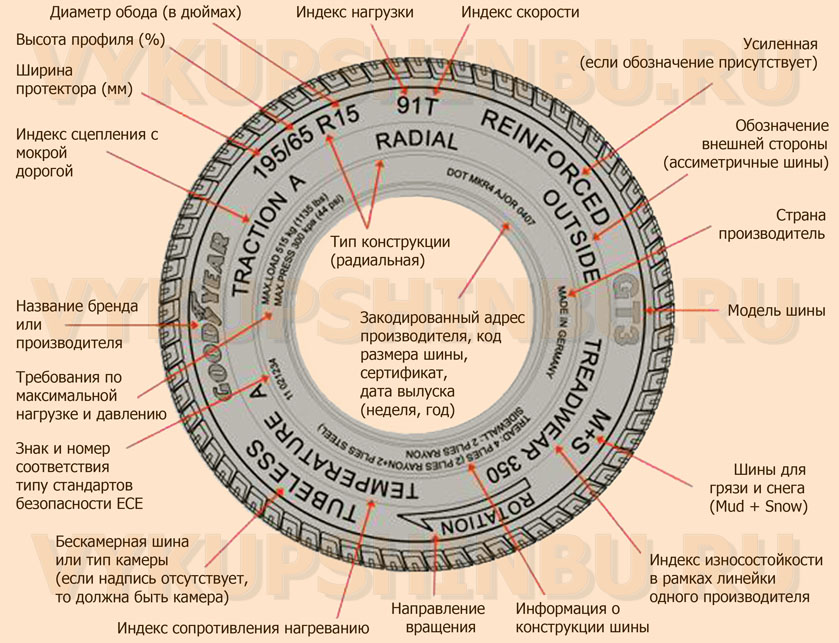

Basic markings

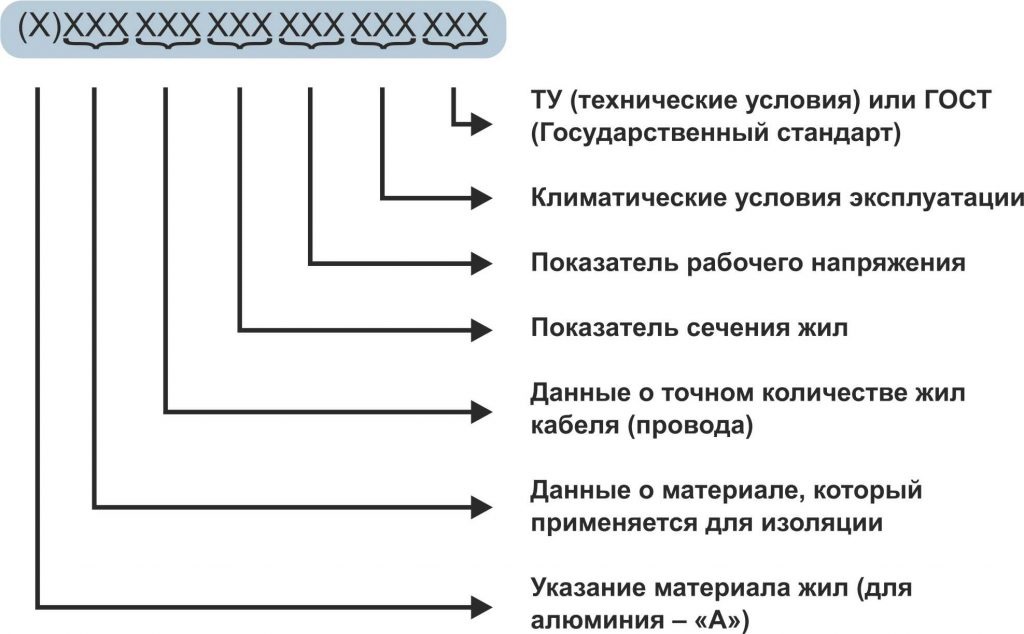

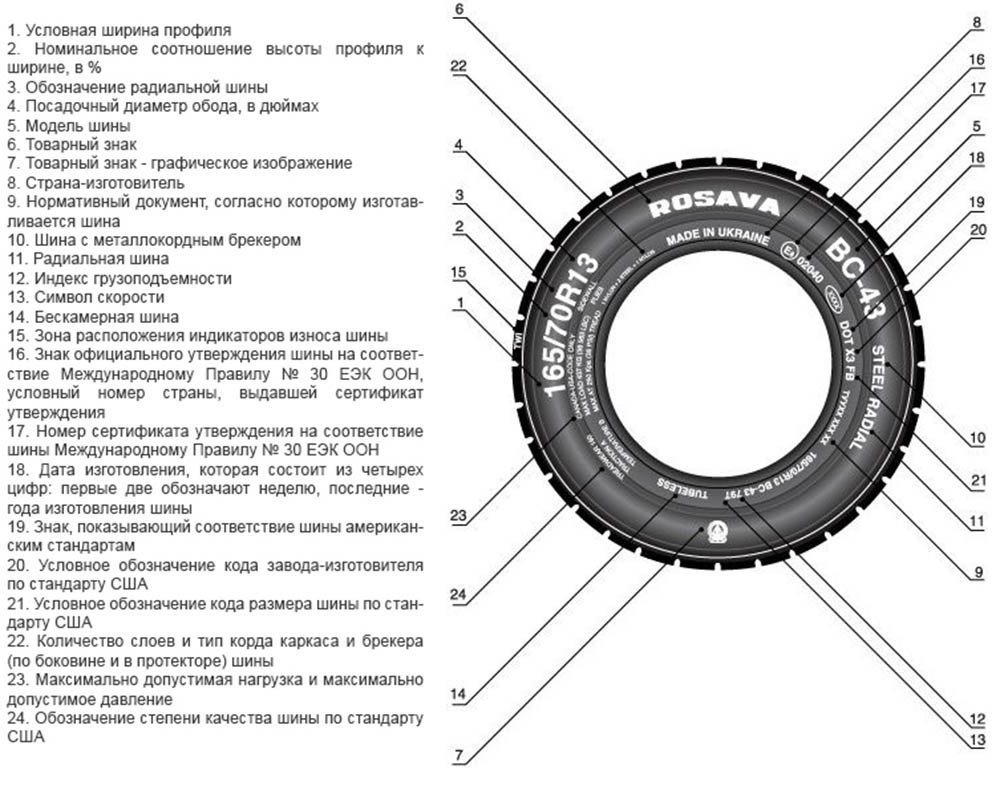

As you know, markings on the side surfaces of tires have many parameters. The main parameters that must be included in the marking designation include:

- manufacturer (company name);

- tire model and brand (a manufacturer can have many brands);

- tire size;

- maximum load index;

- speed index;

- appointment;

- level of protection;

- season (winter, summer, all-season);

- Additional Information.

Let's take a closer look at what each of the above items includes:

- Manufacturer. It is indicated in capital letters. Currently, there are a huge number of manufacturers of quality car tires.

- Models and brand. Car tire manufacturers can have many brands.

- Tire size. This is the most basic thing to know when choosing tires. Take, as an example, such a code in the marking - 195/60 R 14. The first number 195 is the width of the tire profile in millimeters, that is, this is the distance between the outer boundaries of the side faces of the inflated wheel, but without taking into account the protective belts. The second number, which is after the fraction, 60, is the ratio of the profile height to its width in percentage. In the example of this designation, it turns out 195 * 0.6 = 117 mm. The Latin letter R stands for Radial tire. Another bias type tire, but now almost all radial type tires are used. And, as for the last number in this designation, that is, 14, it denotes the bore diameter, that is, the diameter of the disc in inches. There are ciphers in the marking, where after the designation of the bore diameter, the letter C (comercial) is indicated, which indicates that the tire has additional layers. These tires can be used for small trucks, jeeps, minibuses, vans. In recent years, the load capacity index has been denoted by two numbers, the first of which gives information about what load can be used for one wheel, the second for double wheels.

