How to choose material depending on the room

In order to correctly determine the material for the manufacture of interior items for different rooms, it is necessary to take into account some recommendations.

Each variety is created for its own purposes, so it is fundamentally wrong to declare unequivocally that some material is better or worse.

Each variety is created for its own purposes, so it is fundamentally wrong to declare unequivocally that some material is better or worse.

Hallway furniture

This is a room with high traffic and fluctuations in temperature and humidity. Water carried from the street can create problems. Therefore, the following rules exist for furniture in this room:

The standard economy option assumes the use of products made entirely of chipboard. But all the outer edges are processed with a PVC edge of 2 mm, and the inner ones - 0.4 mm. Printed piping can be an alternative for some areas.

Particular attention is paid to the racks located directly on the floor: they are additionally raised above the surface with the help of special "boots"

Melamine and thin (up to 1 mm) PVC or ABC tape is considered an unreliable option, it is used only for processing internal surfaces, the outer edge is processed with an edge from 2 mm, while the highest protection is given by PVC and aluminum moldings for a milled groove

Melamine and thin (up to 1 mm) PVC or ABC tape is considered an unreliable option, it is used only for processing internal surfaces, the outer edge is processed with an edge from 2 mm, while the highest protection is given by PVC and aluminum moldings for a milled groove

A better solution involves a combination of materials. For facades, MDF is used, where HDF is suitable for insertion with a frame version. The body is made of laminated chipboard with maximum edging.

The box, assembled from laminated chipboard and decorated with an MDF facade, significantly reduces the price of the headset, and without losing quality in operation and appearance

The box, assembled from laminated chipboard and decorated with an MDF facade, significantly reduces the price of the headset, and without losing quality in operation and appearance

Kitchen set

While Medium Density Fiberboard (MDF) is the optimal solution for high humidity, it is not used for all kitchen items. Therefore, when they say that products are made of MDF, only facades or a dining table cover are meant.

For the kitchen, the same rules are true as for the hallway, but there are additional nuances:

- The table top of the headset must be moisture resistant. Such a protective impregnation is clearly visible on the cut: most often it gives the structure a greenish tint.

- It is better to refuse laminated chipboard facades with melamine edges. It is easy to distinguish it: to the touch, the surface resembles very thick paper. The best solution is with a 0.4 or 2 mm PVC tape. The latter has slightly rounded corners.

The ends of objects located next to the stove must be covered with a special aluminum plate. The attachments are positioned to minimize steam ingress.

In kitchen sets, it is not so important whether the facade is made of MDF or chipboard, the main thing is to choose a good countertop and provide protection from moisture in the floor area

Children's room and bedroom

Furniture for a child's room (as well as for any other premises) must have mandatory certification. But unlike previous objects, beds for a nursery can be made entirely of MDF.

Particular attention is paid to the internal stiffening ribs, on which the mattress flooring is located: such parts are made of wooden beams, which provide the necessary strength and reliability

Both MDF and laminated chipboard are widely used for the production of children's furniture, in this case, it is not so much the material that is important as the level of trust in the brand.

Both MDF and laminated chipboard are widely used for the production of children's furniture, in this case, it is not so much the material that is important as the level of trust in the brand.

The rest of the furniture should be as functional as possible. The following requirements are imposed on them:

- For children under 6-7 years old, it is better to choose products with rounded edges, which is inherent in milled parts with a wood-fiber structure, or to equip them with special overlays.

- The fittings should be matched with a smooth closing of the facades, which will exclude injuries.

Furniture for the bedroom and walls in the living room are selected based on personal preferences, but the best solution would be a combination of MDF and chipboard.

The presence of a strong odor

First of all, furniture should not have a sharp, pronounced chemical smell, which appears in the case of using low-quality chipboard

After all, it is important for all of us to be surrounded by environmentally friendly pieces of furniture.

For residential premises, chipboard with E1 marking is allowed, if the value of E2 and higher is indicated - such material cannot be used for the manufacture of furniture. A pungent odor characterizes a low quality slab in which formaldehyde levels are exceeded. This will affect the health of all family members; not only headaches, but also serious disorders in the human body can become constant companions.

Permissible formaldehyde content for the CIS countries: 10 mg per 100 g of the board. In Europe, the requirements are stricter: 8 mg per 100 g of chipboard

Permissible formaldehyde content for the CIS countries: 10 mg per 100 g of the board. In Europe, the requirements are stricter: 8 mg per 100 g of chipboard

The smell in products appears when the content of formaldehyde is from 14 mg per 100 g of the plate

The smell in products appears when the content of formaldehyde is from 14 mg per 100 g of the plate

MDF or chipboard. What's better?

