Concrete mortar for strip base

When arranging a strip foundation, one should especially seriously approach the problem of choosing a brand of cement and concrete.

When arranging a strip foundation, one should especially seriously approach the problem of choosing a brand of cement and concrete.

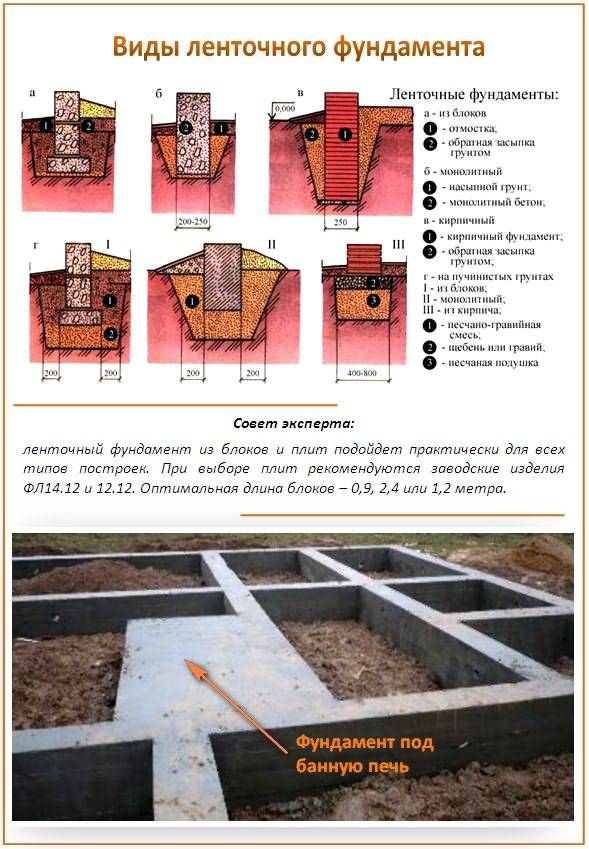

The question requires special attention - what grade of concrete is needed for a strip foundation? Tape bases are the most demanded in private buildings today. In turn, strip bases are subdivided into several types, differing from each other in design features.

