Types of acrylic putty for indoor and outdoor use

The putty is presented in several varieties, depending on the scope of application:

- Facade - putty for outdoor use has a specially developed composition that provides high strength, protective characteristics of the coating. The material is resistant to temperature extremes, climatic precipitation, mechanical damage, has thermal insulation properties and insulates the room from the outside.

- The universal putty can be applied to different types of surfaces (walls, partitions, ceilings), various materials (brick, concrete, wood, metal, etc.).

- Water-dispersive - putty is characterized by increased protection against moisture. The coating is durable, aesthetic, resistant to temperature changes.

- Putty for interior work - the material is used for finishing rooms in an apartment, house. The composition is suitable for spaces with standard microclimate conditions without high levels of humidity and steam.

According to the form of release, the putty is divided into the following types:

- Powdery - dry composition must be diluted with water before use. The variety is offered by manufacturers less often ready-made. The advantage of a powdery material is the ability to independently select the required consistency. The composition can be saved, because the cost of production is lower than the mass diluted with water.

- Ready-made - it is offered in plastic buckets of 15-20 liters. The mass does not need to be kneaded, the material is ready for application, easy to use, optimal for beginners in the construction industry.

Separation of the putty according to the components:

- Starting - used for the initial stage of finishing work and provides for the elimination of irregularities, depressions and cracks on surfaces.

- Finishing putty - the material is intended for the final coating, because consolidates previously applied layers. The composition is distinguished by decorative characteristics, presented in different colors.

Usage

Before the immediate start of the repair, the putty must be kept at room temperature for a certain period. In advance, the surface of the finishing work should be processed. It must be dry, cleaned and free from fragments of the previous finish.

Surface cleaning

The next stage of work is the preparation of the mixture. The process of divorcing latex putty is similar to the preparation of an ordinary cement mortar.

Mix preparation

Putty and liquid must be in equal proportions (1: 1). Next, the mixture should stand for about 2 minutes and then stir once, if necessary, add water.

Accordingly, the latex mass, like other types, gives off water quite rapidly, regardless of the primed surface. Faced suddenly with this kind of problem, when it is impossible to do the "stretch", you need to resort to the following resolution of the situation.

It is necessary to soak the gypsum a little with liquid and everything will return to normal. In addition, it is necessary to carry out such a manipulation if the temperature is more than 30C.

Application

How long the putty will dry depends on the country of origin, marking. The specified characteristics are indicated on the product label. Most often, the drying time is from 2-6 hours, and the consumption is from 0.5-2.5 kg / m².

You can't use sandpaper all the time. You can accidentally "dump" excess or this grinding will bring a lot of difficulties.Therefore, for leveling, use a damp sponge if the putty is not completely dry. Look carefully to ensure that no excess liquid drips off the sponge.

Sponge smoothing

Finishing putty - applying the final layer of the substance to the surface.

Despite the thick layer, it does not burst, unlike the final one, which must be applied in a thin layer (1-2 mm) so as not to crack.

Types and features of polymer putties

Polymer putty is a general definition that is used in relation to several types of compositions made on the basis of polymers. It is customary to distinguish three types of putty, which differ in the main polymer component:

- Polymer cement putty. The product is used as a leveling agent for cement-lime, cement-sand, brick and concrete surfaces. The plastic mass can be applied with a layer of up to 20 mm, which allows using a polymer-cement putty as a starting coating;

- Latex. Styrene is considered the main component; it is also often called acrylic latex. With the help of the mixture, a neat and even finish layer is obtained. The area of application of the solution is very extensive. The composition can be used both on wood and on brick, concrete or gypsum board. There are two forms of release of latex putty: dry and ready-made.

- Acrylic polymer. The main component is acrylic. The product is considered universal and can be divided into the following subclauses:

- Starting putty. It is used to eliminate large flaws on the surface: cracks and potholes;

- Finishing putty. Completes the finish and gives the surface a perfect smoothness. It is applied under the wallpaper or coloring composition;

- Universal putty. Includes properties of starting and finishing mixture.