MDF and chipboard have been arguing among themselves for a very long time. Here it is impossible to say unequivocally what it is better to order a wardrobe from and point out the winner and the loser. After all, it all depends on each specific case: goals (what do you want to buy?), Purpose (which room and who will use it?), Budget (the amount that you put in your personal estimate marked “for furniture”?) And, of course however, wishes in appearance (how should the future product look like?).

Both materials have long been successfully used in construction and interior decoration. We are interested in their march through the furniture market.

Mr.Doors uses both MDF and particleboard in his collections, giving you the opportunity to decide which material to choose. But you don't have to choose! They perfectly combine and match with each other. Let's talk about their differences further.

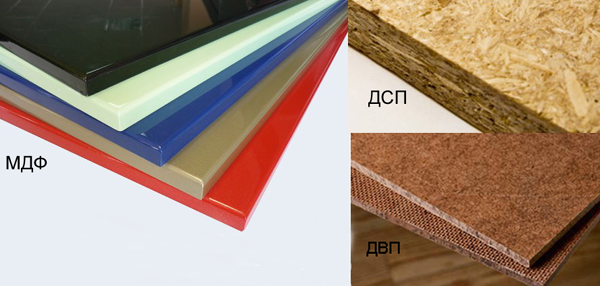

MDF - Medium Density Fibreboard. This is the Russian version of the English term. Transliteration sounds like "medium density fibreboard". The production of MDF is structured as follows: finely dispersed wood chips (technological chips) are pressed under high pressure and temperature. Only natural substances are used as a binder: lingin (wood resin) or paraffin.

Already from the description of the production process, it becomes clear that the main advantage of MDF is environmental friendliness. And indeed it is! During operation, MDF does not emit any impurities harmful to humans and animals. It is a durable wood-based furniture material with a high density at the same time. Thanks to this, the plate reliably holds the fixing fittings and the holes do not crumble. MDF is easy to process. It can be used to make curved facades and perform curly milling (panel), which not every material can boast of.

MDF has an amazingly huge number of processing options: PVC films of any colors and textures, high-gloss films and enamels, veneer and solid wood. Believe me, this is a lot! Even the most demanding buyer will find what he is looking for.

MDF loses to chipboard in value, and loses seriously. This can be called his only serious drawback. But this is completely justified, since MDF will last you much longer and will look like it was just bought.

Chipboard - chipboard, raw materials for which are sawdust, shavings, dust. In the case of chipboard, formaldehyde resins act as a binder. Particleboard is widely used in furniture and shows itself from good sides. Of course, if it meets high quality standards.

We would like to draw your attention to the edge.Chipboard is safe only in one case: if it is laminated with high quality and seamlessly (covered with a film)! Only under this condition can you sleep peacefully without fear for your health and the health of your loved ones.

Mr.Doors cannot afford to use materials that are hazardous to health, so our range contains only high quality E1 class particleboard. This is the standard for which formaldehyde emissions are lowest. E1 class chipboard is recommended for use in the production of furniture for children's institutions.

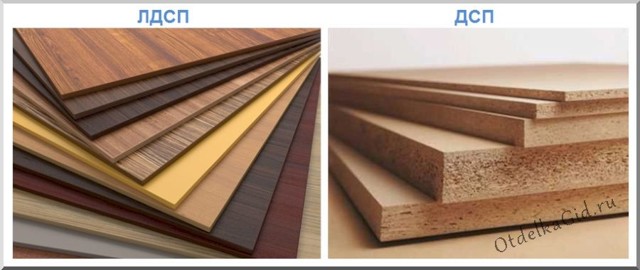

Particleboard, as a rule, has a laminate finish. There are also a lot of colors and textures. The main competitive advantage of chipboard as a material is its cost. Moreover, it looks more than presentable.