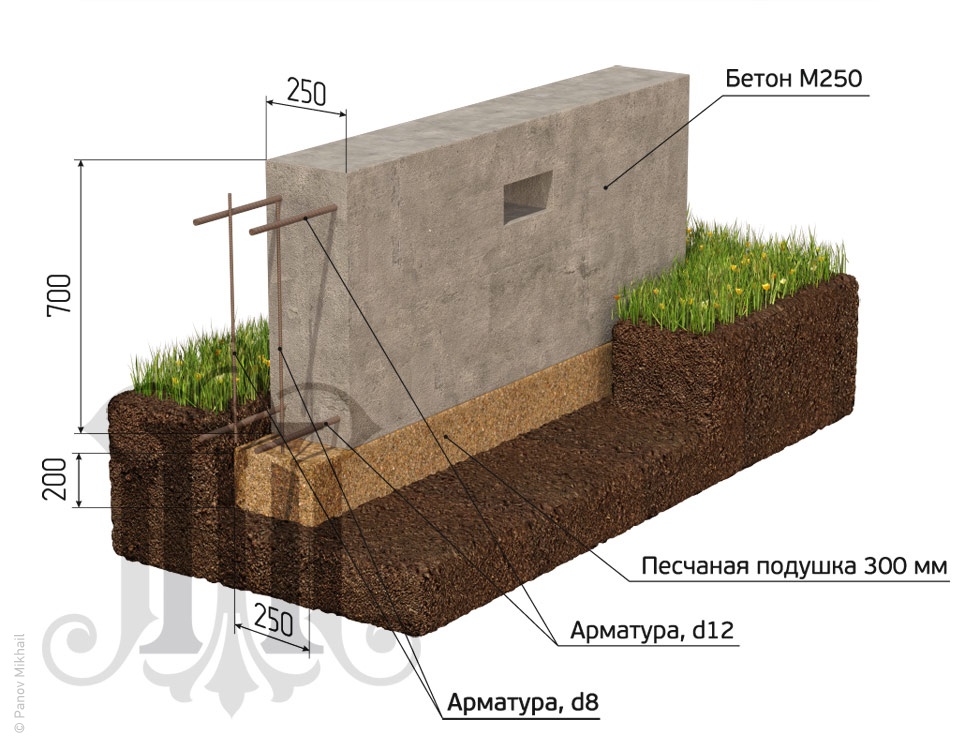

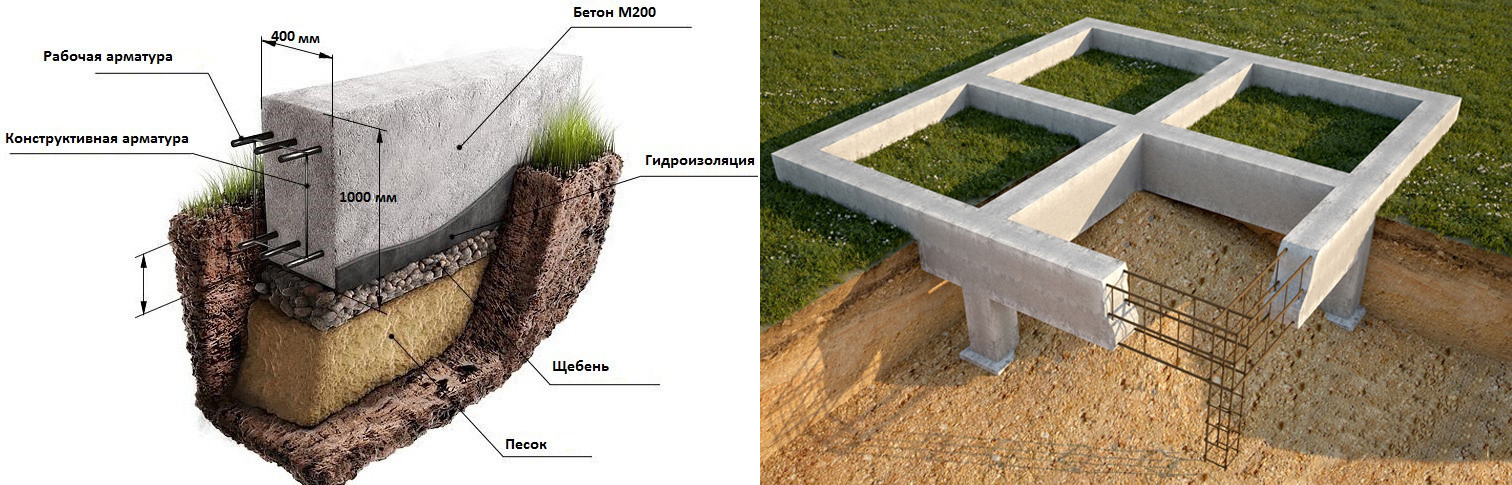

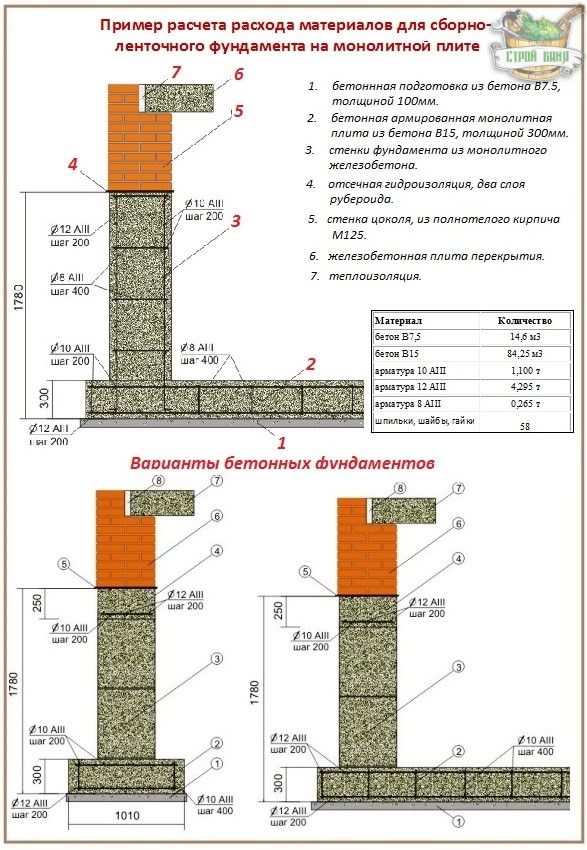

- Monolithic strip foundation. This is the most common type of all concrete foundations used for both residential and industrial buildings. The main distinguishing feature of such a structure is the presence of a reinforcement frame inside it. In this case, the reinforced frame increases the tensile and bending resistance of the entire structure, increasing the overall strength of the base tenfold.

- Butovy. In this case, rubble stone is used as a filler. It makes it possible to strengthen the structure without the use of a reinforcing cage. But at the same time, rubble foundations, together with high compression rates, are not very resistant to tensile forces. In this regard, this type of foundation is used mainly on solid soils with a low level of groundwater.

- Made. Such a foundation is assembled from ready-made concrete elements manufactured at the factory using special technologies.

Let's take a closer look at what brand of concrete is needed for a strip foundation of different types. For information on what kind of concrete is needed for a particular foundation, see this video:

Monolithic reinforced

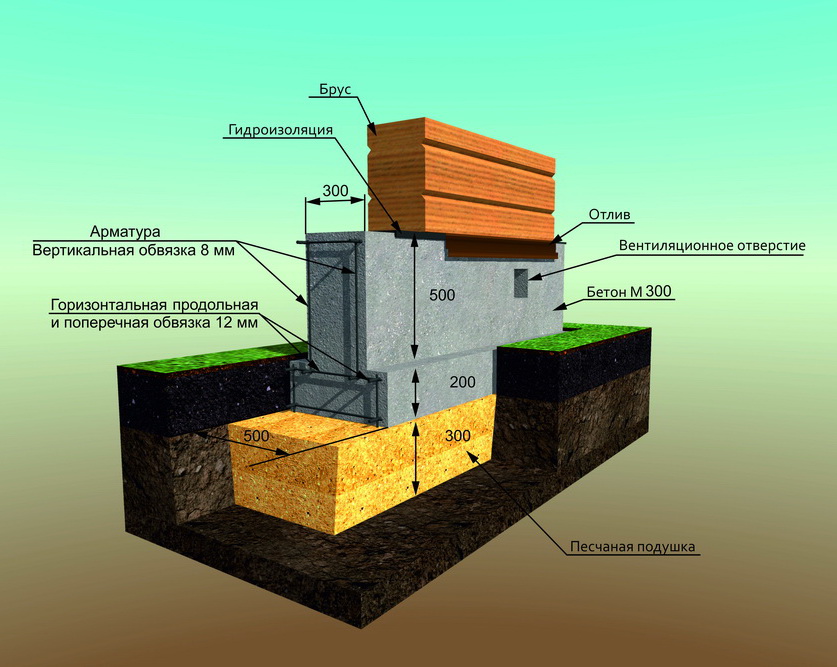

The monolithic reinforced foundation serves as the basis for a wide variety of buildings - light garden houses, massive brick mansions and multi-storey buildings. Depending on the expected load, concrete of grades M-150 and higher can be used for the construction of a reinforced base.

Butovy

A feature of the construction of a rubble foundation is the alternation of layers of concrete mortar and stones.

A feature of the construction of a rubble foundation is the alternation of layers of concrete mortar and stones.

In this regard, increased requirements will be given to concrete in this design.

Since the rubble base does not provide for the presence of internal reinforcement, increased requirements are imposed on concrete in this case.

Made

The main load in such a foundation is carried by concrete blocks.

The main load in such a foundation is carried by concrete blocks.

This type of strip foundation is assembled from individual structural elements, cast at the factory. However, in this case, according to the technology, it is impossible to do without the use of concrete mortar.

Here it is used as a binder, with the help of which a single foundation tape is created from individual components.

For the connection of concrete blocks, it is permissible to use the so-called "lean concrete" - grades from M-75 to M-150, in which cement is much less in volume than other ingredients. This is allowed because in prefabricated foundations, the main load of the building weight is carried by ready-made concrete blocks.

What brand is for what:

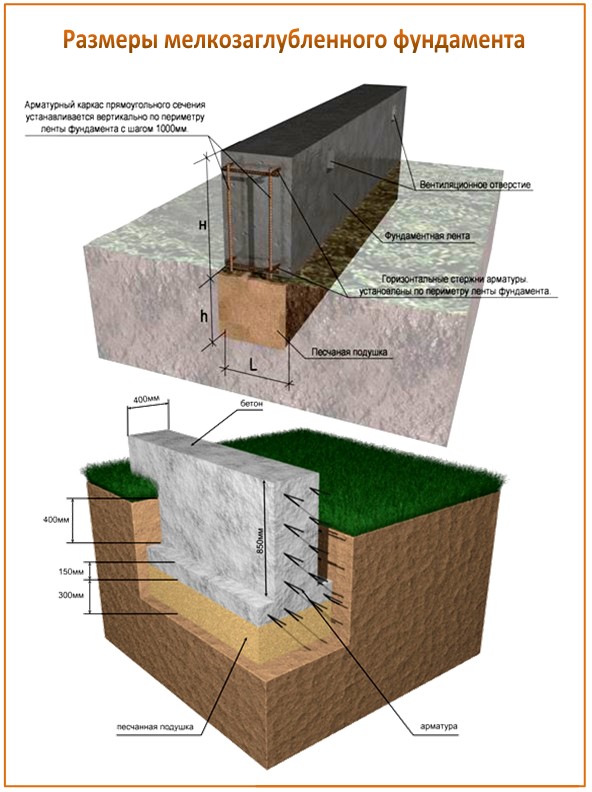

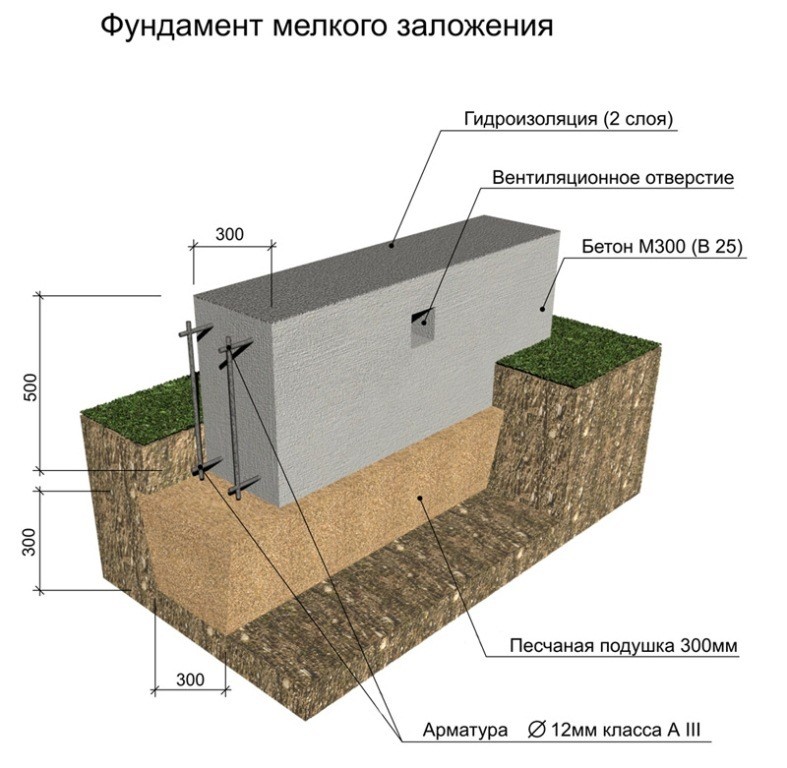

- For shallow tape options, on which one-story wooden houses will be erected (without subsequent brick cladding), M100 is quite suitable, maximum M150, withstanding from 130 to 180 kg / cm². Typical examples include summer cottages, garages, gazebos, and some kind of outbuildings. But this does not apply to cases where there is a shallow bed of soil waters. In this case, a higher grade of concrete is required (M250 and even M350).

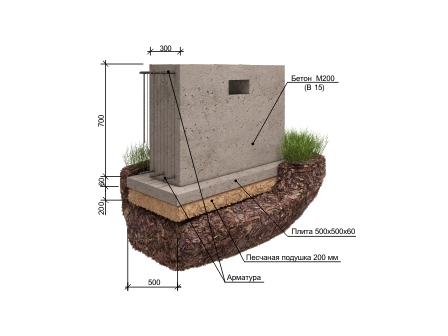

- For buried strip foundations, as well as shallow ones, on which it is planned to erect a two-story wooden or one-story brick house with ceilings made of reinforced concrete (monolithic) slabs, concrete M200 or M250 will be required.

- For pouring the foundation for heavier buildings (2-3-storey cottages with brick walls, etc.), experts recommend M300 and even M350. It is the most durable concrete commonly used in private housing construction.

The correct choice of concrete grade

What brand of concrete is the most optimal for building a bathhouse foundation? According to most experts, M350 concrete is the most acceptable. It is he who is used in most cases in private construction. This includes private houses, a bathhouse, greenhouses, and so on.

The numbers in the brand name were not chosen by chance. They indicate for the admissible strength at compression process, which is measured in kg / cm2. There is another classification system according to which this concrete can be designated as B25. This parameter indicates the ultimate resistance at which the pressure is maintained, measured in megapascals.

Today it is the most popular and demanded brand of concrete in construction, which is ideal in most cases. If you decide to use this particular type of concrete, you will get a bath foundation that has a perfectly acceptable level of strength for this structure. In addition, such a foundation is durable.

Sometimes the choice can fall on concrete with the M200 brand, and such a structure will also be quite strong and reliable. Nevertheless, using the M350 brand, you can be more calm about the foundation of your bath.

Selection and mixing of concrete solution

Concrete grade and cement grade have similar meanings, but are completely different concepts. The number of the cement grade indicates the strength of the cement mortar.

It is important to reinforce the foundation structure to resist lateral loads, and lay crushed stone or sand under the foundation. In theory, sand for concrete foundations requires marine sand, but it can be replaced with washed or alluvial quarry sand, which has its advantages over marine sand in the form of sand grains (angular shape) providing high adhesion

It is better not to use sand with a high content of clay and other foreign inclusions or rinse it yourself

In theory, sand for concrete foundations requires marine sand, but it can be replaced with washed or alluvial quarry sand, which has its advantages over marine sand in the form of sand grains (angular shape) providing high adhesion. It is better not to use sand with a high content of clay and other foreign inclusions or rinse it yourself.

Any tap water is suitable, there are no special requirements for it

It is important to maintain a 2: 1 ratio Two parts cement to one part water

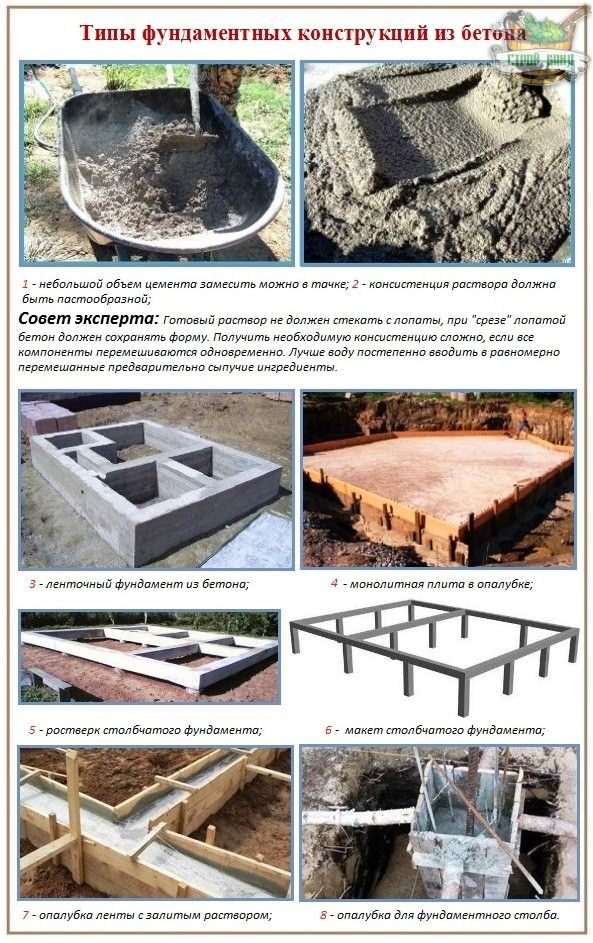

A concrete mixer is best suited for mixing, but you can do with improvised means. Sand, crushed stone and cement are mechanically mixed with the gradual addition of water until a homogeneous mass is formed. Try not to overflow with water, it will wash the cement out of the mixture.

What foundation for a garage to choose?

