Concrete porch - preparatory work and calculations

Before starting work, it is necessary to complete a set of preparatory measures:

- Dismantle the existing entrance structure.

- Free the area of work from construction debris.

- Measure the distance from the zero mark to the door threshold.

- Calculate the height of the steps by dividing the height of the platform by their number.

- Calculate the dimensions of the door platform, focusing on the width of the door opening.

Before buying materials and tools that will be needed in the work, you should initially decide on the type and shape of the porch being made.

Determining the minimum possible dimensions of the site, it is necessary:

- add 15–20 cm to the width of the door opening;

- the depth of the structures must be at least 100 cm.

At the design stage, it is necessary to decide on the following parameters:

- the configuration of the entrance staircase;

- constructive performance.

The shape of the entrance staircase may resemble the following figures:

- trapezoid;

- circle;

- square;

- rectangle.

Execution options:

- open access;

- in a closed version;

- with glazing;

- with railings;

- without railings.

The size of the area in front of the entrance to the house should be such as to ensure optimal opening of the front door

When carrying out work on the design of the entrance staircase, you must pay attention to the observance of the recommended dimensions, which should be:

- entrance width - 0.8-1 meter and more;

- staircase slope - no more than 40-45 degrees;

- step width - more than 250 mm;

- the distance between the steps is 16–20 cm;

- overhang of the step support platform - up to 30 mm;

- the distance from the door opening to the level of the upper platform is up to 50 mm.

Before starting manufacturing activities, remember the main rules:

- the depth of the foundation for the main staircase must correspond to the distance from the zero mark to the lower plane of the base of the building;

- the entrance staircase to the house should be a single structure with the building, which is ensured by mutual reinforcement with steel bars;

- the durability of the concrete structure depends on the brand of the solution used, as well as the high-quality waterproofing.

Compliance with these recommendations guarantees a long period of use.

Shapes and lines of the concrete base must match the architectural style of the house

This is interesting: How to get rid of basement fleas in an apartment - what you need to know

Technologies by which a porch is made of concrete

There are only three of them:

Reinforced concrete products (foundation blocks, slabs, flights of stairs, curbs, tiles) of industrial production are used. This approach speeds up construction, but is not always suitable.

- It limits the possibilities of the designer, fetters his imagination. The porch, assembled from prefabricated structures, almost never fits into the architectural appearance of the building. Therefore, the method is rarely used for small buildings.

- There is only one advantage: for the prefabricated device of the porch made of concrete, the estimate is less than that of other options.

- Although, if the prefabricated elements were made specifically for the entrance to a particular building, then everything may look good - for example: the entrances of serial prefabricated reinforced concrete houses.

Precast porch in panel house

Precast porch in panel house

Monolithic reinforced concrete. Most attractive technology. The shape and dimensions of the porch are limited only by the design capabilities of the material: its strength and the skill of the carpenter when arranging the formwork. The monolith is most often used for small houses and cottages, especially when building a porch with your own hands.

Monolithic porch option

Monolithic porch option

Prefabricated monolithic porch.In this case, both industrial parts are used, for example: staircases, columns, and monolithic concrete. The price for this construction is the average between the first and second options.

Blanks for industrial production steps that can be used for a prefabricated-monolithic porch

Blanks for industrial production steps that can be used for a prefabricated-monolithic porch

Note that concrete is often used in combination with other materials - for example, tiled.

Porch cladding option

Porch cladding option

How to choose the size and shape of the porch

The form can be very diverse

The form can be very diverse

Let's immediately determine the size. First of all, it depends on them how the drawing of a concrete porch will look like.

Now we are talking about the most common rectangular structures - if they are semicircular, or of a more complex shape, then everything should correspond to the rectangles inscribed in them.

- Naturally, the height of our porch is always equal to the height of the lower edge of the door to which it adjoins. Sometimes the porch is made a little lower so that there is a threshold, but this is undesirable and inconvenient.

- The width must be at least the width of the doorway. But it is desirable a little more, more precisely, not less than 0.2-0.5 meters wider than it. If you want even wider - please, no one bothers to combine the porch with the terrace.