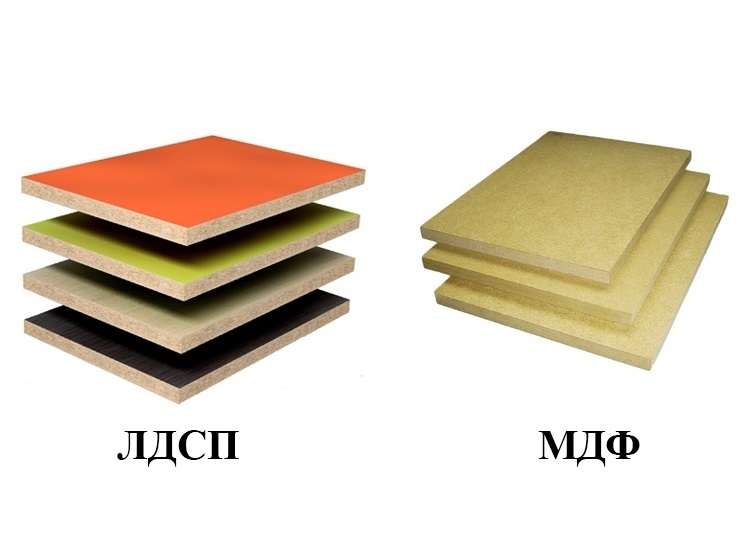

MDF and chipboard: what is the difference

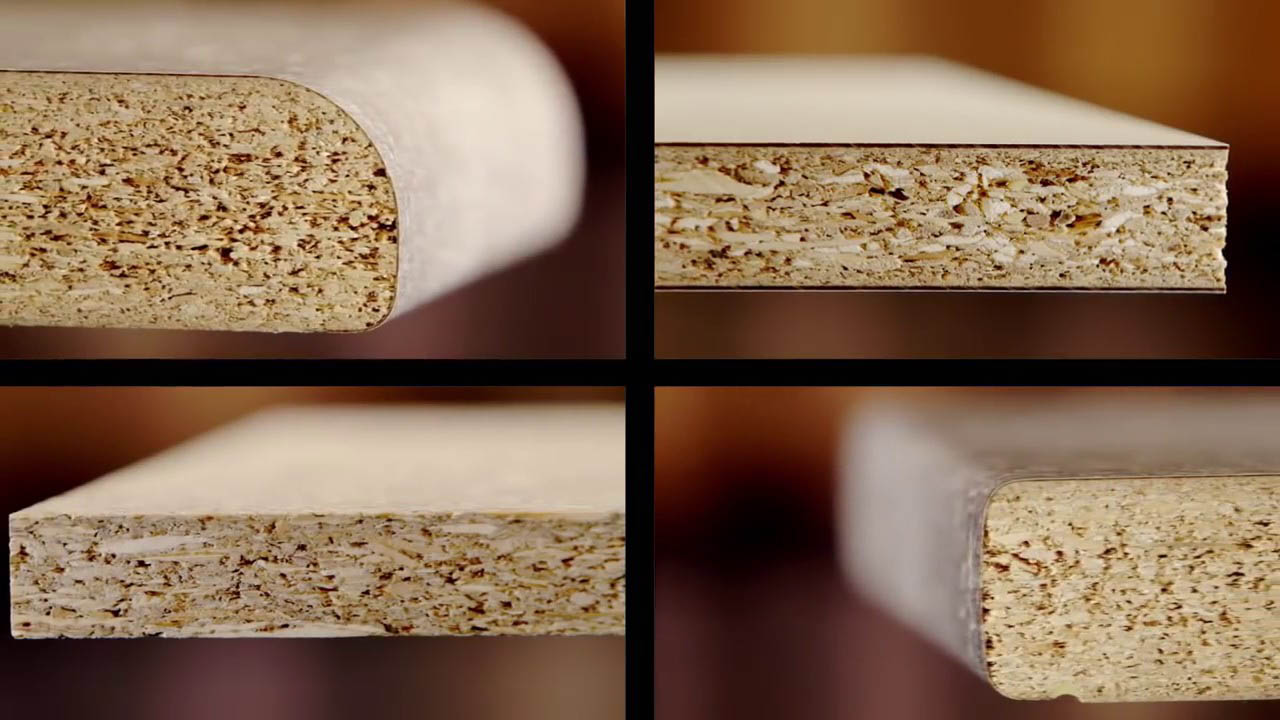

Particleboard (chipboard) contains compressed shavings and sawdust impregnated with formaldehyde resins. Depending on the grade, chipboard has different quality characteristics: from loose material with a density of 300 kg / m 3 to a more durable and expensive 600 kg / m 3, which is used in the manufacture of furniture.

