Capacity

Red

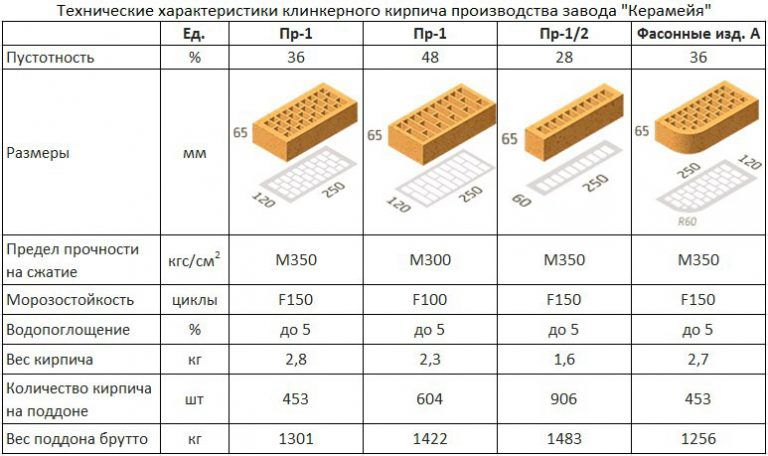

The capacity of bricks in a pallet, depending on the size of the product.

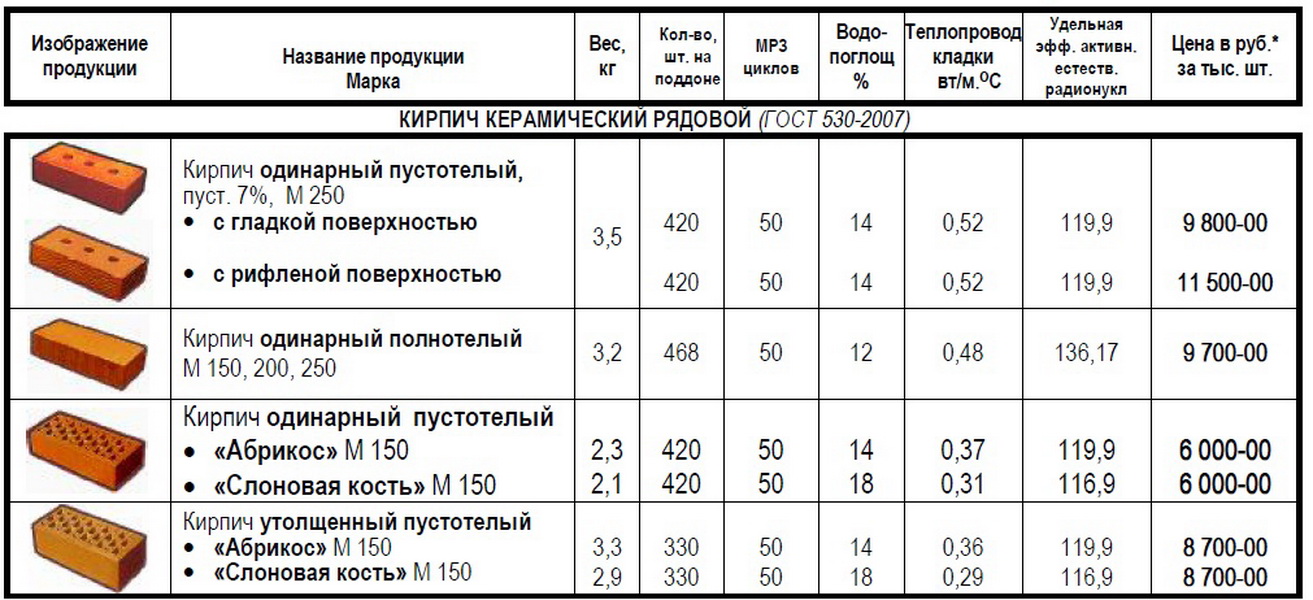

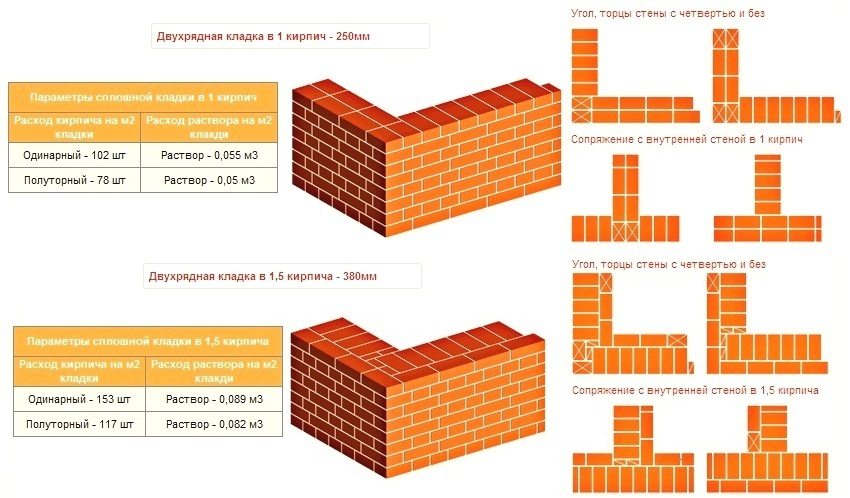

How many bricks are included in one pallet of regular size? Usually, the unit of measurement is taken as a pallet of 103x77 cm. In this case, in 1 stack per meter in height (standard), the amount of backing or ordinary material will be quite standard. You just need to clarify the specific parameters. For example, a hollow ceramic block will be placed on a large pallet in the amount of 420-480 pieces. On a small one it will fit from 308 to 352 pieces. Let's consider in more detail the data on the most popular types of bricks.

|

Solid brick type |

250x120x65 |

250x120x88 |

worker |

stove |

basement |

M100 |

facing |

|

number of pcs. in a pallet 130x77 cm. |

420 |

390 |

200–400 |

420 |

420 |

420 |

360 |

White

Standard pallet size amount of white sand-lime bricks usually depends on what type of product you plan to transport. It is worth adding that the platforms themselves will also be reinforced - due to the greater mass of the elements. On wood-metal pallets with the size of 1915x600 mm or 1740x520 mm, 240-300 pieces are placed. single sand-lime brick. For a one-and-a-half product, this figure will be 350-380 pieces, but the manufacturer can also ship half-packs of 180 units. For the facing option, the number of bricks per pallet will be 670-700 pcs. For slotted - from 380 to 672 pcs. Hollow double bricks are placed on a special pallet in the amount of 448 units. All these indicators are relevant exclusively for packaged products. In its absence, the number of pieces of goods available for delivery will depend on the stacking method. But with such transportation, the volumes of damaged and broken building material will be much higher.

Shamotny

For kiln or fireclay blocks, the number of units per pallet is also of great importance.

Here you should definitely pay attention to the product labeling. Among the most popular options are end wedges, which are placed on wooden pallets of 415 pcs.

In addition, the brand ШБ-5, measuring 230x114x65 mm, is stacked and transported on pallets of 385 pcs. If you buy fireclay bricks ШБ-8, with dimensions of 250x124x65 mm, 625 pieces are stacked on a standard pallet. Standard standards are not the only correct ones, and it is imperative to take into account the dimensional characteristics of the selected pallet option. Fireclay bricks of any brand are placed on a more spacious Euro pallet in the maximum volume.