- Length (distance from the edge of the porch to the wall). There are no restrictions here, but they take into account the height of the porch itself. It is necessary that there be a flat area in front of the entrance, and a non-steep staircase (about the dimensions of the stairs a little lower).

- The area in front of the door should be such that a trolley or stroller can be placed on it. Therefore, it is desirable that its edge recedes from the wall by 1.5 meters. And if the porch is not wide, and you cannot put anything on the side so that it does not interfere with opening the door, then more. You can reduce the length by planning the stairs not perpendicular to the wall, but parallel. Sometimes, when it is necessary that the porch adjoins an already finished path or sidewalk, it is specially lengthened.

- Ladder dimensions. The width of the stairs should be such that a person can easily walk along it - or, preferably, two people miss each other. Therefore, do not make it less than 1 meter.

- How to make concrete steps for your porch? - it is enough to fulfill several requirements. The height of the steps should be no more than 15 cm so that any person, including children, can easily overcome it, if you do less - increase the size of the porch. The width is not less than 25 cm, but not more than 32 cm. Moreover, it should not be increased in any case, since this will not only make the stairs longer, but also walking on it will become uncomfortable. People are accustomed to the standard, and with wide steps, the step is lost.

Be sure to make a ramp in addition to the stairs with an optimal slope of 1:20. This is necessary not only for people with disabilities, but also for those who are quite healthy. It is inconvenient, for example, to drag a bicycle, stroller or bag on wheels up the stairs.

Comfortable porch with a ramp

Comfortable porch with a ramp

Now a little about the form:

- There are no restrictions here - the main thing is that the project of the concrete porch fits well into the architecture of the house.

- A cover, parapet or side walls are welcome (it is inconvenient to open a door lock in the rain or in the wind). In addition, they provide the best conditions for the materials from which the porch is made.

- Everything should look like one whole. For example, it is extremely inappropriate against the background of a house made in austere, almost modernist forms, a porch with an elaborate staircase shape, an arch and railings on carved balusters.

Soil preparation, site preparation and structural analysis

Clean the area for pouring the porch from debris, and then measure the distance (height) from the ground surface to the threshold of the front door. According to the height, calculate the number and height of the steps. The recommended step height is 150-180 mm with a width of 250-320 mm.

Next, you should calculate the dimensions of the porch platform in the plan.In this case, the minimum width of the area under the porch is equal to the width of the doorway + 150 mm, and the minimum depth is 1000 mm (1 meter). The configuration of the porch can be different: square, rectangular, semicircular or multifaceted.

We mark the perimeter of the porch using pegs and twine. Around the perimeter of the future porch, it is necessary to dig a pit for the foundation of the structure. The depth of the pit depends on the depth of the groundwater, but not less than 0.5 meters. Further, a "pillow" consisting of 20 cm of crushed stone and 10 cm of sand is poured into the pit. The pillow is well rammed and spilled with water to seal.

The next step is waterproofing the foundation. At home, you can use dense plastic wrap or roofing felt as waterproofing. After finishing laying the waterproofing, reinforcement is installed and the foundation is poured with concrete mixed in the following proportion: 1 part of cement, 3 parts of sand, 3 parts of crushed stone + 0.5 part water (roughly). The poured foundation is planned according to the level, it is well rammed until it is imposed on the surface water, after which it is allowed to stand for at least 72 hours at an ambient temperature of 18-20 degrees Celsius.

How to build a porch?

The rectangular porch is most often used in private homes. Its construction involves the correct implementation of markings and the construction of complex formwork. Therefore, before starting to figure out how to fill the porch with our own hands, we will devote a little time to these issues.

How to make markup

The device of the porch in the country begins with a marking. It is carried out according to the "Egyptian triangle" or "two curves" method.

Layout scheme using the "two arcs" method

Place two pegs on either side of the door at a distance equal to the width of the porch. Measure from one of them equal distances to the right and left. Stick a rod into these places. Tie a rope to one of them with a nail attached to its end and draw an arc along the ground. Tie a rope to the second bar and draw another semicircle. Connect the intersection of the arcs with the peg and measure the width of the porch on the resulting line. Put another stake in the corner you found. Find the point of the fourth corner in the same way.