There are tire models on which the marking does not indicate the ratio of the width and height of the profile as a percentage. If there is no designation, then you need to know that the ratio is from 0.8 to 0.82. If the value is less than 0.8, then it is always indicated on the bus in increments of 0.05.

Example of US Tire Marking Designation

35 / 12.5 R15 113Q stands for marking as follows:

- Tire outer diameter in inches - 35.

- Nominal width in inches is 12.5.

All other parameters are decrypted in the same way as it was discussed in the example above. The main difference is the first two parameters, which are measured in inches in the USA, and in millimeters in Russia and the CIS.

| Rubber designation | 185 / 80R15C | 215 / 80R16C | 225 / 75R16C | 5.90-13C |

| Rim profile designation | 5 1 / 2J *, 5K, 6J | 6J * | 6 1 / 2J *, 6J, 5 1 / 2J | 4J *, 4 1 / 2J |

* - recommended rim profile for this tire.

Load Index

The maximum load index is the maximum weight that a tire can carry. In the marking, the numbers do not show a specific mass, this is a code. An approximate calculation will be as follows: the total mass of the vehicle is divided by 4 and we get the maximum allowable weight per wheel tire. In the tire marking, the load index is indicated immediately after the size designation.

| Load index | Load, kg | Load index | Load, kg | Load index | Load, kg | Load index | Load, kg | Load index | Load, kg |

| 62 | 265 | 75 | 387 | 88 | 560 | 101 | 825 | 114 | 1180 |

| 63 | 272 | 76 | 400 | 89 | 580 | 102 | 850 | 115 | 1215 |

| 64 | 280 | 77 | 412 | 90 | 600 | 103 | 875 | 116 | 1250 |

| 65 | 290 | 78 | 425 | 91 | 615 | 104 | 900 | 117 | 1285 |

| 66 | 300 | 79 | 437 | 92 | 630 | 105 | 925 | 118 | 1320 |

| 67 | 307 | 80 | 450 | 93 | 650 | 106 | 950 | 119 | 1360 |

| 68 | 315 | 81 | 462 | 94 | 670 | 107 | 975 | 120 | 1400 |

| 69 | 325 | 82 | 475 | 95 | 690 | 108 | 1000 | 121 | 1450 |

| 70 | 335 | 83 | 487 | 96 | 710 | 109 | 1030 | 122 | 1500 |

| 71 | 345 | 84 | 500 | 97 | 730 | 110 | 1060 | 123 | 1550 |

| 72 | 355 | 85 | 515 | 98 | 750 | 111 | 1090 | 124 | 1600 |

| 73 | 365 | 86 | 530 | 99 | 775 | 112 | 1120 | 125 | 1650 |

| 74 | 375 | 87 | 545 | 100 | 800 | 113 | 1150 | 126 | 1700 |

For passenger cars - knowing the load index, it is necessary to adhere to the rule so as not to load the weight of the car before the load becomes more than 80% of the permissible tire load.

For SUVs - no more than 70%.

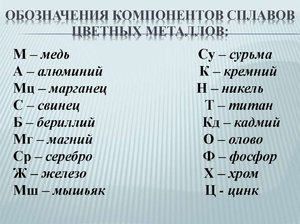

Marking of copper and copper-based alloys

When it comes to technical copper, the marking contains the letter M. Next, the numbers indicate the degree of its purity. For example, M3 copper contains more impurities than M000 material. The letters at the end mean the following:

- B-oxygen-free material;

- P - deoxidized;

- K-cathode.

Pure copper is often used as a conductive material for electrical purposes. The material lends itself well to soldering, deformation and welding, the only drawback is that it is difficult to cut.

In copper alloys, the marking has an alphanumeric system by which you can determine their chemical composition. So, alloying elements are indicated by their initial letters, for example:

- K-silicon;

- P-phosphorus;

- B-beryllium;

- O-tin, etc.

Brass

Brass is an alloy of copper and zinc. They are divided into the following types:

- two-component (simple) - include mainly copper and zinc, as well as impurities in small quantities;

- multicomponent (special) - in addition to the main elements, there are additional alloying ones.

Plain brass markings include the letter "L" indicating the type of alloy, as well as a two-digit number that indicates the average amount of copper in the composition.

Two-component alloys lend themselves well to pressure and can take such forms as:

- tubes and pipes with different sections;

- stripes;

- sheets;

- rods with different profiles;

- wire.

If the products have high internal stress, then they are prone to cracking. And if they are stored for a long time in the open air, then transverse and longitudinal cracks may appear. To prevent this from happening, remove internal stresses by annealing at temperatures up to 300 degrees.

If the products have high internal stress, then they are prone to cracking. And if they are stored for a long time in the open air, then transverse and longitudinal cracks may appear. To prevent this from happening, remove internal stresses by annealing at temperatures up to 300 degrees.

Marking of multicomponent brass after the letter "L" contains letters denoting alloying elements in the composition (in addition to zinc). Next comes a series of numbers separated by a hyphen, the first number is the average amount of copper (in%), and then - of each alloying element in the order corresponding to the letter designation. The order of letters and numbers depends on which element contains how many.

The first are those of which there are more, then the elements are indicated in descending order. Foundry brasses are marked with letters as LC (the second letter is zinc), then comes a number indicating the percentage of zinc content. Further, the marking goes, as in other cases. These types of materials are used in the production of bushings, shipbuilding materials, bearings, fittings and bushings.

Bronze

Bronze is understood as a combination of copper with other elements, while zinc is not the main component. Bronze can be wrought and cast. The marking of such material begins with the letter combination "Br".

Bronze is understood as a combination of copper with other elements, while zinc is not the main component. Bronze can be wrought and cast. The marking of such material begins with the letter combination "Br".

In casting types, these letters are followed by letters with numbers, meaning the elements and their percentage in the alloy. The rest is meant as copper. In some cases, the markings have an “L” at the end, indicating that the material is foundry.

Bronze has excellent casting properties and is used for shaped casting. It is also used as an antifriction and corrosion-resistant material in the production of:

- worm wheels;

- rims;

- bushings;

- gear wheels;

- fittings;

- valve seats, etc.

In addition to the listed features, it is worth noting that all copper alloys are highly resistant to low temperatures.