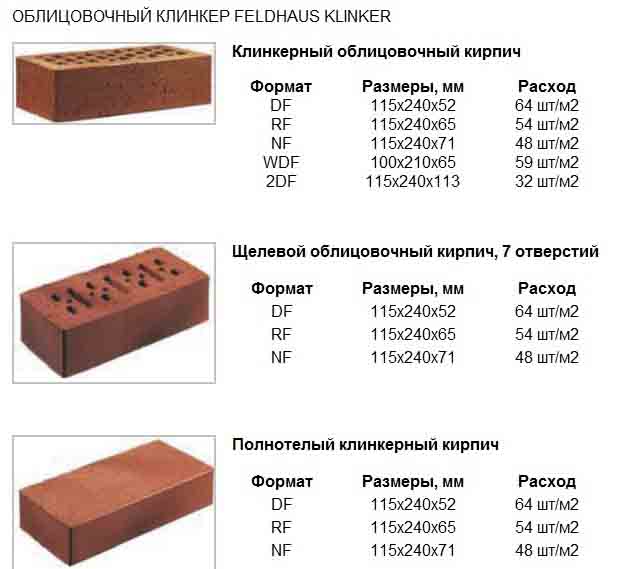

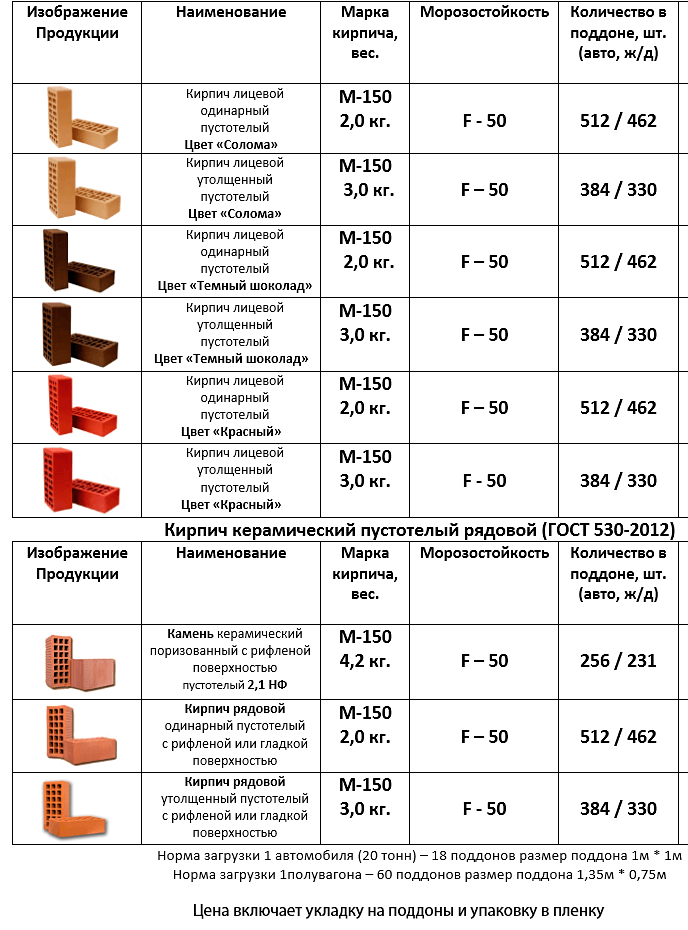

Facing

For facing brick quantity calculation palletised products also include obtaining information based on the size of the product. With a standard size of 250x130x65 mm, 275 units of products are placed on the pallet. A single ceramic hollow body will fit 480 pcs. Silicate and yellow 200 pcs. in a single version. For the clinker variety, this figure will be 344 units. All specified data must be carefully checked, taking into account the standard according to which the product is manufactured, the carrying capacity of the pallet. In addition, when purchasing from a manufacturer, you need to clarify its individual parameters used during transportation. Only taking into account all these factors, it will be possible to accurately calculate the number of pallets and select the mode of transport for their delivery to the object.

Types of bricks by composition

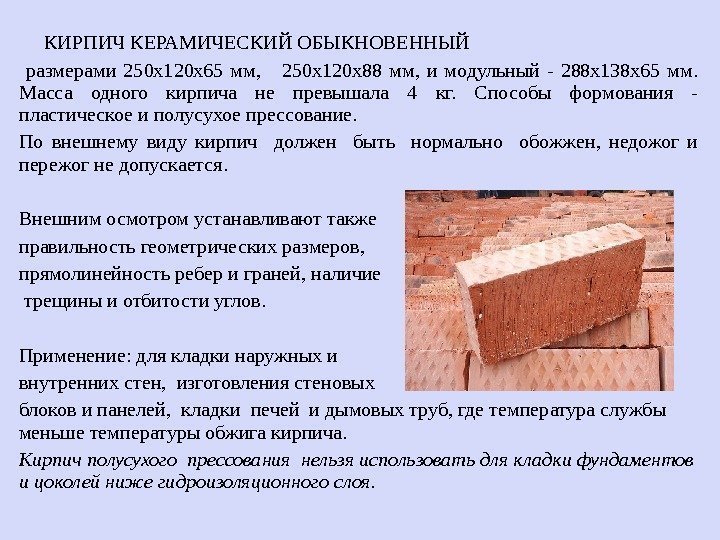

Within the framework of this GOST, there are only 2 types of bricks - white, it is silicate, and red. However, color is not a tribute to decor.

The composition of white or sand-lime bricks speaks for itself. Silicium - in Latin, the element silicon, which in the periodic table of elements of D.I. Mendeleev is number 4. Silicate is actually flint brick. The amount of silicon on the planet ranges from 28 to 30% by weight. It is the most abundant element on the planet after oxygen.

Red brick has this color, not because it is painted in a bright color, but because the clay, when fired, acquires such a muted red color, which in the classification of artists is called brick.

This product is made mainly of red and yellow clay. Recently, in addition to the so-called red brick, pink, purple and yellow products have appeared. These are already painted options. They are more expensive than conventional ones and are used as decorative elements.

