Selection and use

When choosing edges, you should adhere to the basic requirements for them:

pay attention to the compatibility of the edging material and furniture;

for self-finishing, it is better to choose parts with an adhesive base;

the type of fixation (mortise, laid on or rigid) is selected based on the purpose of the edge;

the texture, color and finish of the products must match the characteristics of the furniture and improve its appearance.

Various types of edging are used for finishing MDF, chipboard and laminated chipboard, but are also widely used for decorating cabinets, chests of drawers, headsets and walls, furniture lamps and do-it-yourself cabinet furniture.

Choose only high-quality, durable and suitable for the interior types of cladding that can reliably protect the furniture and last as long as possible.

For information on how to properly glue the furniture edge yourself, see the next video.

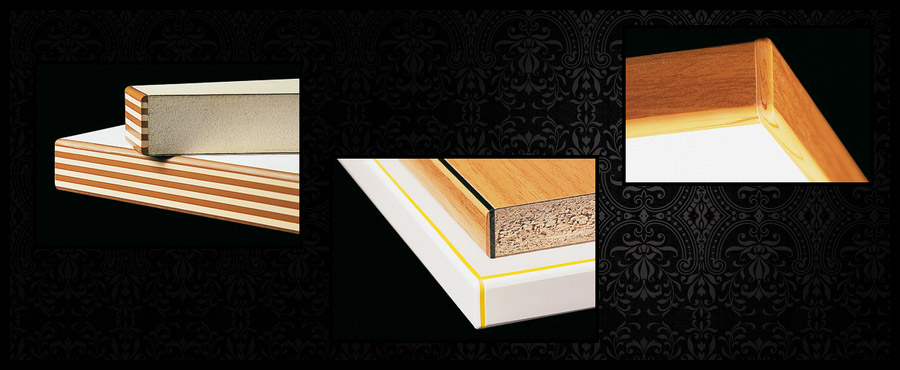

Plastic edging on chipboard: PVC and ABS

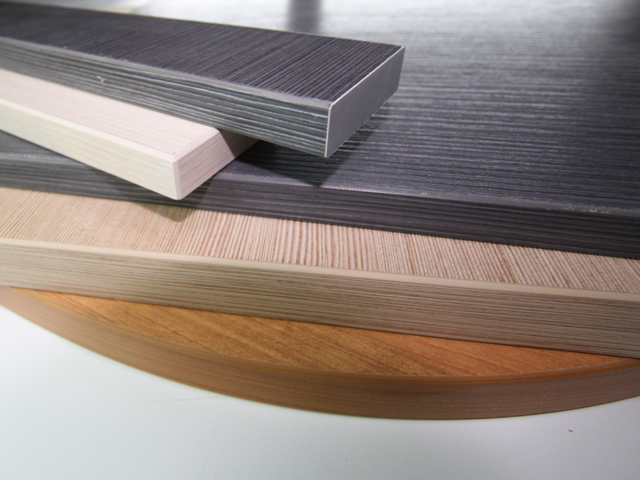

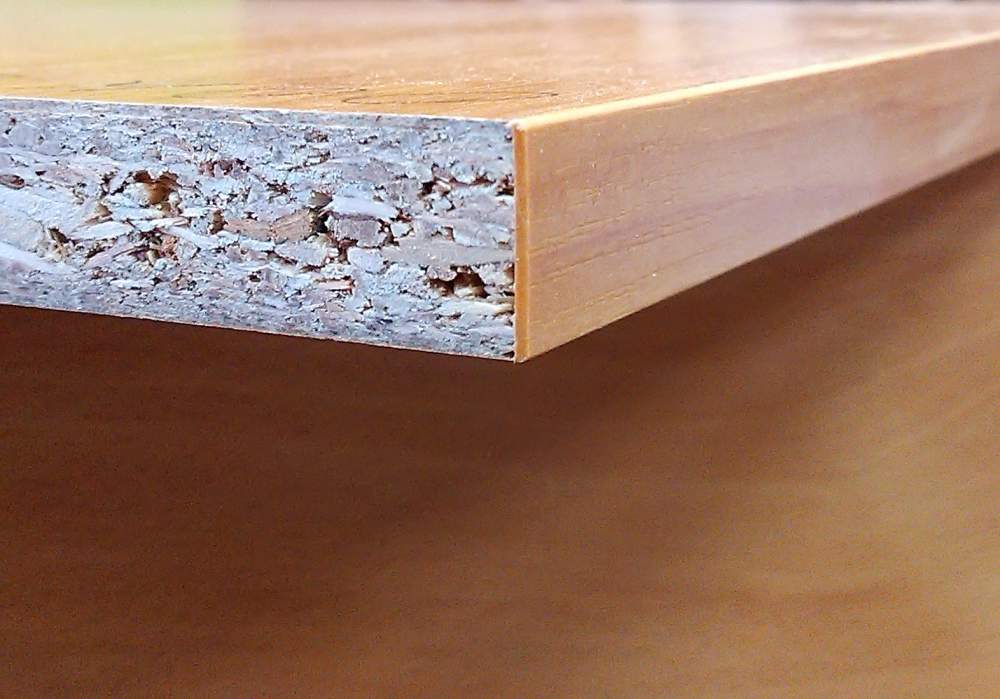

The main disadvantage of conventional melamine edging is its fragility. It shows itself well in operation on the inner ends of furniture, which are not subject to constant wear and tear. On the visible ends (countertops, facades, open shelves) it is rubbed off, chipped off, and takes on an unpresentable look. Another thing is a plastic edge for chipboard.

