Top 7 refractory paints for metal up to 1000 degrees

To protect the heating radiator, metal stove or other objects from corrosion and aggressive external influences, they are covered with heat-resistant paint and varnish enamels. The paintwork can withstand up to 1000 degrees C. The enamel not only protects, but also gives an aesthetic appearance.

It is difficult to make a choice in favor of this or that paint. A fresh coating will give the items a new look. We have compiled for you a rating of the most popular paints and varnishes. All submitted candidates have been verified by operational practice and experience.

Tikkurila termal silikonimaali

Country of origin Finland and Russia. Used for painting metal products. Based on silicone resin. Suitable for indoor and outdoor use. Resistant to high temperatures up to 400 degrees. This property provides protection for chimneys and dampers. Used for painting a car muffler. Black color. After drying, a semi-matt sheen is formed. Protects the structure of the metal.

Apply by brush or spray. The time of complete drying at a temperature of +230 C is exactly 1 hour. You can use the surface cleaners after one month. One liter of enamel is designed for 16-20 square meters. If the paint is applied in one layer. The price matches the quality. The only negative is heat treatment after application for complete drying.

Celsite-600

Black paint. Withstands exposure to temperatures up to +600 degrees. High degree of protection when using metal under the influence of high temperatures and moisture. Resistant to the influence of petroleum products, oil, gasoline. It is used for painting: electric motor, transformer, household heating appliances, bridge, tank, metal structure, railway tanks, calipers. Can be applied to reinforced concrete, asbestos-cement, brick, plastered surfaces. The enamel is applied in three layers. The color is black, the surface takes on a matte shade.

Certa KO-85

Certa is used for items that operate at temperatures from -50 to 900 degrees C. Heat-resistant enamel. It tolerates temperature changes well, including high temperatures. Protects against aggressive environments and high humidity levels. Prevents corrosion, moisture ingress. It is applied at minus 30 degrees Celsius. Transparent paintwork material. Used instead of varnish for covering bricks, concrete, ceramics. Apply in three coats to achieve a matte finish. In one layer, the brick acquires a wet effect.

Elcon

To obtain the desired color, it is mixed with a color scheme. At the same time, the pigment contained reduces the level of protection and durability of the painted coating.

The color palette is very rich. Gloss is matte and glossy. The product, painted in classic black color, can be heated up to 1000. And all other colors are not higher than 700 degrees. You can create beautiful patterns on the stenciled walls without involving specialists. In addition to metal surfaces, it protects concrete, brick, asbestos products from the influence of an aggressive environment.

