Views

It is customary to distinguish three main types of varnish.

- Polymeric. One of the most popular for indoor and outdoor use. Makes the treated surface wear-resistant and durable. It does not require a long drying time, it is quite easy to use.

- Polyurethane. It is very similar in quality characteristics to the polymer look. Its main advantage is its high moisture resistance. That is why it was mainly used in conditions with high humidity. Not bad for outdoor work, saunas, swimming pools, garden paths, sidewalks.

- Acrylic or silicone. The main difference from the above-described types is their decorative effect. They are mainly used for interior work in an apartment or a private house. Quite expensive materials, you should not use them for the street. They cope well with the tasks set, strengthen the surface, and additionally increase its moisture resistance.

All of the above types are classified according to the type of varnish composition. In terms of decorativeness, there is also a division into several types: glossy and semi-gloss, matte and semi-matte. If the first two types are used to create a beautiful coating with a wet stone effect, then the second are more suitable for rooms with high traffic. For example, airports or train stations. Small scratches on the matte surface are less conspicuous.

Polyurethane

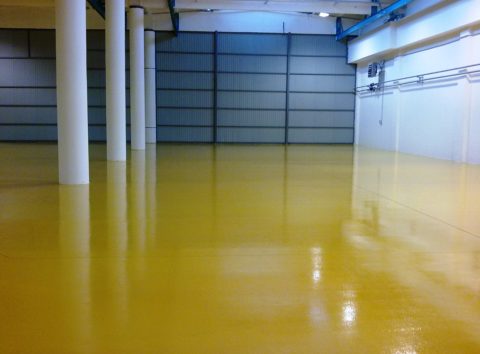

This type of concrete surface coating is the most popular. Strengthening properties and fast, easy penetration into the surface are its distinctive advantages. It fills in microcracks, which increases the strength of the concrete screed. It is used in conjunction with an impregnation of an identical composition, this increases the effectiveness of the varnish itself at times.

Together with it, the impregnation is applied for better adhesion to the surface. Increases resistance to moisture and wear resistance. This, in turn, significantly increases the service life of the entire coating, be it floor or wall. This type of varnish is mainly used for outdoor work.

The advantages of this type of material are that it is resistant to oil, chemical oils, process fluids. It is quite easy to use, but at the same time it has high decorative performance. In addition, during wet cleaning, the qualities of the varnished surface are not lost. Thanks to them, this varnish is often used to protect concrete floors in production areas, in livestock and farms, in utility rooms.

Polymeric

This look also enhances the properties of the concrete surface, resulting in a coating with excellent performance characteristics. Unlike polyurethane varnishes, polymer more repels moisture and resists aggressive external environment. The surface after processing acquires increased strength and durability. We should also note the speed of drying, which allows you to process large areas in a short time.

The basis for the manufacture of such a varnish is styrene, which gives the treated surface additional resistance to chemicals and high strength. The most common material is Teksol, a polymer varnish for stone and concrete. In addition to the listed qualities, it protects well against corrosion. In construction, it is most often used in the processing of paving stones, brick curbs, decorative elements. "Texol" increases the time of use of the coating, it is easy to apply, resistant to atmospheric influences, practically does not wear off.

Silicone and acrylic

These two types are the most expensive in comparison with analogues.But this can be compensated for by the low consumption of compounds per square meter of the treated surface. Work on the application of paintwork materials can be carried out without interrupting the production process. After processing the concrete surface with this composition, it acquires a matte shade.

Sometimes water-based varnish is also used for concrete. It is usually colorless, more often used for decoration. Nevertheless, this type is preferable for protecting wood surfaces. There is also an epoxy varnish based on epoxy resins. This is a two component formulation and must be mixed before use.

Selection rules

When choosing a varnish, you must adhere to several basic rules.

Don't skimp on consumables. Buy products from trusted and trusted suppliers

A certified product is a guarantee of high-quality results and long service life.

If you find it difficult to make a choice among a huge assortment, pay attention to popular and demanded brands. The brands "Texol" and "Tystrom" have earned the trust of buyers.

Each train has its own expense

You need to know it in order to purchase the required volume of products.

Pay attention to the technical characteristics: thermal protection, abrasion resistance, wear resistance, resistance to cold, moisture, heat. The service life of the treatment and its practicality will depend on the correct choice.

The external effect is also important

For some rooms, a matte texture is better, for others - a glossy one. Also, customers have the opportunity to choose semi-gloss and semi-gloss compositions. Matte outdoor lacquer will make the exterior softer and more versatile, and will also create a great backdrop for landscaping. While the glossy texture will attract attention with the play of light and shine.