The most common are two types: PVC edging and ABS edging. Outwardly, they are practically indistinguishable, they are analogs, there are differences only in properties and composition. Both types are available in different widths and thicknesses of 0.4 mm, 1 mm and 2 mm, with and without glue. On the inner boxes of furniture, an edge with a thickness of 0.4 mm or "one" is "allowed", on countertops and facades - "two".

Furniture PVC edgebands are made on the basis of polyvinyl chloride, and ABS is based on acrylonitrile butadiene styrene. ABS edging is considered environmentally friendly, since it does not contain chlorine and heavy metals, and does not emit their harmful compounds when burning. Also, ABS as a material does not electrify, does not attract fine debris and dust, gives less heat shrinkage when glued and looks neater, smoother (without punching) at the ends (if we are talking about a thickness of 0.4-1 mm). But it also costs more than PVC.

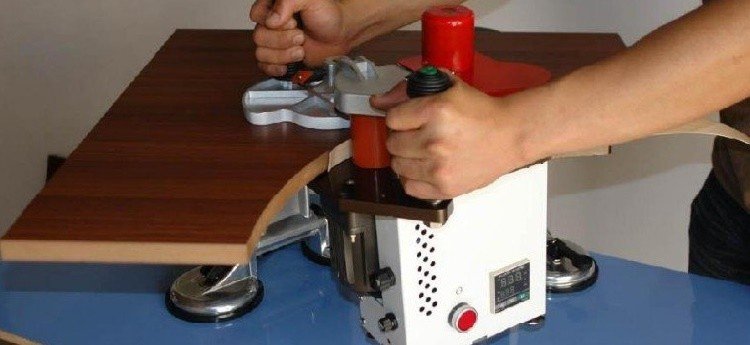

If you are interested in the process of how to glue an edge on a chipboard, then it is much more complicated, requires additional skills and specialized equipment. In the conditions of furniture production, plastic is shredded on special edge banding machines, using high-temperature hot melt adhesives. There are manual edge banding machines for small industries.

At home, it is possible to stick the PVC edge on the chipboard, but it will take more time. Step by step:

It is important to very carefully prepare the end of the furniture part for the sticker, especially if a thick edge, 1-2mm thick, is used. When the PVC or ABS edging is adhered to the base, the glue can "pull out" the chips and the end will take on an untidy bumpy appearance.

If the PVC edge has an adhesive base, then it is heated with a construction hairdryer until the adhesive melts

If not, coat the end of the part with Moment glue, wait a little for drying for better adhesion.

Then the PVC edging (ABS) is pressed against the end (manually or rolled several times) and the glue base is waiting for the glue base to solidify.

Next, you need to carefully cut off the excess edges of the edging and grind, give a uniformly rounded shape along the entire length of the part. Usually a router is used for these purposes. With a certain skill, you can do with a hand tool - a knife, file and sanding paper.

PVC edge

It differs from the first material - instead of paper, PVC (polyvinyl chloride) is used. Most often it is glued on the same hot melt glue (on an industrial scale with special machines - edging machines, but you can also glue it manually with ordinary liquid adhesives (for example, "Moment"). It is produced in several variations in thickness - most common 2 mm and 0.4 mm (there are also 0.8; 1; and 3 mm). There are just a huge number of decors, there are even glossy ones.

This edge is much stronger than the previous one, instead of chipping on impact, it only squeezes a little.

This edge is much stronger than the previous one, instead of chipping on impact, it only squeezes a little.

The disadvantages include the laboriousness of gluing (if the overhangs of 0.4 mm of the edge can be removed with a sharp knife, then 2 mm will have to be cut off with a milling cutter, preferably with a specialized edge (or on a machine), and not everyone has these devices).

Aluminum edging

The installation is similar to its plastic counterpart, but this material bends very badly, so it has to be cut, and even at an angle strictly 45 degrees. A simple miter box is not enough for this - you need a machine (and a milling cutter for the cutting edge), so for home craftsmen  practically unsuitable (I somehow sawed such an edging on a miter box - I was worn out, worn out twice as much material as was required, then refined it with a file, in short, I don't mess with it anymore).

practically unsuitable (I somehow sawed such an edging on a miter box - I was worn out, worn out twice as much material as was required, then refined it with a file, in short, I don't mess with it anymore).

This material looks great, is not subject to abrasion and burnout, it also increases the moisture resistance of chipboard, but at the same time it is difficult to install.