Let's summarize:

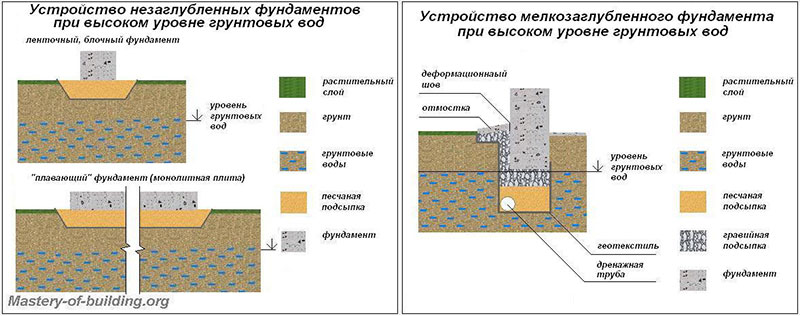

Swampy soil, permafrost or high groundwater levels - forget about the inspection pit and basement, choose a slab or pile structure.

There is no need for a viewing hole - make a slab or strip shallow foundation.

A basement is needed - only a tape base.

A site with a difficult terrain - a pile structure with a reinforced concrete grillage is suitable.

A lightweight garage made of foam blocks - a concrete monolithic slab with a depression of 40-50 cm would be the best choice.

Frame garage - taking into account the soil and water level, 3 main types of foundation are suitable: tape, pile, slab.

A small brick caravan for one car - arrange a reinforced monolithic tape, deepened to 80 cm.

Iron garage - pay attention to the concrete monolithic reinforced slab.

Alternative materials for the foundation can be used: sleepers, road slabs.

Tags: Garage

Reinforcement

Before pouring concrete into the formwork for the strip foundation, the reinforcing frame is installed.The work is carried out, focusing on the drawing, which indicates the layout of the elements, the diameter of the rods and the distance between the reinforcement. It will not be possible to draw up such a drawing on your own without the appropriate knowledge, a specialist should do it.

The reinforcement is fastened using a special knitting wire. It is impossible to use a welding machine to fix the frame elements - such a connection reduces the strength of the structure.

In the places of horizontal connection of the rods, when the length is increased, the elements are overlapped, the length of which is 20 diameters of the reinforcement used (for any values, the length should not be less than 25 cm). In the corner sections, to strengthen the strength of the structure, in addition to the wire, additional rods are mounted.

To maintain the protective layer, it is necessary to use clamps.

How to choose the components of the concrete mix?

We have already found out that in the formula of the solution, the active components are cement and the water that makes it work. Only the brand of cement should not be confused with the brands of concrete, since these are completely different parameters. Under M Portland cement is meant a value that indicates the strength of the cement slurry. Therefore, no matter what concrete is needed for the construction of the future foundation, cement is taken with the M400 or M500 marking.

Most often, Portland cement is used for self-mixing concrete on the foundation. A pozzolanic analog can be used if there is no base, as it shrinks heavily in the open air. The slag version perfectly resists soil moisture, but pleases with frost resistance.

Since the foundation is a structure predominantly reinforced, for mixing concrete in accordance with the building requirements, crushed stone of a fraction of up to 40 mm is needed. The optimal choice is chipped granite gravel, its rough edges optimize grip. Crushed limestone is not suitable for aggressive groundwater. You need river or sea sand, but in the absence of it on sale nearby, a career brother is also suitable. The sand must be sifted and washed. It is unacceptable to include clay and organic inclusions more than 5%.

You do not need distilled water for mixing, but you do not need to draw it from a stagnant lake with mud. It should not contain any biological impurities, oils, salts at all. Usually concrete manufacturers use potable. The amount of water is approximately equal to half the weight of the cement.

Selection of materials and preparation of trenches

To determine which grade of concrete to choose for a strip foundation, the following indicators must be taken into account:

- Class (B or M). This parameter indicates the maximum load on concrete. The concrete grade suitable for the strip foundations of a private house is from M100 to M300.

- Mobility (P). This is one of the most important parameters on which the quality of the erected structure depends. It is not recommended to use either a hard or a completely flowable solution. The optimal solution is a concrete grade for the construction of a foundation for a strip foundation with P3 mobility indicators.

- Waterproof (W). The higher it is, the greater the cost of concrete, therefore it is cheaper to perform high-quality waterproofing of the base than to purchase a brand with the required waterproof characteristics.

- Frost resistance (F). Shows how many cycles of freezing and thawing concrete can withstand without losing its performance. Recommended minimum is F150.

The table will help to determine which brand of concrete you need to fill the strip foundation.

Can be used on difficult soils, the grade is suitable for the foundation of multi-storey buildings

Having understood what kind of concrete grade is needed for the strip foundation, they proceed to calculating the amount. They do it in 2 ways. The first one is online.On special services, key parameters are entered (concrete grade, width, length and height of the tape, some other indicators), after which the algorithm calculates the required amount of material. The concrete volume calculator for strip foundations also allows you to quickly calculate the formwork and reinforcement.

The second option is the calculation of concrete for the foundation device manually. This is done using special formulas. You will need data on the width and height of the tape, as well as the total length (taking into account the elements under internal load-bearing walls).

The calculation of concrete for a strip foundation using a calculator is carried out according to the formula:

V = a * b * c, where a is the length, b is the width, c is the height of the tape.

It is recommended to increase the concrete volume on the foundation obtained on the calculator by 1-2% in order to take into account the losses during delivery and pouring.

After the calculation of the amount of concrete on the strip foundation is made, they proceed to the preparation of materials and tools for work. You will need:

- bayonet shovel;

- building level, square and plumb line;

- concrete mixer;

- bucket;

- hammer;

- drill or screwdriver;

- roulette;

- hammer;

- trowel;

- cement;

- crushed stone;

- sand;

- fittings;

- rope and pegs for marking;

- formwork material (board, timber).

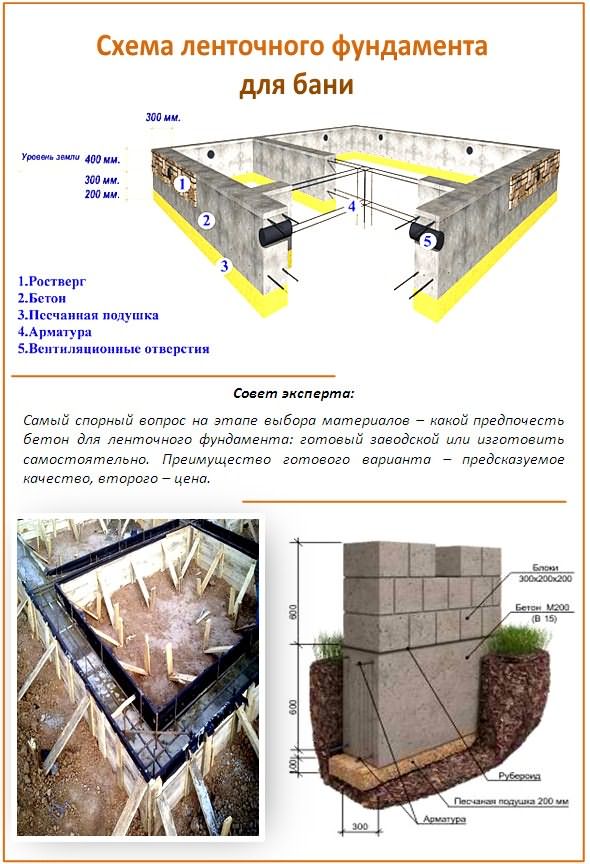

Work begins with marking the site and digging trenches. First, the area allotted for construction is cleared of debris, trees, shrubs. Sod is removed with a shovel. Using a plumb line, mark the point of the first corner, drive a peg in this place. 2 other points lead from it, put pegs there. Pull a cord between them. Using the square, determine the location of the 4 corners. Measure the distance between opposite points. If it matches, the markup is correct. The same method is used for internal marking. It should be 40 cm from the first line (standard trench thickness).

