New generation primer-enamel

Acrylic silicone based paint with the addition of corrosion-resistant pigments, inhibitors, targeted additives in organic solvents.

Designed for long-term corrosion protection of ferrous metal products operating at temperatures from -60 ° C to + 120 ° C, as well as operating in an aggressive industrial atmosphere.

Unique properties:

- Minimum drying time.

- Reliable corrosion protection.

- Creates an attractive semi-matt surface.

- Single layer application thickness - up to 80 microns.

- Excellent mechanical strength.

- Increased adhesion to metals.

- Application on items corroded up to 150 microns.

- First class weather and chemical resistance.

A VERY VISUAL EXAMPLE OF COATING EFFICIENCY

Soldiers painted over frost: 3 years have passed, and the coating is in perfect condition

The military unit in the north of Russia received an order to urgently paint all objects and metal structures. At temperatures below minus twenty, the soldiers applied BYSTROMET in mittens and almost directly on the frost.

And the paint not only lay flat, but is also in perfect condition after 3 years of operation.

TOP of the most popular brands of paints and varnishes for metal

Nowadays, enamels for metal painting are produced by a huge number of manufacturers, but not all of them have gained popularity among consumers. However, there are certain brands that are in particular demand and popularity among developers. These are such manufacturers of high-quality paints and varnishes as Hammerite, Ace Rust Stop Enamel, Sniezka, CERTA and others. The TOP of the most popular anti-vandal and protective compounds includes the following brands:

Enamels of the English world brand Hammerite have long established themselves as high-quality compositions for coating metal surfaces of all types. They have excellent anti-corrosion properties and significantly increase the service life of external metal structures.

The main advantages of the brand are:

- very fast drying speed;

- absence of streaks and splashes during application;

- the ability to apply the composition directly to rust;

- high service life (up to 8 years and more).

This American brand produces weather-resistant enamels for outdoor and indoor use. Glazing wood preservatives for outdoor use comparison? The paint of this brand is able to improve the wear resistance of the metal surface for many years.

The compositions have a huge range of colors and are perfect for painting iron doors and other surfaces.

The advantages of Ace products are:

- high anti-corrosion performance;

- resistance to mechanical action;

- long service life.

Sherwin Williams is one of the largest manufacturers of paints and varnishes in the United States. The characteristic features of the enamels of this brand are a magnificent glossy appearance of painted surfaces and a wide range of colors of compositions.

The main advantages of Sherwin William paint:

- increased corrosion protection;

- resistance to mechanical damage;

- weather resistance;

- low toxicity;

Protective enamels from the domestic manufacturer CERTA have been successfully used in our country for fifteen years. The brand produces a quick-drying paint with anti-corrosion properties.

The advantages of the Certa Plast brand are:

- resistance to ultraviolet radiation;

- immunity to temperature extremes;

- weather resistance;

- long service life;

- economical price.

Additional Information:

