# 1. What is the difference between different wood varnishes?

Varnish is a viscous product consisting of a solvent, resins and polymers. After application to the surface, the solvent evaporates, leaving a dense, durable film. This barrier protects the tree from all sorts of negative factors. Since wood was previously the main building material, the first varnishes appeared in the 12th century. It was the invention of a German monk, and the composition of the protective substance was kept secret for a long time. Attempts to develop a means to prolong the life of a tree have been made constantly. So, in the 15th century, oil-type compositions appeared in England, later in Holland and Portugal they began to produce varnishes based on resins.

Since then, the range of such products has expanded significantly, compositions with specific properties have appeared, so today it will not be possible to just go to the store and buy the first wood varnish that comes across - it is important to take into account the many nuances of various compositions, otherwise you can not only not protect the material, but also harm it

When choosing a varnish for wood, the following factors should be taken into account:

terms of Use. On the street, the material is affected by factors such as high humidity, constant changes in temperature and ultraviolet light, therefore, the composition for protection must be chosen appropriate - only wood varnishes for outdoor use are suitable. As a rule, the manufacturer indicates on the packaging the conditions in which the composition can be used. Parquet, furniture and wall decoration materials can be safely varnished for wood for interior work;

wear resistance. It is not always possible to cover the floor with the same composition as the furniture, since the load on the surface will be completely different. If even the least resistant nitrocellulose varnish is suitable for furniture and other wooden objects that are not subject to severe wear, then more durable compounds must be taken for the flooring;

toxicity. Most modern formulations have an unpleasant, pungent odor when dry, as they contain organic solvents. Of course, this smell will disappear when the varnish is completely dry, and until then, at best, you will get a headache, and at worst, you will get serious poisoning. Polyurethane, acrylic, polyester varnishes and nitro varnishes are applied in special protective equipment in carpentry workshops or non-residential premises. After drying, all of these compounds are safe. If the work needs to be carried out at home, and at the same time the household is not going to leave anywhere, then it is better to take the least toxic composition - these are water-based varnishes, they have practically no smell;

drying time. A coat of varnish can dry from 6 to 72 hours and sometimes longer. Water-based varnishes and oil varnishes dry the longest, alcohol and nitrocellulose varnishes - from 20 minutes. According to this parameter, all formulations are divided into slow- and quick-drying. Consider this characteristic of the varnish when calculating the duration of the work;

resistance to high temperatures. It makes sense to apply heat-resistant varnishes to wood in those rooms where the risk of fire is increased.

It is important not only to choose a suitable composition, but also to properly open the surface with it, because the result largely depends on the application technique;

shine. Thanks to varnish, you can get a glossy or matte surface

The choice in this case is based only on aesthetic preferences, since the performance does not depend little on the degree of gloss.Gloss gives visual volume, and the matte surface is able to emphasize the beauty of the wood. Gloss is measured as a percentage of reflected luminous flux. So, for example, high-gloss varnish reflects more than 90% of light, glossy - 80-90%, and matte - less than 10%. There are also semi-gloss and semi-gloss compositions, so there is a large selection;

varnish components. For performing work on your own, one-component varnishes are best suited, those that are simply applied and form a protective film by evaporation of the solvent. Professionals often use two-component varnishes, in which a protective film is formed by a chemical reaction between two substances. As a rule, such formulations are more persistent;

the need for a primer. Self-priming varnishes can be applied directly to wood. The rest of the compositions require preliminary surface preparation: if you do not prime it, then soon you can face the flaking of varnish, the appearance of cracks and craters.

You can also find toning varnishes on sale. With their help, you can give the wood the desired shade or even completely change the color. However, the classic option is still a transparent varnish, which allows you to preserve the original wood pattern.

Alkyd-urethane varnish "yacht"

For varnishing yachts, special varnishes are produced, which are characterized by increased resistance to external factors. On the basis of alkyd and urethane, two types of paints and varnishes are produced - alkyd-urethane and urethane-alkyd. These mixtures differ in the concentration of the main substance: in alkyd-urethane there are more alkyds and, conversely, urethane predominates in urethane-alkyd varnishes.