1 Latex putty - a lot of advantages!

The compositions we are considering are created on the basis of binding elements, special antiseptics, plasticizing additives, hardeners. The set of these substances, as well as their content in the finished mixture, may be different. It all depends on which manufacturer the latex putty is produced by. In this case, the binder component of any putty is a polymeric substance. It determines the special characteristics of the leveling compound, forming a highly elastic and durable coating on the treated surface.

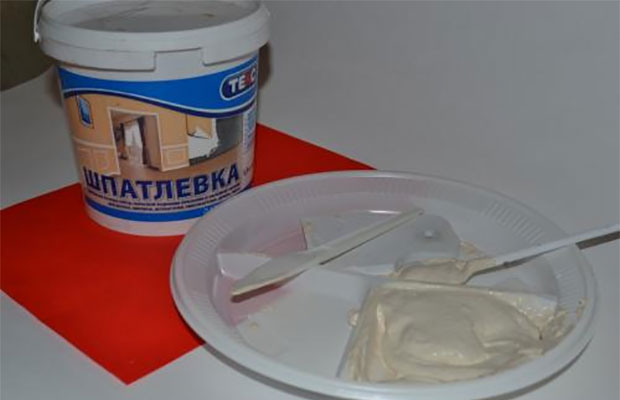

Latex putty is sold ready-made, it is easy and convenient to use

Latex putty has a number of important advantages. First, it is convenient and easy to use. Leveling compounds are sold ready-made in building stores. The consumer does not need to add liquid or solvents to them, dilute to a certain consistency. It is enough just to open the container with the putty and immediately start processing the walls and ceiling. In addition, latex formulations are packaged in cans of different capacities. This makes it possible not to spend extra money on the purchase of a mixture that will not be used. Some types of putty are available dry. They are rare on sale. Such mixtures must be diluted with clean water in a 1: 1 ratio.

Secondly, the described putty is characterized by a uniquely high adhesion to substrates made of various materials. When applied, the mixture completely fills the irregularities, gaps, small cracks on the surface and adheres as tightly as possible to the ceiling and wall. The result is a flawlessly smooth base on which you can stick wallpaper, mount other finishing materials.

Thirdly, the putty can be applied in a very thin layer (less than 1 mm), without worrying about the coating crumbling or cracking. This property favorably distinguishes latex compositions from cement and acrylic. The latter must be applied in a sufficiently thick layer.

Another advantage of this putty is that it is sold in different colors. No other leveling compound can boast of such dignity. If you want to save money on the purchase of paint and on the dyeing process itself, immediately buy a latex mixture of the required color. After processing a wall or ceiling with it, the need to use a coloring composition simply disappears.

In addition, latex putty has high abrasion resistance, reliably and quickly sets, is made from environmentally friendly (non-toxic) components, after drying it can be sanded without problems, and is compatible with other building materials. It is allowed to be used for work on objects with high humidity. And most importantly, the putty gives the treated surfaces the property of vapor barrier.

Technology

Preparing walls for applying Tex Profi putty

First you need to measure the amount of putty treatment. Considering the estimated thickness of the putty, calculate the need. The sellers of the store where it was bought will tell you how to calculate the required consumption of putty per 1 m2 of substance.

Removing old wallpaper

Those surfaces that have been painted must be cleaned of old whitewash or old painting before puttingtying. Sand to a matt surface with a glossy texture. Remove abrasive and dust by wiping with a damp cloth. Places affected by fungus, mold, treat with antiseptics.

Antiseptic treatment

Coat the cleaned surfaces with a water-dispersion primer.

When the primer is dry, you can start puttingty.

Primer

Plasterboard surfaces with joints and cracks are sealed with serpyanka tape. In this place about plasterboard putty under the wallpaper. It is glued on top of the joints and cracks. All the space around it is closed so that the junction is not noticeable.