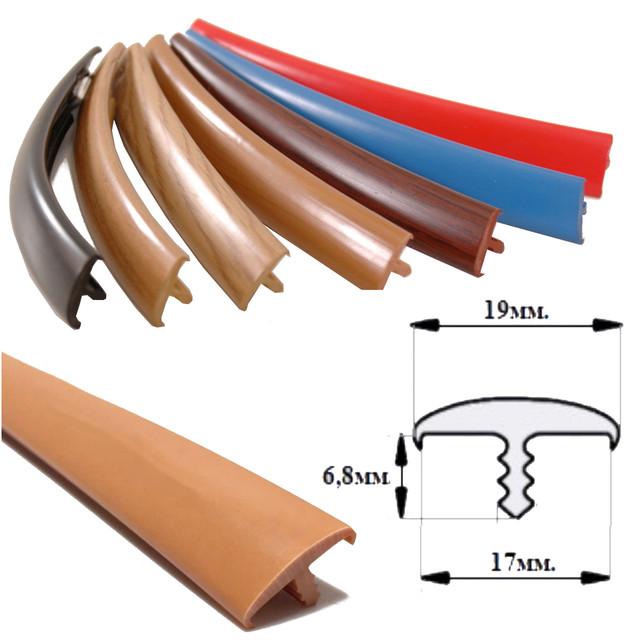

Furniture edge profiles

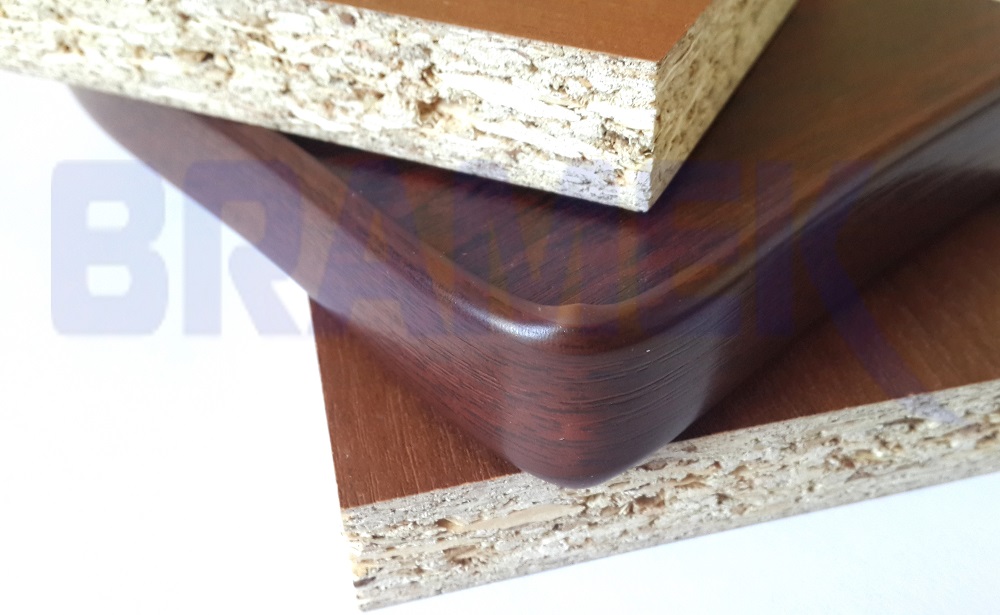

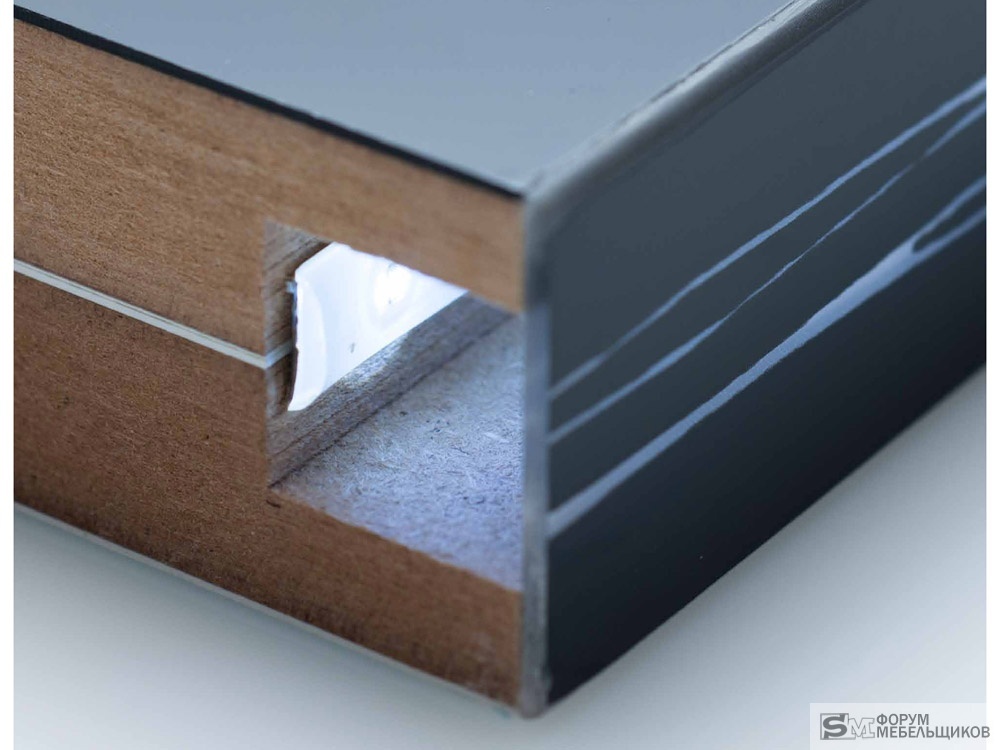

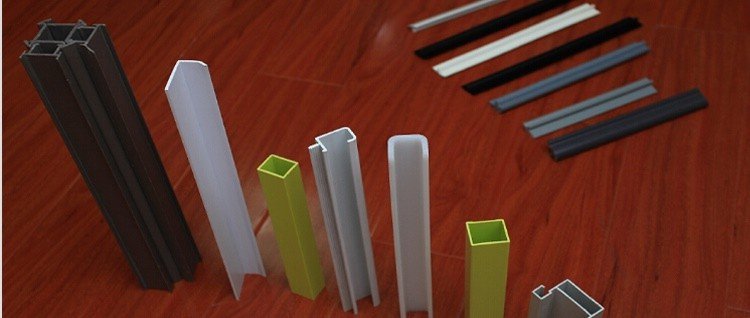

You can trim the edge of furniture not only with edge tape. There are also furniture profiles that are mechanically attached. They have two sections - T-shaped or U-shaped (also called C-shaped).

A groove is milled for the T-shaped furniture profiles in the edge to be processed. A profile is hammered into it with a furniture (rubber) mallet. The edges are trimmed at 45 ° to make the corner look attractive. It is brought to an ideal state with fine sandpaper. This type of profile is produced from PVC and aluminum, with the same installation method they look very different, and the differences are significant.