With the help of the level, the lowest point of the surface is determined, from which the depth will be measured. They dig a trench with a shovel at the depth specified by the project. The bottom should be as flat as possible, so the process is controlled using a level. The walls should not have a slope, they are made strictly vertical.

Move on to creating a sand cushion. The trench along the entire perimeter is filled with a layer of wet sand 10-15 cm high. For compaction, use a special electric rammer or a wooden bar. A layer of rubble of the same thickness is poured on top, a waterproofing material is compacted and laid.

Foundation types for low-rise buildings

The selection of the foundation is the very first task that must be solved at the beginning of construction. A mistake in this case will lead to a short service life, weak strength and unnecessary costs. Therefore, the first step is to choose the type of support, taking into account the parameters below.

- How deep does the groundwater run. If placed too close together, they can cause flooding and uneven ground settlement.

- Composition and density of soil. It is not recommended to lay the same type of foundation on mobile and dense soils.

- Freezing depth. Without taking this parameter into account, you can get cracks not only in the base of the building, but also on the walls and ceilings.

For low-rise construction, one of four types of foundations is used:

- Belt - a solid structure encircling the perimeter of the future building. It is possible to pour into formwork directly at the installation site or collect from previously created blocks.

- Plate. It is laid in layers, each of them has a separate role. Reinforced concrete slab acts as the top layer.