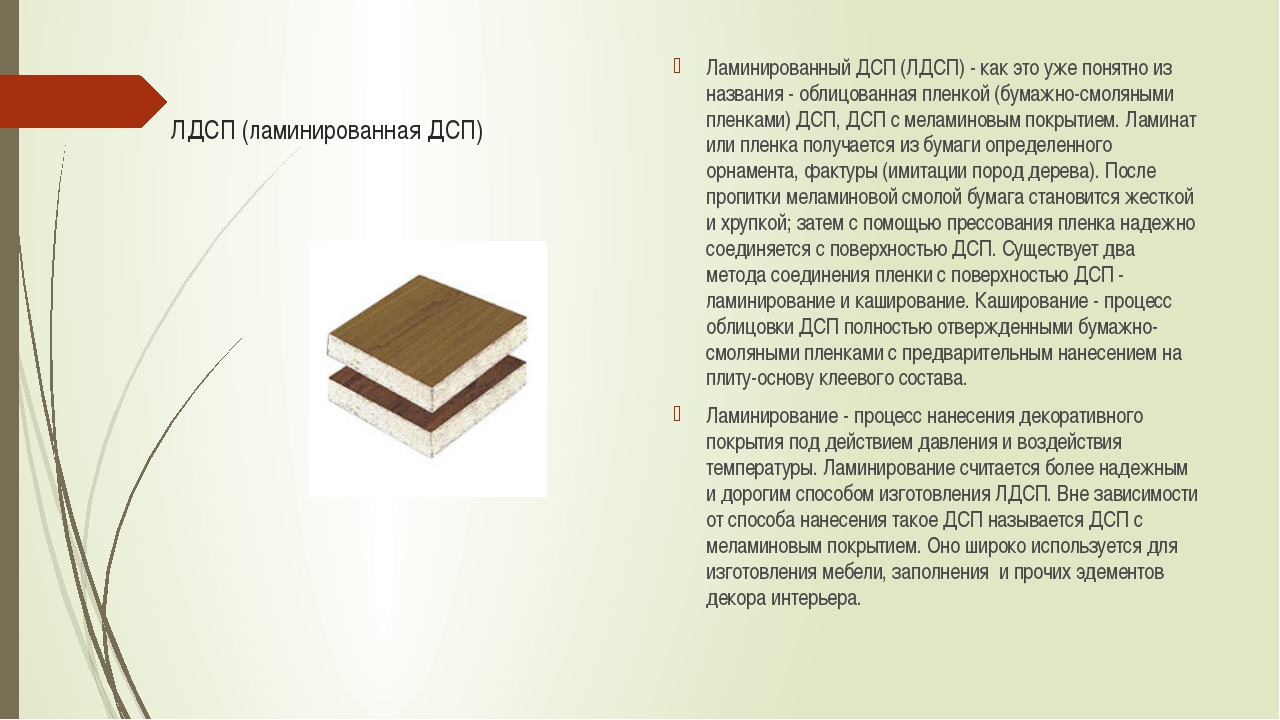

Modern production makes it possible to minimize the harmful effect of the binder resin and improve the appearance of the board with the help of coating with melamine film - lamination. Hence the name "chipboard". The film has good aesthetic properties and does not allow formaldehyde to evaporate.

Manufacturing of MDF board is carried out according to the improved technology of chipboard production - by drying wood fiber and hot pressing. Medium density fibreboard (MDF) contains only the smallest sawdust compressed to a homogeneous state. Unlike chipboard, which must be carefully sanded before being coated with a film,

MDF immediately has a smooth and even surface. Such a board is more dense and durable, resistant to drilling and moisture in comparison with laminated chipboard. It is also better suited for deep milling and deformation when creating curved furniture fronts. In addition, the MDF board has significantly higher environmental properties due to the fact that mainly natural resins, lignin and paraffin are used as impregnation of sawdust. Formaldehyde is also present, but in a much smaller amount.

For greater clarity of the differences between the two materials, you can compare the structure of chipboard with heterogeneous raw materials passed through a blender, and MDF with a product from a meat grinder. The density of the MDF board varies from 600 to 800 kg / m 3, which in conditions of increased moisture allows the material to surpass even natural wood in some characteristics.

Care of laminated chipboard or MDF furniture

There are several general conditions for the care of furniture made of MDF or chipboard.

- Prolonged exposure to high temperatures is undesirable: at 75 degrees and above, the coating may peel off.

- Another factor is sunlight, which can also change the appearance of the slab. The film on laminated chipboard is more susceptible to fading, although MDF can change color somewhat with constant exposure to sunlight.

- You also need to be careful about long-term interaction with water. If the joints of the coating are not airtight, when water gets inside the slab, the sawdust will swell, and the slab itself will lose its appearance and properties. However, this is an extreme case. Under normal living conditions, with short-term exposure to water, which is inevitable in the kitchen, the stove can retain its original appearance for a long time. MDF manufacturers claim that fiberboard can withstand even a small flood.

