Dimensions (edit)

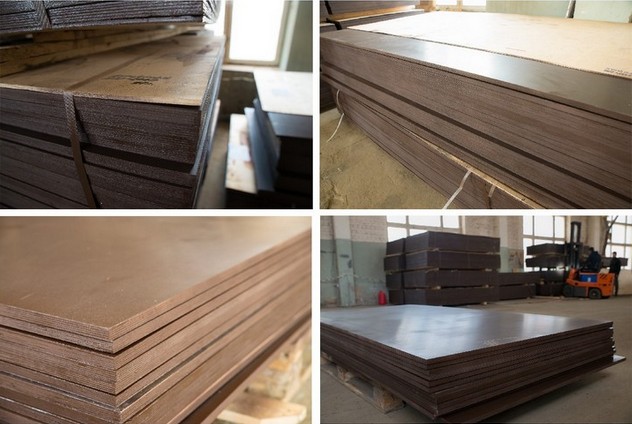

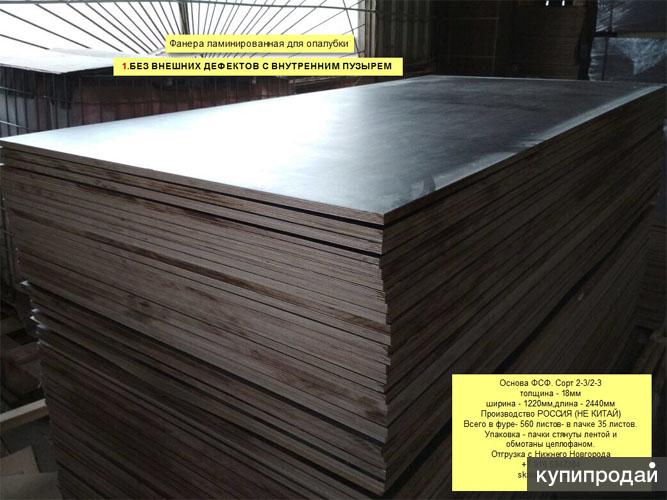

On the Russian market of building materials, you can see the following dimensions of formwork film faced plywood: 6; nine; 12; 15; eighteen; 21; 24 mm thick. To mount the formwork during the construction of concrete mix structures, 18 and 21 mm construction-type sheets are practiced, on the end surfaces of which an acrylic-based lacquer preventing moisture from getting wet is applied. Panels thinner than 18mm have extremely low mortar strength, while 24mm slabs are much more expensive.

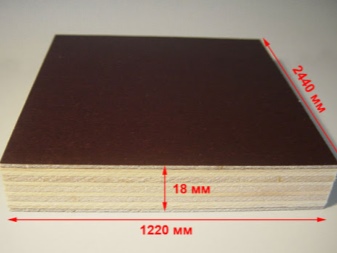

Plywood laminated for formwork with dimensions of 2500 × 1250 × 18 mm, 2440 × 1220 × 18 mm, 3000 × 1500 × 18 mm is especially in demand due to its lower price. The surface area of the panels measuring 2440 × 1220 × 18 millimeters is 2.97 m2 with a weight of 35.37 kilograms. They are packed in packs of 33 or 22 pieces. The area of the panels 2500 × 1250 × 18 mm is 3.1 m2, and the weight is approximately 37 kg. A sheet with a thickness of 18 mm and a size of 3000x1500 has a surface area of 4.5 m2 and weighs 53 kg.

Buy laminated plywood in Moscow inexpensively

The low price of formwork elements directly from the manufacturer will allow significant savings. You can buy moisture resistant plywood wholesale and retail in the STANDARD GROUP company. We offer to arrange delivery of high-quality finishing materials in just a few minutes. Choose a sufficient number of products, click the "Order" button, go to the "Basket" section, click the "Place an order" button and enter all the necessary information to receive the goods. One-click purchase is also provided. To do this, select the "Quick order" option and leave your contact details. Our consultants will contact you to agree on the time and delivery address, confirm the range of the selected product and its cost. In addition, you can make an order by calling the phone number listed on the company's website.

If you need transportation in Moscow and the Moscow region, we kindly ask you to approve entry permits in advance, if necessary, to warn about possible travel restrictions, such as time, dimensions and carrying capacity of transport. These measures will make it possible to deliver the purchase on time.

Are you looking for a reliable supplier of home building products? Please contact us. The STANDARD GROUP will become your best partner for many years.