Use an inelastic cord to tie all the pegs together by pulling them tighter.

Installation of formwork and reinforcement

The construction of a concrete porch begins with digging a pit 30 cm deep according to the markings made. Tamp down the soil well at the bottom. Pour in 10cm of crushed stone and carefully level the surface. Place the first level of plank formwork in the pit. Ultimately, it will look like this:

Concrete porch. Formwork photo

Next, reinforcement is performed. The armature is knitted using 12mm wire.

Tip: Place the reinforcement on 5cm thick blocks located at the bottom of the pit. Thus, when pouring, a layer of concrete is formed under it, as a result of which it will not lie directly on the rubble and rust.

The armature is knitted using wire

Further, the formwork of the next levels is exposed. Tie and place the reinforcement in the future steps and the upper platform. Fasten all the reinforcement segments together. The top of the metal frame should not reach the surface of the future upper platform of the porch from below, also by 5 cm.

Tip: It is not necessary to tie the porch and the foundation of the house rigidly. Otherwise, during spring heaving, it may crack. Place a 2.5cm board shield impregnated with bitumen between the plinth and the staircase

It is important to make the landing area perfectly horizontal.

All elements of the porch must be reinforced

Of course, it is not necessary to make a porch of exactly this shape. Very common are, for example, structures in which the steps protrude only forward, and on the sides there are sides made of brick or cement to the full height. In general, what and how to make the formwork for the porch is a question that depends solely on the imagination and desires of the owners of the house themselves.

Concrete porch.Photo of a fairly common design with bumpers

How to fill a structure with concrete?

The production of the porch is continued by pouring concrete into the formwork. Experts advise to perform this procedure in one go. Be sure to fill the porch with tamping the solution and thus removing air bubbles. To do this, it is best to use a vibration trammer.

Concrete can be shoveled into the formwork

Tip: How to properly fill the porch of a house if this tool is not at hand? In this case, tamping is done by piercing the solution with a shovel or a wooden stake.

It will be possible to remove the formwork in a few days after pouring. However, you should not start walking on the porch earlier than a month later. The fact is that concrete finally gains strength only after four weeks. For the first fourteen days, you need to moisten its surface with water daily. This will prevent cracking of the upper concrete layers.

The formwork can be removed after a few days

Round porch made of concrete

A semicircular monolithic porch is made in the same way as a rectangular one. The only difference is in the form of the formwork. In this case, instead of a board, you can take a thick sheet and bend it in a semicircle. In this case, it is also possible to make the formwork for the porch from concrete from plastic.

The semicircular staircase in front of the house looks very original

DIY concrete porch

This construction will be monumental; in terms of reliability, it surpasses even brickwork. And if it is decided to make a concrete porch with your own hands, then you should prepare the materials in advance:

This construction will be monumental; in terms of reliability, it surpasses even brickwork. And if it is decided to make a concrete porch with your own hands, then you should prepare the materials in advance:

- boards (not rotten) for the construction of formwork - their thickness should be such that it could withstand the mass of concrete that will be poured;

- sand, cement and crushed stone - concrete mortar will be prepared from them;

- metal rods with a cross section of 10 mm - they will become a reinforcing device in concrete.

Underlay for a concrete porch

This is the first step in building a concrete porch with your own hands. And there is nothing complicated here:

- We pour a layer of sand directly onto the ground - its height should be 10-15 cm.

- Thoroughly ram the sand, for a better effect, you can moisten it with water.

- Pour a layer of medium fraction crushed stone on top.

- Thoroughly ram and rubble - so that it "drowned" in the sand.

Foundation for a concrete porch

You can make a columnar foundation - in principle, the structure being erected does not differ in its enormous weight. But for this, you will need to erect pillars (pour them out of concrete using formwork and reinforcement), then wait for them to dry completely ... In general, this is a waste of time, and of finance, by the way, too. We propose to make the foundation directly on the substrate, which has already been equipped with sand and gravel. Everything is simple here - a mesh of metal rods is laid on top, and the compacted layers of the substrate are simply spilled with cement mortar and leveled.

