Mode of application

Varnish "ZELEST VERESTA" is applied to the surface of the wood cleaned of dirt, dust and coatings with a brush, roller, spray in 1-2 (for humid or sunny conditions - in 3) layers with intermediate drying for 45-60 minutes at normal humidity and air temperature. below +5 оС. It is not recommended to paint in hot sunny weather in order to avoid a decrease in the absorption of the composition due to premature drying. Do not apply to surfaces previously treated with linseed oil!

The color intensity and protective properties depend on the number of layers. Treat the ends with particular care. The coating is available in a ready-to-use form. Do not mix with other formulations. Stir before use. Drying time to tack is 1 hour under normal conditions. The final color is formed after complete drying!

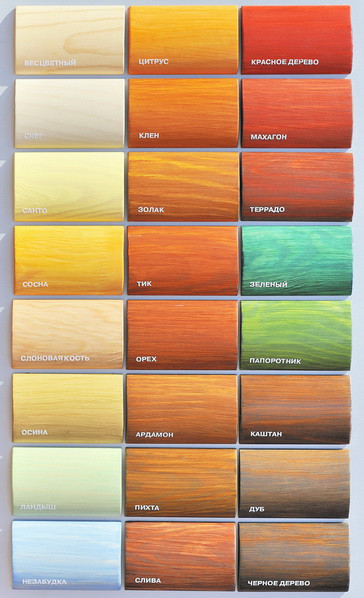

Color selection

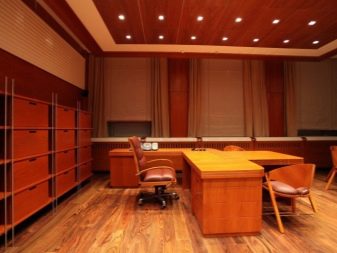

The choice of colors when toning parquet is an important procedure that will determine the style of your interior and its originality. The standard oak color, made in yellow-brown tones, has already become boring for our compatriots

Therefore, more and more original shades are becoming more and more popular, for example, smoky or bog oak.

In addition, if you want to make your interior more modern and interesting, then you can choose a varnish in the color of bleached or blackened oak.

In addition, tinting makes old floors more presentable. At the same time, the pattern and texture of the wood is completely preserved.

Optimal colors of tinted varnish:

- Deep, dark shades will give the floor an elegant and solid appearance. This finish works best with warm, cozy tones. Most often, dark tint is used in interiors made in the Art Nouveau style. The most beautiful dark tones are dark chestnut, bog oak, chocolate shade, and so on.

- White tinted paint and varnish material will allow you to emphasize your individuality. Such a coating is at the height of fashion today. Of course, a floor tinted in white does not require particularly careful maintenance. On such a surface, dust will be almost invisible, unlike a subfloor. White tinted parquet will make your interior lighter and weightless.

- The brown tinted floor symbolizes comfort and reliability. It is a very versatile color as it suits almost any interior style. The brown lacquer is successfully combined with all shades of furniture, from yellow to dark tones.

- Gray tinted paint and varnish material will help to make the parquet more elegant and solid. This color is combined with white and black interior elements. In addition, a gray lacquered floor will look good with cold and autumnal tones.

- Dark red and cherry tint will add coziness and warmth to your interior. At the same time, it will be more difficult to find the optimal combination with other interior elements for such a floor color. For example, a floor like this is ideally combined with yellow, brown and green interior elements. At the same time, the red tinted paint and varnish composition is not combined with cold tones.

Thus, the tinting paint and varnish material will make the parquet or any other wood covering more presentable and stylish. In addition, applying a tinting varnish will make the coating more wear-resistant and durable.

Selection Tips

The varnish for parquet processing is usually chosen by the client - on the advice of a parquet flooring master who knows all the nuances

When restoring the floor yourself, it is important to pre-grind and remove the old layer. It is incompatible with innovative new generation formulations

The number of layers and the concentration of the color can change the intensity of the color color - it all depends on the preferences of the owners.

The number of layers and the concentration of the color can change the intensity of the color color - it all depends on the preferences of the owners.

When choosing, it is important to take into account the functionality of the room and the expected load. If the room is rarely visited, walking in soft slippers on the bedroom floor, partially covered with carpet, no heavy-duty film is needed

It's better to play it safe in the hallway. These are included in outdoor shoes, abrasive particles will easily scratch the unstable coating.

You can give the parquet a pronounced gloss, which will act as a decorative element.

You can give the parquet a pronounced gloss, which will act as a decorative element.