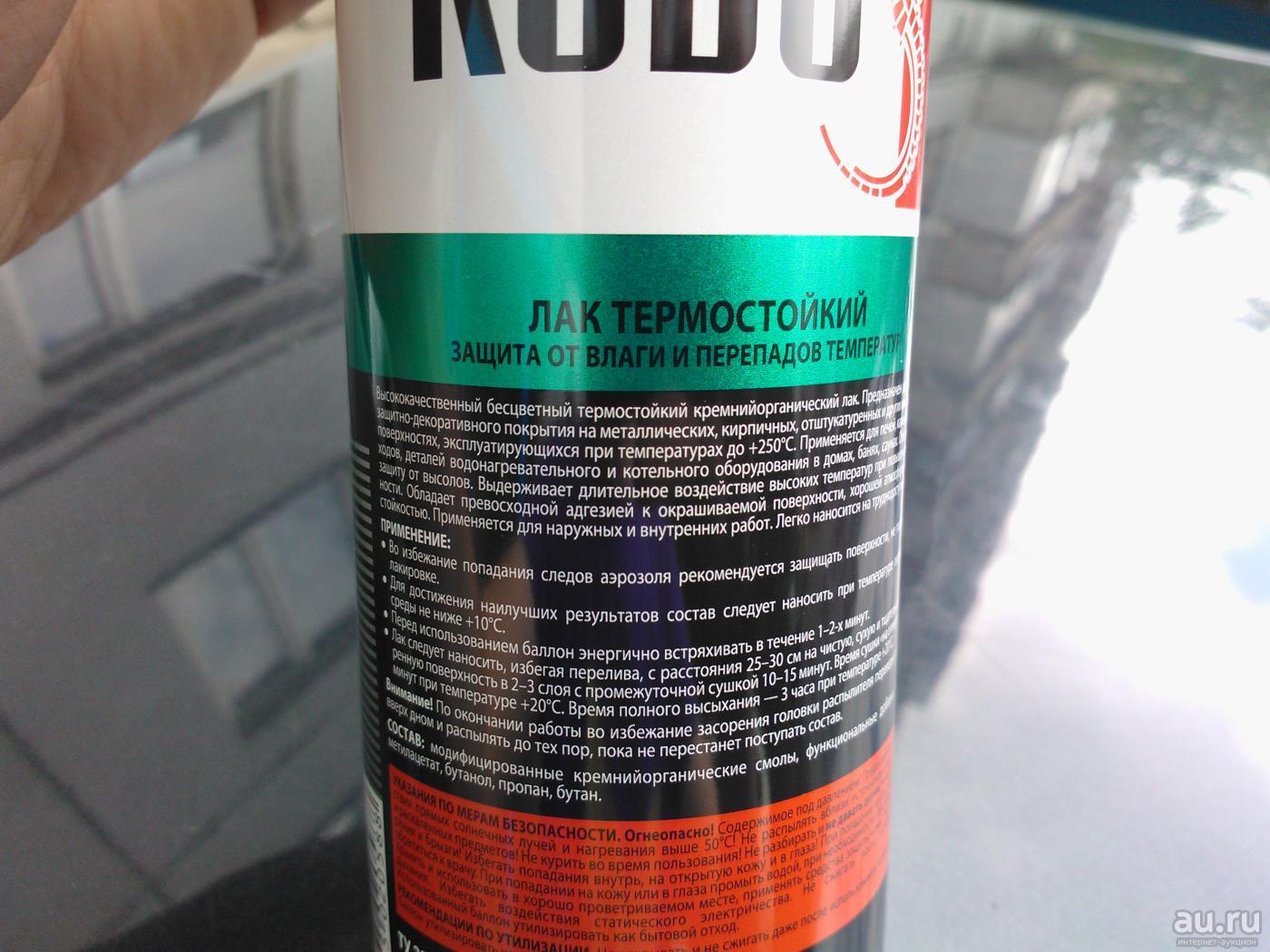

Kudo

The composition does not include toxic components. When used, no harmful substances are released into the air. Can be used inside living space, stove or fireplace, chimney. No primer is required before application. Complete drying time 2 hours. It is considered to be slightly flammable, difficult to ignite. The room temperature is not lower than + 3C. The service life is not less than 20 years. Universal, used on products of different surfaces.

Dali

Matt paint for interior and exterior use. It is used for painting the exhaust systems of a car, chimney, chimney. Black color. Before opening the can, the manufacturer recommends mixing the contents well. Apply by brush or spray. Drying time from 1 to 3 hours.If you want to apply several layers to the product, then the time interval for each layer is 1 hour. Thermal hardening for 2 hours at a temperature of 200 degrees.

Serebryanka heat-resistant Novbytkhim

Heat-resistant universal. Used for glass, brick, concrete, plaster surfaces. The formed layer protects against oil, gasoline, water, and vapors, salt fog in the range from -50 to +600 degrees Celsius. Withstands sudden changes in temperature, but within the range indicated on the package. The enamel is waterproof, dries quickly. No more than three layers are applied. Stir not only before application, but also during application. Prepare the surface in advance. Remove dust and dirt. The composition includes organic substances.

Recommendations for the purchase of varnish

The quality of the varnished coating depends largely on the quality of the substrate. It needs preparation to get positive results. First of all, the working base is subjected to grinding using a special tool - grinding.

It allows you to remove burrs, traces of rust and other defects. After using sanding, you should clean the surface from dust and additionally sand it with sandpaper. Coarse paper is used first, followed by fine grain paper. Sanding should be carried out along the surface to avoid noticeable scratches.