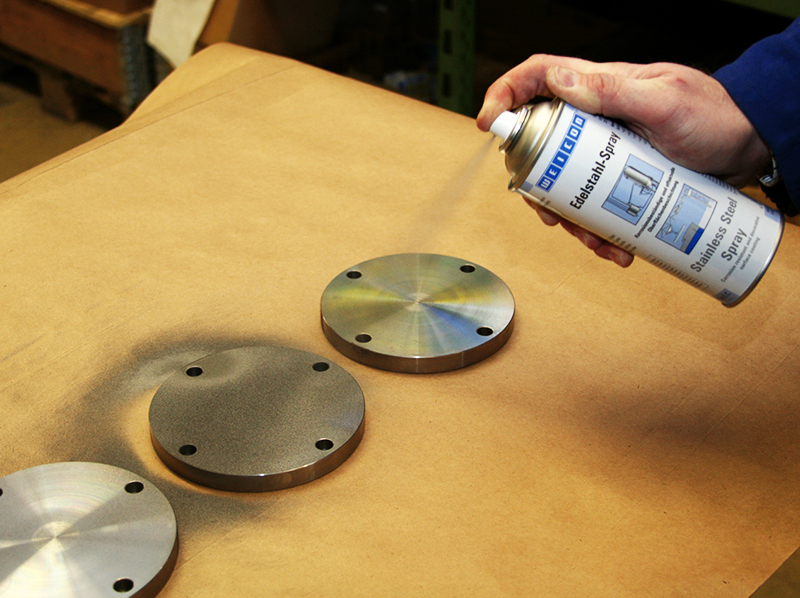

This is a special type of mortar for metal, which allows you to get an interesting external effect. The basis of such compositions may be different, but the decorative result is achieved due to aluminum powder and fine glass fractions. Silicone oil is a special additive.

Today the construction market is replete with a huge amount of paints for exterior metal work. In any building supermarket, you can easily find enamels of various types and types, differing from each other in their composition, technological characteristics and price.

We present a catalog of paints for metal for special purposes: primer-enamels, enamels, paints "3 in 1". The main advantage of our product range is the ability to choose a paint for specific operating conditions, application and for a specific type of metal. An optimally selected protective material is the key to effective operation of metal structures.

It is possible to purchase enamels for metal wholesale and retail at the LKM Torg company. Rust paint for galvanized metal? For more than ten years we have been producing high-quality paints and varnishes, which under the trademarks "Unicom", "Dakril", "Polyureton" in a wide range are presented in the website catalog.

Similar compositions are applied to various surfaces made of metal. They are actively used on rust for outdoor use. There is no need to use primers before applying the enamel to the surface. This is due to the fact that the primer with enamel is a combination of the advantages of a primer mixture, anti-corrosion paint and enamel for metal surfaces.

As a result, the sequence of work with primer-enamel is greatly simplified, and you just have to follow simple recommendations.

All of them are used in most cases in everyday life. In addition to them, there are two-component epoxy paints, silicone-based coatings, polyurethane paints and other types, but these are already industrial lines. These paints provide better corrosion resistance, can withstand high temperatures and withstand aggressive environments. However, the cost of such enamels is quite high, therefore, for household needs, a simpler paint for metal is usually used, the price of which is in the range of 200-300 rubles per liter.

Such material is quite consistent with the quality and is not too expensive.

What to paint

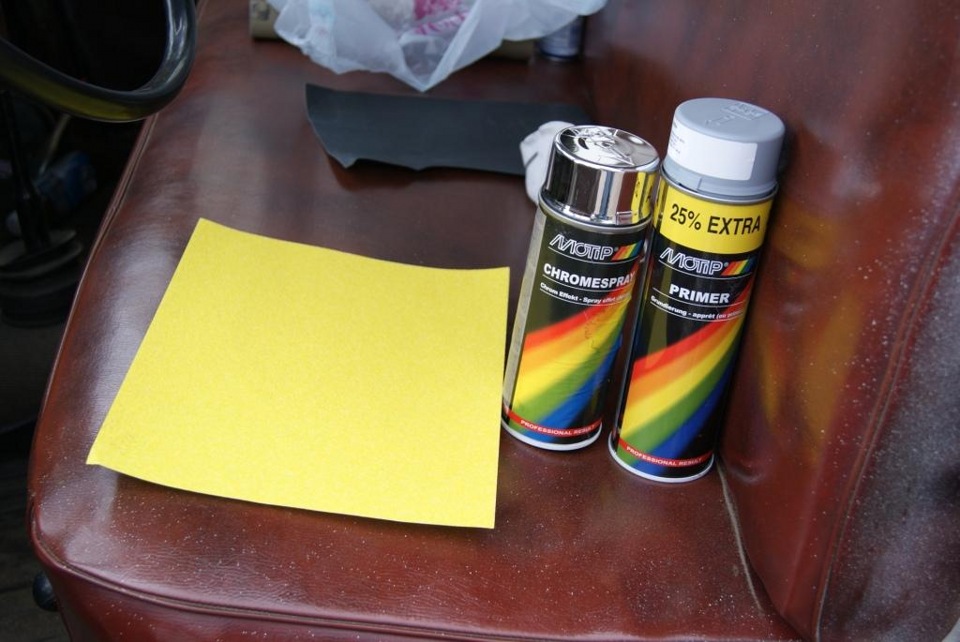

Professional finish with chrome effect in standard packaging

All paintwork materials with a chrome or nickel-plated surface effect on the market can be divided into two general categories:

It would seem that in both packaging there are paints and varnishes, only the method of application is different. But it turns out that there is a difference and it is significant. First of all, the price of a can is higher than the cost of the contents of a can in terms of the same amount of grams.

In addition, the coatings sold in spray cans resemble the chrome surface only slightly, while the materials sold in cans are designed for professional use and guarantee a greater aesthetic similarity.

On the market, paint with a shiny metallic surface effect is represented by one-component and two-component compositions. One-component formulations are, as a rule, what is injected into cans and some types of inexpensive nitro-paint in cans.

Two-component compositions are paintwork materials on an acrylic or epoxy basis. In this case, the procedure for preparing the coating for use will take a certain amount of time, but the result will also be an order of magnitude better than when working with one-component analogs. The essence of paint preparation is that the base is mixed with the hardener until a homogeneous consistency is obtained.

Two-component paints form a dense wear-resistant coating on the surface to be treated.After the paint has dried, varnish is applied without fail. In this case, the varnish will perform a protective function and prevent premature destruction of the paint.

Features of the use of paints for chrome

The use of paintwork materials under chrome for decorating car hubcaps

The problem with using spray paint for chrome is ultra-fast drying. As a result, the coating is sprayed and hits the substrate, but does not have time to adhere to it. As a result, a layer of dried paint is peeled off with a fingernail.

Another important point is that fast-drying paints and varnishes must be applied correctly.

The application technology is as follows:

- carefully prepare the base and apply a black primer or nitro paint on it;

- we cover the base with varnish and dry it until complete polymerization for several days;

- to achieve an optimal result, the coating is polished;

- apply chrome effect paint directly to the gloss;

- after that, we apply another layer of varnish, which will perform a protective function.

In the photo - a reflector of optics, painted with paint from a spray can

A similar technology is applicable to the use of paintwork materials from a can. But in this case, you need to take care of the selection of the appropriate tool.

Browse paint by brand and manufacturer

Consider what chrome paints and varnishes can be purchased in most specialty stores and car markets.

Let's start with inexpensive RUSH Power spray cans, the average price of which does not exceed 300 rubles. The paint is well sprayed, even in one layer it demonstrates good hiding power.

In the photo - products of the RUSH Power trademark

The only problem is the very distant similarity of the painted surface and the real chrome-plated or nickel-plated metal.

Spray cans of this brand are intended not so much for decorating vehicles as for graffiti and other street art trends.

This is also facilitated by the increased penetrating power of the material, which is well absorbed into low-density surfaces.

Bosny CHROME - acrylic spray paint in cans is also a relatively inexpensive way to update a nickel or chrome surface.

Comparatively inexpensive Bosny CHROME paint

It is impractical to work with such paints and varnishes on a surface with a large area, since the coating quickly peels off. The problem of low strength of paintwork materials can be solved by applying a couple of protective layers of varnish from the same manufacturer.

Chrome Effect - this paint is by far the most popular among domestic motorists.

Most similar to real chrome

This is due to the optimal combination of price and quality. Despite the fact that the spray cans of this brand are not the cheapest, it is with their help that you can get the most realistic chrome-like coating.

Then it was necessary to wait for the complete polymerization of the varnish coating. After that, it was possible to proceed with the gentle grinding and polishing of the coating. Immediately after finishing polishing, a final layer of clear varnish was applied.