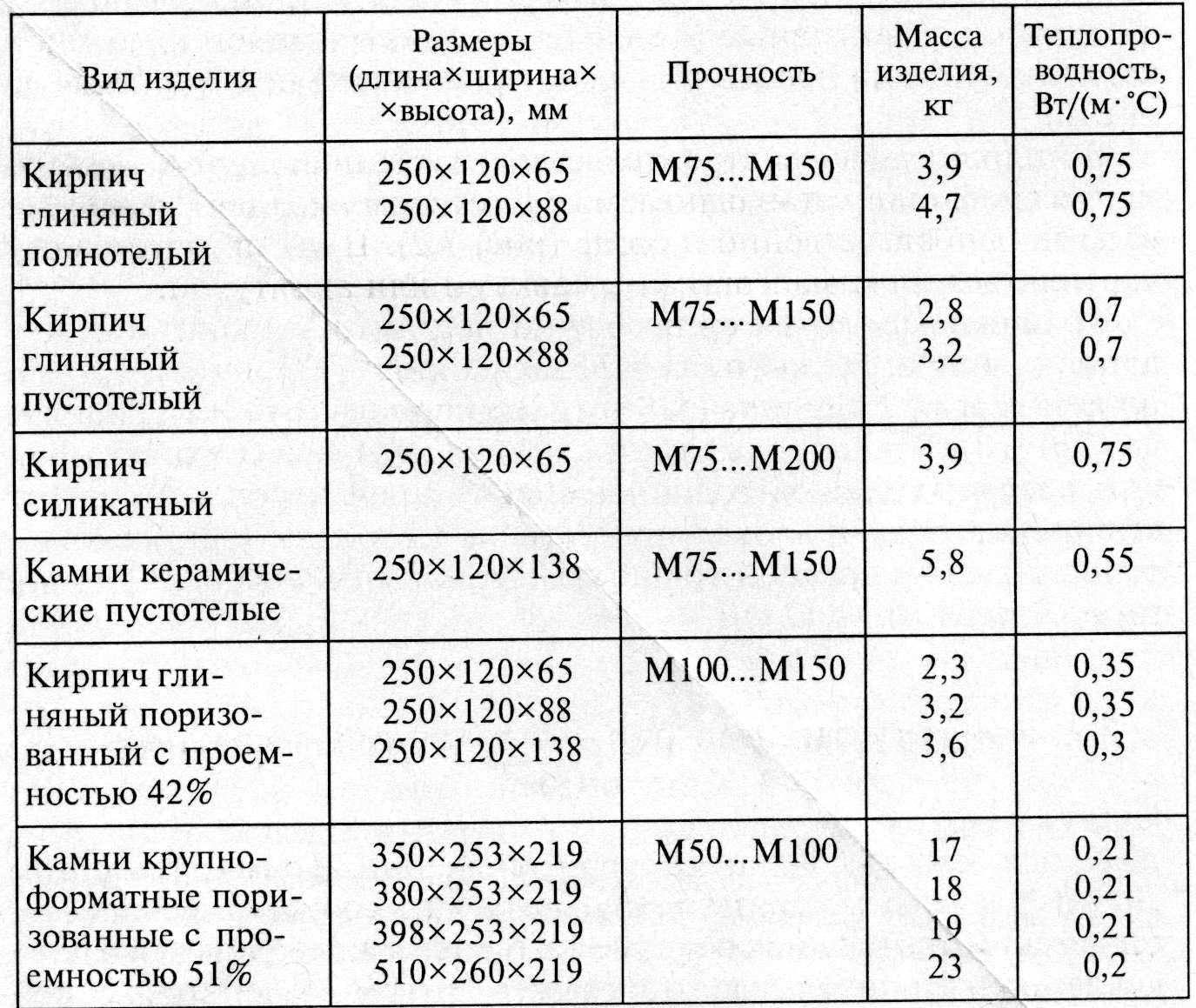

Pros and cons of ceramic bricks

The advantages of ceramics include naturalness, harmlessness. If we compare ceramics and silicate, then clay products win a little in terms of thermal conductivity. If you look at the indicators, then the difference is very small. But a ceramic house is much warmer than a silicate one. The point is in the higher heat capacity. Clay can store more heat and is therefore warmer at home.

Ceramics are inferior to silicate in sound insulation properties, as well as in geometry and stability of characteristics. This is its main disadvantage. Moreover, at a high price, often efflorescence, with which it is very, very difficult to fight. Another drawback is that even the front surface is rarely even.

Ceramic brick is a traditional material for building houses, which is more than one hundred years old.

All these shortcomings are understandable. Ceramic bricks are obtained by firing pre-shaped parallelepipeds from clay mortar. Clay is a natural material that has various properties. The different properties of different types of clay are the main reason that the size of ceramic bricks does not differ in stability. Moreover, a significant spread can be within the same batch. And from party to party, in general, there may be significant differences. The different characteristics of the feedstock also cause a wide variation in the characteristics of the finished product. Such as strength and density.

Service life - reality is not happy

In many respects, ceramics should be better than the same silicate, but the reality turns out to be different. Recently, too often there is a red ceramic brick crumbling, dilapidated after several years of operation under normal conditions. The reasons are the complexity of the technology. For a good result, careful processing and preparation of the clay is required in order to exclude lime inclusions, which are the reasons for "shooting". And this is additional time in an already not short production cycle. And extra energy. And expensive equipment, which is not bought by everyone.

Not the best picture

The second point: holding the temperature regime of firing. Burnt ceramic bricks behave normally in masonry. It only looks worse, as it is darker than the "norm". It's not so scary. But the unburned one collapses, crumbles. And this is why he is dangerous. Ceramics are fired in the furnace for a long time, and so it takes a little to reduce the time in order to increase productivity. Hence the underburning. Or fuel economy, which is far from cheap. So compliance with the technology for the production of ceramic bricks is a high price for products. And expensive bricks are bought very reluctantly. So the collapsed red brick most likely had a low price. And everyone knows that cheap is very rare. Nevertheless, the budget for a construction site is usually not a rubber one and you have to save money.

In terms of thermal conductivity and some other parameters, ceramic bricks should be better

No matter how complex the production technology is, European supplies have a geometry close to ideal, and the dimensions are standard, and the quality is stable. Their price is far from budget, but quality problems are rare. So if the funds allow, they try to buy imported bricks. Domestic clay, even expensive, still cannot boast of stability of quality.That is why, although ceramics should be better in many respects, more and more often the choice is made in favor of silicate. Because for quite reasonable money you can buy good quality building material. He is chosen even though he is much colder. All the same, in order to achieve the required level of energy efficiency, it is necessary to insulate the ceramics too.

Advantages and disadvantages

The wide demand for M100 brick is explained by the large number of its positive qualities. First of all, it is an attractive price range. The cost of the products is relatively low, which allows them to be considered by consumers of various social levels.

Corpulent products can be used in a wide variety of jobs. In addition, it is quite possible to make masonry yourself, it is enough to know the basics of construction technology and follow a number of rules. However, it should be borne in mind that for the construction of complex structures, you should still contact professionals.

Single ceramics M100 create excellent soundproofing of the room. In addition, the thermal insulation properties of the material make it possible to refuse additional insulation.

However, it must be borne in mind that after working with ordinary bricks, cladding will be required. This is not always profitable from an economic point of view, which is why many buyers stop at using face material.

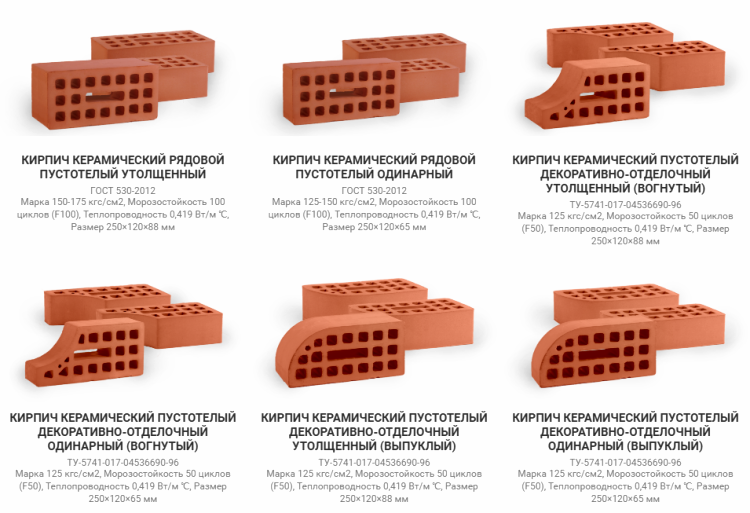

Varieties

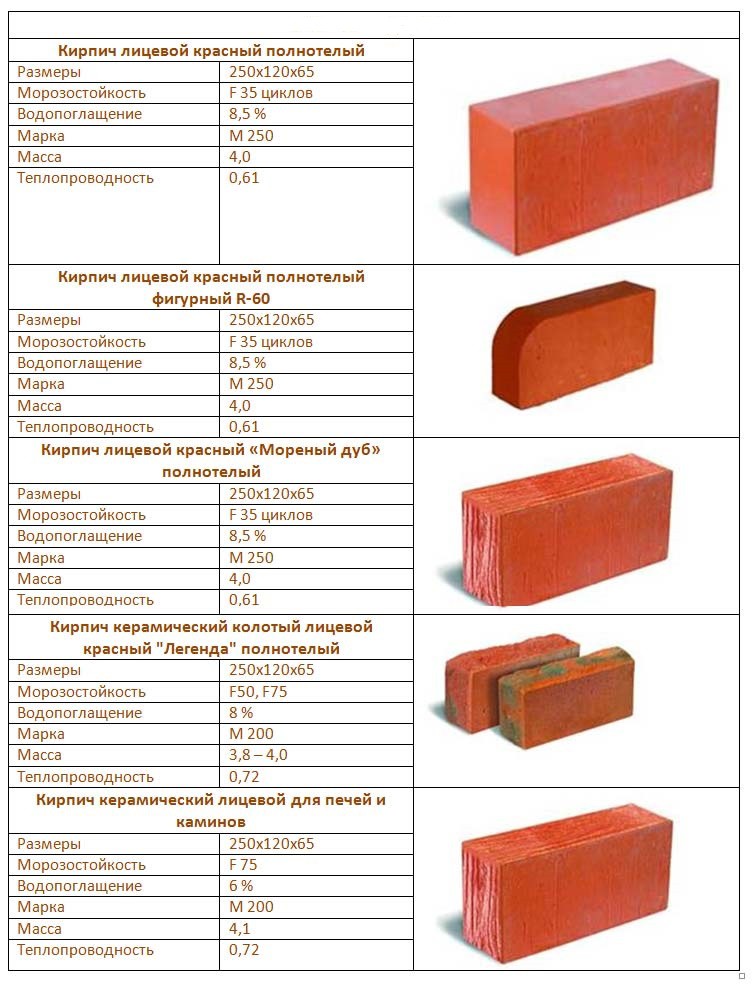

The classification of red solid bricks occurs according to a number of signs, the main of which is the purpose of the material. According to this criterion, ceramic models are divided into several types.