This type of varnish provides a high quality, hard, low temperature and weather resistant coating. However, the main feature of paint and varnish mixtures based on alkyds is the highest drying rate of the varnished surface. Manufacturers achieve this characteristic by adding highly volatile solvents to the formulations. Such substances evaporate very quickly - much faster than ordinary white spirit. However, the use of rapidly evaporating solvents results in a very high toxicity of the varnish.

Urethane-alkyd paints and varnishes are specially designed for indoor use. Unlike alkyd-urethane varnishes, urethane-alkyd varnishes have a lower concentration of organic solvents. Also important is the fact that urethane-based plasticizers are inhibitors that prevent the evaporation of chemicals. Thanks to the urethane component, the coating acquires elasticity and increased resistance to temperature extremes.

Urethane-alkyd varnishes are recommended, first of all, for application on so-called "warm floors". Most other varnishes will crack when heated regularly. And only wood coated with a composition where urethane predominates is guaranteed to retain its performance characteristics.

Alkyd-urethane varnish is one of the best solutions for varnishing a wooden surface, which has undeniable advantages. However, the alkyd urethane coating, like any other, wears out over time. Therefore, after 7-10 years, coverage will need to be updated.

It is also necessary to remember about the toxicity of alkyd-urethane mixtures and take precautions in time when handling this paint and varnish material.

What it is?

Acrylic varnish is crushed plastic dissolved in acrylic. After drying of such a composition, a thin, colorless acrylic film with high resistance to mechanical damage is formed.

The main substances that make up the varnish fit into three points:

- liquid polymer (acrylic);

- antiseptic (to protect wood from moisture and pests);

- plasticizer (the main component that gives the coating maximum strength and durability).

Acrylic varnish is a ready-to-use substance: homogeneous, transparent, practically odorless. It is based on high-quality, color-free acrylic resins and aqueous dispersions.

To get acquainted with this almost universal coating, you should highlight its main properties and characteristics.

Application

It should not be forgotten that all these varnishes are synthetic mixtures. Therefore, personal protective equipment will not be in the way. When carrying out internal work, as well as after finishing the processing, the premises must be thoroughly ventilated.

The surface to be treated must first be prepared for painting: clean, dust, dry, possibly degrease, prime. The maximum air temperature during work should not exceed + 35 °.

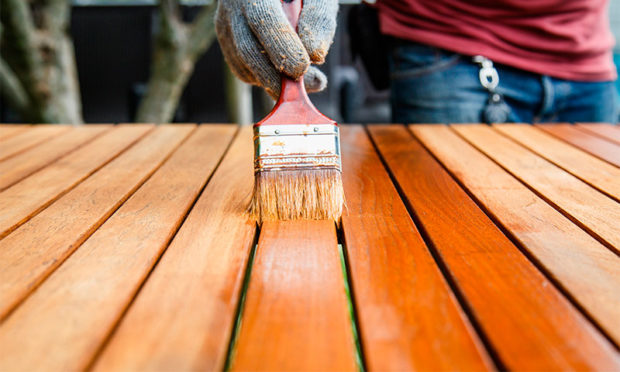

Fast drying polymer compound can be applied by brush or roller, also by airless or pneumatic spraying. In the last two cases, the substance should be diluted to the working viscosity. Acrylic, polyurethane, silicone varnishes are also applied with similar painting tools.

It is recommended to cover the treated surface in at least two layers, especially if the surface of the stone has a porous structure.

Varnishes for mineral materials extend the life of the room or the building itself

Therefore, it is so important to approach the choice of funds with special care. Before buying, you need to determine which of the proposed varnishes is more suitable for your case, calculate the consumption, the cost of preparing and performing work

Special varnishing of concrete and stone surfaces will provide long-term and high-quality protection during operation.

The choice of varnish for wood is made taking into account the desired decorative effect, operating conditions of wood products, durability and condition of the treated surface.

SubCategory: Varnishes for wood

Technologies

Typical defects in the application of varnish to parquet Varnishing is a very important stage in the arrangement of a parquet floor. The varnish not only emphasizes the beauty of the natural pattern of wood, but also protects it from moisture and mechanical wear.