You can make a columnar foundation - in principle, the structure being erected does not differ in its enormous weight. But for this, you will need to erect pillars (pour them out of concrete using formwork and reinforcement), then wait for them to dry completely ... In general, this is a waste of time, and of finance, by the way, too. We propose to make the foundation directly on the substrate, which has already been equipped with sand and gravel. Everything is simple here - a mesh of metal rods is laid on top, and the compacted layers of the substrate are simply spilled with cement mortar and leveled.

Such a lightweight version of the foundation will be able to withstand both the concrete porch and the load on it. And it will be possible to start work on the construction of steps and a platform literally in a day.

Formwork and steps

Before exposing the formwork, be sure to calculate the number of steps, recalling the dimensions of each of them recommended by experts (height - 15-18 cm, width m - 25-30 cm).

Please note: the extreme step or the platform should be located 3-5 cm lower in relation to the front door.This will prevent problems with opening / closing the last

And experts also recommend making a concrete porch with a width of 80-120 cm - so even people "with a wide bone" can feel comfortable on the structure. The number of steps is always taken to be odd - 3, 5, 7.

All calculations have been made - you can start building the formwork. There is nothing complicated in the process, just follow the recommendations below:

- boards are taken with a size of 20x150 mm;

- you can use sheets of thick / thick plywood;

- be sure to prepare and immediately fix the spacers on the formwork - they will prevent deformation of the tree and provide perfectly even steps after the cement mortar has dried;

- between each other, the formwork boards are fastened with nails in such a way that they can be bent by at least 10 mm;

- it is necessary to make a frame from reinforcement - this will strengthen the entire structure of the concrete porch;

- there should be about 5 cm of free space from the formwork to the edge of the reinforcement;

- the reinforcement frame should follow the shape of the steps.

Please note: you can attach the metal rods of the frame to each other by welding or twisting them with wire. What specific method of fastening will be chosen is a purely individual matter, and this does not affect the reliability / rigidity of the structure

As a result of all actions, a structure should be obtained that is identical to the image in the photograph:

As a result of all actions, a structure should be obtained that is identical to the image in the photograph:

That, in fact, is all - it remains only to pour concrete into the formwork, level it from above with a shovel and wait for it to dry completely. After the concrete dries a little (it will take about 10-20 hours), you need to gently use a rubber mallet or a vibrating tool to walk along the formwork boards - this will allow you to easily "bare" the concrete steps.

If rain is expected, then the entire structure should be covered with plastic wrap - the drying time of the concrete porch is on average 8 days.

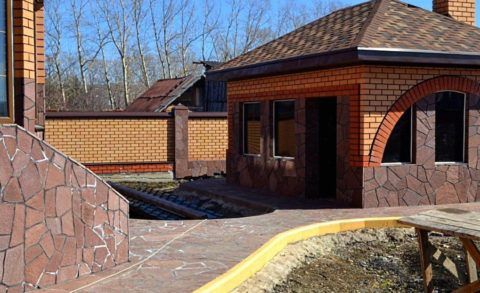

Concrete porch decoration

The finishing of the concrete porch must be present without fail - well, hardly anyone will like ordinary gray concrete. You can use decorative tiles for finishing, you can make a mosaic panel, some prefer finishing "Dagestan" - the choice of finishing materials on the market is huge. And this very choice must be made on an individual basis - it is difficult to advise something.

The finishing of the concrete porch must be present without fail - well, hardly anyone will like ordinary gray concrete. You can use decorative tiles for finishing, you can make a mosaic panel, some prefer finishing "Dagestan" - the choice of finishing materials on the market is huge. And this very choice must be made on an individual basis - it is difficult to advise something.

Whatever material you choose for finishing the concrete porch, you should know - you can start such work only 28-30 days after the completion of the construction of the concrete porch with your own hands. Of course, for each climatic zone, this period will change - for example, in the southern regions, finishing work can begin in 10-15 days, but in areas with a humid climate and low temperature regime - no earlier than 35 days.