In the next video, see an overview of the Tsapon universal varnish.

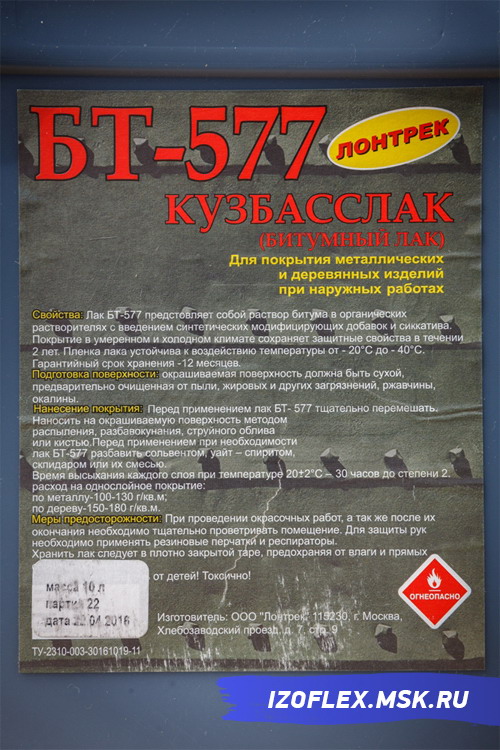

Take a close look at the photo of bituminous varnish. Remember how the solution looks outwardly, in what container it is sold, what packaging by weight exists. This will help you navigate the store. Read the instructions on the product label.

Application in decoupage

The decoupage effect is used to give an aged look to products, which will look appropriate in a certain style of the interior. Decoupage gives the product expressiveness and relief, an original look. You can get the desired result by darkening the pits and lightening the bulges. Also, the designer makes small cracks on the surface.

For aging, bituminous varnish is usually used. It is applied with a small brush, then with a rag or foam sponge, remove drips, excess, wipe until the coating dries. In parallel, they regulate the dimming and highlighting in individual areas. Also, after complete drying, they give the final look to the decor, wiping in the desired areas with white spirit to lighten. The excess is removed with a solvent.

If the surface is wooden, then the varnish penetrates the cracks, emphasizing the structure of the wood. It is used to decorate stucco, furniture, bas-reliefs.

The base of bituminous varnish and its varieties

The binder underlying the bitumen varnish is natural petroleum bitumen. We know bitumen as a solid that is black or one of its shades. Natural bitumen can have a solid or fluid state depending on the ambient temperature.

At temperatures above 100 degrees, bitumen melts and turns into a liquid state. In this way, the production of asphalt concrete mixtures takes place.

The bitumens used to make varnishes can be classified as follows:

- natural asphaltites. Qualitative characteristics, slightly differ depending on the place of origin;

- artificial. The technological process for obtaining light and heavy petroleum products provides for the distillation of oil. A by-product of the distillation is bitumen;

- coal. In the technological process of coke production, coal is distilled. The residual product in this case is coal tar pitch.

In the production of varnishes, organic solvents, corrosion inhibitors, antiseptics are added to petroleum bitumen to obtain the required paint viscosity.

Depending on the composition of the components, bituminous paints are subdivided as follows:

- containing oils. In turn, they are: bitumen-oil and bitumen-resin-oil. Bituminous paints contain rosin and glyphthalic additives. Depending on the mass fraction of oils, there are very fatty, medium fatty and fat-free varnishes;

- not containing oils. Solutions of natural bitumen and organic solvent, in which the presence of rosin in the additives is allowed;

- based on coal. Varieties of compounds of pitch coal, peat, wood.

Cost and consumption

Bituminous composition BT-577 is made by different manufacturers, for example, "Kolorit", "Novbytkhim", "Kuzbasslak" and others. Before buying these products, you need to correctly calculate the volume of this composition, taking into account the consumption per square meter. In most cases, the consumption of BT-577 varnish per 1 m2 is about 150 grams, with a single layer. The manufacturer indicates in the instructions that it is necessary to apply the composition in two layers.