Necessary materials

Before getting started, you need to purchase the following materials:

deep penetration primer. It is applied on the surface of the treatment in order to strengthen and reduce moisture absorption. This will greatly facilitate all subsequent operations.

Deep penetration primer

serpyanka ribbon. This attribute is required to be purchased. When puttingty walls under wallpaper from sheets of various purposes, it will not allow cracks to appear in the docking nodes.

Serpyanka ribbon

Required tools

To work, you need the following tools:

brush;

Brush

roller;

Roller

- the dishes are smaller than the bucket with the purchased putty.

A latex substance in an open container gives off moisture to the surrounding air, loses its elasticity and its best consumer properties;

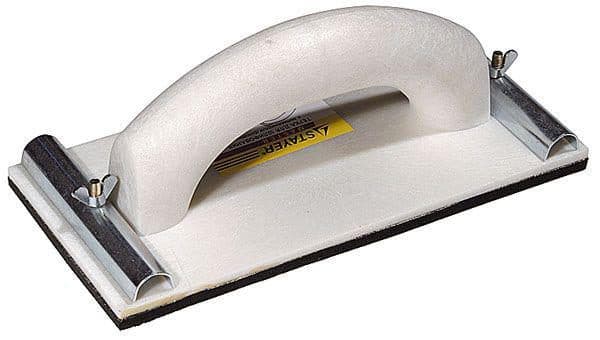

- grater. This tool will need to grind the surface after processing;

Grater

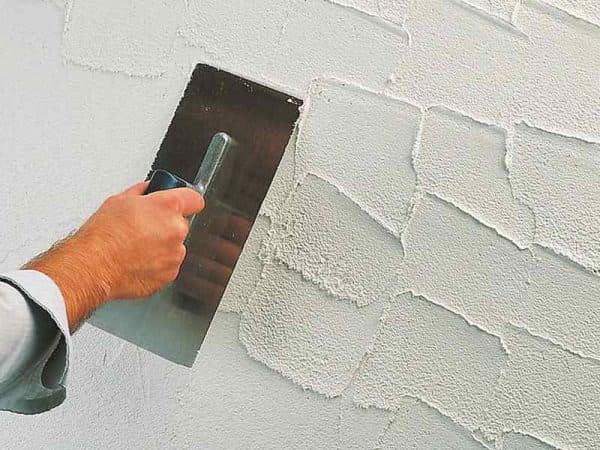

one trowel 35 cm wide. It is needed to apply the putty mixture to the walls. The second spatula 10 cm wide. It is needed for the subsequent processing of hard-to-reach places;

Spatula

an angled spatula is required to level the inner and outer corners.

Angle spatula

Application

When all treated seams are dry, they are sanded and primed on top. Here is how much the putty dries. The puttying process is simple, since the substance is completely prepared by the manufacturer for work, elastic, easy to apply. Even a beginner can handle it.

It is carried out with non-traditional abrasive paper of various grain sizes. The operation is performed with a damp foam rubber sponge. It washes away excess putty mixture

It is important not to allow the filler to dry completely, but to sand the slightly damp surface

Latex putty and its properties

Putty (or putty) is a building material used to smooth out irregularities, eliminate various surface defects of any type (concrete and brick walls, wood, drywall, etc.). It is unlikely that anyone managed to carry out repair or construction work without using putty.

Latex putty reduces the consumption of subsequent applied topcoats

Latex putty reduces the consumption of subsequent applied topcoats

The modern building materials market offers a wide range of putty mixtures, which differ in their characteristics: composition, form of release, features of use. On the shelves of specialized stores, you can easily find cement, gypsum, acrylic, polymer putties, as well as latex, which has recently become increasingly popular among finishing specialists.