Formwork assembly algorithm

The frame must necessarily repeat the shape of the future structure. It must be durable and reliable. To assemble the formwork, you will need to prepare plywood and boards. You can also use metal sheets and bricks.

What dimensions should the boards have? The width of the boards for assembling the frame is 20 cm, and the thickness is at least 2 cm. First, it is necessary to install the sides, after which the supports are installed. Next, the steps are assembled.

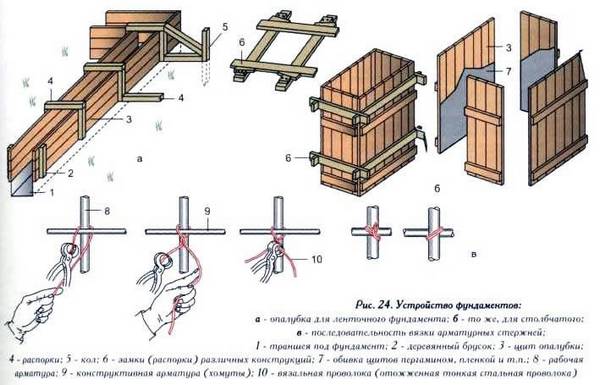

Methods for fixing the formwork and tying reinforcement

Methods for fixing the formwork and tying reinforcement

Important! The individual formwork elements must fit snugly together. If there are cracks, the water that is part of the concrete solution will flow out through them.

Assembly of formwork and reinforcement cage Fiberglass reinforcement. The next step is to insert the reinforcement into the inner space of the formwork.

The optimal pitch for the rods is 20 cm.The last stage of the formwork assembly takes into account the filling of the frame with soil (outside), which is subsequently compacted

The next step is to insert the reinforcement into the inner space of the formwork. The optimal pitch for the rods is 20 cm. The last stage of the formwork assembly takes into account the filling of the frame with soil (outside), which is subsequently compacted.

Construction stages

When the drawing is ready and all the calculations are done, you can start building. It has several conventional stages, laying the foundation, installing the formwork, reinforcing, preparing and pouring the mortar, facing.

Porch to a wooden house.

Laying the foundation

There are several options here.

The safest way, of course, is to fill in a common monolithic reinforced slab over the entire quadrature of the structure, but the price of this option will be quite solid.

- Most often, a strip foundation is poured along the perimeter, and the inner space is filled with sand or gravel. The depth of the laying should be at the level of the depth of the foundation of the house or below the freezing point of the soil by 150 mm.

- Ideally, it is better to plan a reinforced concrete porch even before pouring the foundation of the house, so that they form a single whole, then no frosty heaving of the porch is scary.

- In places with a high level of soil freezing, you can mount a strip-column foundation. In this case, the slab or tape is laid to a depth of 40 cm, plus support concrete pillars are made at the nodal points 30 cm below the freezing of the soil.

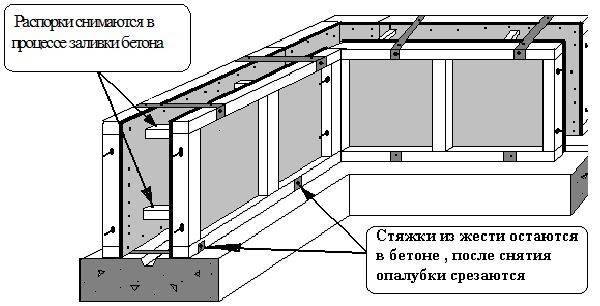

Formwork installation

The simplest formwork reinforcement.

- Traditionally, formwork can be equipped with sheet metal or thick plywood, USB boards and wooden planks. The price of the iron formwork "bites", plus it is heavy. Therefore, most often it is mounted from wood materials.

- The size of the side sheets is selected taking into account the immersion in the ground to the blind area. They are reinforced with stiffeners and struts. From the inside, after the installation of the reinforcement, the riser limiting strips are installed and fixed to each other and to the side plates of the strip.