Parquet varnishing Parquet varnishing is the last step in parquet construction. The quality of the varnish directly affects the durability of the floor covering

Glossy or matte varnish? Varnish is used to cover and protect wood. Glossy lacquer reflects light rays, giving the product a shine and making the grain of the wood more visible

The technology of applying varnish on the door leaf And only after impregnation with a primer can you start covering the door leaf with a transparent or slightly tinted varnish

Restoration of windows with paints and varnishes Restoration with paints and varnishes is a great way to return the window to its previous appearance, because after it the tree retains its texture and acquires an aesthetic appearance

How to varnish a tree correctly Knowing which wood the product is made of, you can calculate the amount of varnish to properly varnish the wood

Alkyd varnish for wood. Description and application Alkyd varnish for wood forms a hard, durable film with good adhesion, moisture resistance and can be used for both indoor and outdoor work.

Removing varnish from wood. Description of work + Video For more delicate work, such as the restoration of old furniture, wooden products, when working with which you need to remove the varnish without damaging the surface of the product, the so-called removal of varnish from wood by a chemical method or washing is used

How to choose and correctly use black wood varnish Black wood varnish is most often used for processing furniture parts, so this composition is worth choosing

Wood varnish: how to choose In no case should you come to the store and ask just a cheaper wood varnish News

LLC "StroyTechnoKhim" LLC "StroyTechnoKhim" offers paints and varnishes for special purposes: ...

The company "Vapa" presents a new universal water-based varnish for wood The St. Petersburg company "Vapa" has launched the production of a new water-based varnish for wood, ...

New urethane-alkyd varnish for wood from the St. Petersburg company The St. Petersburg company "Vapa", specializing in the development and production of high-quality ...

High-quality, environmentally friendly novelty for parquet finishing from the TBM company. The TBM company expands the range of products produced under the Lignum trademark ...

A novelty for decorative processing and protection of parquet from "YAK" A new highly effective protective paintwork material for parquet has appeared on the domestic market, ...

New wood-protective varnish from YAK A new product under the Yaroslavskiy kolorit trademark has recently appeared on ...

New decorative weather-resistant varnish for wood was presented by ABC Farben Voronezh company ABC Farben, one of the five largest domestic ...

Empils has started production of a new product for wood protection Empils has started production of a new product for wood ...

Preparatory activities

Surface preparation is carried out taking into account the following rules:

It is unacceptable to paint the surface in direct sunlight, as well as in drafts.

Before processing, remove dirt, grease and oil stains from the surface.

If the wood is hardwood, soak it with White Spirit solvent.

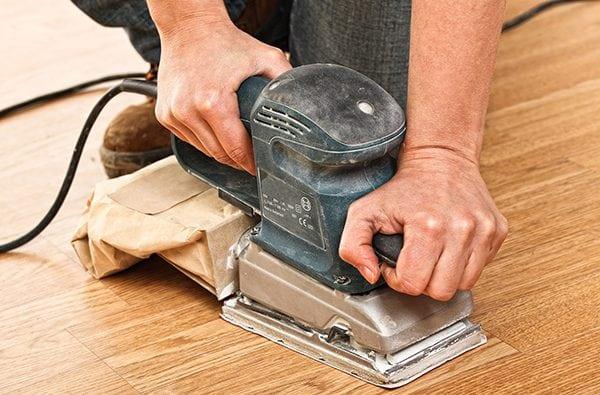

We treat rough places with water from a spray bottle. When the surface is dry, sand it to remove the raised wood fibers.

If the surface was previously varnished, we check the paint and varnish materials for compatibility. To do this, we do a test staining in a small area.

Please note: the final color of the coating depends on both the type of wood and the number of layers of paint and varnish applied.

The varnished surfaces do not need to be primed, but if the varnish peels off, it must be removed and then sanded twice.

Please note: sanding wood for the first time with obvious effort using coarse sandpaper

Sand a second time more carefully using fine-grained sandpaper.

If the varnish will be applied to fresh wood, it should be primed with White Spirit. Recommended proportion: for five parts of solvent one part of paint and varnish composition.

After sanding the surface, remove dust with a vacuum cleaner

Moreover, dust should be removed not only from the floor, but also from all nearby areas: a heating battery, baseboards, window sills, etc. A situation should not be allowed when shavings or dust fall on the floor that is not dry from the varnish.