In the dining room, in the kitchen or in the combined room, the parquet board must be impregnated with a primer and protected with a waterproof LKS.

For non-residential premises in a large house (billiard room, wine cellar, dressing room, home theater), a universal basis is selected.

Lacquers, which are used to treat the surface of parquet flooring for the purpose of protection, are preferred by most consumers.

Lacquers, which are used to treat the surface of parquet flooring for the purpose of protection, are preferred by most consumers.

For a bar, a small restaurant or a cafe where it is difficult to care for the parquet, it is preferable to treat the wood with wax mastic after thorough grinding.

Scope of use

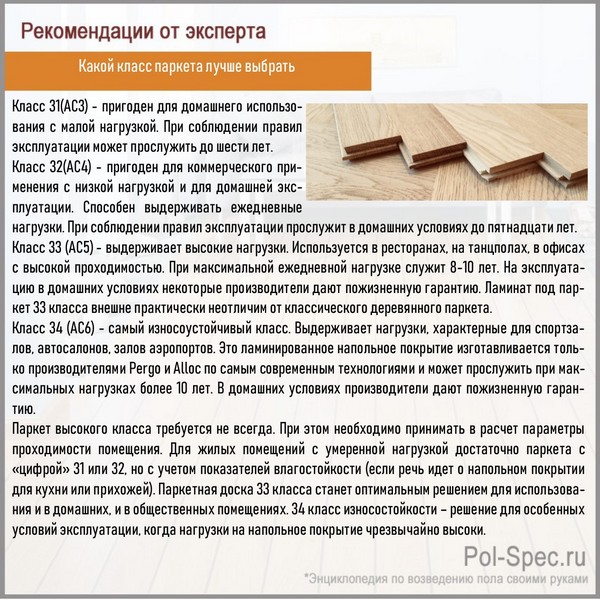

Based on the European standard C 2354 "Transparent coatings for wooden floors and varnishes made from them, minimum requirements and checks" dated March 1, 2009, there are three categories.

| Category | Description |

|---|---|

| A | Intermittent operation of the coating, infrequent loads of walking in shoes (rooms for receiving guests, kitchens, bedrooms). According to the classification of wear resistance for laminated and linoleum covering, it is similar to the 23 and 31 classes. |

| V | Continuous operation of the coating, walking in shoes (lobby, corridors, school, university premises, office rooms). Compliance with 32-33 wear resistance classes. |

| WITH | Intensive exploitation (places with a large flow of people, supermarkets, hospitals, cafes). According to the classification of wear resistance for laminated and linoleum flooring, it is similar to the 33, 41-43 classes. |

Regulatory document C 2354 does not have information about the maximum possible level of exposure to furniture wheels (tables, chairs). This is due to the fact that the ability to withstand the load of the rollers is directly dependent on the species and grade of the wood material.

There are several types of parquet, depending on the type of use

When operating sports facilities and gyms for physical activity, it is usually necessary to use varnish coatings that maximally protect the flooring from wear and tear.

For example, the Petri series has a lacquer based on alkyds with SPAR GYM technology that does not allow slipping, in addition, it is able to protect the coating during its intensive use, and does not interact with water during wet cleaning.

What class of parquet is better to choose

Views

Such attractive properties cannot be realized with the same degree by the same composition, therefore the chemical industry has established the production of a significant range of varnishes. Water-soluble formulations are either matte or glossy. In factories, a solution of dry emulsifiers in water is mixed using special equipment.

The formulation almost always includes additives to help form protective films on painted surfaces. One-component varnishes are created using acrylic or urethane compounds; in two-component mixtures, both are present at once.

Also, if necessary, you need to carry out regular wet cleaning using detergents and abrasives.

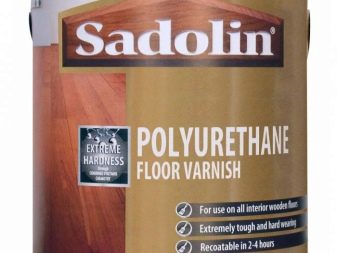

Therefore, the main objects of application of polyurethane paintwork materials are:

- administrative and office buildings;

- educational institutions;

- trade organizations;

- institutions of health care, culture and mass leisure.

Acrylic varnishes have their advantages: they can and should be used where the foreground is not wear resistance, but the elasticity of the layer being created and its microventilation. These qualities are extremely important for living rooms with a simple operating regime. Regardless of the chemical composition, water-based varnish must be stored at positive air temperatures, otherwise it will deteriorate.