How to paint rusty metal

Choosing the right paint is not all. It is necessary to properly prepare the surface to be painted. Only correctly applied paint guarantees long-term protection against metal corrosion.

Surface preparation of metal structures

If paint is used that does not have anti-corrosion properties, then it is necessary to remove all rust, down to the smallest traces. For this, the base is sanded with sandpaper. This is the simplest and cheapest method, but rather laborious.

There is a tool that greatly facilitates the preparatory process. It is a rust converter containing phosphoric and tannic acids. Work with such a composition is carried out in the following order:

- Remove the top, most loose layer of the rusty surface;

- Apply a rust converter;

- After a few hours, according to the instructions, wash off the layer of converted rust with water.

A protective work suit and respirator must be worn when working with the transmitter.

After rust treatment, the surface must be primed. The primer is applied in a thin layer, after stirring well. For application, you can use ordinary painting tools - brushes, rollers or spray guns.

Unusual effects

Thermochromic materials have earned the name "chameleon paints" due to their special qualities. Such coatings are capable of changing their appearance under the influence of temperature extremes, for example:

- initially colored paint becomes invisible;

- when heated or lowered in temperature, colorless paint takes on a certain shade;

- Due to changes in ambient temperature, the coating may change color completely.

There are formulations capable of producing any of these effects each time the coating is exposed to heat or cooling, and some are designed for a single "transformation". They call them, respectively, reversible and irreversible.

There are materials commercially available that, when painted with chrome, give the coating a matte finish. In the production of such paints, a special component is added to the composition to reduce the reflective potential of the coating. Plumbing elements, furniture fittings and much more are chrome-plated with this paint. Matte chrome looks austere and sophisticated.

Types of paints for metal

Paints are classified according to composition, purpose and properties. For metal, not only specialized coatings are suitable, but also some universal ones, which can also be used for painting wood, concrete and other types of surfaces. The basis for the manufacture of the coating is of paramount importance - it determines the strength, durability and heat resistance of the composition.

The composition of the following types of paints is distinguished:

- Epoxy. They are extremely toxic, therefore they are not used for internal work. Produced on the basis of silicone resins with a hardener. The coating withstands high temperatures well.

- Oil. Less toxic. The composition is based on natural oils or drying oil. They are used for interior work, as they are unstable to large temperature ranges. Not able to protect metal from corrosion. Therefore, the surface to be painted must be primed.

- Alkyd. They have a low level of toxicity. Used for interior work. They adhere well to the surface even without priming. Cannot withstand strong heating, combustible.

- Acrylic. Non-toxic, odorless. Produced on the basis of polymers. Diluted with water. Versatile in application. Suitable for painting parts that are exposed to heat. Provides protection against corrosion.

- Rubber. These paints are ideal for metal roofs. Toxic, suitable for outdoor use only. Provides additional protection against leaks. Easily removable if necessary.

There are specialized coatings for metal, they are divided according to their properties:

- Anti-corrosion - compounds that protect the metal from moisture and oxygen. Does not require a primer coating.

- For rust - applied directly to oxidized iron. Such paints significantly reduce the time and financial costs for metal processing. Quick drying. Produced on the basis of synthetic epoxy resins with the addition of anti-corrosion pigment.