Types of varnishes for processing stone surfaces

- Polymer varnish for stone. Among the most popular paints and varnishes for indoor and outdoor use. It has excellent strength, moisture resistance, wear resistance. It adheres well, dries quickly, has high adhesive properties.

- Polyurethane varnish for concrete. In terms of performance characteristics, it is little different from polymer coatings. The main advantage is water resistance. It is better to varnish with this agent where surfaces are constantly exposed to high humidity. Ideal for exterior facade work, stone processing in swimming pools, paving slabs.

- Silicone and acrylic compounds. They have a high decorative quality, which distinguishes them from polymer and polyurethane mixtures. More often used for interior work. Among paints and varnishes, they are among the most expensive goods. Therefore, it is irrational to use acrylic or silicone varnish for mineral materials in outdoor decoration and for varnishing large areas. Nevertheless, the products have increased wear resistance and durability.

Polyurethane protects well from moisture, therefore it is more often used in outdoor work or in rooms with high humidity.

Polyurethane protects well from moisture, therefore it is more often used in outdoor work or in rooms with high humidity.

Polymer varnish

This type of protective agent is used for coatings with mineral components. These include bricks, concrete, etc. The main features of the polymer composition are decorative properties and increased wear resistance. The substance resists cold and moisture well.

Over time, stones coated in this way do not fade and retain their bearing capacity. Most often, polymer compositions are used in construction for external facing work. They can be used with natural materials and artificial products.

Surfaces coated with polymer varnish do not fade and retain their bearing capacity

Surfaces coated with polymer varnish do not fade and retain their bearing capacity

All polymer varnishes are made of one-component substances that can dry much faster than other solutions. This is due to the small proportion of water components.Due to this, the substance can even be used for gypsum products.

The structure of the substance allows to achieve a matte effect upon application. This is especially noticeable when adding paint to the composition of solutions. Thus, you can achieve the appearance of any product with a design.

Polyurethane varnish

The substance can be used for all types of materials used in the construction of buildings. The solution is an oligomer with polyurethane components. The consistency is added to an organic solvent. As a result, the substance forms a transparent film during hardening. Adding paint can change the color, which is useful for matching textures of the same type.

This type of varnish is used for outdoor use. Lacquering products with a polyurethane substance allows you to achieve the effect of a wet stone.

Polyurethane varnish allows for a wet stone effect

Polyurethane varnish allows for a wet stone effect

High protective properties, make it possible to use the agent for coating concrete and brick. The properties of the material are excellent for artificial and decorative items. When they are combined, durability and wear resistance are significantly increased.

The advantage of polyurethane varnishes is their high moisture resistance. Therefore, it is rational to use such means to protect concrete, thereby increasing the anti-corrosion properties of the structure and overall waterproofing.

Silicone acrylic varnishes

The most popular protective equipment when working with interior decoration of buildings. The substance is suitable for decorative products made of stone, brick and other materials. Due to its special properties, the construction, coated with a silicone-acrylic agent, does not turn yellow over time. Also, the substance forms a film that provides protection against moisture.

The base of the solution is acrylic acid with the addition of acetylene. Thanks to this, the varnish is odorless, safe for use in rooms with people living and has high protective properties.

It can be used with any material, even plaster or metal. The addition of special paints allows you to achieve the required texture and scale. Most often it is used for working with artificial materials.

Acrylic based varnish can be used for interior decoration

Acrylic based varnish can be used for interior decoration

The use of silicone acrylic varnishes is not recommended for outdoor use. The protective characteristics do not differ much from polymer or polyurethane substances, but the cost is an order of magnitude higher. The most rational use of acrylic and silicone varnishes is wall coverings made of artificial material and concrete floors, which are subject to severe wear.

Polymer varnish for concrete, stone, brick with the effect of "wet stone"

- versatility and ease of application

- extremely high weather resistance

- provides wear resistance and low abrasion

- protection of concrete against corrosion

- excellent decorative qualities

- has a "wet stone" effect

- semi-gloss

- after 3 hours - small order

- the next day - a big order

- 3-5 work. days - for goods made to order

- free - for orders over 500 kg

- from 300 rubles. - for orders less than 100 kg

More details

- Description

- Application

- Specifications

- Documentation

- Reviews

Teksol is a wear-resistant polymer varnish for concrete, stone, brick and tile protection.

Varnish Teksol is a one-component fast-drying varnish based on acrylic copolymer and alkyd resin in a mixture of organic solvents with the addition of targeted additives.