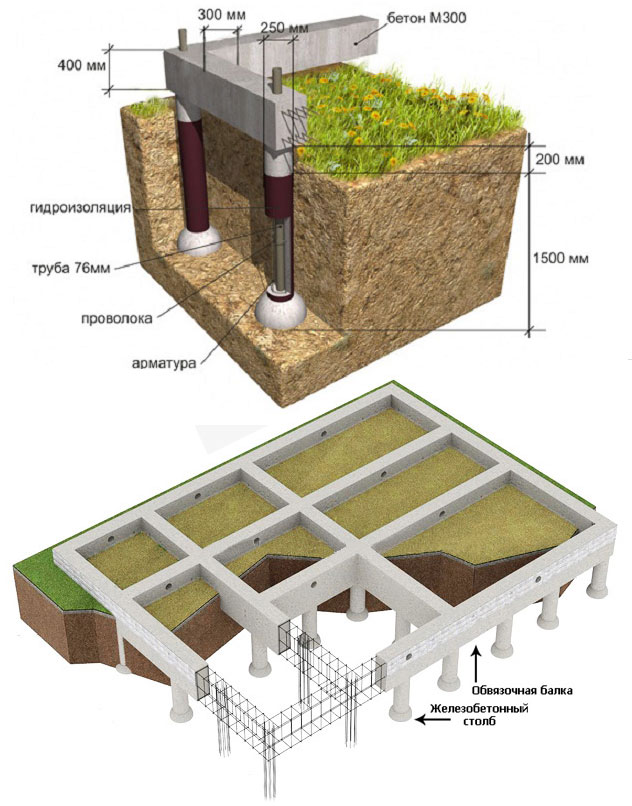

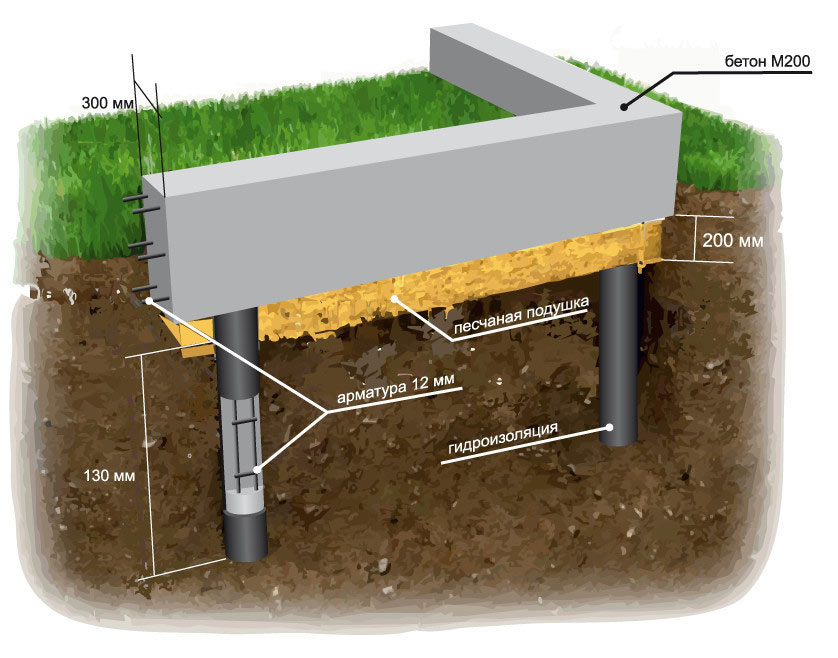

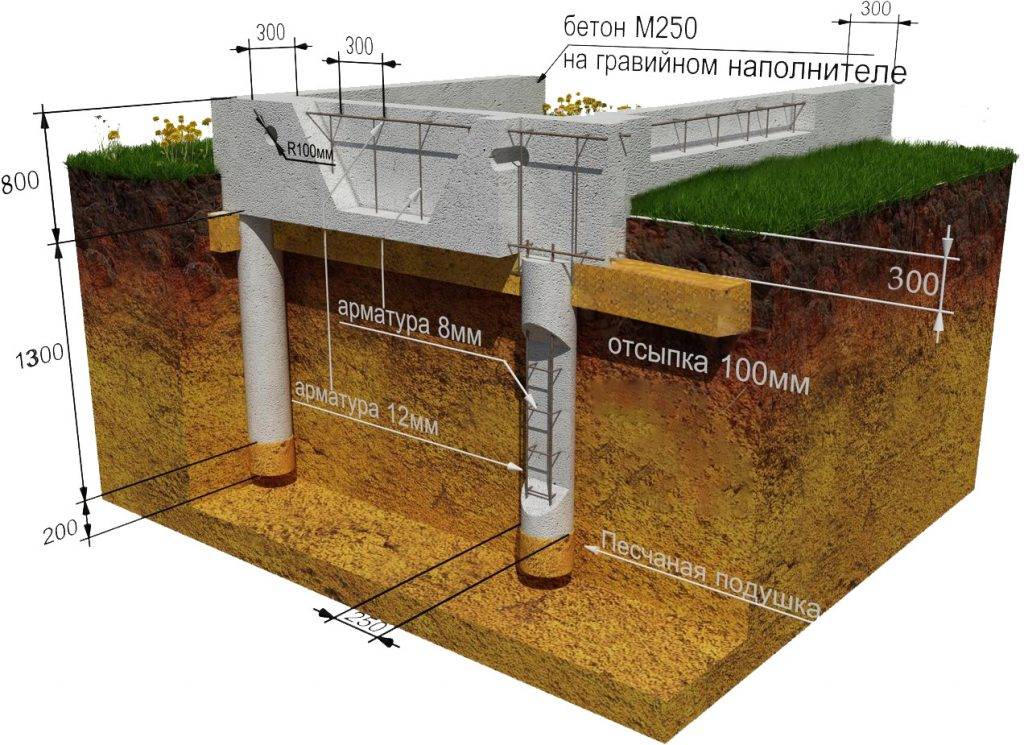

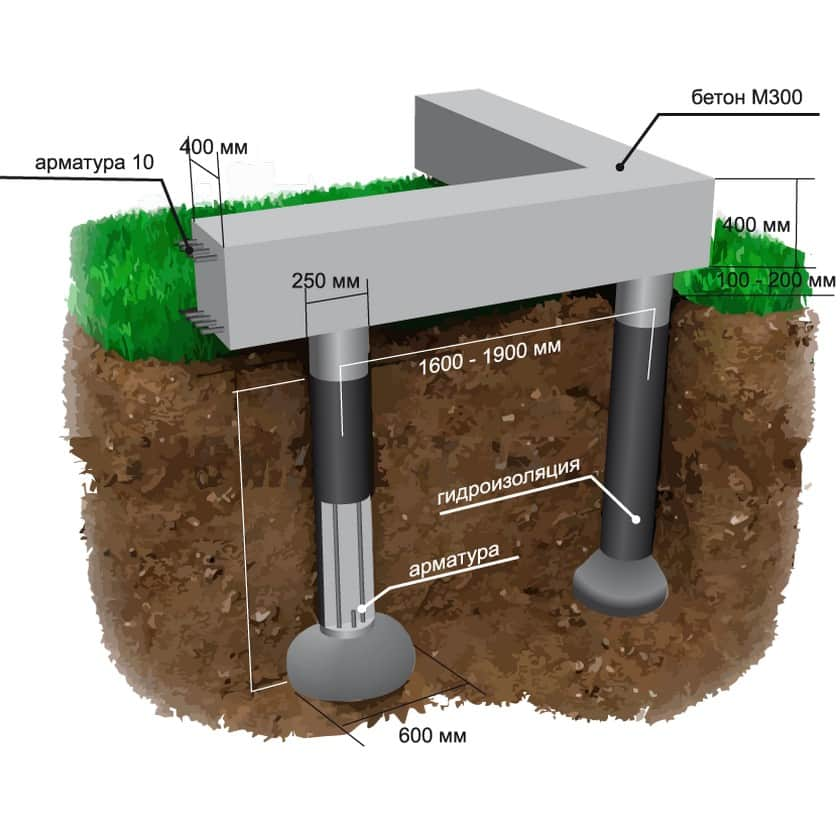

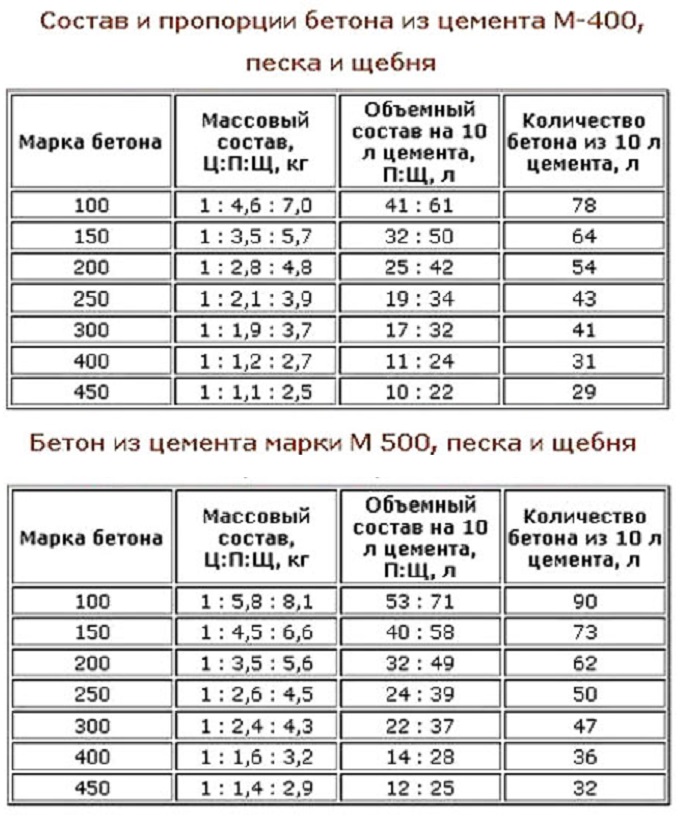

- Pile-grillage. At the base are pillars buried in the ground, connected on top by a jumper (grillage), which allows you to correctly distribute the load.

- Pile. It is assembled from supports installed over the entire building area or under areas with the highest load: corners, walls, ceilings and partitions.

The foundation project is developed taking into account the described factors, the materials used in the construction, and the final dimensions of the future structure.

Reinforcement types by location and purpose

A whole frame is assembled from the reinforcement, in which the steel rods are located in different directions. Working rods are those that take on the main load. To connect them together and the correct orientation in space, auxiliary rods are used, the so-called. clamps. The working fittings are located horizontally, in the longitudinal direction, and the clamps can be transverse (located horizontally) and vertical. Not all foundations require the use of all three types of reinforcement.

- the section of the working reinforcement is selected based on the calculations. The location of the rods depends on the type of foundation. For example, in a strip foundation, the working rods are arranged longitudinally in one or two rows. The number of rows of reinforcement depends on the thickness of the foundation: if the thickness is less than 150 mm, only one row can be used;

- transverse reinforcement is necessary to connect the working reinforcement. When erecting a strip foundation, transverse rods are necessary, and when pouring concrete into a monolithic slab, they do without them;

- vertical reinforcement is used where the working reinforcement is located in two or more layers.

According to their purpose, the fittings are divided into working, structural and assembly fittings. Constructive - the one that takes on the maximum load. Structural reinforcement takes on the load from shrinkage, and assembly reinforcement is used to combine structural and working reinforcement into a single frame. Anchor reinforcement is sometimes distinguished separately - these are embedded parts.

Foundations for wooden houses

Wooden houses have less weight than brick and concrete counterparts, but more than frame structures. The best option for wooden buildings is a strip type of base on a small deepening or a pile-grillage foundation.

If you install the first type, then it becomes possible to create a basement. It will require low costs and is quite stable. For a long service, it is worth remembering about hydro and thermal insulation and a sandy substrate of sufficient size and thickness.

The use of a pile-grillage base requires preliminary preparation of pits (it is advisable to dig them at the level of freezing of the soil) and connection with isthmuses. After that, the pits and ditches are filled with concrete.

How cement is marked

Not only the operational life of the structure, but also its tensile and bending strengths - those types of loads that the concrete tape experiences most of all - depends on the cement used for pouring the foundation base. To know what brand of cement is needed for the foundation of a house, it is recommended to understand its differences.