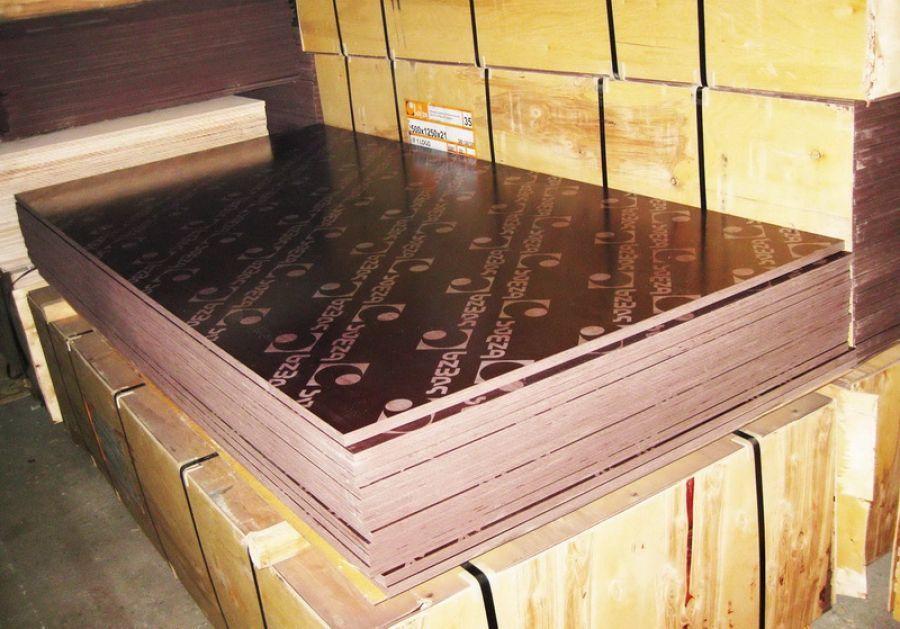

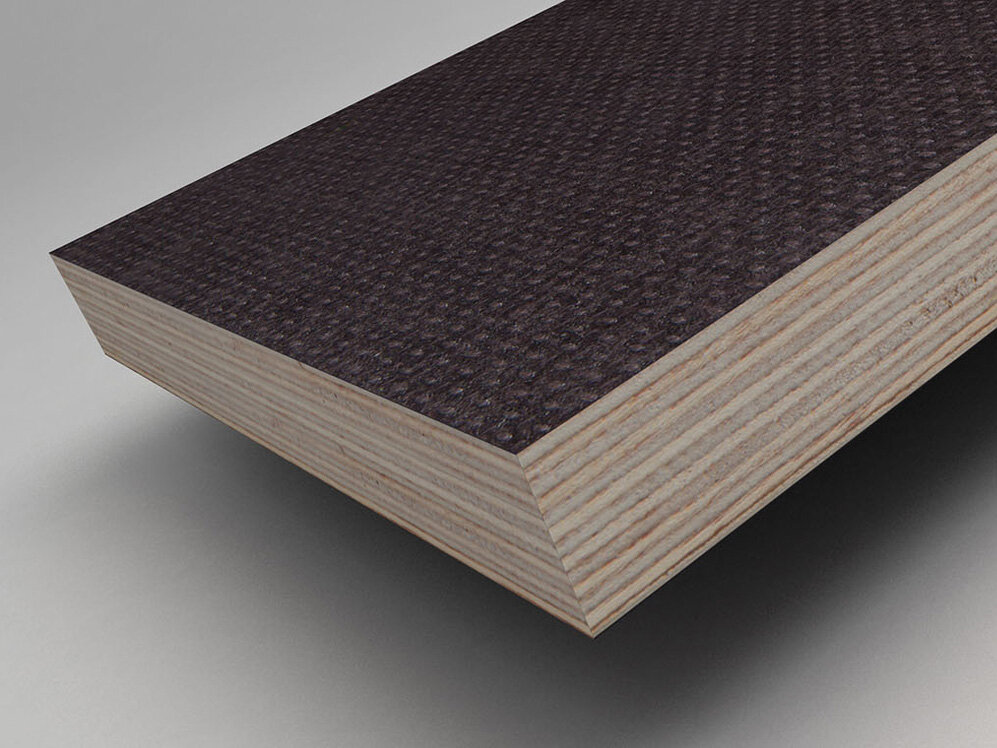

What is Film Faced Plywood?