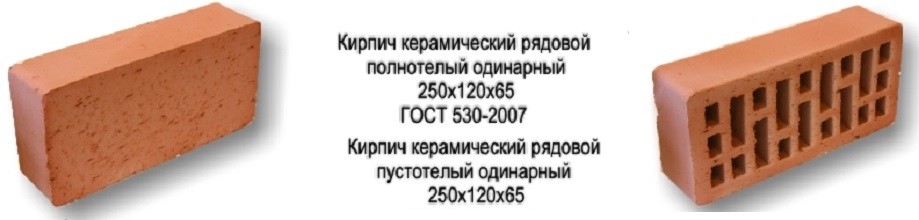

Ordinary brick

It is the most popular and demanded type and is used for the construction of foundations, load-bearing walls and interior partitions. The raw material for the brick is ordinary red clay, and it is made in two ways.

- The first is called the semi-dry pressing method and consists in the formation of workpieces from clay with low moisture content. The pressing takes place under very high pressure, so the fired raw material sets quickly enough, and a dense and hard material is obtained at the exit.

- The second method is called the method of plastic formation and consists in the design of the raw material by means of a belt press with further drying and firing of the blanks. It is in this way that most modifications of red brick are made.

Fireclay brick

It bears the name of refractory and is made of fireclay clay. Its share in the total mass of the product reaches 70%, which makes the material practically invulnerable to open fire and allows the masonry to withstand its impact for five hours. For comparison, it should be noted that reinforced concrete structures are able to withstand a flame for two hours, and metal structures - from 30 minutes to an hour.

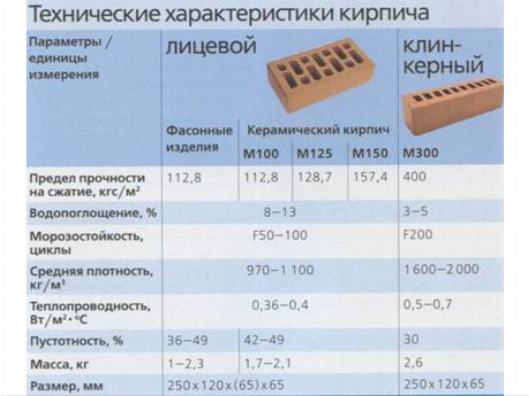

Facing brick

It has a smooth or corrugated surface and is widely used for finishing facades of buildings and interiors.

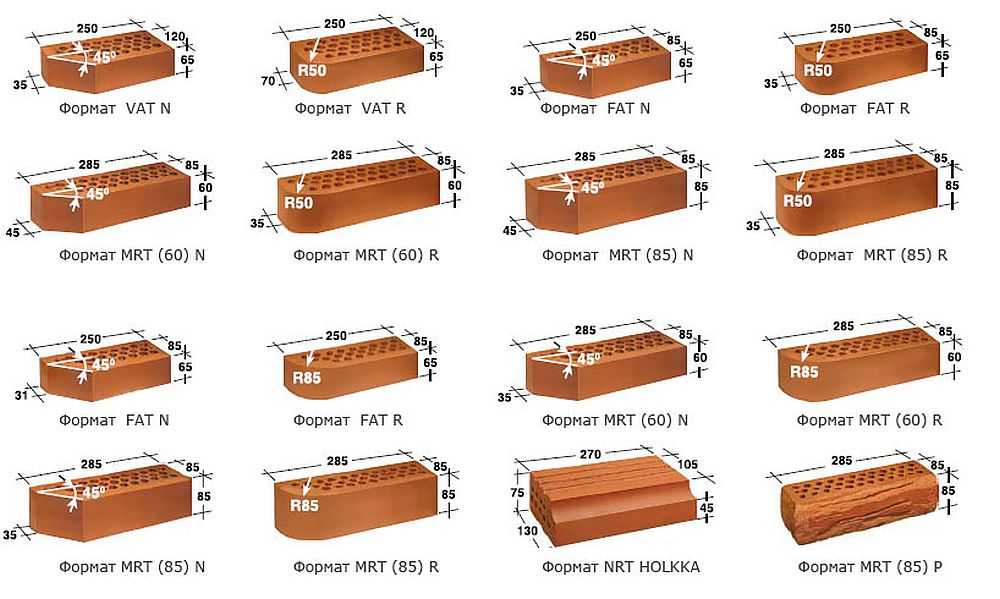

Shaped or shaped bricks

It is produced in non-standard forms and is used in the construction and decoration of small architectural forms, including arches, columns and pillars.

Clinker brick

It is the most durable type and is widely used for paving sidewalks and roadways. The clinker has a long service life, high strength reaching the M1000 index, and increased frost resistance, which allows the material to withstand up to 100 freezing cycles.