Not so long ago, a concrete mixture was prepared on the basis of one of the binders - PC (Portland cement) or SHPC (slag Portland cement). The main differences were in powder composition and strength characteristics. Cement grades for the foundation corresponded to the current GOST.

In addition to the name, the brand of cement material for the construction of foundations and other works contains a designation with numbers that indicate the maximum strength under load until complete destruction.

Now let's see what brands of cement are, how the marking is applied and what its decoding means.

According to the old designation system, several brands were distinguished:

- M 300 - withstands loads of up to three hundred kilograms per square centimeter of surface;

- M 400 - corresponds to a pressure of 400 kg;

- M 500 - withstands impacts of at least five hundred kilograms per site unit;

- M 600 - carries a load of six hundred kilograms.

The characteristics given here are not able to give unequivocal advice on what brand of cement to use for the foundation of a house, and what to use in the construction of lighter structures.Naturally, for large structures it is necessary to take material with a greater load. But you can prepare a concrete solution with the required indicators by changing the amount of a lower grade cement composition, increasing its amount.

This criterion is present in the marking of the material, and its presence is indicated by the corresponding letters and numbers D0 or D20. Before making the final choice in cement, it is recommended to clarify how the mineral components affect the quality of the binder. For example, D0 does not contain any components, and the solution is of the highest quality. But the brand with the designation D20 carries up to twenty percent of impurities that lower not only strength, but also cost. When choosing a cement material, for example, for the foundation of a fence, you can use a powder with a lower strength indicator, thereby reducing the cost of the total cost of construction work.

When deciding which material is best to use for pouring a strip foundation, you should study the remaining characteristics of the component indicated in the marking. The following designations are most often found:

- PL - there are plasticizers in the cement. Such material for the foundation is used when temperatures are low in the region in winter;

- VRC - this abbreviation denotes the moisture resistance of the mixture and the increase in volume during solidification. If you are in doubt about which cement is best for a foundation in a swampy area, then you will not find another option;

- B - such material requires less time before final solidification. If you have a choice of what to use on the foundation of a house, when the terms of work are limited, choose this particular cement material;

- SS - sulfate resistant cement. It is rarely used by private developers, because its main purpose is considered to be the concreting of hydraulic structures. When plugging oil and gas wells, plugging cement is used - a mixture of clinker powder, gypsum and other components;

- H - cement with this marking has undergone additional rationing using clinker. This additive ensures high strength of the material;

- BC - "white cement". A distinctive feature is that it brightens after hardening. It is rarely used, mainly for finishing work.

What factors influence the choice of the brand of composition

Unfortunately, there are no universal recipes, the price is not always a fundamental factor. After all, even expensive formulations have their own recommendations and restrictions on use.

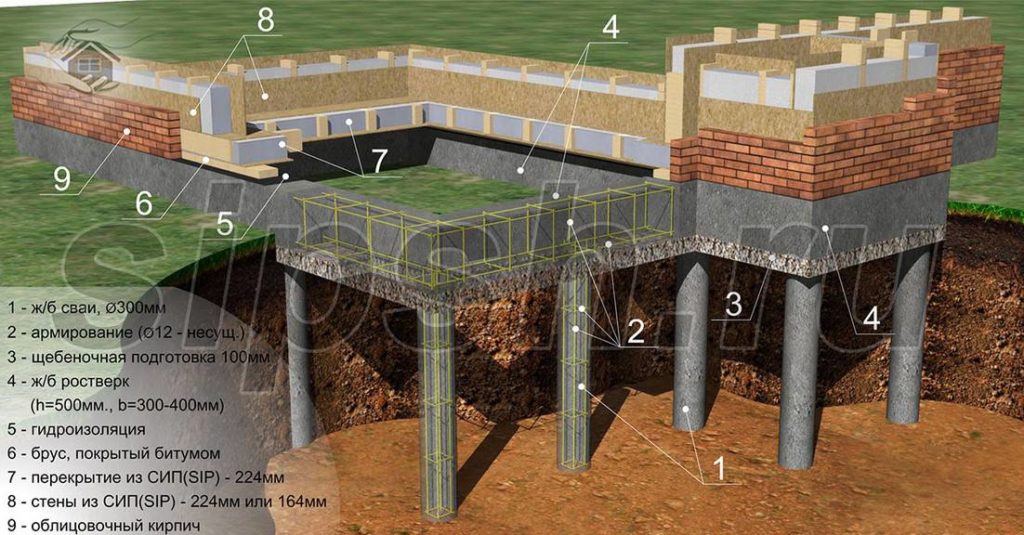

Scheme of the formwork option for the strip foundation.

Dependence on the weight of the building

If you want to build a house with your own hands, and you do not have a ready-made project with prescribed recommendations, then, first of all, you should pay attention to the total weight of the building. This is the first indicator from which they start when choosing a brand of composition.

Here are some general guidelines:

- A prefabricated panel house with a height of 2 floors, in most of our country, will comfortably stand on a reinforced concrete foundation filled with the M200 brand.

- For 2 - 3 storey log buildings, as well as for houses built of foam concrete, gas silicate blocks or other cellular concrete, M200 - M300 grades are recommended.

- For heavy, permanent buildings made of bricks, solid concrete structures or other heavy materials, it is recommended to use the M300 grade and above.

Reinforced blank for filling the structure.

Soil characteristics

Much depends on the geology of the soils in a given area, their composition and how deep the groundwater is.

Sandstones and rocks are considered the most favorable. They can be poured with concrete M200 - M250.

Clay soils and loams are quite a problem. The fact is that these soils, when frozen, are prone to heaving.That is, they do not freeze evenly and are able to squeeze out a shallow-buried strip foundation in some places, which leads to a general deformation. In this case, you can do it in two ways.

-

- First, to deepen the structure to a level higher than the average total soil freezing in the region.

- Secondly, you can equip a strip-columnar, well-reinforced foundation. This is when at key points support concrete pillars are poured to a considerable depth, which stabilize the entire structure.

- If we talk about what grade of concrete is needed for a strip foundation laid on clay, then experts recommend taking a grade an order of magnitude higher, approximately M250 - M300.

Scheme of a tape-and-column structure.

Waterproofing on the foundation.