Panel varnish coating is a type of surface treatment with water mixtures

Compared to other options, such a finishing material attracts attention with its impressive environmental and sanitary characteristics. Modern technologies make it possible to form a layer with a pronounced tonality, and completely colorless in appearance

Steam transmission is very important when decorating wood panels, as otherwise excessive pressure will build up inside the material. Other positive features of this option will be resistance to swelling, shrinkage and household standard contaminants.

It is convenient to use varnishes in aerosol format - while their protective properties are no worse than those of liquid packaging. The chemical composition is the same: acrylic or polyurethane. After application, there will be no problem with bad smell or long drying time.

Some aerosol varnishes are made on the basis of nitrocellulose, and within 60 minutes after surface treatment, they become sanitary.

Transparent balloon varnishes look harmonious even on expensive wood species and do not spoil their appearance. If the base is made of cheaper wood or stone, concrete, brick, then it is worth making a choice in favor of a colored composition.

In cases where deep absorption into the surface is very important, it is undesirable to use mixtures on a water basis. It should be noted that aerosol varnishes can only be sprayed outdoors or with intensive ventilation, away from open flames and sources of strong heat.

Glitter varnish has increased decorative possibilities. They can be holographic, iridescent, or imitating neon light. In the rays of reflected sunlight or electric light, such coatings look charming.

Stepping aside a bit, it should be mentioned that there is even a varnish for printed circuit boards. It is unlikely that anyone will consider these details, except for repairmen and specialists. Therefore, they are covered exclusively for protection from water. The required mixture is formed by mixing polyurethane and epoxy components, but technologists are actively working on obtaining simpler one-component mixtures.

Sometimes varnish is applied to the walls under alkyd paint - in this case, the appearance of a smell will not be a critical moment

It is important to remember that alkyd and acrylic components do not tolerate each other. If they are used in any combination, then swelling inevitably appears, and soon the painted surface will look completely ugly.

The polyester composition differs in that it forms an insoluble film on the surface, the thickness of which ranges from 300 to 400 microns. For the most part, such mixtures are applied by spraying or pouring installations. If you polish the surface, it will quickly take on a mirror-like appearance.

Luminous (luminescent) wall varnish belongs to the category of specialized mixtures - such paintwork materials create impressive effects, but it is recommended to entrust all the work to professionals.

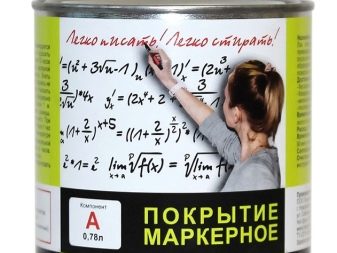

The highlighter transforms any surface on which it is applied into a kind of real whiteboard.

Choosing a varnish for wood: important criteria

In order to reliably protect wooden surfaces, you need to know what requirements must be met for paints and varnishes.The varnish must have several main qualities, these include:

Wear resistance. For different surfaces always choose "their" material

For example, for wood floors, it is important to assess the expected load level. If it is not high, then the owners just need to purchase an ordinary varnish.

However, a large amount of furniture, the same permeability (for example, in hallways) are conditions that force you to choose a material that has increased wear resistance.

Color or transparency. If the wooden surface has small defects, then they buy a colored material, or add pigment to a colorless varnish. A small proportion of the coloring matter will preserve transparency, but give the wood a light shade. Colorless formulations are recommended to be applied to elements of ideal quality. This is an opportunity to preserve the structure, the appearance of a natural material.

Components included. All varnishes are divided into one- and two-component paintwork materials. In the first case, the solvent evaporates, and the remaining material forms a strong film. In two-component materials, two ingredients react - a solvent and a hardener. Thanks to it, more reliable protection of the tree is guaranteed.

No less important is the smell, or rather, its absence. Heavy, harsh "aromas" will adversely affect the well-being of people and animals, so not all types are recommended for use in living quarters. For interior work, the best option would be water-based varnishes. Any product is suitable for outdoor decoration.

Other characteristics

These include:

- Shine. With the help of the material, you can get both matte and glossy surfaces. In this case, the choice of wood varnish depends on the preferences of the owners. Gloss adds volume to the surface, while matt lacquers emphasize the texture of the wood better.

- Fire safety. A heat-resistant varnish should be selected if there is a risk of surfaces burning. Protection is especially necessary for those rooms where electrical heating devices are located.

- Drying period. Many paintwork materials can dry for a very long time, others need an hour. Therefore, the varnish must be selected depending on the surface to be treated.