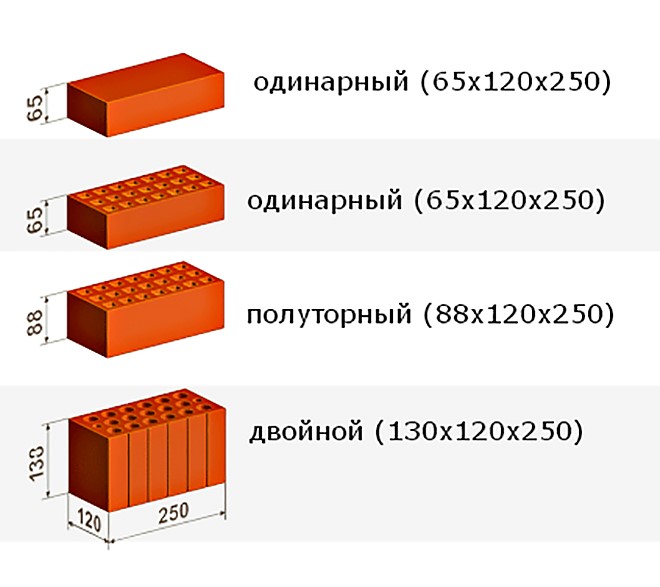

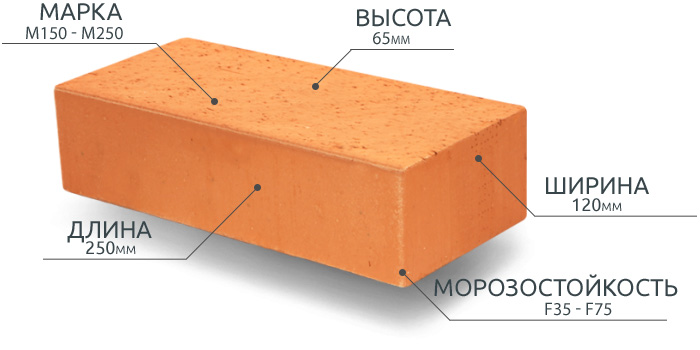

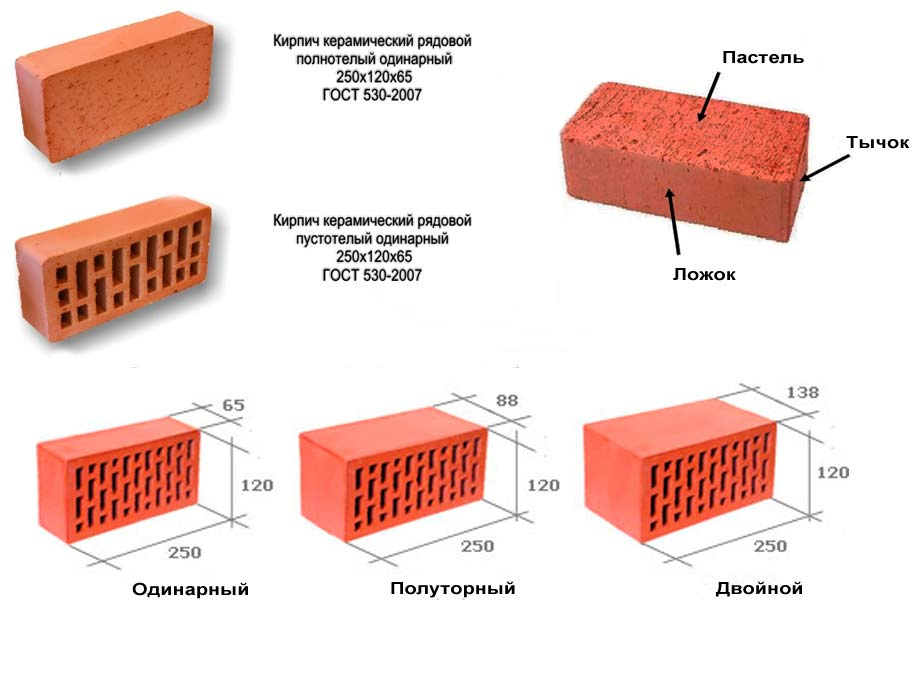

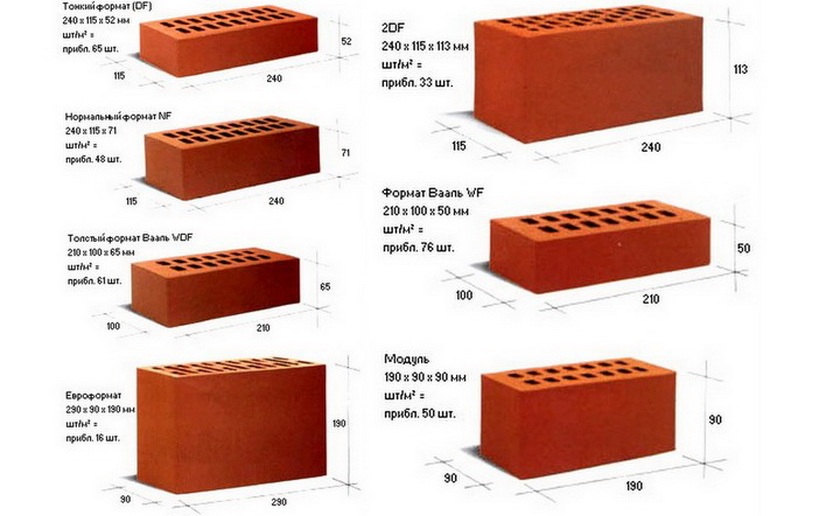

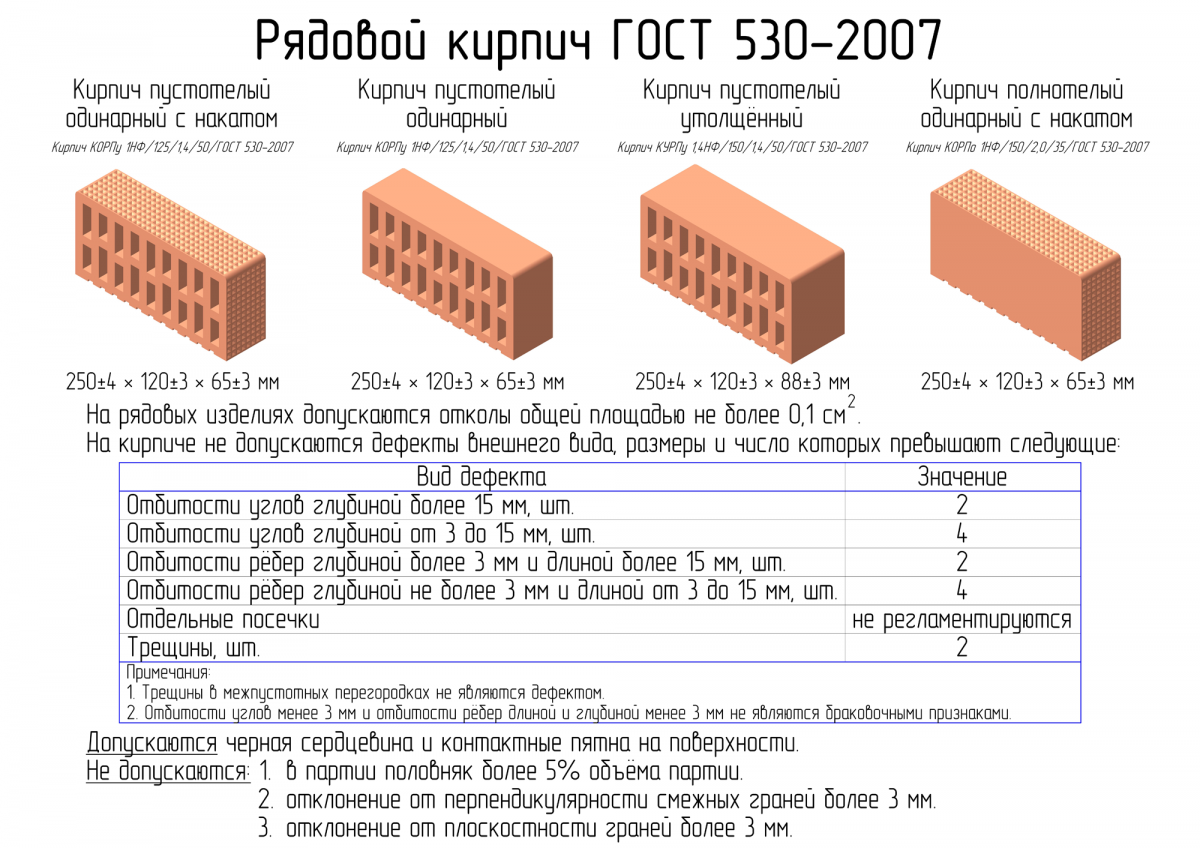

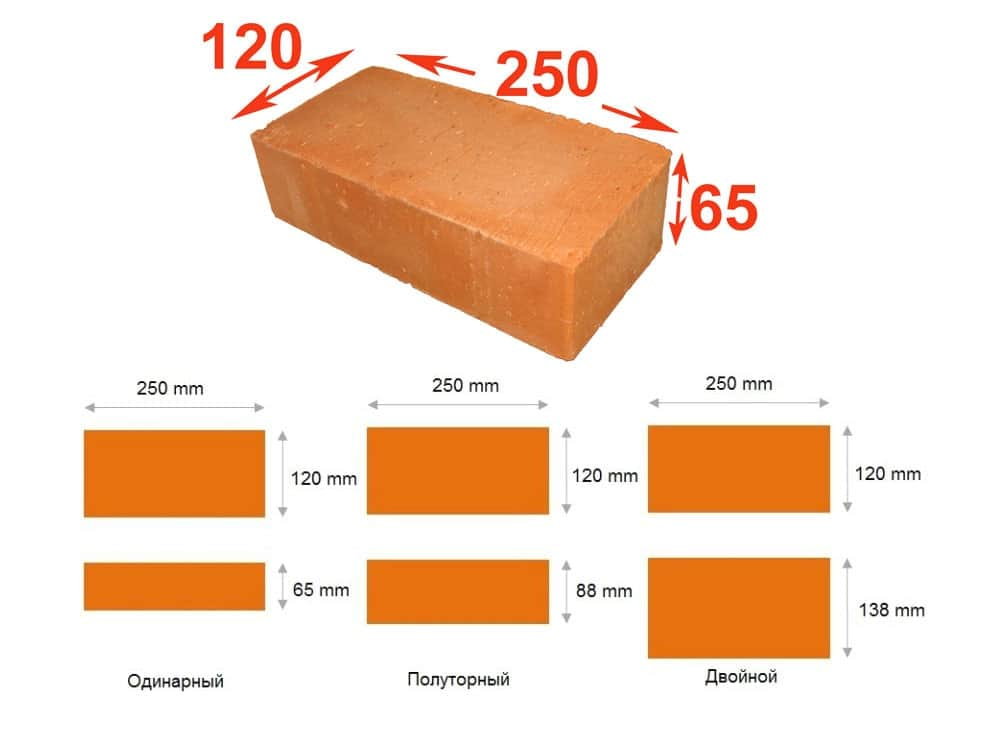

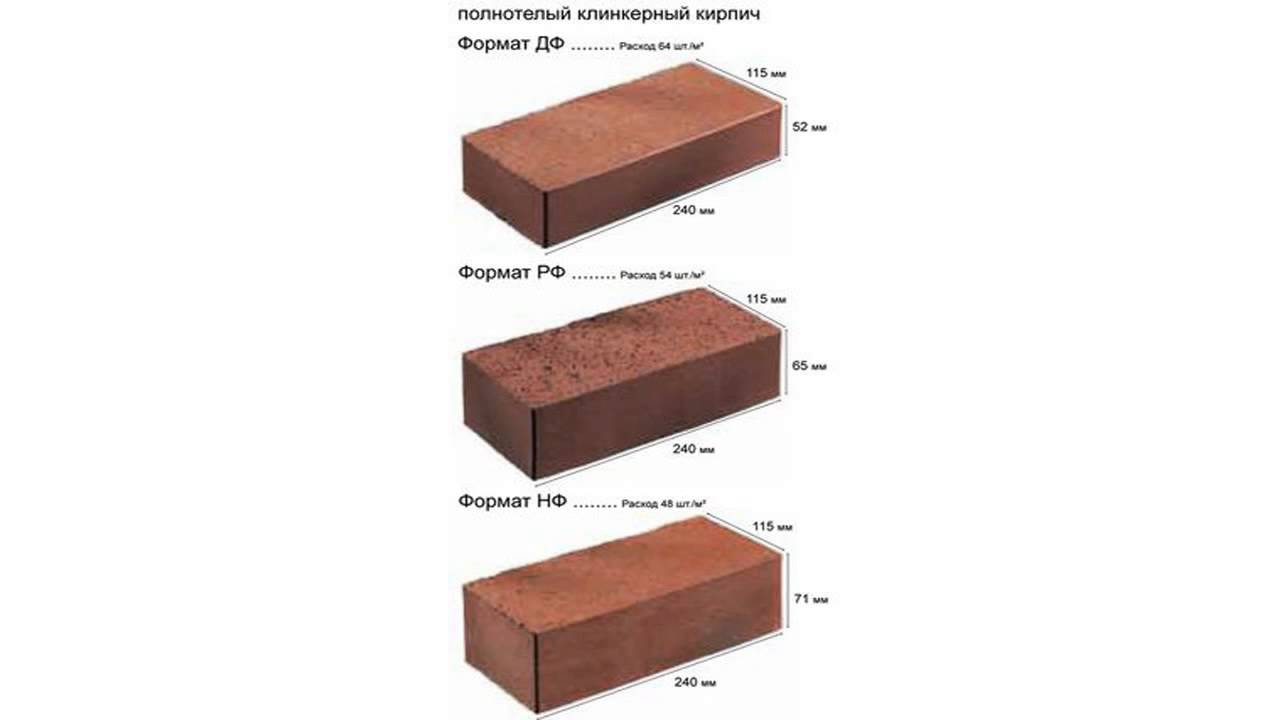

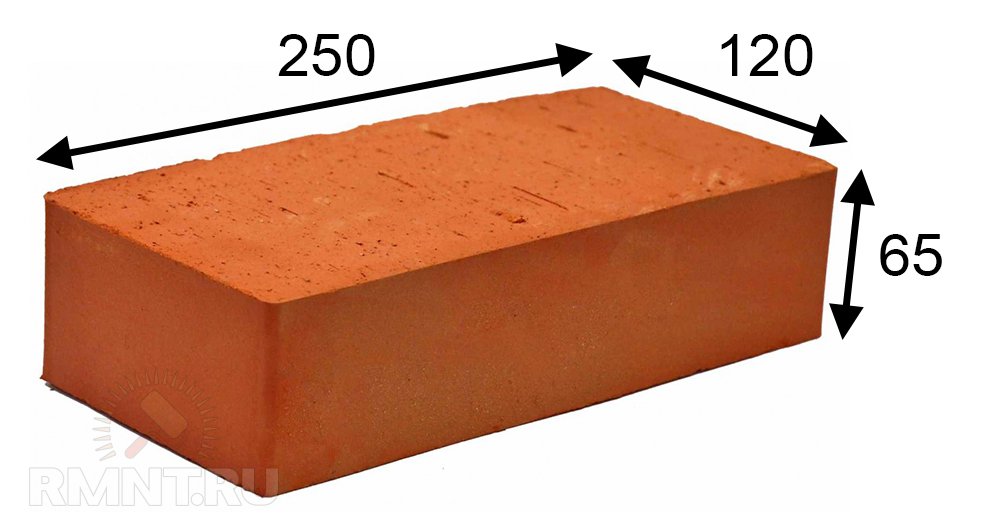

In addition to their functional purpose, ceramic full-bodied models differ in size. According to the accepted standards of GOSTs, bricks are produced in thickness in single, one-and-a-half and double versions. The most common sizes are single (250x120x65 mm) and one and a half (250x120x88 mm). Dimensions of double bricks reach 250x120x140 mm.

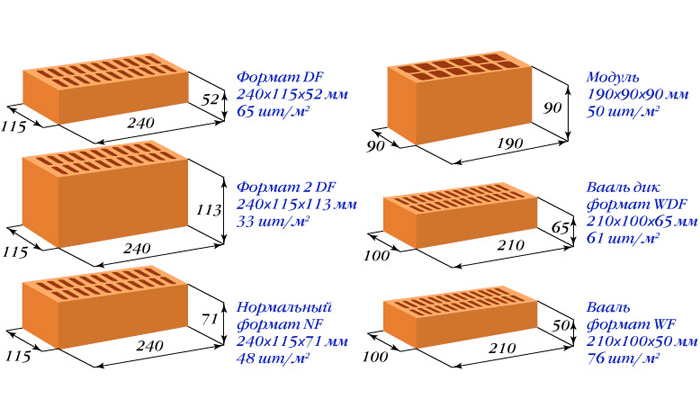

However, in addition to products with standard sizes, there are often options with unconventional dimensions. These include eurobricks with dimensions of 250x85x65 mm, modular specimens with dimensions of 288x138x65 mm, as well as non-dimensional models with lengths of 60, 120 and 180 mm and a height of up to 65 mm. Bricks of foreign manufacturers have slightly different dimensions, of which the most popular are 240x115x71 and 200x100x65 mm.

In the next video, you will find a film about the technological process of the production of clay bricks.

Views

The varieties of single bricks transported in pallets or pallets are quite diverse. The following main categories are usually distinguished.

- Red - made from natural clay, by passing molding and kiln firing. The finished product combines excellent strength characteristics, not too heavy weight - 3.6 kg for a full-bodied version, resistance to external weathering. The dimensions of the brick block are 215x12x6.5 cm.

- White - silicate, produced not from clay, but from quartz sand, the mass of which reaches 90% of the total volume. In addition, lime and various additives are present in the composition. The process of forming the product takes place by dry pressing, followed by processing of raw materials in an autoclave under steam action. Its high strength characteristics make it an attractive choice for finishing and cladding. But to lay out a stove or pipe made of white brick will not work - when heated over 200 degrees Celsius, it will simply burst.