- As for the reinforcing cage, its scheme should also be drawn in advance in the sketch. The entire structure is reinforced with at least 2 layers of reinforcement with a step of 100 - 200 mm. The optimal section of the rod is 12 mm here. The structure can be welded, but it is often faster to tie it with strapping wire.

- The installation of the formwork should be taken seriously, since if you fill in the curved structure, you will need to cut the reinforced concrete with diamond circles to correct the defects, and this is expensive and time-consuming.

Concrete additive.

Pouring solution

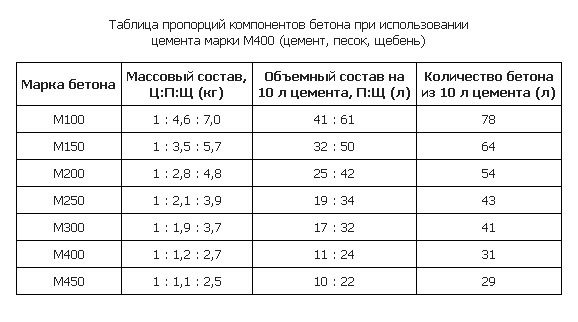

The reinforced concrete porch does not belong to objects with increased load, therefore, concrete of the M200 brand is enough for it. If cladding with porcelain stoneware or other durable material is planned, then you can do with the M100 brand.

But it should be remembered that the lower the grade of the solution, the longer it will harden.

The ratio of the components is shown in the table below.

The ratio of the components in the solution.

- As a rule, concrete is prepared directly on the site, it is better to use a concrete mixer, it is difficult to mix it manually with high quality. For compacting concrete, it is convenient to use a submersible electric vibrator, which can be rented or bayonetted with rods by hand.

- To increase the plasticity of concrete, people are advised to add slaked lime and soapy water or detergent. But we recommend buying a special additive for concrete, it can improve all the characteristics of the composition by an order of magnitude.

- It is recommended to remove the formwork no earlier than after 3 days, but concrete gains strength within 27 days. Moreover, during this time, it must be regularly moistened.

Submersible electric vibrator.

In the video in this article, you can find some more useful tips for yourself.

Concrete porch cladding

Concrete surfaces can be finished with a variety of facing materials. Let's list the most popular ones and provide a few photos.

Variety of ceramic tiles

Variety of ceramic tiles

Ceramic tile. I would especially like to note the clinker grades, which are almost the best option for cladding

Such a porch will always attract the attention of the viewer, and will delight the owner with its appearance for many years in a row.

Porcelain stoneware steps

Porcelain stoneware steps

Another popular material with excellent performance characteristics. Such tiles can imitate various natural materials, and also have a large assortment of colors and textures.

Natural stone tiles

Natural stone tiles

Made of concrete and molded to imitate natural stone.It fits like a regular tile.

Concrete tiles

Concrete tiles

Rough concrete tiles go well with equally heavy facades.

Polished concrete

Polished concrete

But to this state, you can polish the concrete. Such a coating does not need maintenance for many years.

A natural stone

A natural stone

Rough natural sandstone is solid, beautiful, and most importantly practical. This solution will very well fit into the facade of a country cottage.

Natural polished stone

Natural polished stone

Tiles made from natural materials are made by cutting from whole pieces of the mineral. As you might guess, this is not a pleasure for everyone.

Terrace finished with garden parquet

Terrace finished with garden parquet

WPC garden parquet is an excellent modern solution. Such a terrace is not afraid of scratches, water and ultraviolet radiation, which means that it will retain its original appearance for a long time.

Wood in the veranda decoration

Wood in the veranda decoration

Where are we without a tree. This material does not lose its relevance for hundreds of years in a row, and is perfect for cladding concrete surfaces.

Rubber tile

Rubber tile

Seamless rubber tiles are an original, practical, comfortable, safe modern product that will transform the look of your porch beyond recognition.

Here's a short summary. After reading the material, you learned how to pour concrete steps for the porch - the procedure will be within the power of any person "with hands". If you also want to see the process in action, then watch the video in this article. That's all! Good luck!