Like all others, latex putty consists of several components, but latex, known for its amazing elasticity, acts as a binder in it. It is thanks to this component that the material has excellent qualities, such as:

- low shrinkage - you can be 100% sure that cracks will not appear on the surface after drying;

- high plasticity, which greatly facilitates finishing work and allows you to apply the thinnest layers;

- excellent adhesion - the putty adheres firmly to the wall surface, does not crumble after hardening;

- is produced ready-made, which saves time and does not involve additional tools and containers;

- well polished;

- has a long shelf life, provided that the container is hermetically closed.

If we compare the latex putty with other types in order to identify shortcomings, then we can name, perhaps, only two: a relatively high price and poor tolerance to low temperatures, which makes it impossible to use it in cold rooms.

Latex putty is produced ready-made, which increases its shelf life, provided the container is tight.

Latex putty is produced ready-made, which increases its shelf life, provided the container is tight.

However, with a deep analysis, it can be concluded that, despite the high cost, the latex analogue even helps to save money: its excellent qualities lead to less consumption of finishing materials when painting the walls, and it also takes less time to work. And in order to avoid damage to building materials at low temperatures, containers with them should be stored in rooms where freezing is excluded, and work should be performed at temperatures close to room temperature.

3 Surface preparation for processing - important points

Latex putty is ideal for do-it-yourself work, its use does not require special knowledge and special skills.

Before starting work, a primer must be applied to the surface.

Moreover, if you want to get the maximum effect from using the mixture, you should before starting work:

- Decide on the desired coating layer. Measure the area of the wall, ceiling, which will be processed. Based on these data, calculate the required amount of putty, focusing on the manufacturer's advice (they are contained in the instructions for the material).

- It is good to clean the surface from contamination, and then treat it with a primer Betonokontakt or another deep penetration solution. This is done to reduce the moisture absorption of the ceiling or wall base and to further strengthen it. After priming, the surfaces will not shrink.

- If the latex putty will be applied to drywall sheets, it is advisable to glue their joints with a special material. Serpyanka tape is best suited for such purposes.

Also, stock up on all the necessary tools in advance. There are a minimum of difficulties. You will need a foam-coated trowel and two spatulas: one wide (25-30 cm), the other narrow (8-10 cm). You are now ready to do the basic work.

Views

Most mainstream building material manufacturers have seen widespread and increased demand for their products. Which one is better? Each company has decided to take advantage of this popularity and create its own company for the production of latex putty.

Today, there are a significant number of building materials manufacturing companies, and this complicates the choice of material.

Tex

Specialists in the field of repair activities are satisfied with this type, in cases of non-fake purchases.

Tex

It does not burst, lays down very delicately, and when processing the surface of products with sandpaper, it is not particularly difficult. The surface is just as smooth and even.

Vetonite

According to the characteristics, it has an average. But in work it is easy to use, it is elementary to breed, the speed of drying will only be a plus.

Vetonite

But in the case when you start pasting the tapestries, difficulties may then appear, since you will be able to remove the old wallpaper together with the putty. Often, in addition, it is able to soak and lag behind the wall in pieces along with the wallpaper.

Knauf

More suitable for renovation experts. In this regard, which is more difficult to skin, it should be applied very carefully in order to make fewer mistakes.

Knauf

The highest quality putty is the composition from the German manufacturer "Knauf". It is used by leading renovation and design professionals. It must be applied very carefully, for this reason it is not recommended for beginners.

Shitrok

In use, it is soft, does not curl, it is well polished. It is only necessary to buy from a manufacturer of a foreign manufacturer (for example, the United States) - others did not fit in quality.

Shitrok

In addition, it is possible to highlight the Sheetrock brand. If you decide to buy a putty from this manufacturer, in this case you need to highlight the fact that currently there are many fake putty consistencies of this manufacturer.