In stores, the bituminous composition BT-577 is sold in containers of different volumes, from 0.5 kg to 50 kg. The price of a half-liter container ranges from 40 to 60 rubles, depending on the manufacturer. A container with a volume of 1 liter costs 80-130 rubles. The price of 5 liters is about 520 rubles. The larger the container volume, the lower the cost of 1 liter of the mixture. 50 kilograms of the composition costs 3500-4000 rubles.

Specifications

Nominal viscosity according to the viscometer ВЗ- ± 2 ° С, sec …………………………………………………………………………………………………… ………………………………………………………… 18-35

Mass fraction of non-volatile substances,% …………………………………………………………………………………………………………………… ………………………………………… 39 ± 2

Time to dry degree 3:

- at 20 ± 2 ° С, hour, no more ………………………………………………………………………………………………… …………………………………………………………… 24

- at 100-110 ° С, min, not more ………………………………………………………………………………………………… ………………………………………………………… twenty

Film hardness according to the pendulum device M-3, conventional units, not less than ……………………………………………………………………………………………… ……………………………………………………………… 0.20

Flexibility of the film, mm, not more than ………………………………………………………………………………………………………… ………………………………………………… 1

Resistance of the film to static impact of water at 20 ± 2 ° С, h, not less …………………………………………………………………………………… ……………………………………………………………………… 48

Film resistance to static effect of 3% NaCl solution at 20 ± 2 ° С, h, not less ................................................................................. ………………………………………………………………………………… 3

Certification

Sanitary and Epidemiological Conclusion No. 12.RTS.11.231.M.000386.07.02 from to.

When carrying out painting works, as well as after their completion, it is necessary to thoroughly ventilate the room.

Use rubber gloves to protect your hands. Avoid inhalation and digestion.

If nail polish gets on your skin, wash it off with warm water and soap.

Protect from children! Keep away from fire!

Storage

Varnish BT-577 must be stored in a dry, unheated room, in a tightly closed container.

The varnish should be stored in a tightly closed container, away from electrical appliances, food, in places inaccessible to children.

Protect from moisture and direct sunlight.

Advantages of varnishes in aerosols

These formulations are immediately ready for use It does not matter which varnish you use, Plastik from Cramolin, Kudo Ku formulations or other brands, they all have the following advantages:

- Such formulations are immediately ready for use. They do not need to be diluted, mixed. Also, you do not need rollers, brushes and other auxiliary tools that you have to clean after use. Thus, the spray lacquer is highly mobile. You will save money on the purchase of additional tools and solvents. And thanks to the convenient volume of 200-400 ml, the varnish can be used even in the field.

- As a rule, the spray can indicates how long the varnish dries. This usually takes a few minutes. Due to the fact that the composition dries so quickly, smudges do not have time to form on plastic, steel or wood surfaces.

- Such compositions can be used not only on products made of different materials (plastic, wood, steel), but also on planes of different shapes. The surface can be flat, curved, open, or difficult to access.

- Plastik spray varnish or another variety can be used even by beginners. No special knowledge or experience is needed. If you are interested in how much varnish you need, then we can confidently say that its consumption will be minimal. This will give you an even, continuous, smudge-free layer.

- Any varnish in aerosol (universal, matte or glossy) has excellent physical and chemical characteristics. All of them are resistant to steam, moisture, high temperatures, various aggressive substances and detergents. In addition, surfaces made of steel, plastic, ceramics or wood will be reliably protected from mechanical stress, burnout in the sun, and temperature jumps. At the same time, depending on the type of varnish, you will get a matte or glossy effect.

- Thanks to the transparency of the varnish, you will retain the original color of wood, plastic, glass, cardboard or steel surfaces.

- Affordable price for a small volume (200 ml or 400 ml). As a rule, liquid varnishes are sold in large containers, so for small areas it will be more economical to buy formulations in aerosols.

Product certification

All varnishes can be divided into several large groups according to the type of solvents in the composition: oil, turpentine and alcohol. Each has its own functions and properties.

In our country, the presence of a certificate of conformity for varnish is advisory in nature. It is required only in rare cases. But all paints and varnishes must have a declaration of conformity. How are they different? According to the certificate of conformity, responsibility for the information lies with both the certification body and the declarant. Only the certification body is responsible for the declaration.