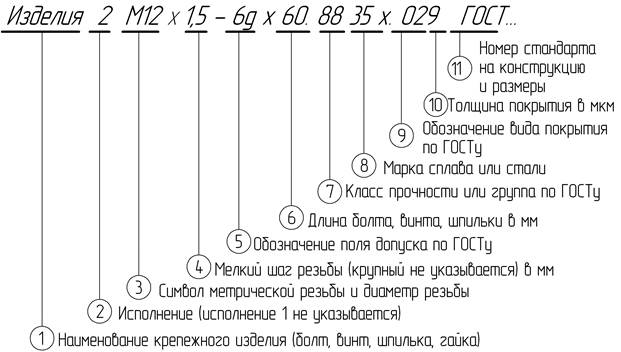

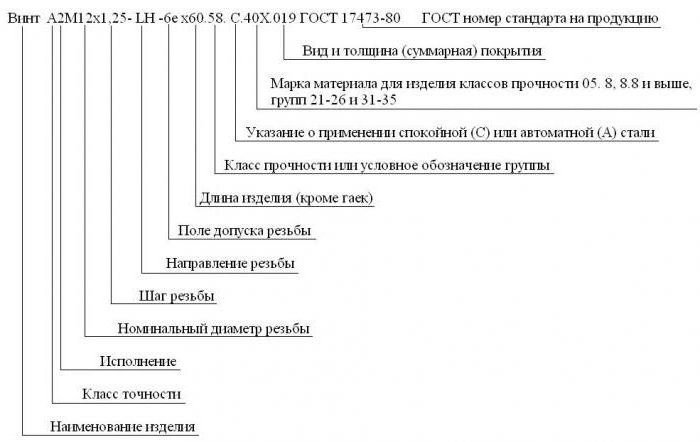

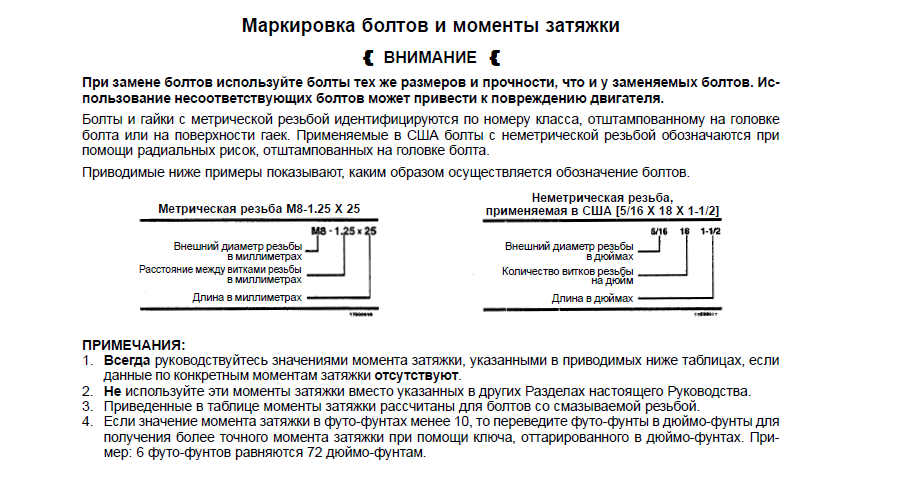

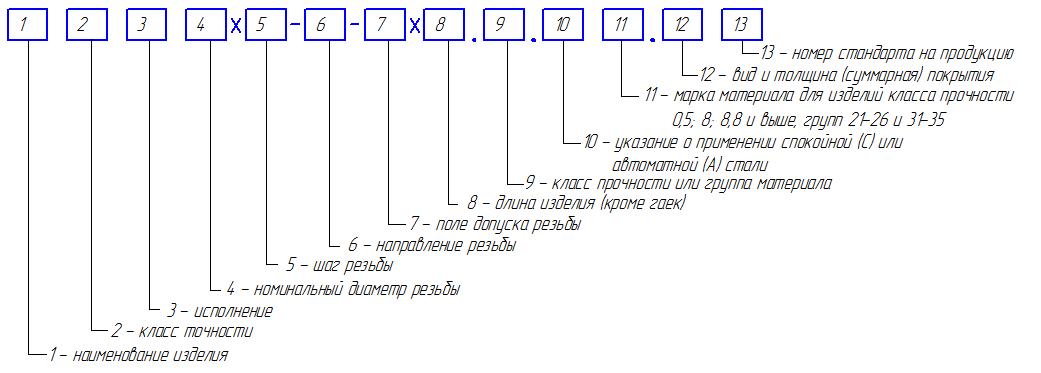

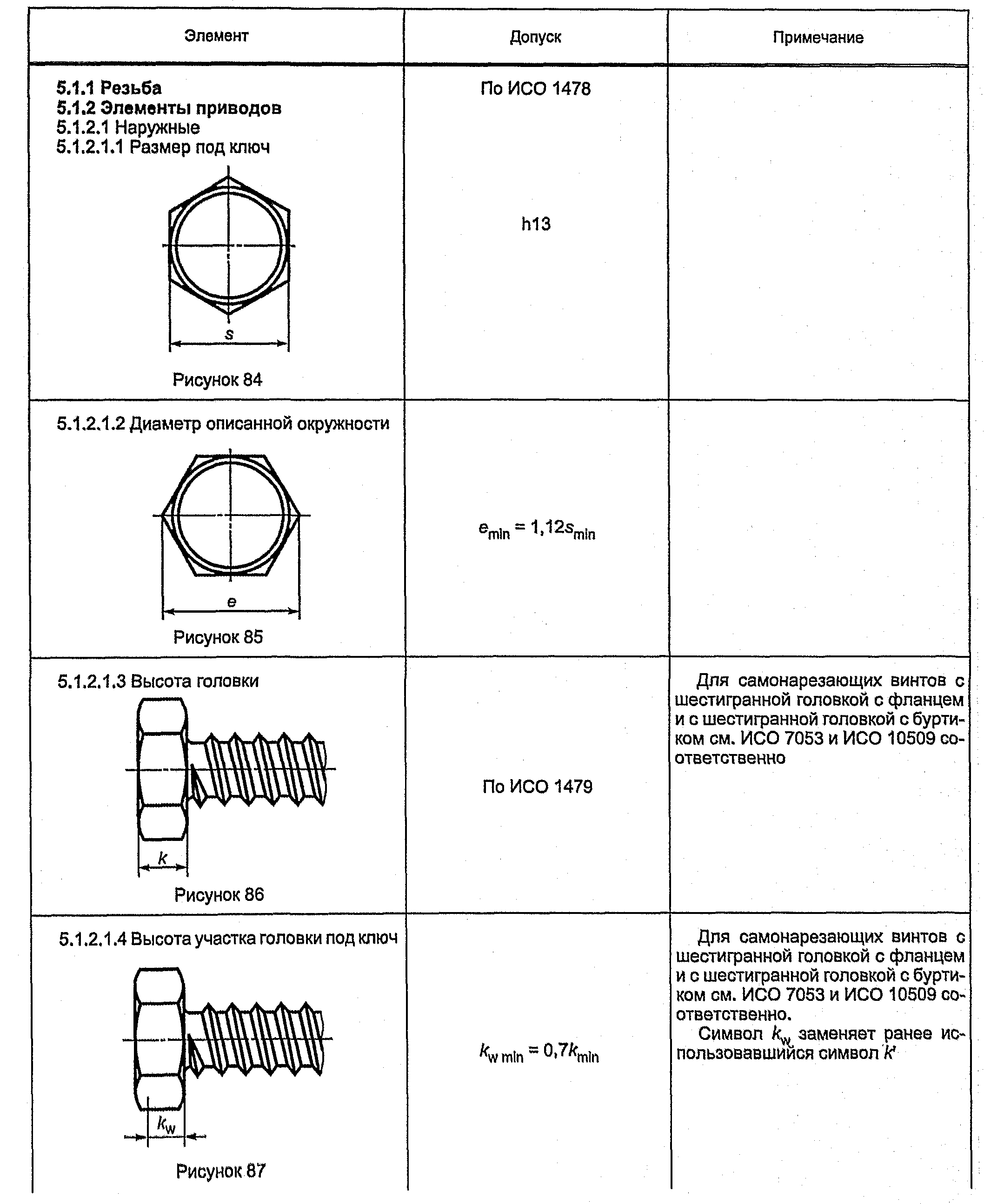

Parts designation

The designation system for threaded fasteners was created by the International Organization for Standardization (ISO). It should be noted that standards created in Soviet times were based on similar principles. All the intricacies of decoding bolt markings can be found in the corresponding technical documentation.

The designation system for threaded fasteners was created by the International Organization for Standardization (ISO). It should be noted that standards created in Soviet times were based on similar principles. All the intricacies of decoding bolt markings can be found in the corresponding technical documentation.

It should be noted that the symbols must be applied to all screws and bolts with a diameter of 6 mm or more. Products with a smaller diameter can be labeled at the request of the manufacturer. Parts made in accordance with metal cutting technology may not be marked.