Laminated (facing) plywood or FOB is a durable building material. It is characterized by a high degree of resistance to moisture, to various physical and chemical influences, which is a guarantee of a long service life. Due to sufficient protection, wood sheets are not prone to shrinkage and deformation, therefore they are often combined with other building materials. These operating parameters make wood-based panels indispensable for domestic needs and in manufacturing industries. The quality of a veneered panel directly depends on the characteristics of the raw materials from which it is made.

How to choose laminated plywood for formwork?

First of all, it is necessary to decide for what kind of work plywood is required: wall cladding, formwork in monolithic construction, etc. In addition, the requirements for the quality of the resulting surface should be taken into account.

The most important criterion when choosing is the turnover of the formwork plywood. In other words, the number of working cycles that plywood will withstand without losing its performance.By correctly calculating this indicator, you can significantly increase the profitability of construction work, since the cost of sheets strongly depends on the size, grade, thickness and brand.

For individual developers who use the formwork system 1-2 times, an economical option is suitable - low-grade pine needles plywood (FSF). If a small number of cycles is expected, then you can choose birch plywood of the FK and FSF brands. For multiple use of the formwork system, the ideal option is to use film faced plywood.

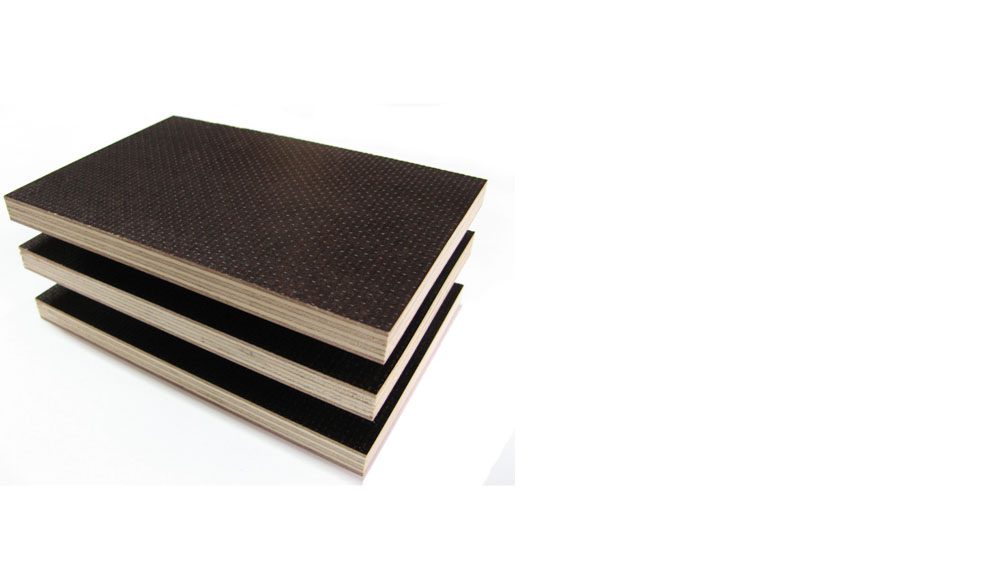

Varieties

The companies produce several types of plywood:

- ordinary lined with film;

- glue FC (plywood, urea glue);

- adhesive FSF (plywood, phenol-formaldehyde glue);

- construction.

FC is practiced for interior decoration work or when creating pieces of furniture. For the construction of a foundation, walls or floors, this type is used exclusively when forming a fixed formwork, or if it is used no more than 3-4 cycles.

For the construction of the formwork structure, ordinary, FSF or construction plywood lined with film is used. The choice depends on the type of building being created and the strength of the concrete impact on the formwork walls. Construction plywood is stronger, more durable and more durable. If used correctly, this material can be used many times.

The turnover of sheets coated with film for formwork can reach more than 50 cycles if it is construction plywood, which is considered a good result. The turnover is significantly influenced by the type of wood used in the manufacture of the material and the country of origin. So, the best characteristics are for plywood from solid birch, next on the list is poplar, and then coniferous timber.