T-shaped furniture profile for furniture edging

In width, they are under laminated chipboard 16 mm and 18 mm. There are wide ones, but they are much less common, since they work less with such material.

C- or U-shaped profiles are most often mounted on glue. They coat the edge with it, then put on a plastic profile, press it well and fix it. These PVC profiles are available in both soft and hard. Hard ones are worse to bend and it is difficult to paste over curved edges with them. But they have great strength.

The gluing of the C-shaped furniture profile does not cause problems

If, nevertheless, it is required to "plant" a rigid C-shaped furniture profile on a bend, it is warmed up with a construction hairdryer, then given the desired shape and fixed with masking tape until the glue dries.

Views

In modern furniture production, manufacturers offer several edgebanding options at once. It is convenient to increase or decrease the cost of custom-made furniture. In addition, when making products on your own, the question arises of which type of furniture edge to choose. In order not to get confused, it is necessary to understand in detail the features of each, highlighting their pros and cons.

| Name | Description | Dignity | disadvantages |

| Melamine | Sold in reels, attached with glue only. Edging tape can be single-layer and double-layer, made on the basis of paper. | A large selection of colors, the material easily repeats the outlines of the furniture, no additional equipment is required for work - everything can be glued on your own. Melamine edging is affordable. | Lack of protection against moisture penetration, has a weak level of protection against mechanical damage. |

| Pvc | Made from polyvinyl chloride. Available in two thicknesses to suit different pieces of furniture.The cost of the material is slightly higher than the melamine analogue. | The edge will provide protection against acids, alkalis and moisture. The assortment is represented by a rich variety of colors. The PVC edge has a high level of protection against mechanical damage, and is also considered durable. Another undoubted plus is the incombustibility of raw materials. | The film is too stiff, which will not allow you to properly handle the bends of the product. In addition, it can only be fixed with a special machine. Self-fastening is excluded. |

| ABS | Manufacturing material - acrylonitrile-butadiene-styrene. This species is considered the most resistant to all types of damage. | The most durable edge on the market. It does not contain chlorine, which is safe for human health. The ABS edge has a fade-resistant surface. It is soft and easy to cut, and does not emit toxic substances. | No significant disadvantages were found for this type of edge. The only thing that can stop you from choosing is the high cost, due to which the price of furniture will increase. However, this disadvantage is compensated for by durability. |

| U-shaped from the overhead profile | The use of the U-shaped furniture edge finds its application on products that are constantly exposed to moisture. | The special shape more reliably protects the ends from mechanical damage. The material can be fixed by yourself using glue. Additionally, it allows you to hide existing defects in the edges of furniture. Prevents any objects from slipping off the shelves or table. | Such framing is considered bulky and does not always look appropriate on furniture. |

Based on the information provided, we can conclude that the ABS furniture edge is considered the most optimal for home use - it reliably protects the edges of the products, preventing damage.

Pvc

Pvc

U-shaped

U-shaped

ABS

ABS

Melamine

Melamine

Dimensions (edit)

When choosing edging for furniture, it is important to take into account the size of the products - this will allow the interior items to look as natural as possible. Parts made of different materials have certain parameters.

- The usual width of PVC products is 26.5 mm, but wider tape from 150 to 300 mm is also found. Their thickness is 0.4, 1 and 2 mm.

- The width of the ABS plastic edge is 19-22 mm. The thickness of the finish is from 0.4 to 2 mm, but the most reliable protection is provided by a thick tape 3 mm thick.

- Overhead U-shaped profiles are available in sizes 16x3 mm and 18x3 mm.

It is worth measuring the thickness of different objects and pieces of furniture before edging. If chipboard boards are used - 16 mm, and when it is necessary to finish the worktop - 32 mm.

Applied and cut-in edges

This type of edging is more decorative. It does not protect furniture parts from swelling and drying out, but only gives an attractive volumetric shape to the ends. Used only for decoration visible ends - facades, cornices, countertops, open shelves, etc.

As the name implies, the invoice (U-shaped) and cut-in edge does not require a sticker (in rare cases, only additional fixation, support), it is attached due to protruding parts, clasping the end of the part or cutting into a specially prepared groove in the center of the end. They make flexible overhead and cut-in PVC edges, used to decorate tabletops in office and student furniture.

Particularly noteworthy is the aluminum end, which is used to frame the facades and countertops of kitchens, office furniture of the premium segment, reception desks, etc. Since the aluminum end is not able to bend around corners, additional accessories are required for its installation - internal and external corners. Sometimes craftsmen do without them, sawing and butting the butt at the right angle.

ABS edging

It is made from acrylonitrile butadiene styrene - to be honest, it does not differ much from the PVC edge, the differences are more of a marketing ploy, but it is believed that such an edge does not fade in the sun, has more saturated colors, does not electrify (which is convenient when milling - it does not stick to equipment), does not contain poisonous impurities, and is simply stronger than PVC edging.

Naturally, such a wonderful thing costs a little more.

Standard sizes, and work with it, are similar to the PVC edge.

Another option for processing the ends is edge padding. This technique is already a thing of the past, but nevertheless, it still uses due to its simplicity.

We glue the furniture edge with our own hands

There are two technologies for gluing furniture edging tape. The first one is for those who have glue on the back. In this case, you need an iron or a hair dryer. The second is for gluing tapes without glue. In this case, you need a good universal glue that can glue plastics and wood products and a furniture roller, a piece of felt or a soft rag so that you can press the edging well against the cut.