- Fireclay. Refractory bricks for laying out stoves, fireplaces, chimneys are made from finely crushed chamotte, and special types of clay. It is produced in several of the most popular size ranges, depending on the brand, it can be transported on platforms of different sizes.

- Facing. It is produced in a hollow version, with a different pattern of recesses. Has standard dimensions 250x90x50 mm. There is also a yellow variety, produced both in ceramic and clinker or hyper-pressed form. The size of one product in this case will be 250x120x65 mm.

The types of pallets used when transporting bricks are also of great importance. For example, when it comes to the size range and carrying capacity, only two options are used in the transport sector. Standard pallets or pallets have a loading capacity of no more than 750 kg, with a platform size of 1030x520 mm. There are also reinforced options. In this case, the pallet has dimensions of 1030x770 mm, and can withstand a weight of up to 900 kg. There are also Euro pallets used in the field of international transportation, and meeting the requirements of the standard GOST 9078-84. Their dimensions are 1200x800 mm, the maximum carrying capacity is 1500 kg. All products for transportation are made of natural wood, with bars as stiffeners.

Production technology

Depending on the type of bricks produced, their production has its own characteristics. This is due to the specificity of the ingredients used, which requires the use of various technological processes.

Red

There are two main methods for the production of ceramic bricks - semi-dry molding and plastic. The latter, which is more popular, involves the step-by-step solution of the following tasks.

- Preparation of the main component - clay. It is allowed to include additives in the mixture - no more than 1/3 of its total amount. In this case, the fraction of the main ingredient should not exceed 1.2 mm.

- Transfer of the prepared mass for further molding.

- Dividing a common array into standard sizes.

- Drying of ceramic bricks.

- Perforation of products (relevant in situations where products need to be made hollow).

- Burning. This type of processing provides for a smooth change in the temperature in the furnace (first upwards, and then vice versa).Following this rule allows you to avoid the appearance of cracks on bricks due to sudden temperature changes.

As for the production of ceramic bricks by the method of semi-dry molding, it implies the following procedure:

- preparation of raw materials and their grinding;

- drying and re-crushing;

- slight humidification with steam;

- re-drying;

- removal of the last traces of moisture from ceramic products.

It is reasonable to mention the production of red brick at home: in this way it is quite possible to make a full-bodied "raw" variety of this material.

To solve such a problem, it is necessary:

- make a ball from a homogeneous piece of clay, previously moistened with water;

- carefully inspect the sample after 4 days - for the presence of uneven shrinkage and cracks;

- if there are no visible defects, the ball must be dropped to the ground;

- if the sample does not pass the strength test, its composition must be reinforced with appropriate additives.

Upon completion of all preparatory procedures, the mixture must be distributed over the forms made of wood. Finished ceramic products will be left to dry in the shade, after which they can be used for the construction of light one-story buildings.

White

One of the main features of the manufacture of sand-lime bricks is the complexity, which does not allow solving this problem at home. In particular, this is due to the impressive list of necessary equipment - conveyors and conveyors, crushers and batchers, mixers and autoclaves, cranes and loaders.

There are two main production methods for the products under consideration - drum and silo.

Silicate brick manufacturing technology includes the following stages:

- checking and preparing the main components - sand and lime (the first is separated from large inclusions, and the second is crushed);

- mixing of components followed by settling in the bunker;

- grinding the mixture and adding water to it;

- slaking of lime, carried out in a drum or silo (determined by the selected production method);

- removing moisture from sand;

- molding with a press;

- steam treatment in an autoclave (recommended temperature - 180-190 ° С, pressure - 10 atmospheres).

At the final stage, the temperature and pressure are gradually reduced. Upon completion of all procedures stipulated by the technology, ready-made sand-lime bricks are packed and sent to the customer.

Plasticity test

The following test can be used to check the quality of the plasticity of the clay. Download a piece of clay as thick as your finger. Screw it onto the bottle. If it does not smear on the bottle, cracks have not formed, and the test specimen has not burst, then we can say that the consistency is suitable for molding.

The need for additives is determined by the condition of the samples and their destruction or notches. In this case, the additive will act as a strengthening "reinforcement". 30% of additives can be used to strengthen oily clays. But for the manufacture of bricks, it is better to refuse them and use only non-greasy clays.

Use as an additive: peat crumbs, hulls from grain crops, sawdust, river sand. To reduce the fat content of raw materials, sand is used, which is added in an amount of no more than 3-5%. And also no more than 20% of other fillers are used to bond bricks.

It should be borne in mind that the size of particles in additives should not exceed 3-5 mm. The amount and percentage of additional materials is determined in the process of trial batching and drying of raw samples.

Low-rise construction and corpulent pattern

The foundation is the first thing that needs to be built for the house. The most important thing in this stage of construction is that the influence of water must be taken into account. It has a destructive effect on bricks. To keep the foundation for a long time, you can buy an ordinary corpulent private.

Ventilated façade - keep in mind that this will serve as a support.That is, it has an important constructive function. The load from the cladding will be transferred to the frame. Therefore, it is worth choosing corpulent as the material for the frame.

How to use bricks for laying stoves and fireplaces can be found in this article.

The video shows more information about the front red solid brick:

A very important property of a brick is its thermal conductivity. Heats up quickly in the sun, and cools down slowly enough

In this regard, in houses that are made of bricks, approximately one temperature is always maintained, it changes slightly. The wall, which will be located below the level of waterproofing, is built from burnt.

The partitions located in the house are also made of solid bricks. If you use dowels-nails, then you can hang the structures on the walls, they will be fixed well enough. Column and building vaults can be made from the red pattern. Not only is the strength high, but it will also help solve complex architectural decisions.

It is worth noting that even the buildings in which kings and kings lived have survived to this day. This once again emphasizes the strength and reliability of the material.

Many churches and temples have also survived to our times.

Having learned about the areas in which red solid brick can be used, you are convinced of its reliability and availability. It became widespread in the construction world.

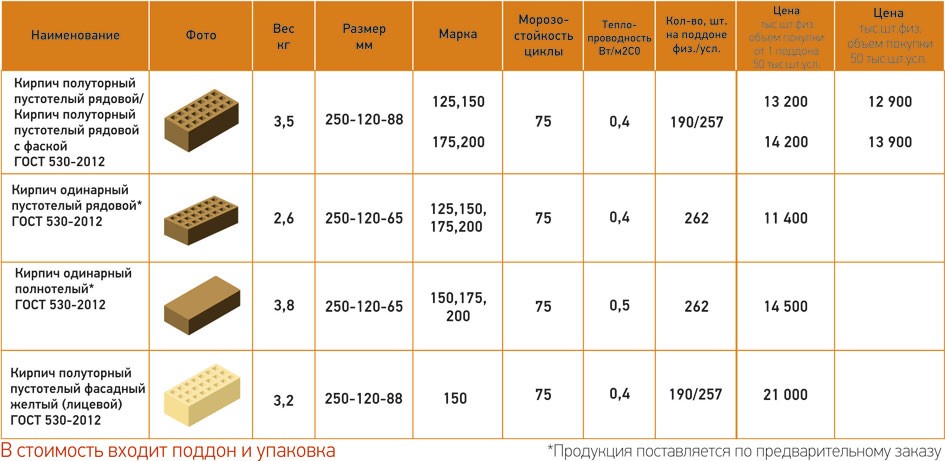

Consider what prices for bricks are offered by different manufacturers:

This form of brick is found according to descriptions in the Old Testament. Red brick was especially expensive. Previously, chopped straw was added to it to increase strength. He occupied a special place in pottery. In the 10th century, a fairly large number of builders arrived from Byzantium, who began to make bricks in Russia. Byzantine builders knew the secrets of brick making.