Material turnover

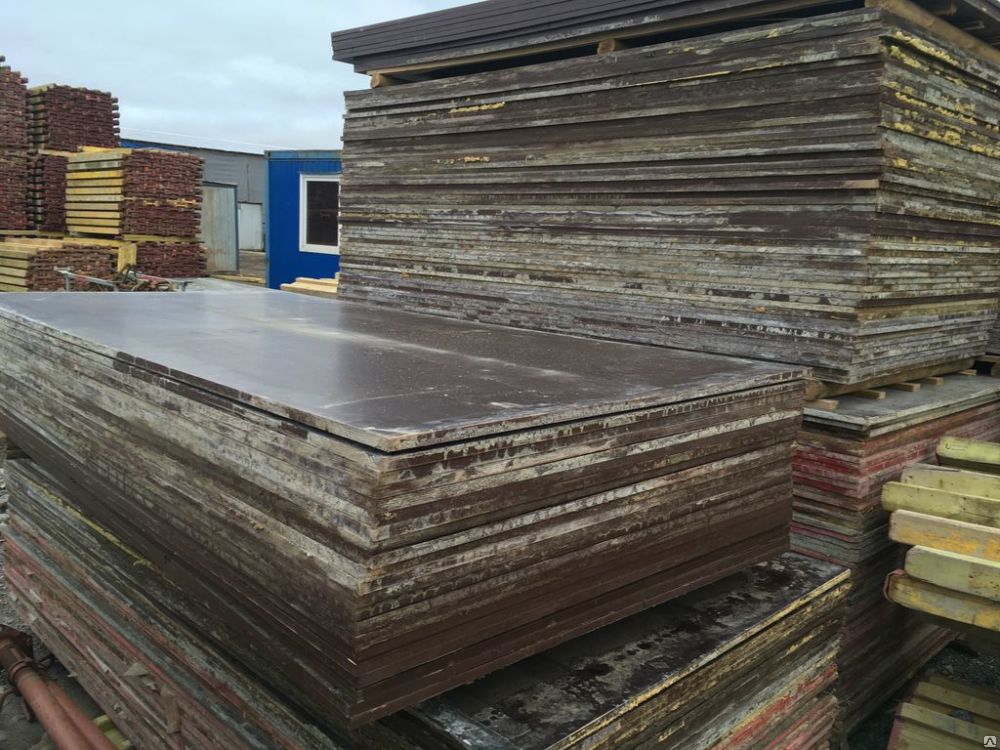

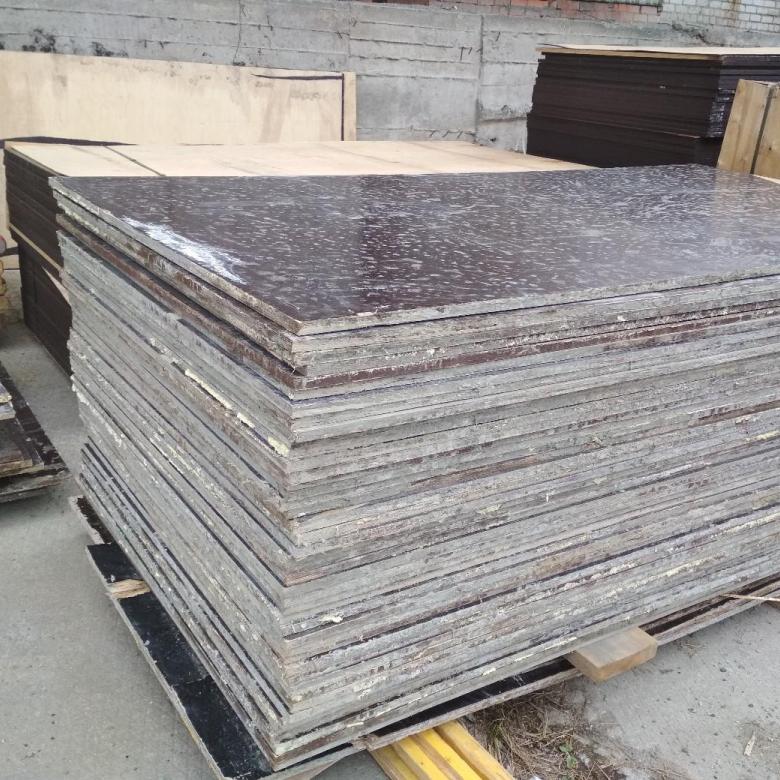

This definition implies the number of cycles that plywood can withstand in case of reusable use. At this time, there is a conditional division of the material into categories depending on the manufacturer.

- Sheets made in China. Usually, such plywood has low quality characteristics, the formwork can withstand no more than 5-6 cycles.

- Plates produced by the bulk of Russian companies are considered a good solution in terms of price and strength. Based on the brand, the products can be used from 20 to 50 cycles. This gap is due to the technology used and the equipment used.

- Plywood produced at large domestic factories and imported from European countries (in particular, Finland) is considered to be of high quality, which affects its cost. It can withstand up to 100 cycles.