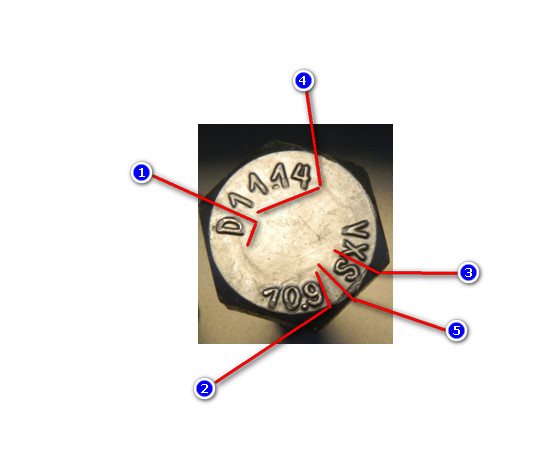

Most often, the designation is applied to the end or side surface of the bolt head. In this case, in the second case, for this, in-depth signs should be used. Several requirements are imposed on the parameter of the height of convex symbols, depending on the size of the product:

- 0.1 mm - for fasteners with threaded diameters up to 8 mm.

- 0.2 mm - bolts with thread diameters ranging from 8 to 12 mm.

- 0.3 mm - for all products with a thread of more than 12 mm.

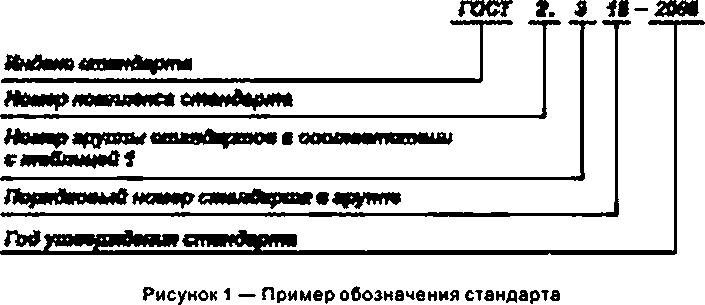

Some normative documents regulate the geometry of threaded connections. For example, according to GOST 7798-70, products must have a hex head and belong to the normal accuracy class.