Concrete porch - how to make steps

The use of a reinforcing cage increases the strength of the concrete array, contributes to an increase in the service life. When making steps, follow the given sequence of actions:

- Cut the reinforcing bars into pieces that match the dimensions of the entrance structure.

- Tie steel blanks with annealed wire, ensuring the strength of the power grid.

- Place stone, construction waste, reducing the volume of concrete poured.

- Prepare a working mixture in a concrete mixer, guided by a standard recipe for mixing.

- Gradually pour the concrete mixture into the formwork by levels, starting from the bottom tier.

- Tamp the poured concrete with a vibrator to eliminate air inclusions.

- Smooth the surface of the concrete, controlling the absence of slopes with a building level.

- Ensure the immobility of the formwork structure with the hardening mortar for 10-14 days.

- Wet the solid surface with a little water to maintain the required moisture content.

- Cover the flooded array with plastic wrap, which reliably protects against moisture evaporation.

- Dismantle the formwork elements after the final completion of the concrete hydration processes.

This operation completes the roughing phase of the work prior to finishing.

Smooth the surface of the concrete, controlling the absence of slopes with a building level

Porch decoration

After the concrete has dried, the formwork can be dismantled, it will no longer be useful. But be careful during this process. The final stage will be the final finishing. It can only be carried out 1 month after dismantling the formwork.

The choice of materials for this is very large. It all depends on the final appearance of your home. You can choose the finish:

- natural stone;

- artificial stone;

- wood finishing of the stairs;

- finishing the stairs with tiles;

- porcelain stoneware.

It is important that it is designed specifically for external work. A slightly more expensive option, but no less popular will be pebbles

Fancy patterns can be laid out from it, but it is worth considering that such work is done manually even at the stage of pouring concrete.

It is very important that the design you choose is in harmony with the main decoration of the house. An experienced designer or your own imagination will help you in this matter.

The choice of material for construction

The modern construction industry offers various materials for making a porch with steps with your own hands:

Wood: the most unreliable option

The tree is prone to rotting, grinded by insect pests. Overdried wood before the start of work will be covered with cracks, wet wood will become a "refuge" for mold and mildew. Permanent staining, impregnation with linseed oil, and other materials that prevent the destruction of the structure are inevitable. Outdoor steps made of soft wood will break, hard ones are quite expensive. Processing logs, sawing, cutting planks, turning balusters for railings requires some experience. In an inept "master" and appearance will not be too attractive, and strength will suffer;

Metal

For a porch and steps - not the most suitable option. The platform in front of the door will thunder with every step. The echo will be heard throughout the house, at least. Steel treads are acceptable for an office, industrial building with a high plinth. In a private house, it is better to complement a metal porch with concrete or wooden steps. An additional relative disadvantage: for construction it is necessary to use only stainless steel grades or composite alloys.

It is possible to weld the structure on your own only if you have experience, a high-quality welding machine. Poor quality work will "catch" the eye, spoil the appearance of the entire building;

Concrete

The best option for both a country house and an office building

An important advantage is the ability to give any shape, extend to a veranda or terrace. The possibilities and advantages of making porches and steps from concrete are worth mentioning separately.

What do you need to consider?

Construction is completed successfully and correctly only when you competently approach the issue of planning

After all, there are a number of points that must be taken into account.

In order not to miss anything important, you need to draw up an appropriate project

Consideration of the project includes:

- Is the veranda being built together with the house, or is it an extension to the finished structure.

- The height is determined from the ground to the lower edge of the house sill.

- The width is determined depending on how many people can walk up the stairs at the same time, as well as whether you need to bring large things into the house. So, for one person, an opening of at least 80 cm is required.To pass two, you need at least 100 cm.

- Steps. An unpaired number of steps is made, which makes it easier to climb and descend. The optimal dimensions are a height of 12 to 20 cm and a width of 25 cm.

- The porch should be approximately 5 cm below the threshold of the front door. This will allow the extension not to interfere with the opening and closing of doors.

Taking into account all these parameters, you can create a project. Based on the drawings, it will be much easier to carry out the work in stages, comply with the established norms, and avoid mistakes

To learn how you can make a reliable concrete porch on your own, see the video.