Wipe the wood with a clean, barely damp, lint-free cloth.

Note! Although urethane alkyd varnishes are more commonly used on wood, they can also be used on concrete.

Decorative properties

Most often, consumers choose glossy or matte varnishes, for example, polyurethane or acrylic compounds. However, if any special components are added to the varnish mixture, then the surface can be made unique, very attractive and decorative. For example, for a structure made of wood, you can use the technology of toning, artificial aging, as well as enhancing the natural texture. The following types of varnish compositions are used for surface decoration:

- Craquelure varnish solutions are most often applied to a layer of plaster, on which they create the appearance of an aged surface on which cracks have appeared.These cracks appear when the composition is applied in two layers, after which the crack network is patinated;

- Pearlescent Blends are an excellent finish that creates a unique spectral shimmering effect. Pearlescent solutions are made on the basis of acrylic components, they are safe for humans, applied to wallpaper, plaster, wood and mineral materials;

- glitter varnishes have an acrylic base with glitters, intended for finishing on walls. The decorative components are available in various shades and must be purchased separately. Glitters are added to the varnish mixture on their own, resulting in an original and unique coating.

So, there are many varnish varieties, each consumer chooses the most suitable composition for his room. Many people ask how to varnish a brick wall, how to varnish a concrete or wooden surface? To do this correctly, you must definitely adhere to the technology specified in the instructions. And if you do not have the necessary knowledge and skills in the field of repair and decoration, then it is better to entrust this work to professional craftsmen.

How to add haze to a dye

Are there ways how to make a matte polish from a shiny glossy one? Craftsmen have come up with several ways to create a matte varnish at home.

Polishing

This method is often used by motorists to give a new image to a car, it is convenient to matt with polishing and using a glossy floor varnish. Polishing is applied immediately after the varnish for parquet or car body has dried. To cover the floor, you can use the usual polishing products for caring for parquet, and for a car body it is recommended to purchase a car spray in a can and apply as indicated in the instructions.

Gasoline use

It is possible to make the glossy varnish matte by rinsing the surface with gasoline immediately after drying. But this method is inconvenient because gasoline is combustible and retains a pungent smell for a long time. If the floor varnish to be coated with gasoline is alkyd based, the risk of fire increases. In addition, it is difficult to apply the gasoline evenly and the surface will have different dull shades after drying.

Adding chalk

A glossy regular varnish is taken and finely crushed chalk is added to it in an amount of 10% by volume and thoroughly mixed until smooth. It is not recommended to add more than 10% of chalk, otherwise, wanting to make a super matte tone, you can only lighten the shine too much, and such a coating may acquire an ugly whitish shade after drying.

It is allowed to apply a matte chalk solution only with a roller or a brush, the aerosol method is not suitable: chalk particles will quickly clog the spray gun nozzle, even if the composition is pre-filtered.

Applying fine rice flour

Rice flour, like chalk, removes gloss well and is used in the same proportion. Recommended for water-based paints and varnishes. For example, a water-based wood varnish with rice flour after drying has no shine and looks silky velvety. Also, rice flour is well suited to polymer clay formulations, giving decorative products made from this material a beautiful soft tone. If you don't like the color of the product, you can paint the polymer clay.

Using tooth powder

If there is enough tooth powder at home, then this is also a good way to make a matte tone from a glossy one. Tooth powder contains chalk and some additives. A formulation made with tooth powder will coat the surface with an even layer due to the abrasive properties of the additives contained in the powder.

If various additives are introduced into the paint and varnish, then it is necessary to determine how to apply them: if the aerosol method is acceptable for flour and powder, then if chalk was used, you can only use a brush or roller.

Purpose of varnishes

All materials are divided into those that are used for outdoor work (weatherproof) and those that are used only indoors. However, there are universal types. There are three types of paintwork materials, depending on the purpose.

- Parquet. They are applied to parquet or other wood flooring. This group includes acrylic, acrylic-urethane, alkyd-urethane products, because the main requirements for these materials are wear resistance, resistance to moisture.

- Furniture. This category includes varnishes applied to furniture, wooden decorative objects, and musical instruments. These include acrylic, alkyd, epoxy, alcohol and other varieties.