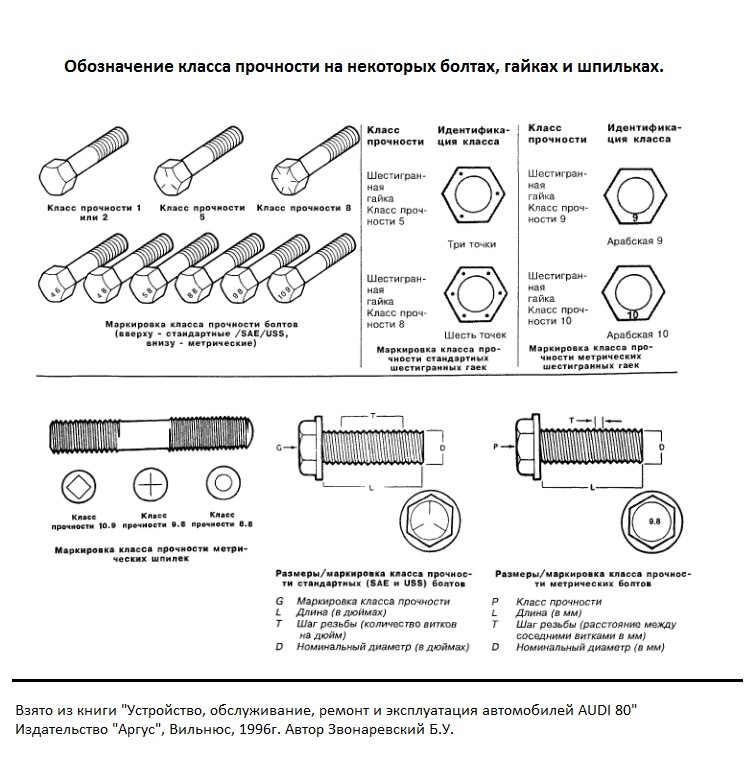

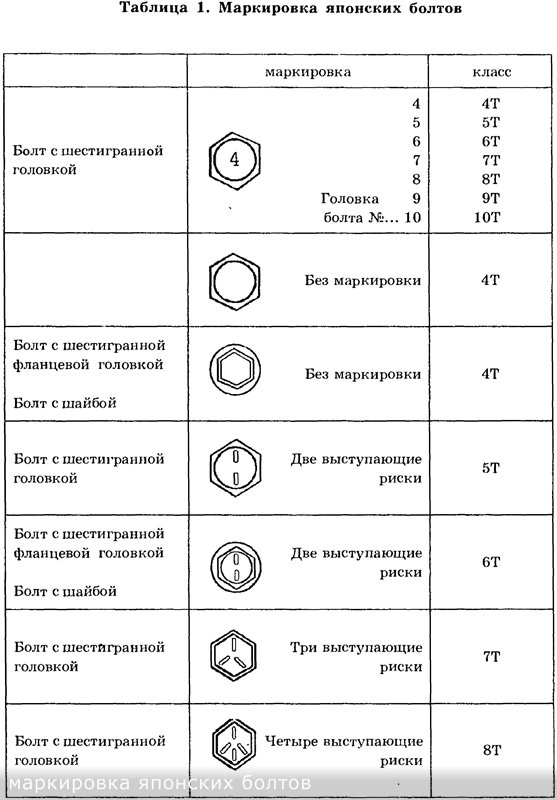

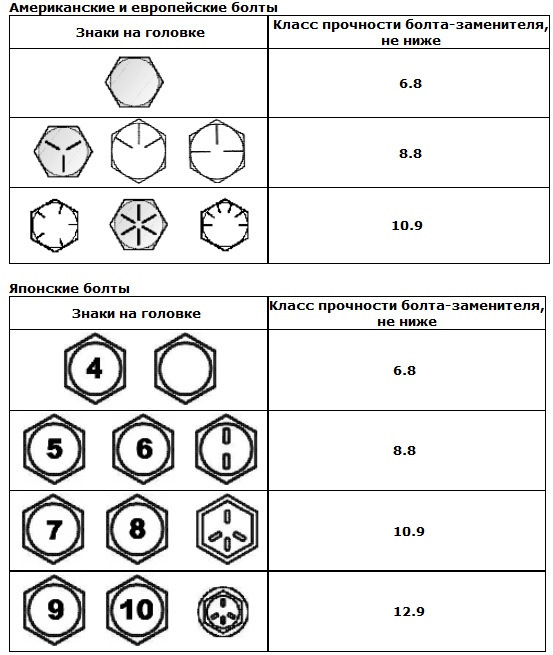

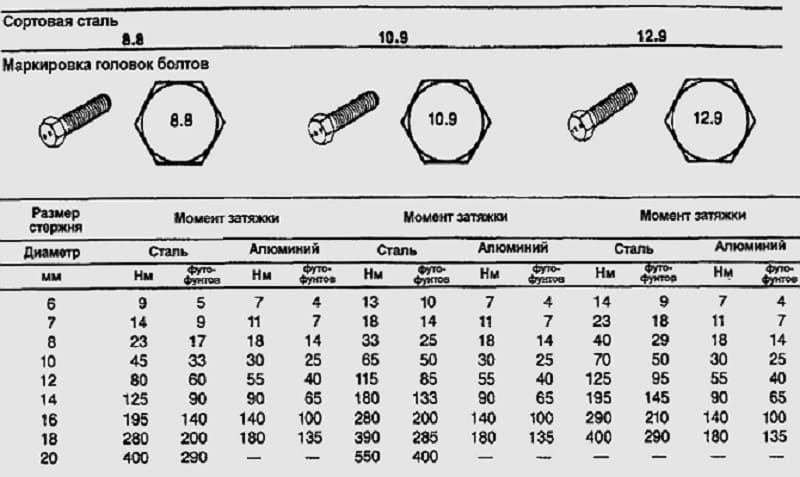

Bolt strength

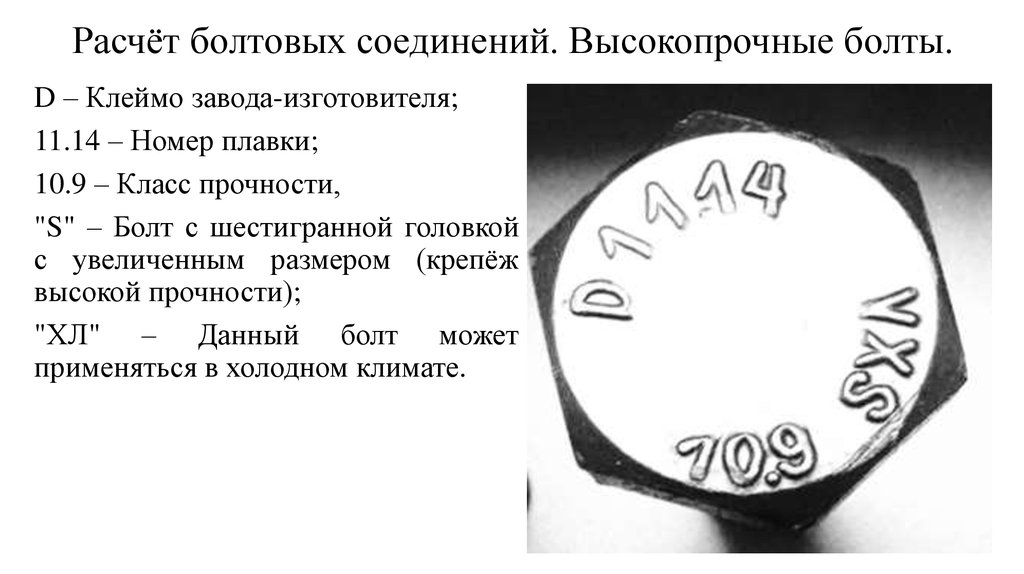

All bolts with threads greater than M6 must be marked. The bolt head is marked with the strength of the bolts in accordance with GOST or ISO, as well as their design. If the thread of a bolt or screw is more than M6, and there is no marking on the head, then the use of such a bolt should be discarded. Consider what the bolt strength class means and how it is indicated directly on the head.

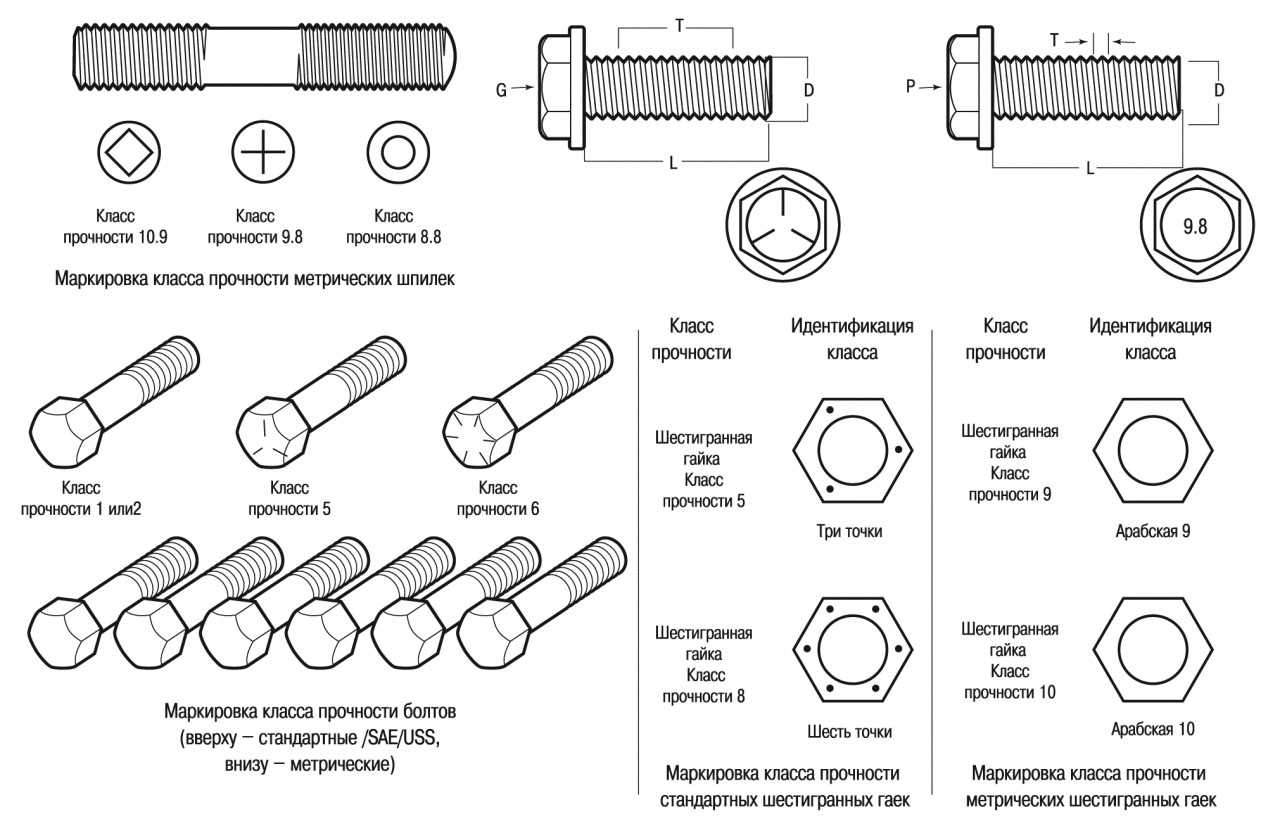

The picture shows three types of markings. Bolt strength 8.8 is the most common. The bolt has a strength class of 10.9 and is therefore stronger than 8.8. An “X” on the head of the bolt indicates that the bolt is hardened, usually this is the designation on propeller bolts. There are bolt strength classes 3.6, 4.6, 4.8, 5.6, 5.8, 6.6, 6.8, 8.8, 9.8, 10.9, 12.9. The period between numbers may be missing.

Now let's talk about what these numbers mean. The first digit of the marking is equal to 0.01 the tensile strength of the bolt, in order to understand the ultimate strength, we divide the first digit by 0.01 and we get the tensile strength in MPa. The second figure is 0.1 of the ratio of the bolt's yield strength to tensile strength. If we multiply the numbers, and the result is multiplied by 10, then we get the yield strength in MPa. Let's give an example of decryption. The strength of the 12.9 bolt is deciphered as follows:

12 / 0.01 = 1200 (MPa) - tensile strength.

12x10x9 = 1080 (MPa) - yield point.

Bolts of strength class up to 5.6 are most often used in furniture production, the rest are used in mechanical engineering and construction. Moreover, the strength class 10.9 and 12.9, due to the high price, is used in the assembly of particularly critical units.

In addition to standard hex head bolts, socket head screws, flange bolts, pan head square head bolts, and others are also used. The location of the markings for these bolts is different from the standard bolts. The markings can be applied to a cylindrical surface or under the head of a bolt.

The picture shows examples of markings on a panhead bolt (left) and an Allen bolt (right).

There are also bolts intended for use in certain assemblies; they may have additional markings. For example, bolts for the construction of bridges can be marked with "ХЛ", which means the permissible use of the bolt at temperatures up to -65 0 С. Sometimes the steel grade used in the manufacture is indicated on the bolt heads.

The strength class is also indicated on the studs, it is applied to the cylindrical part, where there is no thread, but with two significant differences: 1) On the bolts, the marking protrudes above the surface, on the studs, on the contrary - the marking goes deeper into the material. 2) Studs are marked starting with strength class 5.6. On stud diameters less than M12, sometimes not numbers are marked, but conventional signs, each of which corresponds to a strength class.