Chipboard or MDF: which is better

The common plus of both materials in comparison with natural wood is resistance to pests and fungal infection.

Advantages and disadvantages of MDF:

Chipboard and MDF: combining materials

The best option for a wallet, not at the expense of quality and durability, is to choose furniture with a combination of materials.

Chipboard will perfectly fulfill its functions as a basis for the kitchen body, and MDF, thanks to the variety of films for covering and the possibility of decoration, will make beautiful facades that fit perfectly into the interior of the kitchen. So you shouldn't choose which is better for the kitchen: MDF or chipboard? The answer lies in the correct combination of both materials and their rational purpose.

For example, laminated chipboard, in addition to being used in the furniture body, can be used as an inexpensive but durable and reliable tabletop of various thicknesses: from 25 to 38 mm. The slab is covered with multilayer plastic using the Postforming technology. Such a plate is resistant to moisture and mechanical damage, so it will last for many years without requiring special care.

High-quality laminated particle board in combination with MDF can be used in the production of other furniture, including wardrobes, beds, furniture groups for a children's room. If the joints and joints of laminated chipboard are reliably protected, and the manufacturer has the appropriate certificates confirming the environmental friendliness of the material, then such furniture is safe to use and can deservedly take a place in the apartment.

Security

The technology for the production of board materials implies that the content of harmful substances in MDF is less than in chipboard. We are talking about volatile substances, which are harmful to humans, released by resins (used as binders), which gradually (during long-term operation) "evaporate" and accumulate in the air if there is no sufficient ventilation of the room. All these substances do not cause instant damage to the human body and have a harmful effect only with prolonged contact with them (in other words, if you decide to lie down for a long time on a chipboard or MDF plate, then you will not die from poisoning by the substances they release, but from thirst, hunger or from old age).

However, the manufacturers nevertheless established a certain gradation:

- MDF - with strict adherence to the technology and the implementation of high-quality cladding of the surfaces of the structure, it is considered the least dangerous in terms of the release of harmful substances into the ambient air. In the production of MDF, the main binder is lignin, which is released during the heating of wood. Therefore, high-quality MDF is environmentally friendly;

- Chipboard class E1 - takes the second place in terms of safety for the human body (but also only with the appropriate facing of surfaces);

- Particleboard of class E2 - emits the largest amount of harmful substances, is prohibited for production in foreign countries, and in Russia - is prohibited for the production of furniture and products used inside public and residential premises (GOST 10632-2007).

The difficulty in determining the harm actually caused by these materials lies in the fact that the information recorded in the certificates does not always correspond to reality (and sometimes certificates are attached to the materials not "native", that is, drawn up based on the results of tests carried out, but "purchased"). In addition, not all manufacturers (especially Russian ones) follow the recommended process technology for the production of MDF and chipboard, trying to save money when using lower quality resins.

MDF or chipboard. What's best for kids?

When choosing a nursery, we are, of course, concerned about the safety and environmental friendliness of future furniture. Of course, a lot depends on the nature of the child and on the period for which you purchase the furniture. For a long time, or, for example, until the moment the child goes to gnaw the granite of science.

If you have a hooligan boy growing up, conducting experiments on everything where the eye falls, then your option is MDF. And if you have a gentle and neat excellent pupil, then you may well make a choice in favor of chipboard.

Visit any of our Mr.Doors furniture showrooms with your kids! We guarantee that you will experience a lot of positive emotions and get an answer to your every question! You will be pleasantly pleased with professionalism, willingness to help, individual approach and high quality service.

The kitchen has an elusive atmosphere of coziness and warmth of a home. It is she who daily gathers all household members within her walls: in the kitchen, adults and children meet to have a snack and share news. How to make the interior of this room as cozy and comfortable as possible?

A dressing room is not just the dream of most women, but also the most comfortable form of storing clothes. In most modern apartments, a small dressing room is already provided for in the layout. However, if your home does not initially have a separate storage room, you can create a small dressing room yourself by separating part of the room with a stationary or sliding partition.

Creating an interior design for a small children's room is a difficult task. After all, every parent wants to give their child the best. However, if the room is small, this is clearly not easy. How to place everything you need in a small nursery? Leave enough free space for games and activities? Create a cozy atmosphere? You will find the answers to these questions in our article.