It's real to get such an edge at home

A little about how thick the edge to glue on what parts. Those edges that are not visible, according to GOST, can not be glued at all, but basically they are trying to process them so that moisture is less absorbed into the chipboard, and also to reduce the evaporation of formaldehyde. Melamine tape or PVC 0.4 mm is glued to these edges. The edges of drawers are also processed (not facades).

It is better to use PVC 2 mm for the front ends of the facade and drawers, and PVC 1 mm for the visible sections of the shelves. The color is chosen either to match the main surface or "in contrast".

How to glue a piping with glue yourself

The adhesive is applied to the melamine edge, sometimes it is on PVC. If you have chosen PVC, it is easier to start with thin ones - they are easier to process, any melamine is glued simply.

We take an iron and a fluoroplastic nozzle on it. If there is no nozzle, a thick cotton fabric will do - so as not to overheat the tape, but to melt the glue. A construction hair dryer is also suitable for this purpose. We put the iron on about "two", while it heats up, cut off a piece of tape. Length - a couple of centimeters longer than the workpiece.

We put the edging tape on the part

We apply the edge to the part, level it, smooth it out. There should be small pieces hanging from both sides. We take an iron and, through a nozzle or a rag, iron the edge, heating it until the glue melts. Warm up evenly over the entire surface. After the entire edge is glued, let it cool. Then we start processing the edges.

Warm up with an iron

The edge can be cut with a knife, both with a sharp and a blunt side. Someone uses an ordinary metal ruler, someone is more comfortable with a stainless steel spatula.

So, take the tool of your choice, cut off the hanging edges of the edge. They are cut close to the material. Then cut off the excess along the part. Melamine and thin plastic can be easily cut with a knife. If the PVC edge is thicker - 0.5-0.6 mm or more, difficulties may already arise. Such edges can be processed with a hand router, if available. This guarantees a good result in a short time. The processing will take longer if you use sandpaper, but the result may not be worse.

Even a trowel with a hard blade can be used

One important point: when gluing thin edges, the cut of the part must be even, without protrusions and depressions. The material is plastic, which is why all defects are visible. Therefore, you will first go through the cuts with sandpaper, and then carefully dust, degrease. Only then can you glue.

Edging with PVC tape (without glue on the back)

With this method of self-gluing PVC edges, you need a universal glue and a piece of felt or rag. We read the instructions for the glue, carry out all the actions according to the recommendation.For example, for the Moment glue, it is necessary to apply and distribute the composition to the surface, wait 15 minutes, and firmly press the surfaces to be glued.

Apply glue and wait - no problem. To tightly press the edge to the cut, you can use a wooden block wrapped in felt. Instead of a bar, you can take a construction float, and fasten felt on its sole. As a last resort, you can roll up the dense fabric in several layers and thus press the tape to the surface.

Press down firmly, leaning on with all the weight

The selected tool is pressed against the laid edge, pressed with all weight, pressing it against the surface of the chipboard. At the same time, the movements are stroking. So iron the entire edge, achieving a very tight fit. The part is left in this form for some time - so that the glue "seizes". Then you can start processing the edge.

How to choose an edge for parts and shelves of a wardrobe

If you decide to make a wardrobe with your own hands, then you will have to face the choice of the edge and the determination of the sides of the parts that need to be pasted over with the edge.

It happens when you can't find an edge that matches the color perfectly. Then you have to choose something contrasting or echoing in shade with the front fittings, profile, design of handles, lamps, mirrors and other furniture. It all depends on the overall design of the wardrobe and the interior decoration as a whole.

Recommendations for the selection of the edge and determination of the sides for seaming:

- Different edge thicknesses and types can be selected for different parts. For example, internal partitions, shelves can be pasted over with melamine edging or PVC with a thickness of 0.4 mm. Drawer fronts are usually trimmed with PVC with a thickness of 1-2 mm. The visible ends of the sidewalls, bottom and visor can also be pasted over with PVC with a thickness of 1-2 mm or use an overlay profile.

- The sides of the wardrobe parts, which will adjoin the front surfaces of other parts, do not need to be pasted over with an edge. As well as the ends, which will be covered with a back wall made of fiberboard. If the cabinet is built-in and it does not have a back wall, then it is better to process the ends adjacent to the walls, at least stick a melamine edge.

- Removable shelves must be pasted over from the front edge. If you decide to cut them around the perimeter, then be sure to take into account the thickness of the edge. Even under the melamine edge, it is better to subtract 1-2mm along the width of the removable shelf so that it fits freely into the allotted niche.

How to glue the edge with your own hands

At home, the easiest way is to stick the melamine edging with glue. This will require a hair dryer or iron, a piece of felt or rags to press the heated edge to the end, a clerical knife and fine sandpaper for cutting and sanding the edges.

How to glue melamine edging with your own hands

How to glue melamine edging with your own hands

Step-by-step instructions for gluing melamine edging:

- The chipboard end face is sanded and dust-free before gluing. The melamine edge is thin and all irregularities, protruding parts of the shavings will show through untidy "bubbles".

- The melamine edge is cut to the length of the butt end with a margin of several centimeters.

- Next, the edge is applied to the end with the glue side and pressed with a heated iron. The melting point of the adhesive is determined experimentally. Do not overheat the edge - the outer surface may turn white.

- If it is impossible to do this procedure with an iron (for example, with sharp corners in parts, radius places), use a hair dryer. Here you need to "work" with two hands at the same time - one to hold the hair dryer and warm the end with the edge, the other - to press the edge with a piece of felt or rags for uniform and tight adhesion.

- After the edge cools down, using a clerical knife, the excess on the sides is carefully cut off and sanded with sandpaper.