Nuts are marked in a slightly different way. When marking a nut, take into account the ratio of its height to the thread diameter. According to the ratio of nut height to diameter, nuts are divided into 5 types: 1) Low H / d less than 0.8 2) Normal with a ratio of height to thread diameter 0.8 3) High with a ratio of 1.2 4) Extra high with a ratio of 1, 5. 5) Ultra low, usually not marked.

For low nuts, there are only two strength classes - 04 and 05. To calculate the tensile strength, we fold back 0 and multiply by 100. We get 400 and 500 MPa, respectively.Based on the obtained value, we look at what class of bolt strength the nut should be used with.

Normal, high and extra-high nuts have 7 strength classes - 4, 5, 6, 8, 9, 10, 12. Similarly, multiply by 100 and get the tensile strength value. Therefore, a Grade 8 nut is best used with an 8.8 bolt. In such cases, the load distribution in the thread will be uniform.

Sometimes there are other bolt markings, but this is usually very rare. The vast majority of bolts are marked according to this principle.

In the next article, I'll show you how to calculate a bolt for tension, shear, and shear.

Ask questions, leave comments, share your impressions of the article!

Lead and tin in pure form and alloys

Lead in its pure form is almost never used in the refrigeration or food industry, and tin is used in the food industry as a coating for food containers. When it is marked "O" means tin, while the numbers are its conditional number. As the number increases, the amount of impurities increases. The letter combination "pch" indicates the increased purity of the material. In the food industry, for the purpose of tinning canning tin, tin is used, marked as O1 and O2.

Depending on the purpose, lead or tin alloys are divided into two categories:

- babbits;

- solders.

Babbits are complex combinations of lead and tin, additionally they contain copper, antimony and so on. They are marked with the letter "B", as well as a number indicating the percentage of tin in the composition. In addition to the letter "B", there may also be letters denoting special additives, for example:

- H - nickel babbit;

- C - lead babbit and others.

It is impossible to establish the full chemical composition only by the brand of babbitt. In some cases, even the amount of tin is not indicated, although the BN grade contains about 10 percent. There are babbits without tin (in particular, lead-calcium).

It is impossible to establish the full chemical composition only by the brand of babbitt. In some cases, even the amount of tin is not indicated, although the BN grade contains about 10 percent. There are babbits without tin (in particular, lead-calcium).

This material is recognized as the best anti-friction material and is mainly used in plain bearings.

The second category is solders. They, depending on their characteristics, are divided according to the following criteria:

- by melting temperature;

- by key component;

- by the melting method and other features.

In particular, according to the melting temperature, solders are of the following types:

- especially low-melting (melting point is about 145 degrees);

- fusible (from 145 to 450 degrees, respectively);

- medium-melting (from 450 to 1100 degrees);

- high-melting point (1100-1850 degrees);

- refractory (temperature from 1850 degrees and above).

The first two categories are used for the purpose of low-temperature brazing, and the others for high-temperature brazing, respectively.

According to their key component, solders are of the following types:

- pewter;

- aluminum;

- cadmium;

- gallic;

- lead;

- zinc, etc.

Non-ferrous metals and their alloys can have different purposes and different technical characteristics. You can determine their features by the applied markings, which you need to be able to decipher.

How to choose a wheel disc

When choosing one or another disc, car owners often have a problem - how to choose the right disc in accordance with the available rubber. Let's look at a specific example of tires marked 185/60 R14. The width of the rim, in accordance with the requirements, should be 25% less than the width of the tire profile. Accordingly, it is necessary to subtract one quarter from the value of 185 and convert the resulting value to inches. The result is five and a half inches.

Note that for wheels with a radius of 15 inches or less, a maximum width deviation of one inch from ideal conditions is allowed. If a wheel with a radius of more than 15 inches, then the permissible error can be one and a half inches. Thus, after the above calculations, it can be argued that a wheel with a radius of 14 inches and a width of 5.5 ... 6.0 inches is suitable for a 185/60 R14 tire.

The rest of the above parameters must be specified in the technical documentation for the car.

Thus, after the above calculations, it can be argued that a wheel with a radius of 14 inches and a width of 5.5 ... 6.0 inches is suitable for a 185/60 R14 tire. The rest of the above parameters must be specified in the technical documentation for the car.

Below is a table that summarizes information about the standard (factory) installed disks acceptable by their manufacturers. Accordingly, for cars it is necessary to choose wheels with suitable parameters.

| Automobile model | Sizes and data on factory wheels |

|---|---|

| Toyota Corolla 2010 release | 6Jx15 5 / 114.3 ET39 d60.1 |

| Ford Focus 2 | 5JR16 5 × 108 ET52.5 DIA 63.3 |

| Lada Granta | 13 / 5.0J PCD 4 × 98 ET 40 CH 58.5 or 14 / 5.5J PCD 4 × 98 ET 37 CH 58.5 |

| Lada Vesta 2019 release | 6Jx15 4/100 ET50 d60.1 |

| Hyundai Solaris 2019 release | 6Jx15 4/100 ET46 d54.1 |

| Kia Sportage 2015 release | 6.5Jx16 5 / 114.3 ET31.5 d67.1 |

| Kia Rio | PCD 4 × 100 Dia 13 to 15, Width 5J to 6J, offset 34 to 48 |

| Niva | Bolt pattern - 5 × 139.7, offset - ET 40, width - 6.5 J, centering hole - ЦО 98.6 |

| Renault Duster 2011 | Size - 16x6.5, ET45, bolt pattern - 5x114.3 |

| 2019 Renault Logan | 6Jx15 4/100 ET40 d60.1 |

| VAZ 2109 2006 | 5Jx13 4/98 ET35 d58.6 |

Conclusion

The choice of a wheel rim should be based on the technical information provided by the car manufacturer in the car manual. In particular, the dimensions of disks allowed for installation, their types, overhangs, hole diameters, and so on. Most cars can be fitted with discs of different diameters. However, their key parameters must necessarily correspond to the technical documentation.

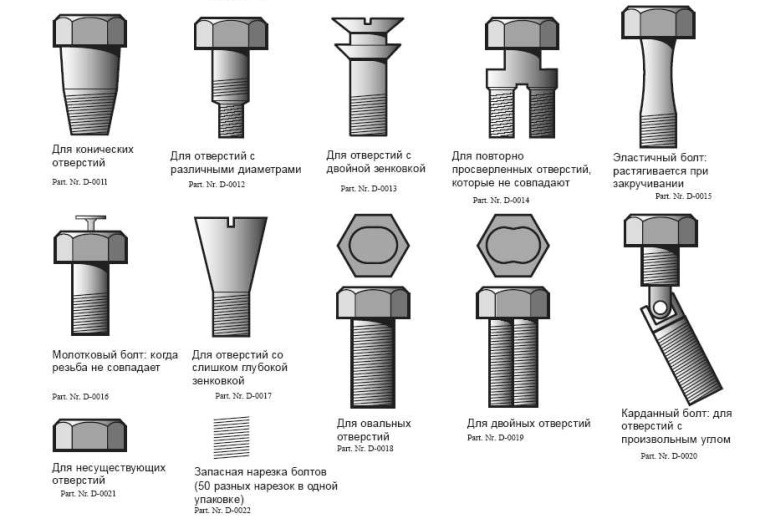

By appointment

Based on the purpose, the following types of bolts can be distinguished:

- Plow - designed for fastening heavy suspended structures. Based on the name, it can be understood that it is widely used in agriculture, usually for attaching plowshares to tillage equipment.

- Furniture - differs from other types in that the thread is not cut along the entire length of the rod. The third part remains the usual integral part. The head of such fasteners is usually smooth, which is necessary so that the bolt does not protrude above the surface of the furniture. Despite the names, such elements are used in other areas, especially in construction.