Difference between panels

Despite the popularity of both types of boards, each of them occupies its own niche in the furniture business. Materials differ:

By density

- MDF is a dense and moisture resistant material. Its structure is strong and lends itself to fine processing. Used in the manufacture of carved wardrobes, headboards and other places where grace and fine lines are required. Products from MDF are durable and massive.

- Chipboard is a loose material that strongly draws moisture. Has a solid facade surface, but inferior to MDF in fracture strength. The material suffers in the places of fasteners with frequent disassembly and assembly or dragging of pieces of furniture. Chipboard is 2 times inferior in strength to fiberboard. At the same time, the laminated protection makes the chip structure stronger, while simultaneously protecting it from moisture and temperature. Therefore, chipboard boards are popular in the manufacture of kitchen sets and bathroom furniture.

Environmental friendliness

- MDF is close to wood by its naturalness, it is allowed for all rooms.

- Chipboard contains toxic components (formaldehydes), which limits its use in rooms with children and patients.

By design

- The design of MDF panels is limited.

- Chipboard has many colors and textures due to the laminated coating. Chipboards are used to make cabinet furniture with imitation of any wood.

By cost

- MDF is expensive. It is used in the manufacture of luxury furniture.

- The price for laminated chipboard is more affordable. The facades of cabinet furniture of the "economy" class are mainly assembled from laminated plates.

How to choose material depending on the room

In order to correctly determine the material for the manufacture of interior items for different rooms, it is necessary to take into account some recommendations.

Each variety is created for its own purposes, so it is fundamentally wrong to declare unequivocally that some material is better or worse.

Hallway furniture

This is a room with high traffic and fluctuations in temperature and humidity. Water carried from the street can create problems. Therefore, the following rules exist for furniture in this room:

The standard economy option assumes the use of products made entirely of chipboard. But all the outer edges are processed with a PVC edge of 2 mm, and the inner ones - 0.4 mm. Printed piping can be an alternative for some areas.

Particular attention is paid to the racks located directly on the floor: they are additionally raised above the surface with the help of special "boots"

Melamine and thin (up to 1 mm) PVC or ABC tape is considered an unreliable option, it is used only for processing internal surfaces, the outer edge is processed with an edge from 2 mm, while the highest protection is given by PVC and aluminum moldings for a milled groove

A better solution involves a combination of materials. For facades, MDF is used, where HDF is suitable for insertion with a frame version. The body is made of laminated chipboard with maximum edging.

On a note! If the lower ends are not protected, then they can be additionally covered with silicone sealant.

The box, assembled from laminated chipboard and decorated with an MDF facade, significantly reduces the price of the headset, and without losing quality in operation and appearance

Kitchen set

While Medium Density Fiberboard (MDF) is the optimal solution for high humidity, it is not used for all kitchen items. Therefore, when they say that products are made of MDF, only facades or a dining table cover are meant.

For the kitchen, the same rules are true as for the hallway, but there are additional nuances:

- The table top of the headset must be moisture resistant. Such a protective impregnation is clearly visible on the cut: most often it gives the structure a greenish tint.

An ordinary chipboard sheet is not suitable for a countertop, such a plate should be thicker and denser than the facade material and have a higher class of moisture protection

It is better to refuse laminated chipboard facades with melamine edges. It is easy to distinguish it: to the touch, the surface resembles very thick paper. The best solution is with a 0.4 or 2 mm PVC tape. The latter has slightly rounded corners.

The ends of objects located next to the stove must be covered with a special aluminum plate. The attachments are positioned to minimize steam ingress.

In kitchen sets, it is not so important whether the facade is made of MDF or chipboard, the main thing is to choose a good countertop and provide protection from moisture in the floor area

Children's room and bedroom

Furniture for a child's room (as well as for any other premises) must have mandatory certification. But unlike previous objects, beds for a nursery can be made entirely of MDF.

Particular attention is paid to the internal stiffening ribs, on which the mattress flooring is located: such parts are made of wooden beams, which provide the necessary strength and reliability

Both MDF and laminated chipboard are widely used for the production of children's furniture, in this case, it is not so much the material that is important as the level of trust in the brand.

The rest of the furniture should be as functional as possible. The following requirements are imposed on them:

- For children under 6-7 years old, it is better to choose products with rounded edges, which is inherent in milled parts with a wood-fiber structure, or to equip them with special overlays.

- The fittings should be matched with a smooth closing of the facades, which will exclude injuries.

Furniture for the bedroom and walls in the living room are selected based on personal preferences, but the best solution would be a combination of MDF and chipboard.