Polymer varnish is recommended for use wherever there is a need to protect mineral materials (concrete, mortar, brick, stone) from corrosion. The varnish is both protective and protective and decorative (it has a pronounced "wet stone effect") with excellent characteristics in terms of wear resistance and abrasion.

Lacquer Texol forms a durable coating on the surface, resistant to atmospheric and mechanical stress.Polymer varnish has a universal set of properties. Among them, one should highlight such undoubted advantages as the ability to quickly cure and the ability to apply at subzero temperatures.

Appointment

Polymer varnish Teksol is used for protective and decorative finishing of concrete and mosaic floors, paving and facing tiles, natural and artificial stone, decorative paving stones, curbs, bricks and other surfaces exposed to atmospheric influences.

Wet stone varnish Texol is also suitable for production and storage areas for application to concrete floors.

Container 0.7kg, 2.5kg, 9kg, 18kg

Attention! The label is equipped with security elements against counterfeiting

Mode of application

The varnish is ready to use. If necessary, dilute to working viscosity with a solvent: solvent, butyl acetate, R-Universal.

It is applied to a dry cleaned surface with a spray, brush or roller in one or two layers.

Temperature range for varnish application: from -20˚С to + 35˚С.

Drying time, at a temperature of + 20˚C, is 4 hours.

Varnish consumption is 0.25-0.3 kg per 1 sq. M. depending on the type and type of surface.

What you need to know about varnishing a concrete base

Polymer varnish on painted concrete floor

Polymer varnish on painted concrete floor

For those who decide to varnish with their own hands a concrete surface of any plan - whether it be the floor in the garage or the countertop in the kitchen - you should know some of the features of the production of such work:

- the approximate temperature during varnishing should be +20 - +25 degrees on average;

- if work is carried out on the street, then it is advisable to choose a calm day, since a mass of dust and fine litter can stick to the not yet dried varnish;

- the number of layers depends on the type of varnish, but there should be at least two of them;

- layers are applied at intervals of at least 4 hours;

- complete drying of the paintwork occurs on average in a day.

Mock shoes

Mock shoes

It is impossible to list all the conditions for each particular type of varnish. They are contained in the instructions on the packaging or just ask the manager in a specialized store.

Concrete base varnish technology

The varnishing technology for each type of varnish is similar. Consider a simple and affordable way for everyone to reanimate an old concrete floor with painting, decorating with ordinary confetti and varnishing.

Before and after the repair of the concrete floor in the garage

Before and after the repair of the concrete floor in the garage

What is required to carry out the "confetti operation":

- any varnish for concrete;

- good detergent for cleaning floors;

- polyethylene;

- waterproofing tape;

- respirator;

- five-liter bucket;

- plastic spatula;

- concrete paint;

- cement paste;

- special primer;

- if desired, ordinary confetti, which can be cut from any shiny paper;

- special spatula with a rubber pad, as in the photo below for epoxy, or a roller with a brush for any other varnish.

Necessary kit for epoxy resin concrete flooring

Necessary kit for epoxy resin concrete flooring

So:

Stage 1. Thoroughly sweep all the debris from the treated surface.

Thorough cleaning of the concrete floor

Thorough cleaning of the concrete floor

Stage 2. We wash off all oily and other contaminants that are present on the concrete base. If they are old, just leave the soapy degreasing solution in place of the stains for a couple of hours, and then rinse thoroughly with water.

In case they are not removed, scrape them off carefully. At the same stage, cover all cracks and irregularities with cement paste. After the repair mortar hardens, which takes about a day, grind the concrete surface well.

Removing old grease stains from concrete floors

Removing old grease stains from concrete floors

Step 3. Treat the floor with a special primer and dry it.

Drying the primed floor

Drying the primed floor

Step 4. Glue waterproofing tape around the perimeter of the room, as in the photo below.

Waterproofing

Waterproofing

Step 5. Dilute the paint and paint the concrete surface. It may need to be reapplied.Depending on the paint, the application interval can vary from 4 to 24 hours. Sprinkle confetti on the final layer of uncured paint and let it dry completely.

Painting and decorating the concrete floor

Painting and decorating the concrete floor

Step 6. Apply the varnish to the floor using a roller. Depending on the type, a different number of layers will be required. For example, for acrylic varnish, two are enough, while for polymer varnish at least three. Wait for the last layer to dry - at least 24 hours later, and enjoy the result of your labors with pleasure.