- Road - widespread in the installation of fences. It features a semicircular head, under which there is a square head. This design allows you to firmly fix the fence elements to the posts. It is used in all areas where there is a need to fix thin sheets of metal, wood, plastic and other materials.

- Machine-building bolts are the most common type of bolts used in machine-building. It is distinguished by increased strength properties and resistance to aggressive external environment.

- Track - used in the railway sector, most often to connect separate parts of the rail. They differ in that the thread can be less than half the length of the rod.

You can understand what type of hardware is based on the symbol of the bolts.

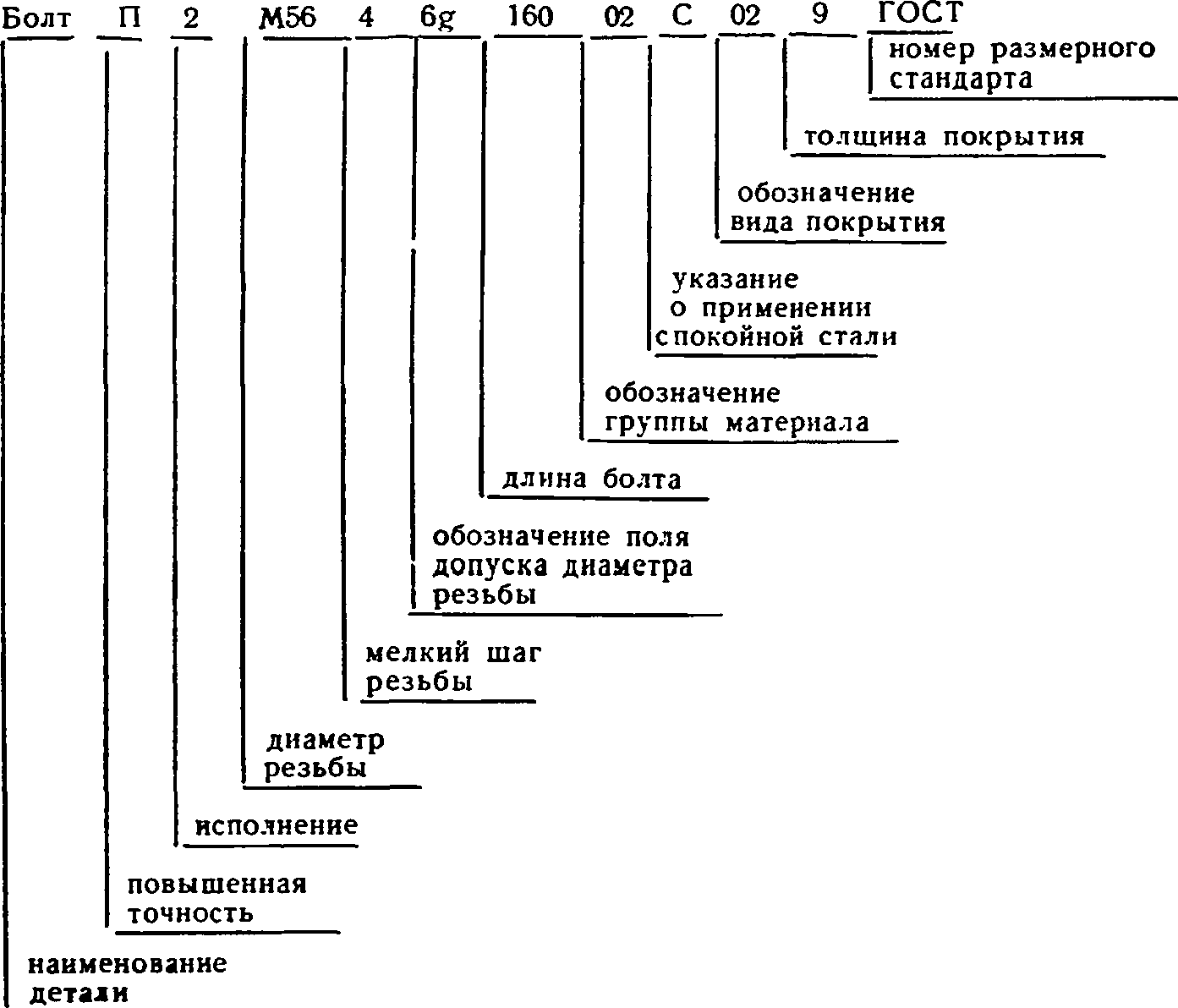

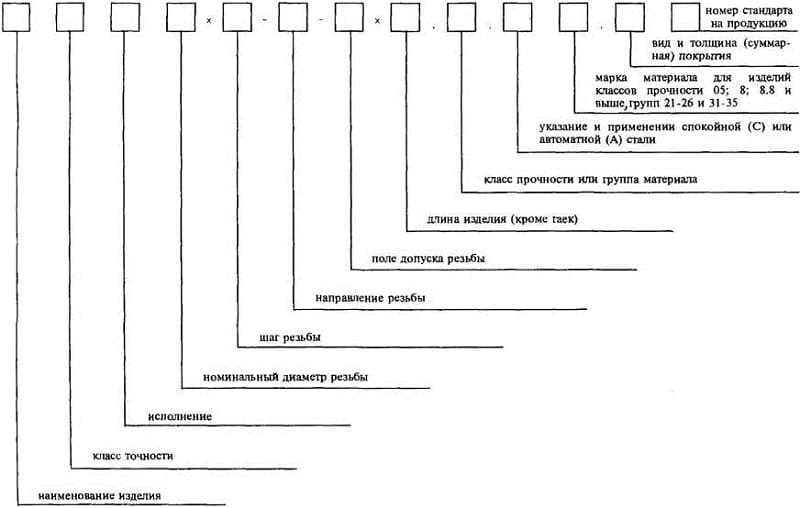

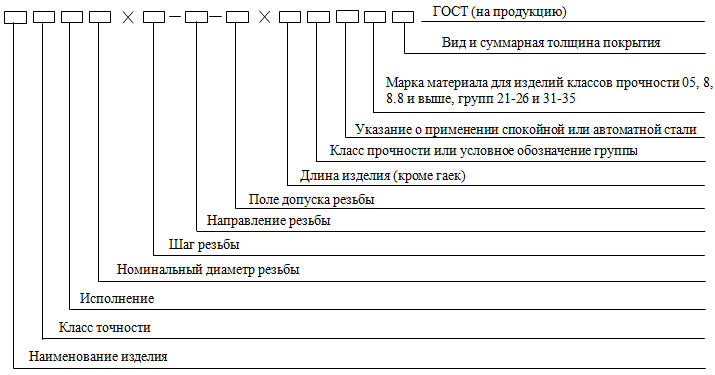

Decoding numbers

The most complete marking of the mounting bolts is given in the table. It has both an alphabetic and a numerical meaning, and all these symbols are located in a strictly defined GOST order. If you indicate such a marking in the specification of a construction or installation project, any engineer can easily understand what kind of hardware is in question and what characteristics they have.

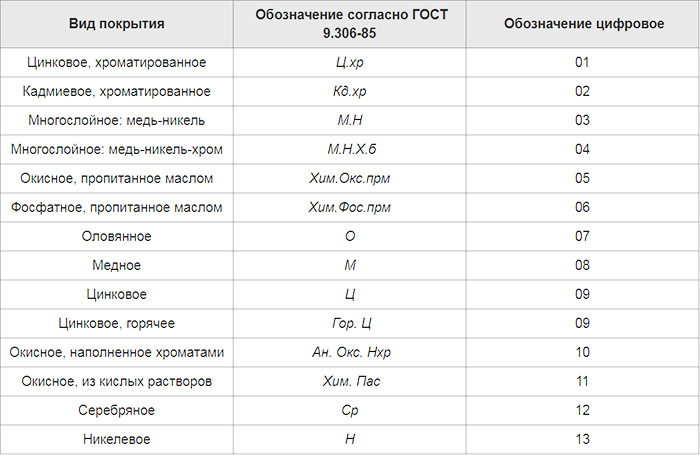

As an illustrative example, consider the designation of a hardware, for which the marking is located on the head: Bolt A3M12x1.50LH-4gx60.66. S. 097.