For bitumen varnish, it is not necessary to issue a certificate of conformity for its release on sale in the territory of the Russian Federation. But this document is required if the product participates in government tenders and transactions. It enhances the competitiveness of the varnish on the market. State certification centers carry out tests in laboratories, on the basis of which a certificate is issued. The document must be drawn up in advance.

Using quick dry primers

Practice shows that the use of quick-drying mixtures before applying enamels and paints, minimizes the likelihood of surface damage. This is due to a number of protective measures against negative environmental influences.

A special type of composition is distinguished, which helps to get rid of rust due to the components included in the mixture. These properties are used when working with metal structures that have undergone the action of corrosion. Primer treatment of their surfaces will significantly extend the service life.

Quick-drying mixtures for priming car body parts are considered a product of narrow use. On sale you can find both universal primers that are used in the restoration of corroded metal, as well as parts untouched by it. Such compositions are also used for forged products and cast structures, the surface of which has a slight roughness.

Fast-drying formulations are used:

- in mechanical engineering;

- in construction and finishing works;

- in shipbuilding;

- in the production of technology.

Before starting work, it is important to make sure that the composition of the primer is universal. If you neglect this rule, then some types of metals can react with the components of the mixture.

As a result, the adhesive properties will be reduced.

Characteristics of soil-mixture for metal

The soil mixture is used both in large-scale production and at home. It is a solution used to combat corrosive phenomena and smooth out small errors on the product. The film formed by the primer is resistant to temperature extremes and high humidity.

There are several types of primers and each of them has its own consumption parameters per unit surface area.

This solution is always applied before the topcoat is applied to ensure a high quality result. Advantages of treating the product with a soil mixture before painting:

- The finishing layer will hold much stronger and the surface will not have to be repainted in the near future. In cases where the application of the primer-mixture is neglected, the paint begins to peel off, fall off and the process will quickly have to be repeated again.

- Corrosion protection prevents the formation of rusty spots on the surface.

- Significant savings in paints and varnishes.

If, during repair or final work, in a short period of extra time, apply a primer coat, before painting, this will save both finances and time. The next repairs will need to be carried out much later.

Variants of soil mixtures for metal

There are some of the most common processing solutions that can help facilitate final product handling and improve performance:

- Alkyd primers are the most widely used option. It consists of an alkyd composition in the base, with the use of various stabilizing agents and additives. The color of the coating is gray or brown. It is highly durable and dries quickly. Also included are: red lead iron, whitewash and other components. Combines with virtually all finishes.

- Funds, for the most part consisting of phosphoric acid. Suitable for surface varieties already slightly corroded. The solution helps to restore the material, free it from rust. Phosphorus primers stop all oxidative processes and, as a result, strengthen the product. When using such products, it is imperative to remove rust from the treated surface.

- Acrylic, water-dispersed versions are used indoors, increase adhesion, level the surface. Such a composition dries quickly, it is suitable for coating the actual iron surfaces and non-ferrous metal alloys.

- Inhibitory primer. This composition does not provide a general film over the product, but penetrates directly into the surface at the level of molecules. As a result, some properties of the material change, it turns out to be denser and harder. When processing, they combine the properties of the primer-mixture itself and the enameled surface. Every day, such a coating is becoming more and more popular for various metal surfaces.

- Protective. This product includes magnesium and zinc. The higher the content of powders in this mixture, the better it is considered to be. Compositions that contain red lead are especially popular. Thanks to these components, the metal surface hardens, and even the smallest scratches are not formed on it. Perfect for those structures and products that have frequent contact with fresh and sea water.

- Converter. A variation of a mixture that is mixed with a corrosive coating. As a result, the structure of these spots becomes more porous and can be easily removed from the metal surface. Therefore, at the beginning of work on such a material, it is not necessary to clean rusty areas from the surface. Therefore, transforming compounds are an option for the lazy.

- Insulating mixtures. In this embodiment, the base is a neutral pigment. But the primer itself has a short duration.