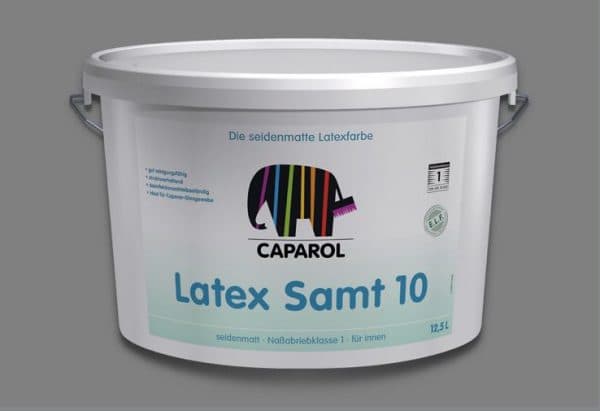

Caparol

Fits perfectly on walls, so they appear flawlessly straight and smooth. Relatively inexpensive in terms of cost and consumption with other options. For people who have made the decision to start repairs for the first time, it is better to buy Caparol latex putty.

Caparol

You need to directly purchase building materials only in branded shopping centers, or you can choose a putty directly from the manufacturer's plant.

By wood

- common color palette;

- easy to apply and easy to sand;

By wood

- slight thermal shrinkage after drying;

- excellent adhesion.

Latex wood putty “Colorika Aqua” is an environmentally friendly, odorless product:

- ready-to-use products;

- does not require one or another high-quality training;

- possesses optimal adhesion (adhesion);

- dries quickly;

Colorika aqua

- easy to apply, including vertical materials;

- has a slight shrinkage after drying;

- produced in different colors.

Wood putty “Colorika Aqua” - specialized in the processing of holes, filling cracks, as well as correcting deficiencies in wood products, designed to prepare the surface for further painting.

It contains acrylic copolymers, fillers, additional additives and chemically prepared liquid.

2 Disadvantages of putty - what to fear?

The compositions of interest to us for leveling ceiling and wall surfaces have some disadvantages. Latex putty is not afraid of temperature changes after it has been applied to concrete, wood, brick or other substrates. But it cannot be stored at negative temperatures. If the latex compound freezes (in a store, in a warehouse), it is better not to use it for its intended purpose. The putty will lose almost all of its performance characteristics.

The main disadvantage is the high cost

- excellent finishing work results;

- ease and speed of leveling even very difficult surfaces.

Note! Latex type putty is stored for a long time in the original container after using some of it

It is only important to take into account a small nuance: when you close the container with the remnants of the leveling material, carefully make sure that no dried pieces from the lid get into the jar. With subsequent use of the putty, these particles will leave scratches on the treated surface.

Such defects will have to be additionally putty

With subsequent use of the putty, these particles will leave scratches on the treated surface. Such defects will have to be additionally putty.

Advantages and disadvantages

With the support of such a composition, you will get a fairly flexible putty layer on the desired surface that dries uniformly. Thus, the material has the smallest volume and linear dimensions of the casting during their formation, as well as cooling from the casting temperature to the ambient temperature.

Due to these features, cracks and bubbles will not appear, and the putty will not crumble.

Key benefits:

- comfort in use, plasticity due to latex;

- very easy to apply, in the thinnest layers;

- perfectly holds together;

- no shrinkage, due to which cracks do not appear;

- after complete drying, they do not crack.

Has two minor drawbacks that can be easily overcome:

price. In comparison with other types, the price of latex putty is quite high. But you will reimburse these expenses by the result of the repair work done and the speed of activity;

low temperatures - a rather weak reaction to temperature changes

If during the period of activity you notice that the product does not meet the listed requirements, the mixture may have frozen;

buy it preferable in stores with a guarantee of the return of goods or exchange for a fresh product.

Please note that the product is completely covered with a lid and there are no traces of dried particles on it. Because after the performed manipulations, scratches appear during work, which again need to be putty

Specifications

Latex putty Tex Profi 16 kg has the following characteristics:

- the thickness of the coating applied to the surface is from 0.5 to 3.0 mm. There is no longer such a substance that could create such a miniature film;

- the amount of coverage has a direct impact on the volume consumed. Here about the finish consumption per 1 m2. It ranges from 0.5 to 2 kg / m². • The period of drying of the substance is 24 hours;

- warranty period of storage in the warehouse: 1 - 2 years;

- the conditions of detention recommended by the manufacturer are to prevent freezing and defrosting, the presence of a special container of a closed sample;

- the recommended temperature regime at the processing site should be at least + 5 ° С;

- material packaging: plastic buckets with a capacity of 1-30 kg;

- chemical indicators: Tex putty latex class Profi 16 kg does not contain toxic substances.