- The first is the product name. The word "bolt" can be replaced by the name of another product, which is subject to marking.

- The letter A denotes the accuracy class of the product. In total, there are 3 classes of accuracy: A, B, C. A means that the accuracy of the bolt is high.

- Number 3 tells us about the type of product execution. According to the standards, there are 4 types of execution, but type 1 is not indicated in the marking.

- The next letter M informs about what type of thread on the bolt shank. The type of thread is distinguished by conical, metric or trapezoidal. The letter M stands for metric.

- The number 12 indicates the diameter in millimeters at the bolt shank.It is noteworthy that only class A products have the M12 marking.

- The number 1.50 gives information about the pitch at which the bolt is threaded. If the thread pitch is standard for the diameter, it is not indicated in the marking.

- The letters LH indicate that the bolt has a left-hand thread. In the case where threading is done as standard right-handed, this is not displayed in the marking.

- The 4g designation indicates the accuracy class. The thread is cut with an accuracy on a scale from 4 to 8. The lower the indicator, the more precisely the thread on the hardware is made.

- The number 60 indicates the length of the bolt. In this example, it is 60 mm.

- The number 66 speaks of strength. These temporary hardness parameters are separated from the length by a dot.

- The next letter denotes the grade of steel alloy from which the bolt is made. The letter C means that the hardware is made of so-called calm steel. If the letter A was in the marking, it would mean that the steel is automatic.

- The numbers 097 show what kind of coating the hardware has. In total, 13 types of coating are distinguished, with the number 9 marking galvanized hardware. The number 7 denotes the thickness of the coating in microns, in our case the thickness of the galvanized coating is 7 microns.

Uniform requirements for hardware and their marking, adopted in our country, make it possible to accurately and quickly select fasteners. For products of European or American production, the marking is different, since the dimensions are indicated in inches. Conversion tables are used to read inch designations.

All about bolt marking in the video below.

Bolt legend decoding scheme

The bolt symbol is represented as a long list of numbers and letters, each of which denotes a specific parameter of the product. This information is indicated on the manufacturer's original packaging and allows you to obtain comprehensive information about the part.

At first glance, it may seem that it is very difficult to decipher what is indicated on the package, but this is not so. All designations are in a specific order and characterize a separate parameter of the product. One of the most commonly used quality standards is GOST 7798-70, which describes the main parameters of hex bolts. Let's look at the decryption of the record using an example.

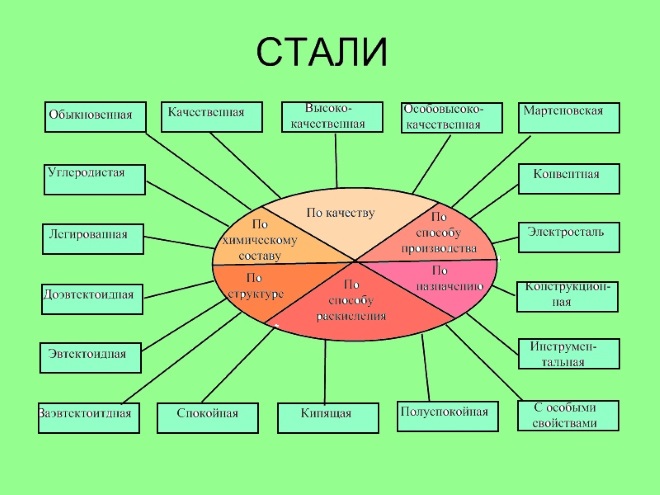

Types of steels and features of their marking

Steel is an alloy of iron with carbon, while the content of the latter in it is no more than 2.14%. Carbon gives the alloy hardness, but too much carbon makes the metal too brittle.

Varieties of steels

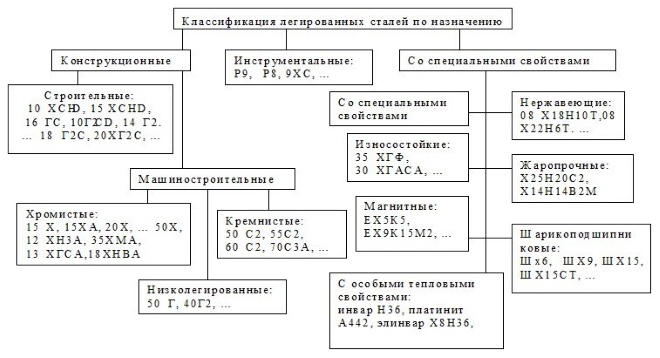

By including alloying elements in the steel, it can be given the required characteristics. It is in this way, by combining the type and quantitative content of additives, to obtain grades with improved mechanical properties, corrosion resistance, magnetic and electrical characteristics. Of course, it is possible to improve the characteristics of steels with the help of heat treatment, but alloying additives make it possible to do this more efficiently.

The classification of steels is carried out according to their purpose. So, there are instrumental and structural types, brands that differ in special physical properties. Tool types are used for the production of stamping, measuring, and cutting tools, constructional - for the production of products used in construction and mechanical engineering. Alloys with special physical properties (also called precision alloys) are used to make products that must have special characteristics (magnetic, strength, etc.).

Classification of steels by purpose

The steels are also opposed to each other in terms of their special chemical properties. The alloys of this group include stainless, scale-resistant, heat-resistant, etc. What is characteristic, they can be corrosion-resistant and are different categories.

If we consider the main harmful impurities, then phosphorus increases the brittleness of the alloy, which is especially pronounced at low temperatures (the so-called cold brittleness), and sulfur causes the appearance of cracks in the metal heated to a high temperature (red brittleness). Phosphorus, among other things, significantly reduces the ductility of the heated metal. By the quantitative content of these two elements, steels of ordinary quality (no more than 0.06-0.07% of sulfur and phosphorus), high-quality (up to 0.035%), high-quality (up to 0.025%) and especially high-quality (sulfur - up to 0.015%, phosphorus - up to 0.02%).

Steel markings also indicate the extent to which oxygen has been removed from the composition. By the level of deoxidation, steels are distinguished:

- calm type, designated by the letter combination "SP";

- semi-calm - "PS";

- boiling - "KP".

Seasonal and road marking on tires

- Aqua, Rain, etc. are tires that perform well on wet roads.

- A / T (All Terrain) - tires for any terrain (balance between comfort and flotation).

- AS (All Season) - this is the designation for an all-season tire.

- All-Season (All-Weather) is another mark for all-season tires.

- M + S (Mud + Snow) - suitable for driving on mud and snow (this is how all-season or winter tires are marked with an extended temperature range compared to summer and a more developed tread pattern that provides traction not only on smooth asphalt, but they are off-road, as usually are not).

- M / T (Mud Terrain) - tires for mud landscapes.

- R + W (Road + Winter) is an all-season road tire.

- RAIN, WATER, AQUA (or umbrella icon) - means that these tires are specially designed for rainy weather and have a high degree of protection against the effect of aquaplaning.

- Winter - coding for winter tires.

Steel marking according to American and European systems

The marking of steels of domestic production and in the post-Soviet space allows you to approximately determine the composition, purpose and characteristics without resorting to reference literature. In American and European standards, such a decoding is, for the most part, absent. This is due to the large number of organizations involved in the standardization of metal products.

For the most part, the designation of steel according to American and European standards does not contain an indication of the chemical composition. The types of steel for their intended purpose are characterized by an alphabetic or digital code, which can be deciphered using reference literature.

Only in the European standard EN10027 there is a variant of marking alloys by chemical composition, which has a close resemblance to domestic designations.