No less simply "put on" the overhead edging and a rigid profile on the ends of the partitions and shelves of the wardrobe. This requires a mallet and your own strength.

Types of furniture edges

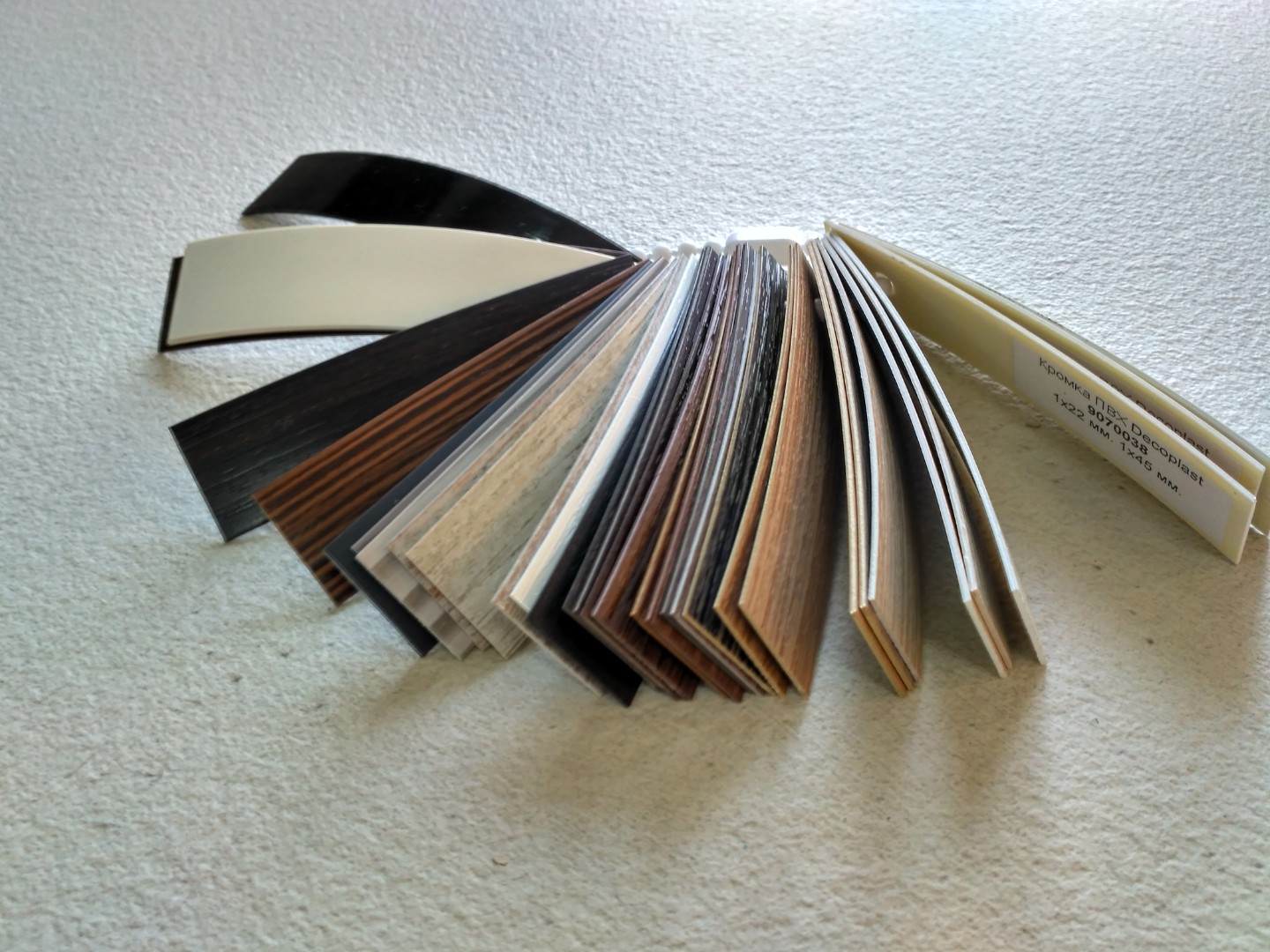

One of the most popular materials for making furniture is laminated chipboard.Its disadvantage is the ugly edges that remain when the part is cut. These edges are masked by the furniture edge. They make it from different materials, respectively, it has different properties and prices.

You can also get such an edge yourself.

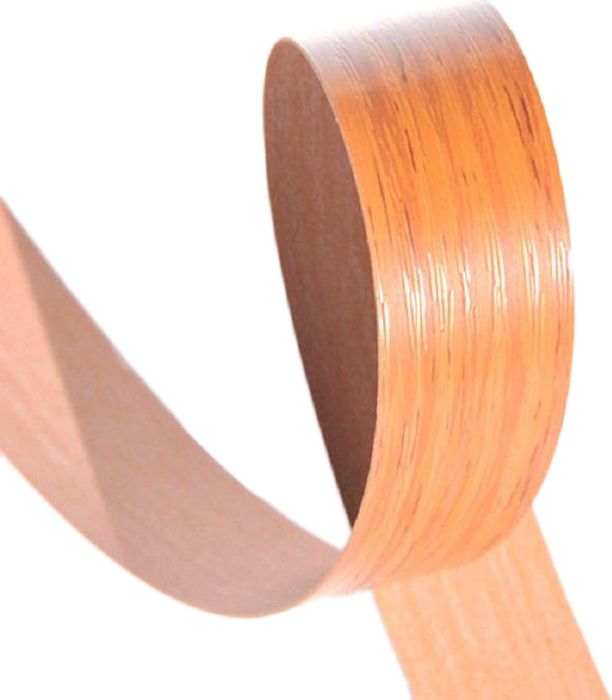

Edges paper or melamine

The cheapest option is melamine-impregnated paper edging. The paper is taken with a higher density, impregnated with melamine to increase strength and glued onto papyrus paper. Papyrus can be single-layered (cheaper) and double-layered. To prevent the melamine coating from being erased, everything is covered with a layer of varnish. To make it more convenient to trim the parts, an adhesive is applied to the reverse side of the melamine furniture edge. When working, you only need to slightly warm this composition and press it well to the end.