Until the 19th century, bricks were practically made by hand, that is, they were shaped by hand. And they dried it exclusively in the summer. And only after this stage did they move to a new level of production. Now, experts recommend solid red brick for the construction of their houses. This is a guarantee that the house will be preserved for years to come.

No. 8. The nature of the brick filling

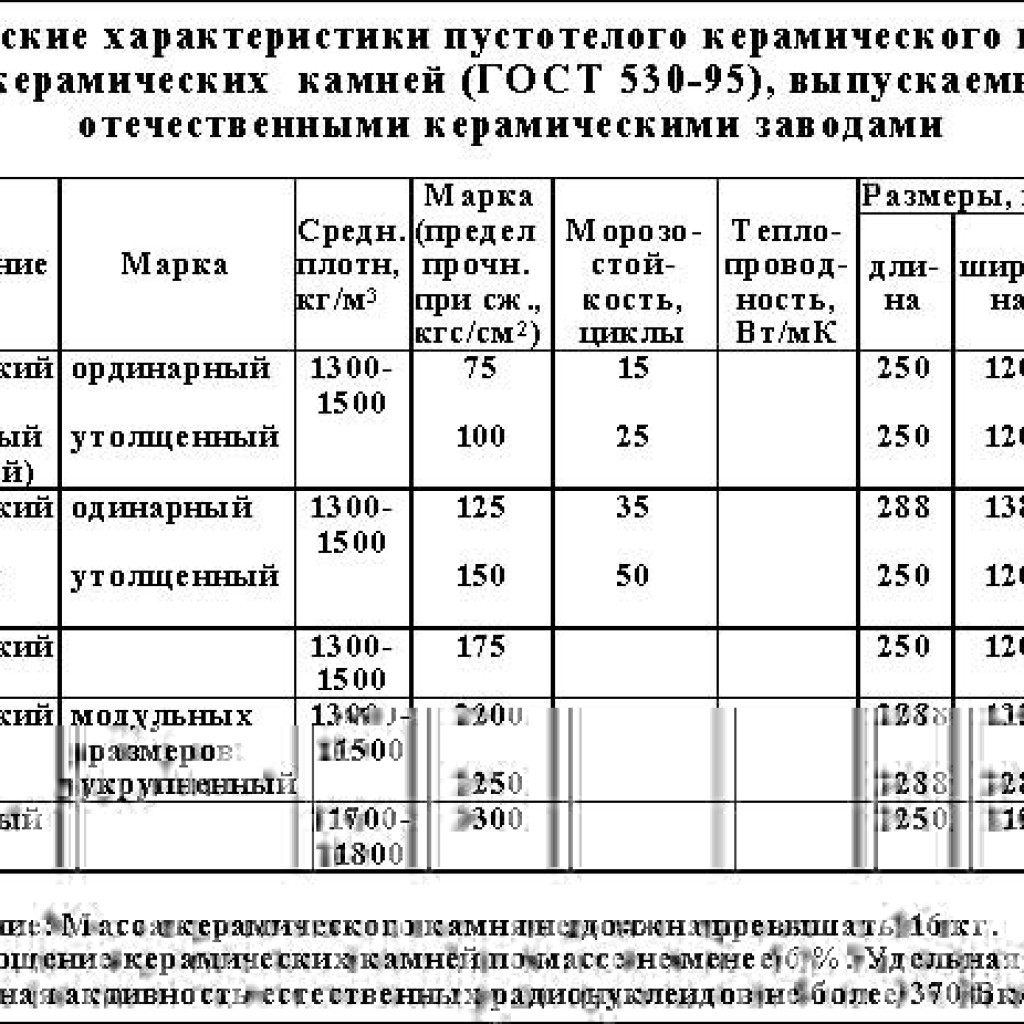

Depending on the filling, the brick can be:

- corpulent;

- hollow;

- porous - a separate type of brick.

Solid bricks have no holes or chambers. They are more durable, therefore they are used for the construction of foundations, walls, columns and other critical structures. Such a material has high bending strength, frost resistance, but has a high thermal conductivity, so the walls must be insulated.

Hollow brick is characterized by the presence of chambers or holes of a round, rectangular or square shape, they can be through or closed on one side, horizontal or vertical. The hollowness of silicate bricks can reach 30%, ceramic - up to 45%. Due to the voids, raw materials are saved, so such a brick costs less, and due to its low weight, it is more convenient to work with it. But its main advantage is its thermal insulation properties, since air is trapped inside the voids. Usually, such a brick is used for the construction of interior partitions and facades, rarely for laying lightweight external walls and never when arranging stoves and chimneys. It is worth remembering that this is a rather fragile material, and the masonry mortar should be thick so as not to flow into voids.

We should also mention porous bricks. These are blocks of rather large sizes, the thermal conductivity of which is 0.14-0.26 W / mC, and the larger the block, the lower its thermal conductivity. Such indicators bring the brick closer to foam concrete, wood and even gas silicate, and record values are achieved due to a special production technology.Porous brick differs from ordinary ceramic bricks in that wood sawdust is added to the clay, which burn out during firing, forming voids, and they, in turn, contribute to thermal insulation. Depending on the desired thermal conductivity and strength grade, a certain amount of sawdust is added.

Working with porous bricks is not very convenient, but walls are being erected very quickly. Moreover, such products have special channels where vertical reinforcement can be poured, and this is an excellent solution for the construction of warm houses in earthquake-prone areas. At first glance, it may seem that porous bricks are too expensive, but if you calculate the price per cubic meter, you may find that it is not much higher than for ordinary ceramic bricks.

The most popular brick colors and textures: facing for every taste

The color of the fired clay itself is quite bright and attractive and is often the preferred color. It is the natural colors that are in the greatest demand and have held the leading position for many years. But still, other options are used.

The most popular color range of facing bricks

It is very easy to give the surface of the facing brick the desired texture. To do this, a textured pattern is applied over the not yet solidified element, after which the element is sent to the oven.

But this is far from the only way to design and decorate the surface of facing bricks. So, along with the main one, the following technologies are also used:

- shotcrete - the process of applying mineral chips to the surface of a brick;

- engobing - the application of a special composition, which, under the influence of high temperature, provokes the appearance of a glassy film;

- glazing is a process slightly similar to the previous one, with the exception that the composition that is applied to the surface forms a film of greater thickness and strength.

Each of these options is worthy of consideration and can be used in the process of facing work. Moreover, bricks designed using various methods can be combined with each other, making out with their help individual sections of the facade, doorways, etc. This will avoid monotony in the design.

Black cladding brick is a rather popular solution for cladding modern or high-tech buildings.

Available colors of facing bricks from various materials

The color of ceramic bricks depends on how much and what kind of additive was mixed into the raw material, as well as on firing. Therefore, we often have to deal with the fact that in different batches the bricks have slight differences in color. In order for this not to be striking and not to spoil the appearance of the wall, it is recommended to take bricks from different batches one by one. So, the color of the surface will be as uniform as possible.

If we talk about the colors of ceramic bricks, then it really is represented mainly by red and brown shades. But on the other hand, their variety is so great that the choice is simply impressive.

But hyper-pressed bricks, in the manufacturing process of which there is no firing, are painted in the desired color by adding pigment to the raw material. This allows you to produce uniform coloring throughout the product and avoid color mismatches in different batches. The most popular are concrete bricks of white, black, pistachio, brown, red, peach, gray, chocolate and blue colors. And those who like non-standard solutions can consider ivory, straw, terracotta and even green.

Concrete bricks can have different color shades

According to the same principle as hyperpressed, silicate bricks are painted. The pigment is added during the mixing of the solution using a special dispenser.

Important! Too much paint in the composition of the solution can negatively affect the strength of silicate bricks, therefore, for this type of product, they often resort to painting only one side. Among the main colors of silicate bricks, it is worth noting white, pink, yellow, orange, gray purple

Among the main colors of silicate bricks, it is worth noting white, pink, yellow, orange, gray purple.