Updated concrete floor in garage

Updated concrete floor in garage

You can see how concrete varnishing is carried out in this video.

As you could already see, concrete varnish is not only reliable, but also beautiful. With little effort and expense, you can create a very beautiful and durable concrete floor not only in your garage, but at home or in your garden.

Peculiarities

There are many types of varnish with different properties. It can be a varnish for high temperature surface treatment or with increased wear resistance, fire resistant or moisture resistant. However, each species has characteristics inherent in this particular material.

Let's consider the main features of the varnish.

- Easy to apply. This important characteristic allows the surface to be coated faster without wasting a lot of time.

- Versatility of use. This varnish is suitable for processing not only concrete, but also bricks, for example.

- Wear resistance. All types of varnish provide the treated surface with strength and resistance to all kinds of damage.

- Decorativeness. Any kind of material gives the surface an attractive appearance.

Concrete is one of the main building materials in the modern world. Large structures and small walls are erected from it, the floor is poured with it and various surfaces are finished. But its surface is vulnerable in its raw form. It can crumble, be chipped due to mechanical stress, and dust.

A special concrete varnish helps to cope with this. It is used after pouring, complete drying and gaining strength with concrete. The varnishing of the concrete surface significantly improves the quality characteristics of the material. The concrete surface acquires protection from moisture and temperature extremes, becomes stronger and more durable.

Most often, concrete varnish is used for fences made of concrete walls, in parking lots or car parks, in production, sidewalks or street screeds that are exposed to rain, snow, and temperature changes.

Lacquered concrete screed is much more durable than untreated concrete. The service life of the concrete surface is significantly increased. It acquires resistance to abrasion and low temperatures. The surface protected by the varnish composition looks much more attractive.

There are also separate classifications according to the degree of fire resistance or colors. However, like all other types, it is most competent to classify concrete varnish according to its basis.

The use of varnish compositions of different types

Stone varnish is a facing material that is in demand for several reasons:

- used both for indoor work and outdoors;

- weatherproof, tolerates temperature fluctuations;

- moisture resistant;

- high threshold of wear resistance;

- the resistance of the base to mechanical and physical stress increases.

Polymer varnish

In construction, lacquer polymer is often used. It dries quickly, with an increased level of water resistance, frost resistance, quickly covers a large area of concrete surfaces. Decorate a concrete floor or indoor surface. The appearance of the covering layer does not change throughout the entire service life, its brightness is not lost.

LK polyurethane

The base is covered with polyurethane varnish from any building material, including stone. For its use, polyurethane material is added to an organic solvent. After drying, a transparent film appears. In order for it to become colored, paintwork of the desired shade is introduced into the composition.

The polyurethane look is more often used indoors. It creates the effect of a "wet" stone.

Silicone and acrylic composition

Silicone or acrylic varnish is applied as a decorating layer. They are used indoors. The stone, brick surface is painted. Due to the high price, it is not profitable to use it outdoors. A coating of any color and desired texture is created. For this, a special paint is used as a component. Acrylic look is not thinnable with solvent.

Before using it, it is thoroughly mixed. Silicone and acrylic LM gives the surface the effect of a "wet" stone, increasing the wear resistance of the stone. A beginner in the painting business will cope with the work. The protective properties of the coating do not appear immediately, 1.5 months after application.

Epoxy varnish

The stone is rarely faced with epoxy LM. This is a mixture with two components, mixing takes place before application. A coating is formed that is resistant to chemical and physical influences.

LM coal

The product of coal coking is called a solution of coal tar pitch in oils. This group includes: "Kuzbass lacquer", bitumen composition BT-577. Coal varnish is produced in three grades. The choice of grade depends on the performance requirements for the coating, and not on the type of substrate. The coating is applied to concrete, stone, brick, wood, metal. The technical characteristics of the stone base are enhanced, the metal one is protected from corrosion, the wooden one is protected from biological damage.

It is used for external and internal works. A minimum of three coats are applied. The covering layer is completely ready for use after 22 hours. It is applied with a brush, spray, dipping technology is used. A semi-matte black film is formed. In a liquid state, it is a fire hazardous LM, has a specific smell of coal tar. You need to work with him in personal protective equipment.

Concrete varnish family

Protective varnish for stone surfaces

Protective varnish for stone surfaces

So, we got to the most important and interesting thing - the main criterion for choosing varnishes for a concrete surface. We consider their features and choose the most suitable one for our particular situation.