Each subspecies of soil mixture has its own characteristics, which should be clarified when selecting. It must be suitable for the type of metal that is supposed to be processed.

Optimum performance for a standard metal primer is:

- semi-gloss or matte appearance of the film;

- the period during which the mixture dries should be no more than 12 hours;

- parameters of elasticity of the finished film without taking into account bending - no more than 1;

- conditional viscosity parameters more than 45.

Such a primer will significantly increase the service life of the metal surface and paintwork.

Varieties

Varnish spray can serve for different purposes depending on its type Varnish spray can serve for different purposes depending on its type:

Glossy varnish acrylic based floor varnish

- Tinting varnish compositions are suitable for the treatment of car bodies, individual units and parts. For example, such a mixture is suitable for tinting headlights or other glass or plastic parts. As a rule, tinting varnish helps to protect parts from weather factors, mechanical influences and aggressive chemicals. In addition, it improves the aesthetic qualities of the car, creates the effect of novelty and shine. Also, the tint spray perfectly protects wood surfaces after restoration.

- Reflective compositions in cylinders contain special particles, which, in addition to a glossy sheen, allow the surface to reflect light in the dark. That is why such compounds are commonly used to coat auto parts, road signs and other bicycle accessories, helmets, etc. Such varnishes are suitable for surfaces made of steel, glass, plastic, wood. In turn, these mixtures are divided into several subspecies, depending on the special effects they can create:

- shine of diamonds. Such compositions give the surface an incredible shine, volume and depth;

- chameleon. This coating can change its shade at different viewing angles and lighting;

- the effect of the starry sky. This composition contains multi-colored microparticles that create a diffused glow on the surface.

- Polyurethane varnish compositions. These mixtures, like Plastik acrylic varnishes from Cramolin, are designed to protect surfaces from mechanical stress, moisture, scratches, mold, and high temperatures. They are used for plastic, wood, metal products. To increase the protective effect, it is recommended to apply the composition in several layers (3-4). At the same time, each previous layer must dry completely, so consider how long the varnish you choose dries. On wooden surfaces, this varnish only emphasizes the texture of the wood and gives the product a shine.

Types of varnishes for metal

Consider the most popular types of varnishes for metal processing.

Bituminous varnish

Since we have already mentioned bituminous, we will start with it. This is a relatively new type of varnish mixtures. It is produced on the basis of a special grade of bitumen and polymer resins mixed with organic solvents and additives. Possesses excellent physical, mechanical and operational properties. Designed to protect the surface of metals, stone, wood.

Although the formed black protective film is strong and resistant to external influences, manufacturers suggest using varnishing as a temporary rather than permanent solution, that is, during the storage and transportation of products.

Bituminous varnish has the following characteristics:

- environmentally friendly;

- porous structure provides frost resistance;

- lasting;

- elastic;

- heat resistant;

- weatherproof;

- resistant to acids and alkalis;

- has antiseptic properties.

Bituminous varnish is inexpensive, but of sufficient quality. Today, materials in this category are becoming more and more popular.

Bituminous varnish has a dark tint due to the resulting black film

Bituminous varnish has a dark tint due to the resulting black film

Polyurethane varnish

Available in: transparent, glossy, matte.The substance contains modern polymers (polyurethane). It has excellent performance characteristics. Anti-corrosion polyurethane mortar is used as a protective topcoat for internal surfaces of tanks made of steel, cast iron, aluminum, copper and their alloys.

Polyurethane varnish is also suitable for domestic use when performing interior or exterior finishing work. Easy to apply, quick drying, no smudges. Temperature atmospheric threshold during work: from -30 ° C to + 60 ° C.

Characteristics of polyurethane varnish:

- excellent adhesion;

- wear-resistant;

- heat-resistant (operating temperature range from -60 ° С to + 80 ° С);

- durable, resistant, elastic coating;

- moisture resistant;

- chemical inertness;

- atmospheric resistance;

- long-term trouble-free operation of the coating and the product itself (at least 10 years).