- Environmental friendliness is a mandatory requirement for premises, especially when wood processing in children's rooms is to be done. In this case, there is only one option - water-based varnishes.

Choosing a varnish for wood with the current abundance is not an easy task, especially when it comes to the exterior of a building. If you plan to buy material for processing wood indoors, then the best contender is still a water-based varnish. These compositions are absolutely safe, but at the same time have good technical characteristics, guarantee the aesthetics and durability of the coating.

For a little more information on woodworking, watch this video:

Areas of application of aqueous acrylic varnishes

The high quality standards that meet the characteristics of water-based acrylic varnishes ensure a wide range of possible applications. Similar compositions are used both in repair and construction, and in decorative and finishing works.

Consider the main areas in which varnish is used.

- For interior and exterior work in wooden houses, glossy colorless and panel acrylic varnish are most popular. They are effective from an aesthetic and practical point of view, as they emphasize the natural beauty of natural wood and reliably protect it. The coating can be washed regularly, it is environmentally friendly and does not pose a danger to the human body.

- Interior decoration elements. Tables, chairs, sofa frames, stair railings - any pieces of furniture and other structures made of wood will last much longer if acrylic-polyurethane varnish was used for their processing.The strength of the composition prevents the occurrence of minor damage, which is why polishing from the moment of application will not be required more often than once a year.

- Strengthening the finishing wall covering. One of the reasons why water-based varnish is so in demand is its versatility in terms of surface material. Universal acrylic varnish is applied to painted walls, paper wallpapers, tiles and tiles. In all cases, the main goal is to create an additional protective layer that preserves the appearance of the interior wall decoration.

- Parquet processing. As a rule, dense and rough boards are used to create parquet flooring, therefore, for their processing, it is better to choose a matte colorless acrylic lacquer on a polymer-acrylic base. It will provide a more durable coating that can withstand heavy use. Considering how long acrylic lacquer dries, you can treat all floors in one room in just one day.

- To enhance the decorative effect of wood or other products. Modern water-based acrylic varnishes are an effective material for the final stage of processing wood or other products, which can emphasize their beauty. When applied to wood, the composition actively penetrates into the pores of the top layer and is securely fixed to the base.

- Protection of painting objects. Do not be surprised, professional artists, striving to prolong the life of their masterpieces, often use a transparent acrylic compound as a protective layer. It does not affect the brightness of paints and protects them from fading. By the way, another option for the creative use of acrylic varnish is decoupage. This designer find provides for decorative finishing of the interior with small drawings and patterns on a paper basis.

Colored varnish for wood is applied, as a rule, in three layers on the prepared surface with a brush, roller or spray

Typical defects when applying varnish to parquet

Varnishing is a very important stage in the arrangement of a parquet floor. The varnish not only emphasizes the beauty of the natural pattern of wood, but also protects it from moisture and mechanical wear.

Parquet varnishing

The application of varnish to the parquet is the last step in the parquet arrangement. The quality of the varnish directly affects the durability of the floor covering

Glossy or matte varnish?

The varnish is used to cover and protect wood. Glossy lacquer reflects light rays, giving the product a shine and making the grain of the wood more visible

The technology of applying varnish on the door leaf

And only after impregnation with a primer, you can start covering the door leaf with a transparent or slightly tinted varnish.

Restoration of windows with paints and varnishes

Restoration with paints and varnishes is a great way to return the window to its previous appearance, because after it the tree retains its texture and acquires an aesthetic appearance

How to properly varnish a tree

Knowing what kind of wood the product is made of, you can calculate the amount of varnish to properly varnish the wood

Alkyd varnish for wood. Description and application

Alkyd varnish for wood forms a hard, durable film with good adhesion, moisture resistance and can be used for both indoor and outdoor work

Removing varnish from wood. Job Description + Video

For more delicate work, such as the restoration of old furniture, wooden products, when working with which you need to remove the varnish without damaging the surface of the product, the so-called removal of varnish from wood by a chemical method or washing is used.

How to choose and use black wood varnish correctly

Black varnish for wood is most often used for processing furniture parts, so this composition should be chosen.

Wood varnish: how to choose

In no case should you come to the store and ask just a cheaper wood varnish.

news

LLC "StroyTechnoKhim"

LLC "StroyTechnoKhim" offers paints and varnishes for special purposes: ...

The Vapa company presents a new universal water-based varnish for wood

The St. Petersburg company "Vapa" has launched the production of a new water-based varnish for wood, ...