Acrylic and silicone resins as a base for varnish

Example of covering a plinth with acrylic-silicone varnish

Example of covering a plinth with acrylic-silicone varnish

Acrylic and silicone resins, which form the base for the varnish, enable deep surface treatment. Its composition is able to penetrate into deep layers of a stone or concrete surface, protecting it from moisture, various chemicals, oils, salts and all kinds of reagents.

Therefore, it is often this varnish that is used to cover swimming pools and floors around them. Acrylic varnish for concrete can create both a matte surface and a “wet stone” effect.

In the price category, acrylic varnish for concrete is the most expensive. But such a cost is due to its lowest consumption among other compositions and a short drying time. The best is considered to be a varnish based on acrylic and silicone resins of foreign production H&C Chatahoochee Sealer. But you can also choose no less high-quality counterparts from the Element, Wet Stone, Orion and others lines.

Polyurethane varnish

Concrete floor. Coating - colored polyurethane varnish

Concrete floor. Coating - colored polyurethane varnish

Polyurethane varnish for concrete today occupies a leading position in its economic niche.

And this is quite understandable by its excellent characteristics, such as:

- imparting increased moisture resistance to the concrete surface;

- creation of excellent wear-resistant performance;

- not susceptibility to oil products;

- there is an opportunity to carry out cleaning with soapy solutions;

- high decorative qualities;

- availability of application.

To such remarkable performance, it is necessary to add the fact that it is polyurethane varnish for concrete floors and other surfaces that has the lowest cost on the market for such products.

Concrete floor in a supermarket covered with polyurethane varnish

The most popular domestic manufacturer of such compositions is Thistrom - polyurethane varnish of this brand is used exactly where there are increased requirements for wear resistance and non-susceptibility to chemicals. Also an excellent varnish for concrete and stone Petri Concrete and Stone Sealer. It is characterized by a deep action and creates a "wet stone" surface.

Polymer varnish for concrete coating

Decorative concrete coated with polymer-based varnish

Decorative concrete coated with polymer-based varnish

Polymer-based concrete varnishes are also loved by many consumers.

In addition to the advantages of polyurethane varnishes, the polymer component gives concrete additional parameters, namely:

- strength, polymer composition penetrates up to 10 mm deep into the base, strengthening it;

- protection from moisture and any chemicals;

- the ability to operate in a wide temperature range from -60 to +90 degrees;

- service life up to 30 years;

- fast drying - the possibility of using the coating after a 10-hour exposure.

Teksol is the leader in the domestic market among polymer varnishes. This brand is associated with quality products that allow you to create a reliable and relatively inexpensive coating on a concrete base.

Epoxy varnish for concrete is a type of polymer composition. Although epoxy is most commonly used to coat wood and metal, it also works well on concrete to form a very durable and beautiful shell. When installing self-leveling floors, it is epoxy resins that are used. The highest quality epoxy varnish is produced under the Nanten brand.

Epoxy resins for concrete floors

Epoxy resins for concrete floors

In the price category, such polymer varnishing compositions occupy approximately the same positions with polyurethane varnishes. Although, you can find compositions and 2000 rubles. for 1 kg.

Water-based varnish

Water-based varnish applied to concrete

Water-based varnish applied to concrete

Water-based varnish specifically for concrete is rare. As a rule, such compositions are intended for the protection of wooden coatings. Less commonly, an aqueous paint and varnish composition is used for decorative painting of concrete surfaces. The most striking example of such products is PaliStone FP varnish.

It is a waterborne polyurethane varnish with no deep action. It protects only the concrete surface from moisture, giving it an excellent glossy "blush". The price for such a varnish is considerable, although it is fully justified by the quality of the resulting coating.

We carry out delivery in Moscow and Russia!

You can receive your product tomorrow! After placing an order, a manager will contact you to agree on the terms of delivery.

Delivery time and time:

- Orders placed before 17:00 - on the next business day (for some goods, after one business day)

- Orders placed outside working hours after 18:00 or on weekends - after one working day (in some cases after two)

- Possibility of delivery of the order on the same day (agreed with the operator)

Low shipping cost!

- Delivery 400 rub. for orders from 1800r. (Moscow + 5 km. From MKAD)

- Delivery 800 rub. for orders up to 1800r. (Moscow + 5 km. From MKAD)

- Free delivery from 10000 rub. (except for products of the category "Plumbing")

Delivery all over Russia

Sending through transport companies to any city in Russia and the CIS countries. Receipt of goods in your city within a few days, depending on the selected transport company and the distance of the delivery region. The cost of delivery to the transport company is calculated as the cost of delivery in Moscow (see above)