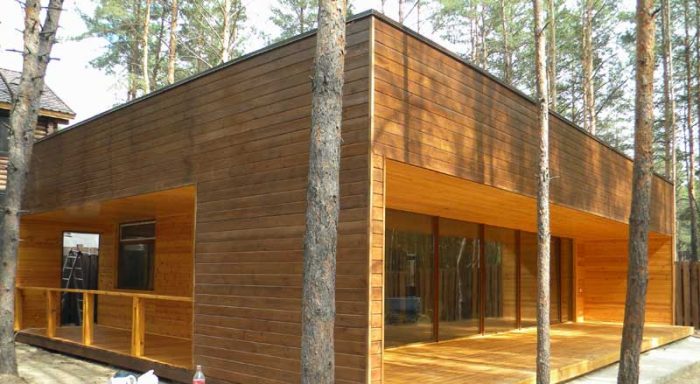

- Weatherproof - intended for exterior wood finishing. They must be resistant to precipitation and ultraviolet radiation. Alkyd varnishes, acrylic and alkyd-urethane varieties are weather resistant. They are used to protect homes, outbuildings, doors, windows, boats and yachts.

If we talk about the most versatile variety, then this is, without any doubt, a polyurethane compound, which is used not only for wood, but also for concrete, concrete tiles, stone, brick and metal. Now they produce a large number of brands of polyurethane varnish, they are intended for completely different materials and work.

Manufacturers

The Eteral company supplies polyurethane varnishes with improved anti-corrosion and strength characteristics. There are options for concrete surfaces and floors, for painting wood and metal surfaces. Finishing concrete floors and other solid substrates can last at least 30 years after application. The developers have made sure that the line contains proposals for a wide variety of temperature and humidity conditions.

VGT acrylic varnishes for outdoor and indoor use are equally suitable, and you can finish any surfaces made of wood, with the exception of floors. The formed film is at the same time transparent, strong and well stretchable. During the drying process, the color systematically changes from milky to colorless tones.

Consumers can tint the resulting coating in any color they like without affecting the unprecedented UV resistance. You can paint concrete, stone and other materials.

Lakra supplies water-based acrylic varnishes, which are reliably protected from UV rays in accordance with the generally accepted approach today. The assortment of "Lacra" also includes offers of paints and varnishes based on solvents. This group includes mixtures for painting parquet, furniture, other wood and metal products. The chemical base is acrylic or nitrocellulose.

Reviews for the products of the famous Finnish concern Tikkurila are always complimentary - the manufacturer does not hide important points and brings them to the consumer in publicly available technical documentation. There is an assortment of protective, high-gloss, semi-gloss compositions. Each of them is very reliable and has a long service life.

Criterias of choice

To choose the right paint and varnish product, you need to decide what work is to be done, and for what premises it will be used.

Internal works

You can safely cover walls and ceilings in rooms with acrylic varnish. It will create a beautiful appearance and will serve as protection. It is especially relevant for the design of wooden ceilings. The composition will only emphasize the unique pattern of wood.

It is good to cover both shelves and other wooden furniture with this varnish. It can also be used to coat painted surfaces.The only condition is that you need to select the appropriate varnish for each type of paint. If, for example, painting was done with acrylic enamel, then after that the surface must be treated with acrylic varnish, and it will hold well. But the same product will hardly fall on alkyd paint, and there is no guarantee that it will last a long time. It is advisable to choose a more durable coating for such paint.

If, for example, work is to be done in the bathroom, then you need to select a moisture-resistant varnish, which means that a polyurethane composition is more suitable here.

Outdoor decoration

In the outdoor varnish there are special components that can protect the surface from the effects of sun, frost and even rain. In addition, some formulations contain components that prevent the appearance of fungus. This varnish is suitable for covering garden furniture, gazebos, swings, benches, houses.

It is recommended to cover the bathhouse with a protective layer, because natural wood in any case needs additional protection. Therefore, first there must be a primer, then painting and varnishing. Only in this case, the building will last a long time.

The yacht varnish has also proven itself well. Among other things, it is also resistant to salt water. Such a coating on boats can serve for at least ten years.