New urethane-alkyd varnish for wood from the St. Petersburg company

The St. Petersburg company "Vapa", specializing in the development and production of high-quality ...

High quality, environmentally friendly novelty for parquet finishing from the TBM company

The company "TBM" expands the range of products produced under the trademark "Lignum" ...

Novelty for decorative processing and protection of parquet from "YAK"

A new high-performance protective paintwork material for parquet has appeared on the domestic market, ...

New wood protective varnish from YAK

A new product under the Yaroslavl Coloring trademark has recently appeared on ...

ABC Farben presented a new decorative weather-resistant varnish for wood

Voronezh company "ABC Farben", one of the five largest domestic ...

Empils has launched a new product for wood protection

Empils has launched a new product for wood processing ...

Peculiarities

Varnish is a viscous solution designed to treat the surface of a material in order to create a reliable protective film. The treated surface can acquire a light or intense gloss.

The lacquer coating was first used in the 12th century by the German monk Theophilus. He strictly kept his recipe secret, only after many years in the course of research it was possible to find out that the varnish was created on the basis of alcohol. Since the 15th century, oil-based products have appeared. England is considered to be their homeland.

It was only in the 19th century that the manufacture of varnishes began in large quantities. Already in 1874, the production of oil varnishes of excellent quality was launched at the Russian plant of Osovetsky. Later, other varieties appeared.

Color spectrum

The main task of the paintwork is to create a durable coating and give it a color effect.

Using colored varnish has several advantages:

- protection from external factors;

- decorative function;

- the service life of the material increases.

Often for the interior, homeowners purchase glossy varnish - this applies to those rooms in which it is rather dark. The colorless appearance is one of the few examples where the natural structure of the wood is emphasized by the application of varnish.

For example, covering a parquet board with walnut-colored paintwork materials, you can get several different color effects. It can be beige, red, black or dark brown.

Home owners love to use tinting compounds as well. They cover doors, furniture, parquet. The wood gets an unsurpassed appearance, as well as resistance to mechanical stress. Blue, mildew and mildew will not form on this surface.

Selection and application

Not only saving time and money depends on choosing the right finishing material, but also the successful processing of the selected surface. Acrylic varnish is so unique and versatile that it can be easily used in any interior design with your eyes closed.

When processing wood, acrylic-based varnish has a practical and aesthetic effect. That only is the processing of a wooden floor! In the case of working with a solid rough board, it is necessary to choose options that form the most dense layer. Also, such a coating should easily withstand temperature fluctuations and be resistant to moisture. Acrylic varnish for parquet was originally created so that the coating was thin, transparent and almost weightless, but if rough boards are covered with this type of varnish, the floor will soon crack.It is worth remembering that you will not be able to quickly varnish the floor, because the first layer dries for at least 4 hours and at least 12 hours after finishing. In order to make the life of the craftsmen as easy as possible, the acrylic floor varnish was originally made white. When dry, it acquires perfect transparency, which gives a signal for the next layer.

For outdoor work, the application of this product is also applicable as a finishing. Resistant to sudden changes in temperature and mechanical damage, it allows the surface to retain its original pattern and shade.

Smaller projects also need acrylic varnish treatment. For example, it is very convenient to use it to cover stools and nightstands, stairs, railings and plasterboard walls, countertops, decorative interior items (figurines, frames, and so on). Even painting requires processing - it is worth covering the picture with acrylic varnish so that it delights longer with its bright primordial colors.

Due to the high cost of acrylic varnish, there are several ways to make your own wood varnish at home. The oldest and most common method is mixing acetone and foam. The consistency turns out to be jelly-like, not the most convenient for application, however, it is not inferior to store-bought ones in its durability and wear resistance. You can use this mass for treating small areas of the surface or for applying a protective layer to decorative interior decorations made by yourself.

Decoupage can be considered another creative area of application of acrylic varnish - decorating various interior items with pieces of paintings, drawings, ornaments and monograms on a paper basis.

Classification of varnishes for parquet boards

Paints and varnishes are classified according to different parameters:

- Method of application, there are varnishes for outdoor and indoor use.

- Technological properties - viscosity, hiding power, fluidity, application method.

- The ability to tint wood (completely colorless, giving additional and saturation to the texture, colored and dark pitch varnish with a golden sheen).

- Resistance to stress and abrasion, resistance to adverse conditions, chemicals and temperature fluctuations.

- Duration of operation.

- The chemical composition (on a different basis) and the method of polymerization.

- The degree of light reflection (matte, glossy, velvety, silky, semi-matt varnish).

- Environmental safety and recyclability.