Features of laminated chipboard (chipboard)

Chipboard is a well-known chipboard coated with a facing film. The manufacturing technology of such plates has been known for a long time; in the 80-90s, chipboard furniture was one of the most popular.

Later, obvious shortcomings were identified, which somewhat reduced the popularity of this material. At the same time, a simple chipboard has fewer advantages than its counterpart with a laminated film on top of the board.

Pros of the material

- different sheet thickness;

- high hardness;

- the widest choice of color solutions;

- good tolerance to humidity and high temperatures.

Furniture made of laminated chipboard has long established itself. Many are satisfied with the value for money, as well as the long service life and ease of maintenance.

Cons of laminated chipboard

One of the most critical disadvantages of laminated chipboard is toxicity. In the manufacture of this type of chipboard, formaldehyde resins are added to the mixture before pressing, providing adhesion and rigidity.

When buying furniture from chipboard, you should pay attention to the class of material. The E1 indicator indicates a lower toxicity of the components.

At the same time, it is always worth studying the quality of lamination of joints - they must be pasted over or closed with special corners made of plastic, rubber or metal.

In addition to the toxic effects of poor assembly or damage to the laminating film, there is one more drawback. It is not so significant, for some this drawback does not even matter. Due to the high hardness of the material, it is impossible to create relief patterns on the surface using milling machines. Instead of a beautiful relief, chips will appear on it, so the surface remains simply smooth. It is possible to create a small imitation of the relief structure of wood or stone by using a special plastic film.

What is best for kitchen furniture? What is the difference between such materials?

At first glance, it is difficult to understand how MDF differs from chipboard. Experienced people can immediately see the difference, but beginners, even after several years of use, cannot guess the difference. The indisputable advantage of the first is its environmental friendliness, which determines the high operational safety, although the cost of the material also dictates its own rules. If you have financial opportunities, it is worth choosing furniture made entirely of MDF for the bedroom and children's room.

The ability of laminated chipboard to withstand high levels of humidity in rooms has made it a frequent companion in bathrooms and kitchens. It is difficult to imagine more suitable inexpensive furniture for these premises. At the same time, with poor-quality laminated joints, chipboard tends to absorb moisture. In order for such furniture to serve for a long time, you need to carefully examine all the ends of the product. At the same time, this allows you to make sure that the laminated chipboard furniture is safe for use.

If the cost of MDF was comparable to the price of laminated chipboard, then the choice is obvious - a finely dispersed fraction of wood. So far this is not the case - laminated chipboard is cheaper than a competitor, which determines its demand among consumers.

Combinability of materials

Many will not be able to determine whether it is chipboard or MDF in appearance. The visual differences between them are understandable only to experienced people. If the product is of a clear rectangular shape without a relief and ends sharpened at an angle, then even professionals who know the difference between MDF and laminated chipboard will not immediately reveal the differences.

This approach to combining the material allows you to use the aesthetic characteristics of the finely dispersed fraction of wood, without spending a lot of money. From the point of view of operational safety, everything remains the same - chipboard must be protected from chips.

What it is?

MDF got its name from the English abbreviation MDF, which in Russian means "finely dispersed fraction". Decoding laminated chipboard - laminated chipboard. Materials are manufactured using different technologies, which is why they have different properties.

Chipboard

This is a common particle board (chipboard) covered with a laminated film. The main raw material for its production is waste from wood processing enterprises. It can be:

- crooked trunks;

- knots;

- branches;

- scraps generated in the process of sawing logs and when trimming sawn timber.

The wood is cleaned of bark and fed to shredding units, for example, rotary knife shredders. This is how shavings are obtained. Its average thickness is 0.5 mm, its width is no more than 5 mm, and its length is about 40 mm.

During the production process, the chips are dried in special chambers and then calibrated. After preparation, the raw materials are fed to the mixers that work continuously. There it is mixed with binders.The next stage is the entry of the viscous mass into the molding equipment, which forms a 1-3 layer carpet. He goes to pressing. When compressing the workpiece, a pressure of 40 kg / cm3 and a temperature of up to 220 degrees are applied.

The boards formed and dried in this way enter the cooling chambers. After that, the edges of the material are leveled, the cut is made according to the specified dimensions. Chipboards are sanded to make them even and smooth.