Paper or melamine edging is the cheapest, but also the most short-lived option for finishing furniture ends.

The thickness of paper edging tapes is small - 0.2 mm and 0.4 mm are the most common. There is no thicker sense to do, and it will be expensive.

This type of edge differs in that it bends very well, does not break when bent. But its mechanical strength is very low - the edge wears out quickly. Therefore, if it is used, then only on those surfaces that are not subjected to stress. For example, on the back of shelves, countertops, etc.

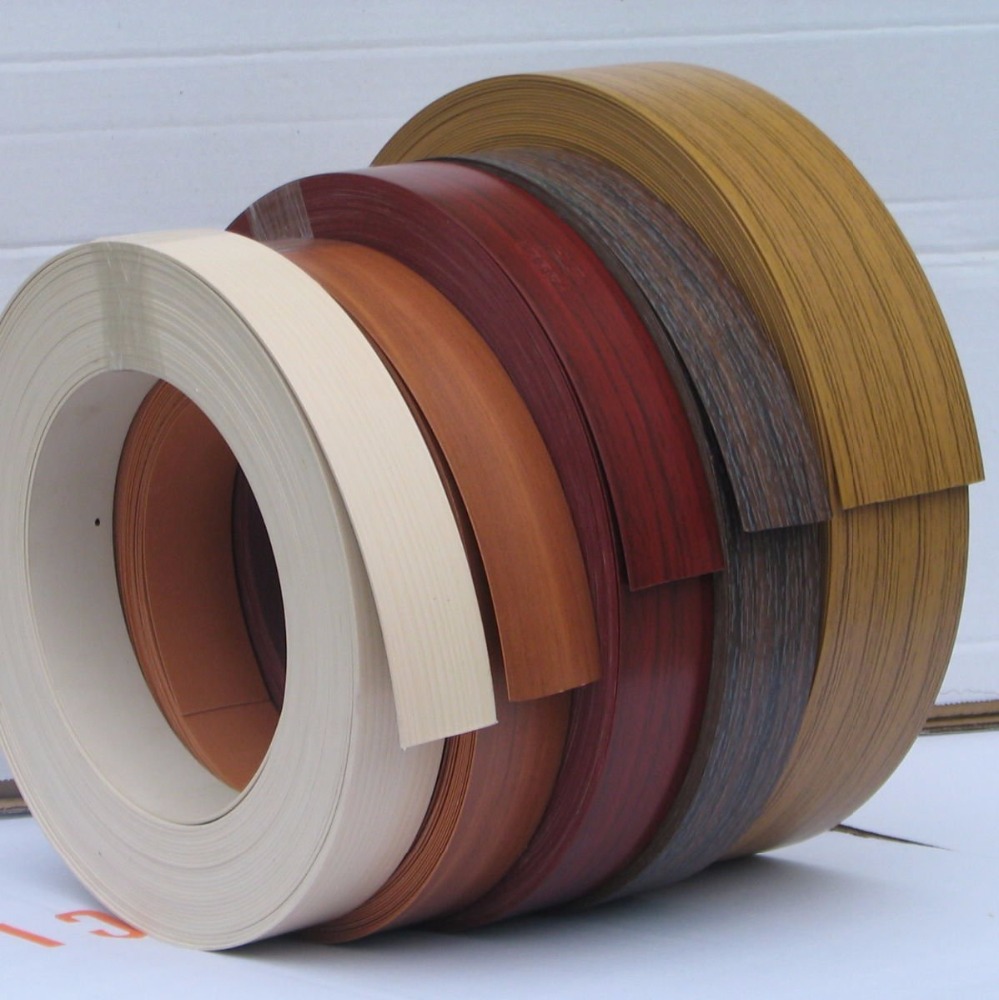

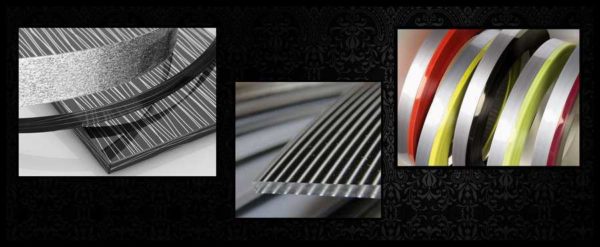

PVC

Polyvinyl chloride, which has recently become widespread, is also used in the production of furniture edgebands. From the mass dyed in a certain color, a tape of a certain width and thickness is formed. Its front surface can be smooth, monochromatic, or it can be textured - with imitation of wood fibers. The number of colors is large, so it's easy to find the right one.

PVC furniture edging is the most popular material used by both DIYers and professionals. This is due to the relatively low price and good performance properties:

- High mechanical resistance.

- Withstands exposure to chemicals (household chemicals, for example).

- Moisture-proof material protects the ends of the product from moisture.

- PVC is an elastic material that allows processing curved surfaces.

-

It is well processed with simple tools, which allows you to get a good result even at home.

PVC furniture edge is available in different thicknesses and widths. Thickness - from 0.4 mm to 4 mm, width from 19 mm to 54 mm. The thickness is chosen depending on the expected mechanical load or appearance, and the width is slightly larger (at least 2-3 mm) than the thickness of the workpiece. There is a PVC furniture edge with an applied adhesive, there is - without. Both can be glued at home (more on that below).