Common grades of concrete

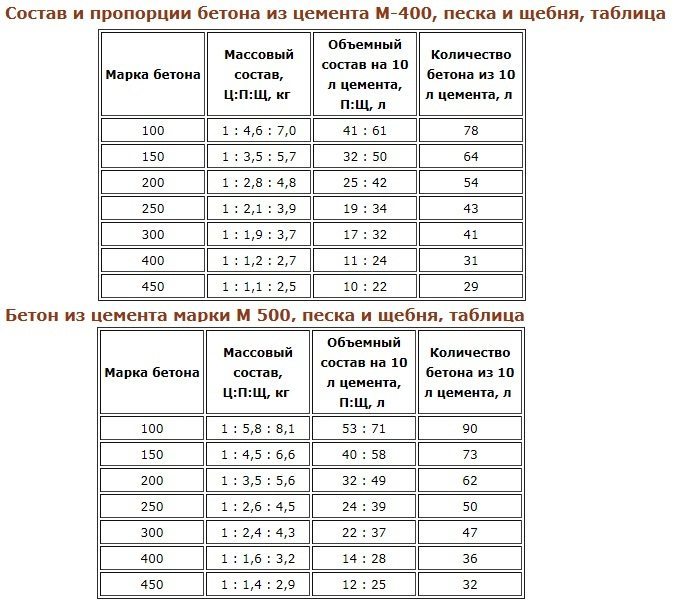

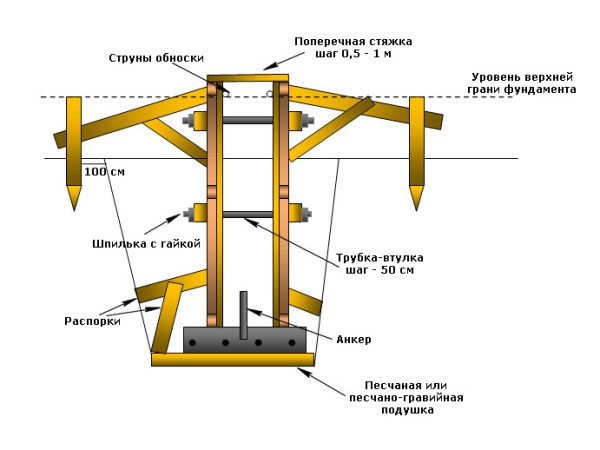

In the production of concrete of different grades for foundations, cement M 400 is most often used, but in different proportions.

- M100 - is used as an underlayment in road construction, deep foundations or floor screed.

- M200 - suitable for shallow foundations based on stable soils. Cellars and all kinds of open areas are poured into it.

- М250 - used for casting fences, all kinds of stairs and tape-and-columnar structures.

- M300 - is considered the most popular brand for pouring the foundation. It is successfully poured into the vast majority of known foundation structures, and can be used in a humid environment.

- М400 - used for filling underwater structures, bridges and other capital structures. It is used for the construction of houses in extreme conditions.

- M500 - used for pouring sheer structures, repairing roads and structures, or as an additive.

Detailed table of proportions.

What else is worth paying attention to

There is also a marking characterizing the strength class of the hardened composition. It is designated by the letter "B", characterizes the compressive strength and is measured in megapascals.

Classification of concretes for cement M500.

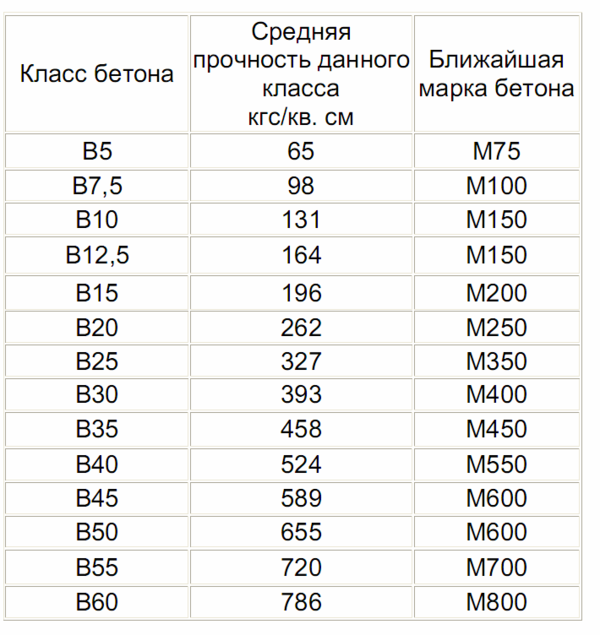

The level of strength and the grade of concrete are related indicators. According to GOST, each grade of concrete corresponds to its level of concrete strength, here are some basic indicators:

-

- B7.5 corresponds to M100

- B15 corresponds to M200

- B20 corresponds to M250

- B22.5 corresponds to M300

- B25, B27.5 correspond to M350

- B30 corresponds to M400

- B35 corresponds to M450

For our country, the frost resistance indicator is also relevant, it is marked with the letter "F" and a certain number after it. The number indicates how many times the structure can freeze

For a larger territory of the country, F200 is enough, the more thaws in winter, the higher this figure.

It is also worth paying attention to the indicator of resistance to high humidity. It is indicated by the letter "W" and the number after it.

Technical characteristics according to GOST.

We evaluate the composition of cement raw materials

To check the composition and practical quality of cement, use mineral water with hydrocarbonate, without gases. The cement powder is kneaded with this water until it is doughy. A cake is prepared, thickened in the center and thin at the edges. If a high-quality material that does not contain additives was used for the manufacture of cement, the cake solidifies in ten to fifteen minutes, and it is quite difficult to destroy it (especially in the center).

At the moment of solidification, the cake heats up and changes its color from gray to bluish green. This effect is not obtained with every cementitious material and depends on the specific manufacturer.

If the cake remains soft for half an hour, the cement does not have good binding qualities, it contains impurities about which you will not find any information on the packaging material.As follows from the reviews of the developers, such material is not suitable for the foundation, because it cracks during the hardening process.

Reinforcement material

Until recently, rebar and steel bar were synonymous. Now, for the manufacture of fittings, not only different types of steel are used.

Foundation fittings can be of the following types:

- steel - a classic of the genre. Steel is an alloy of iron and carbon, and its properties depend on the proportions of these components, as well as on the presence of additives. The quality of steel is influenced by the way it is produced. In addition, the rods can be smooth or embossed, which also affects the performance of the reinforcement. Steel is distinguished by its high strength and reliability, does not deform even under significant loads, and it is relatively easy to work with it - such reinforcement can be bent right on the construction site. Of the minuses, it is worth noting only the susceptibility to corrosion;

-

composite reinforcement is made on the basis of plastics. It is more expensive than metal, but is not afraid of corrosion, does not conduct electricity, weighs less and withstands solid tensile loads (sometimes more significant than a steel counterpart). It can be smooth and grooved. In private construction, it is rarely used because of the high price. Composite reinforcement can be of the following types:

- basalt-plastic is made on the basis of basalt - a strong rock. Basalt is melted, drawn into threads, which are intertwined with plastic threads. It is justified to use such reinforcement in the construction of walls, since it perfectly conducts radio waves without creating interference. Ideal for buildings where you need to set up a wireless Internet;

- fiberglass reinforcement is ideal for the construction of foundations, since it is not afraid of corrosion and does not conduct heat, which means that it will not become a place for the formation of cold bridges that lead to the destruction of structures. Fiberglass, like basalt plastic, transmits radio waves well. Its main advantage is its high tensile strength, 1.5 times higher than that of steel;

- carbon fiber reinforcement is made on the basis of graphite or diamond, hence the high strength, but also the high price. Impact and fracture toughness is higher than steel, allowing fewer rods to be used to achieve the same level of strength;

- glass-reinforced polyethylene terephthalate is produced by interweaving lavsan and glass fibers. The glass is preliminarily highly heated and stretched, due to which it becomes durable. Lavsan, on the other hand, gives the material flexibility, so it is good to use such reinforcement in moving soils.

Plastic reinforcement is still used quite rarely - in most cases there is no need for it, therefore, further we will focus exclusively on steel reinforcement.