The characteristics of a substance from different manufacturers may vary slightly. Although latex putties do not contain toxic impurities and are environmentally friendly, getting into the mucous membranes of a person, they cause severe allergies. The substance that has got on the body must be carefully processed under a strong stream of water.

Advantages

The substance is easily applied, adhering well to the surfaces to be treated. For DIYers and beginners in construction and repair work, it is best to work with similar compounds. They are elastic, do not leave pills after pulling the trowel over the surface.

Reviews of experienced builders and plasterers about their quality are invariably positive.The putty can be applied with an ultra-thin coating less than a millimeter in size.

The variety of colors provides a unique opportunity for users to save on varnishes and paints. Minimal shrinkage of the applied layer. Due to this quality, bubbles, irregularities, height differences, cracks do not appear on the surface treated with the substance.

Creation of a protective film on the surface of the applied layer. It reliably protects the coating, preventing it from drying out and cracking.

disadvantages

Tex latex putty negatively tolerates long-term negative values of temperature conditions. Dry, ready-to-use powders are often packaged by manufacturers in bags.

They are transported for days on long distances in frozen wagons and stored in ventilated warehouses without heating. Our putty categorically does not accept such treatment. Freezing followed by defrosting makes its structure unsuitable for work.

When buying a product, you must carefully check the date of manufacture. If the substance was stored somewhere in the winter, you should find out the storage conditions.

This is fully compensated for by the high consumer quality of use, when it is not necessary to mix the necessary ingredients of the mixture. All these works are professionally done by the manufacturer. Numerous reviews on the websites of manufacturers and sellers of this type of putty are proof of this.

Despite the advantages and disadvantages, the material is gaining more and more popularity. Having recently appeared on the construction markets, the mixture confidently occupies a high place in the ranking of finishing materials, both among home craftsmen and professional builders.

Specifications

Latex putty is quite in demand among specialists due to its positive technological data. On sale there is a huge assortment of different colors for every taste. Latex putties have an advantage over acrylic ones.

Acrylic

Obtaining a latex composition of the required tone eliminates unnecessary costs for the purchase of specialized dyes. Working with ready-made formulations is quite comfortable due to their flexible consistency.

Also, latex putties have significant adhesion and work according to the principle of not thick rubber, perfectly leveling any surfaces, adhering closely to them.

When the latex putty hardens, a non-cracking and non-crumbling shell is formed, which has an advantage in contrast to the use of acrylic.

The disadvantage of latex-based formulations, as already mentioned, is the overpriced and intolerance to low temperatures. Used for leveling planes from a variety of materials.

Latex putty has the following general characteristics:

- cover layer: from 0.5 to 3 millimeters;

- consumption: due to the thickness of the cover from 0.5 to 2 kg / m2;

- period of absolute drying: 24 minutes;

- drying period between layers: 12 hours;

- savings period: 1-2 years;

- preservation requirement: in the original closed container, not allowing freezing;

- conditions: at an atmospheric temperature of +5;

- packing: plastic container from 1 to 30 kilograms;

- not toxic.

For more information about latex putty, see the video:

Tips and tricks for use

When working with polymer putty, professionals recommend adhering to the following recommendations:

- Apply the composition only on a previously prepared surface, free from old coating, grease, dust and other contaminants. Before applying the polymer putty, the work plane should be treated with mineral soil.

- To mix the solution, dry powder must be poured into a container with liquid and the contents must be thoroughly mixed manually or with an electric drill equipped with a mixer attachment.After that, the mixture must be left for 10 minutes and mixed again.