This type of edging material has its drawbacks: not very wide temperature range: from -5 ° C to + 45 ° C. For this reason, furniture on the street in winter cannot be left, and also when pasting with heating, one must be careful not to melt the polymer.

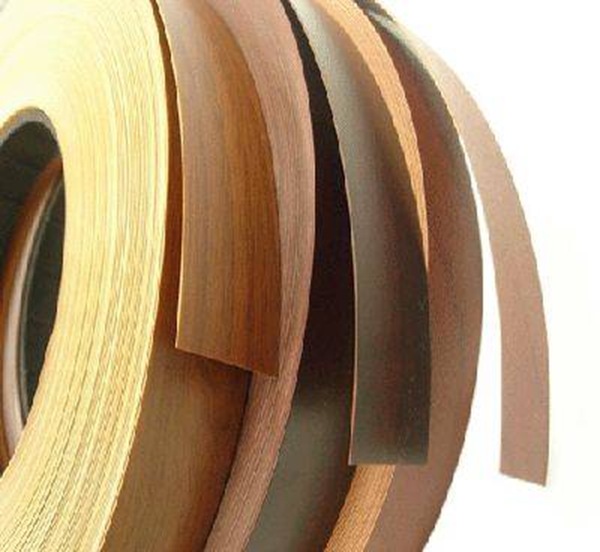

ABS (ABS) plastic

This polymer does not contain heavy metals and is highly durable and durable. The disadvantage can be considered a high price, therefore it is used extremely rarely, although it has excellent properties:

- Resistant to high and low temperatures, therefore, when gluing, you can use glue with any melting point. Small shrinkage on heating - about 0.3%.

-

High mechanical resistance.

This type of edging can be matte, glossy, semi-glossy. There are also options that mimic different types of wood. In general, this material is more convenient to work with and more durable in use.

Veneer edging

Veneer is a thin cut of wood, dyed and shaped like a ribbon. This furniture edge is used in production for pasting veneer sections. Working with this material requires certain skills, and the material is expensive.

Veneer is not the most popular material for edging

Acrylic edging or 3D

Made from clear acrylic. A drawing is applied on the reverse side of the strip. The polymer layer on top gives it bulk, which is why it is called a 3D edge. It is used in the manufacture of furniture in an unusual design.

Acrylic gives the picture three-dimensionality

Criterias of choice

The edge in furniture significantly improves the appearance of cabinets, drawers, tables, as well as any other cabinet furniture. Today it is available in various colors, and it will not be difficult to choose an option for the shade of the furniture.

To make the selection process easier and the result pleasing to the family for many years, pay attention to the following selection criteria:

Material - speaking of material, edging can be divided into paper, plastic and rubber. The pros and cons of each have been described above.

When choosing, you should pay attention to its compatibility with the material of production of the furniture itself;

Width - popular sizes vary between 22 and 38 mm, so before trimming the product, it is worth choosing the optimal width - it should completely hide the edges of the product;

Thickness - today manufacturers use an edge from 0.2 mm thick. It is necessary to take into account the purpose and storage conditions of furniture in order to select the required thickness parameter;

The presence of an adhesive layer

This criterion is important for people who want to fix the edge on the product on their own. If the device does not have an adhesive layer, then it will not work to make the edging with your own hands;

Fastening type - there are rigid, overhead and cut-in edges. Depending on the purpose, one of the options is chosen. Also, the mortise type is divided into T-shaped and U-shaped;

Surface type - edge coating can be glossy, matte, embossed or embossed. Consider this criterion in order to improve the characteristics of the appearance of the furniture.

Having studied all the indicators of furniture edges, you can safely go for a new set of furniture

When purchasing, pay special attention to the quality of the processing of the edges and end parts. It is worth additionally asking the seller about the method of fixing the edge

By purchasing furniture products with a durable edge, you can provide them with a long service life.

Scope of use

Regardless of what type of edge is used, it is designed to protect the end parts of the product. Such a device is especially necessary in the production of inexpensive furniture from chipboard or chipboard. Since the composition of these materials contains harmful formaldehydes, which over time can evaporate their substances into the atmosphere. Edging materials allow you to close raw edges, preventing the spread of fumes.

Self-production of furniture parts implies the mandatory use of edging. If this is not done, then during operation, the uncovered edges of the product will be subject to rapid wear.

Possible reasons - accidental touching of the edge, scratching with a sharp object, careless closing of the doors. That is why the processing of chipboard with edging material is so important in the production of furniture.

To consolidate the information provided, it is necessary to highlight a number of functions that the edge performs - a special tape from various raw materials for processing the edges of furniture:

- Beautiful appearance of the ends of the products. When shopping in a store, the customer first of all looks at the aesthetic design. It is unlikely that he would want to install a sliding wardrobe, where the internal shelves look unfinished, and their edges differ in color and structure from the facades;

- Protection against mechanical damage. Edging materials are designed to protect fragile chipboards from moisture ingress, delamination. Chips and burrs from impacts can cause snags on clothing and scratches on your skin. The laminated surface of furniture can crack even if it comes into contact with a hard object.If the edges of the parts are sealed with edging, the degree of damage and the chances of losing the attractiveness of the models are minimal;

- Protection of human health. As already mentioned, the edge plays an important role in maintaining the health of households. The more time the furniture is used, the higher the risks of the release of formaldehyde resins from the chipboard.

When choosing products for the home, you should pay attention to the specified subtleties. They will help to maintain the attractiveness of furniture and extend its safe use.