Polyurethane varnish can be used for interior and exterior decoration

Polyurethane varnish can be used for interior and exterior decoration

The transparent polyurethane varnish allows mixing with the pigment (to obtain a colored decorative protective layer). It can be used as a base (top) coating or to protect metal before painting.

Acrylic lacquer

It is used to protect products made of ferrous and non-ferrous metals and their alloys. The coating dries very quickly, forming a strong waterproof film on the surface. Among the recommendations for use, we single out: suitable for metal surfaces constantly exposed to high humidity and high temperatures.

The base of the varnish is an aqueous dispersion of acrylic resins. It is recommended to apply it with a spray (like an aerosol) or a paint brush. It can be used for external and internal works. Many automotive paints and varnishes are also acrylic based.

Characteristics of acrylic varnish:

- heat resistant;

- moisture resistant;

- has good adhesion;

- anti-corrosion properties;

- not affected by salts, oils;

- forms a strong, elastic film that can withstand mechanical stress;

- non-toxic;

- fire and explosion proof;

- extends the service life of structures made of steel and other metal alloys.

Application of varnishes for metal

Varnishes are applied to stainless steel. For cast iron, aluminum, copper parts. The type of varnish is selected, taking into account the type of work: internal or external, drying time. There are universal varnishes that are suitable for both types of work.

Acrylic varnishes are used to treat containers for liquids, tank surfaces, vessels for petroleum fractions, alcohols, alkalis.

Equipment at technological enterprises, metal floors, large metal parts, which are unacceptable to rust, are varnished. All varnishes protect surfaces, this is their main purpose. Many varnishes serve as decoration, because they form matte or glossy coatings, while retaining their properties for a long time.

Exterior facade paints: features and benefits

The easiest way to ensure a long lasting facade is to paint it. Modern facade paints for home can quickly change the appearance of a building. In addition to excellent decorative properties, universal paintwork materials for outdoor use have the following advantages:

They form coatings with high weather and UV resistance, which guarantees a long service life. This is achieved by the presence of acrylate binders and other components in the composition of paints for facade works.

- The compositions are tinted, have lightfastness, high adhesion and excellent hiding power. They fit well, do not require professional skills when applied.

- Buying universal paint for outdoor use means permanently solving the problem of cracking of the decorative and protective layer under the influence of heat or frost. Almost all compositions are temperature-resistant and show themselves excellently in the conditions of Russian latitudes.

They are highly hydrophobic. The resulting coating is waterproof, so the facade material is protected from moisture and fungus.

The resulting layer of external finishing of the facade is vapor-permeable.

Affordable finishing cost. It is possible to buy modern paints for facade works at a fairly attractive price (for example, on the site "Building Materials-Cheap"), and the service life, subject to the manufacturer's instructions, is from 5 years.

The presence of antifungal and antimicrobial additives that provide resistance to the development of various microorganisms. Many manufacturers of universal paints for outdoor use even claim that the coating formed by their products protects the facade from the development of blue-green algae.

Question: I am thinking how to choose a facade paint, comparing characteristics and prices. Does the vapor permeability of the resulting coating matter? What does it affect? Isn't this a far-fetched advantage?

Answer: The advantage is not far-fetched. The best facade paints have high vapor permeability. The fact is that the highest this indicator in any system should be for the outer coating. Otherwise, moisture can begin to accumulate in the wall material, and this is fraught with the formation of mold and the gradual destruction of the wall.

Types of varnishes for processing stone surfaces

- Polymer varnish for stone. Among the most popular paints and varnishes for indoor and outdoor use. It has excellent strength, moisture resistance, wear resistance. It adheres well, dries quickly, has high adhesive properties.

- Polyurethane varnish for concrete. In terms of performance characteristics, it is little different from polymer coatings. The main advantage is water resistance. It is better to varnish with this agent where surfaces are constantly exposed to high humidity. Ideal for exterior facade work, stone processing in swimming pools, paving slabs.

- Silicone and acrylic compounds. They have a high decorative quality, which distinguishes them from polymer and polyurethane mixtures. More often used for interior work. Among paints and varnishes, they are among the most expensive goods. Therefore, it is irrational to use acrylic or silicone varnish for mineral materials in outdoor decoration and for varnishing large areas. Nevertheless, the products have increased wear resistance and durability.