- The material is applied to the wall surface using a spatula or clamps, with a layer not thicker than 0.3 cm. In this case, the procedure should be as follows. With the help of a trowel, a certain amount of the composition is collected, which is transferred to the spatula. Further, the tool with the ready-made solution is applied to the working surface at an acute angle. The mass is not distributed in a dense layer over the base.

- When the putty mixture is dry, its surface is leveled with sandpaper. To do this, make movements in a circle without excessive pressure. If one layer of the mixture is not enough, a second one can be applied no earlier than 4 hours after the previous one has dried.

4 Puttying without problems - how to do everything correctly?

The container in which the putty is located should stand in the room where the finishing activities will be carried out for 2-3 hours. During this time, the composition will have time to acclimatize to the existing humidity and temperature. In winter, it is better to leave the bucket with the mixture for 10-12 hours. Pros advise to apply the putty at room temperature in the range of 8-30 ° C. In such conditions, the composition will be the easiest to use.

Apply the latex putty with a spatula. The recommended layer is no more than 3 mm. It is undesirable to make the coating thinner than 1 mm. A thin layer will adhere well to the substrate to be treated, but it will be very difficult to wipe it down later. In most cases, the putty is applied in several layers.

Important! Each subsequent layer is applied only after the previous one has completely dried.

Finishing grouting of the coating is carried out with a foam rubber float. In no case should you use sandpaper or any other abrasive. The trowel should be slightly moistened with water and trowelled with sufficiently intense movements until the leveling layer is perfectly smooth. At this point, the work can be considered completed. Start finishing the leveled surface with the selected materials.

And the last thing. Many home craftsmen are often interested in which putty is better to buy - acrylic or latex. We have already said above that acrylic-based compositions are applied in a thick layer. But latex mixtures are suitable for creating the finest coating. In addition, there is one more difference between the specified putties. Acrylic putty is more suitable for external surfaces. Latex mixtures, as a rule, are used for application to indoor substrates. Consider this when choosing a putty.

Advantages and disadvantages

The use of polymer putty for interior work has a number of advantages, thanks to which the composition has surpassed gypsum mixtures in popularity.

The main advantages of the product is the combination of plasticity and elasticity, due to these characteristics, the solution can be applied in a light layer. In addition, the unsurpassed quality of the mix allows you to work with the material on a rough surface.

Taking into account the properties of the polymer putty, we can conclude that it is easy to use and does not require extensive experience, because the possibility of using a mass in a thin layer greatly facilitates the work. The composition of the product includes plasticizing and modifying substances that ensure flawless adhesion to the working surface

Noteworthy is the fact that well-dried polymer putty is not characterized by flaking, swelling and blistering.

The composition of the product includes plasticizing and modifying substances that ensure flawless adhesion to the working surface. Noteworthy is the fact that well-dried polymer putty is not characterized by flaking, swelling and blistering.

When discussing the advantages of a modern putty mass, one cannot fail to mention the absence of shrinkage.This quality indicates the absence of the possibility of cracking and discharge of the freshly applied solution. In addition, the high elasticity of the composition protects the integrity of the treated surface even in conditions of natural subsidence of the building.

For any type of polymer coating, water-repellent properties are characteristic, which makes it possible to use the putty in damp rooms. The effect of moisture resistance is provided by a specific barrier film.

The formation of the barrier makes it possible to withstand the thermal load. The composition is not subject to spontaneous combustion or melting when the thermometer rises. It is non-toxic and does not emit substances harmful to humans.

The polymer putty is vapor-permeable, which leads to a reduced risk of fungal colonies. This feature is very important for rooms with high humidity.

Among other things, the finishing, starting and universal putty gives the surface additional sound and heat insulation properties, which creates a comfortable microclimate in the room.

The disadvantages of the polymer mixture include the high cost of the product. Moreover, it is this composition that guarantees durability and reliability.