The next step is lamination. It is performed in a specific sequence:

- gluing 1-2 layers of paper onto the base (the first one should have a maximum thickness of about 0.5 - 1 mm, so that in the future it will be possible to push the drawing);

- laying a layer of transparent paper and mixed resinous substances;

- imposing the main layer on the chipboard plate and pressing it with a stamp with a pattern, gluing the decorative layer in the same way;

- gluing with a stamp of a protective layer that protects the product from various contaminants.

At exposure to high pressure and temperature the film adheres reliably to the board, forming a durable laminated coating.

MDF

For the manufacture of MDF boards, raw materials are prepared in the same way as in the production of laminated chipboard.

- Chips are made from wood waste, dried to a moisture content of 9%.

- Further, it enters special cyclones, where large chips are screened out due to air separation.

- The calibrated chips are heated and pressed under high pressure.

- In the process, due to the strong heating of the wood fibers, natural resins (lignin) are released. Thanks to these substances, the chips adhere firmly to each other.

- The MDF boards obtained after pressing are cooled and polished to give the surface smoothness.

- After that, the products undergo further processing - they are sanded, laminated or varnished.

And also manufacturers produce more expensive material - veneered. It involves gluing a thin layer of natural wood to the surface of the slabs.

What is chipboard?

Explanation of the abbreviation Chipboard - chipboard. It is made as follows:

- They take shavings and chips formed as a result of wood production at sawmills. The raw materials are coniferous and deciduous trees of low value species.

- They pass production waste through special crushers.

- The resulting particles are pressed at a high temperature. The smallest chips go to the top layer.

- As an adhesive base, non-mineral substances are used - phenol-formaldehyde resins. At the same stage, fire retardants, antiseptics and other components are added to the stove, which provide protection against fungus, parasites and improve the characteristics of the finished material: they make it stronger, more resistant to moisture and fire.

Covering a board with a melamine resin film is called lamination. This is how chipboard turns out. More expensive items are additionally varnished. Compared to conventional chipboard, the laminated board looks better, has higher strength and water resistance.

The demand for furniture made of chipboard and laminated chipboard is still high due to the low price and a wide selection of color solutions. A big plus of the material is resistance to high temperatures. However, it has a number of serious disadvantages:

Emission (release) of formaldehyde.

Formaldehyde is a gas with a pungent odor and high toxicity. Its content in laminated chipboard can be up to 18%. Possesses carcinogenic properties, irritates mucous membranes (and for this reason it is especially harmful to the eyes, respiratory system), can cause allergic reactions.

There are classes of chipboard E0.5, E1 and E2, depending on the quantitative content of formaldehyde. Laminate makes the wood board more environmentally friendly by preventing toxic gas from evaporating, although it does not completely solve the problem.

Low density

Chipboard easily crumbles and cracks due to mechanical stress, therefore it is suitable for the manufacture of only cases and straight furniture facades. You cannot screw the self-tapping screw into the same place 2 times. Material does not hold hammered nails, glass

In case of careless handling, you can accidentally pull the handle out of the cabinet door or drawer.

Rabies

The outer surface of the chipboard is resistant to moisture, but the risk of water penetration through the side sections, chips and gaps remains. This leads to an increase in the volume of the material by 20-30%. Laminate cracks, and the appearance of the chipboard deteriorates. It is highly discouraged to use the material for bathroom furniture.

MDF or chipboard. What's the best for the kitchen?

The kitchen is, without a doubt, the most important of the rooms in the house. The most significant events of our life take place on it.

For all that, this is not the best place for furniture. Judge for yourself: water, high temperatures, greasy dust, hot steam and cleaning agents are quite an aggressive environment.

The frame of kitchen furniture, as a rule, is made of chipboard. This is due to the fact that the facades take the whole blow. They get all of the above.

If you're after durability, then MDF is definitely a must for your kitchen. It is highly moisture resistant, fireproof and easy to clean. You will be offered a rich selection of colors and finishes, however, it will cost more.

If you are on a tight budget, then choose chipboard. With careful use and careful care, it will also serve you faithfully.

Do not forget to pay attention to the edge and inquire about which class of chipboard belongs to

Video: the difference between MDF and chipboard

Also, when using furniture made of combined materials in the kitchen, it is worth remembering that MDF is afraid of high temperatures. It is necessary to properly hang wall cabinets in order to avoid heating them from a nearby stove or hob. This will prevent the coating from peeling off on the finished product.

My dear readers!

I always read your comments to my articles with great interest. If you have any questions, do not hesitate, ask them, please leave your feedback in the form below

Your opinion is very important to me. Thanks to your criticism and thanks, I can make this blog more useful and interesting.