Polymer varnish

This type of protective agent is used for coatings with mineral components. These include bricks, concrete, etc. The main features of the polymer composition are decorative properties and increased wear resistance. The substance resists cold and moisture well.

Over time, stones coated in this way do not fade and retain their bearing capacity. Most often, polymer compositions are used in construction for external facing work. They can be used with natural materials and artificial products.

All polymer varnishes are made of one-component substances that can dry much faster than other solutions. This is due to the small proportion of water components. Due to this, the substance can even be used for gypsum products.

The structure of the substance allows to achieve a matte effect upon application. This is especially noticeable when adding paint to the composition of solutions. Thus, you can achieve the appearance of any product with a design.

Polyurethane varnish

The substance can be used for all types of materials used in the construction of buildings. The solution is an oligomer with polyurethane components. The consistency is added to an organic solvent. As a result, the substance forms a transparent film during hardening. Adding paint can change the color, which is useful for matching textures of the same type.

This type of varnish is used for outdoor use.Lacquering products with a polyurethane substance allows you to achieve the effect of a wet stone.

High protective properties, make it possible to use the agent for coating concrete and brick. The properties of the material are excellent for artificial and decorative items. When they are combined, durability and wear resistance are significantly increased.

The advantage of polyurethane varnishes is their high moisture resistance. Therefore, it is rational to use such means to protect concrete, thereby increasing the anti-corrosion properties of the structure and overall waterproofing.

Silicone acrylic varnishes

The most popular protective equipment when working with interior decoration of buildings. The substance is suitable for decorative products made of stone, brick and other materials. Due to its special properties, the construction, coated with a silicone-acrylic agent, does not turn yellow over time. Also, the substance forms a film that provides protection against moisture.

The base of the solution is acrylic acid with the addition of acetylene. Thanks to this, the varnish is odorless, safe for use in rooms with people living and has high protective properties.

It can be used with any material, even plaster or metal. The addition of special paints allows you to achieve the required texture and scale. Most often it is used for working with artificial materials.

Scope of use

Varnish sprays of any manufacturer (Kudo Ku, Cramolin, etc.) have an extensive area of use. Varnish sprays of any manufacturer (Kudo Ku, Cramolin, etc.) have an extensive area of use. The most popular is the universal spray varnish. They are indispensable wherever precise work is needed in small areas. At the same time, three main areas of varnish use can be distinguished:

- In the automotive industry, Plastik 200 sprays from Cramolin and other manufacturers are used after body repairs.

- The versatile compound can be applied to kitchen utensils, bathroom accessories, toys, art, furniture and other home furnishings.

- Matt and glossy varnish in aerosols is used in the construction industry.

- Such formulations are indispensable in the electrical field, for example, the Plastik formulation from Cramolin is in great demand in this industry.

Classification

Varnish mixtures differ in composition and characteristic properties, therefore they have different areas of application. The main types of varnishes for metal surfaces are:

- bituminous;

- polyurethane varnish for metal;

- alkyd varnish;

- acrylic resin varnish;

- heat-resistant varnishes.

Bituminous varnish

Bituminous varnish is made from special bitumen and various additives. This relatively new product has such performance properties that it can be used not only for metal protection, but also for stone and wood surfaces.

Acrylic lacquer

Since there are no solvents in the composition, this type of metal varnish is suitable for exterior and interior work. Among the main advantages are resistance to high temperatures and moisture.

Acrylic varnish is best suited for protecting metal products that are regularly exposed to high temperatures or humidity.

Alkyd varnish

Alkyd solutions form a durable shiny coating on a metal surface, therefore they are most often used at the final stage of finishing. The solution can be applied with a brush or as an aerosol.

Stove varnish

Heat-resistant metal varnish is a special type of paints and varnishes, because it can withstand temperatures up to 250 ° C.

This compound is used to protect metal surfaces that are regularly exposed to flames (like parts of a stove and fireplaces). This type of varnish can be used as an additive in all other varnish varieties.