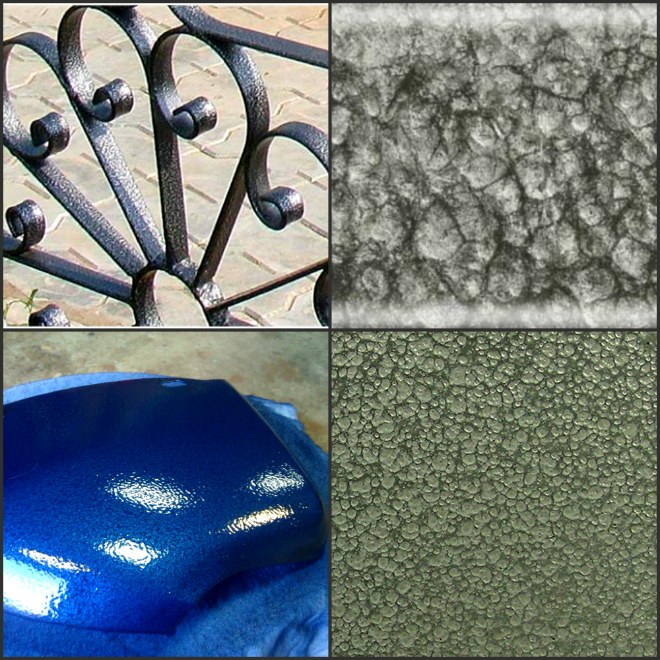

- Hammerheads - when dried, they form potholes on the surface, similar to hammer blows. They can be produced on an alkyd, acrylic, epoxy base with the addition of small particles of glass and aluminum powder. Resistant to mechanical damage.

- Primer-enamels are formulations that combine the properties of a primer, an anti-corrosion coating and an enamel.

- Nitro paints - such compositions are most often produced in spray cans. They are toxic, so the paint in spray cans is used only for outdoor work. Its advantage is that staining does not leave streaks.

- Blacksmiths are made on the basis of polymers. One of the most durable. They have the highest adhesion rates to the base surface.

As a rule, the more expensive the composition, the longer it will last. The most affordable - oil ones - can lose their appearance and crack in just a couple of years. Nitro paints fade in the sun in one season. The hammer has the greatest durability - even after 10 years of operation, it will not change its appearance, but if necessary, it is almost impossible to remove it. The best paint for metal is blacksmith paint, but given its high cost and high consumption, it is not always advisable to use it.

When choosing, be guided by the following indicators:

- Purpose (for indoor or outdoor work);

- Toxicity;

- Consumption and cost;

- Duration of operation;

- The need for preliminary preparation of the metal.

The condition of the metal surface is also important. If it is required to paint ferrous metal with rust, the choice of compositions is narrowed

Also in the case of products that will be exposed to heat or weather conditions.

Grocery list

Rust Beater No.1 Anti-Corrosion Primer for Black Metal Surfaces

Rust Beater No. 1 is intended for priming ferrous metal surfaces. The primer contains zinc phosphate, which provides long-term corrosion protection. Rust Beater # 1 is easy to apply without splashing or sagging. Ideal for priming ferrous metal surfaces in rainy and seaside areas, places with high humidity (for example, in basements, greenhouses). Anti-corrosion primer is extremely lightweight

Primer for metal surfaces from non-ferrous metals and alloys Special Metals Primer

Primer for non-ferrous metals and glass Suitable for priming galvanized, aluminum, chrome-plated, brass, copper, galvanized surfaces and stainless steel structures. It is also recommended for priming hard-to-paint surfaces (glass, tiles, powder coatings, etc.). It is used to create an adhesive layer on the surface of non-ferrous metals before applying a top coat with a hammer, smooth glossy or semi-matt effect. Priming

Hammer effect paint for metal surfaces

Rust paint with “hand hammering” effect Paint for interior and exterior use. Suitable for application on unpainted and previously painted rusty ferrous metal surfaces. It gives an interesting decorative effect of “hand hammering”, hides metal irregularities and is practically invisible in the places where the product is tinted in case of damage to the main paint layer. As part of hammer paint contains

Paint for metal surfaces smooth glossy base for tinting

Rust paint for exterior and interior use Unique 3-in-1 formula: Primer evens out the surface, protection against corrosion - stops rust, the top coat of the scaly structure - blocks the path of water, preventing a drop of it from reaching the metal. Contains active anti-corrosion additives (zinc phosphate). Thanks to its Dual Tech wax technology, Hammerite provides double protection for metal

Smooth glossy paint for metal surfaces

Rust paint for exterior and interior use Glossy Hammerite metal paint for interior and exterior use. Suitable for application on unpainted and previously painted rusty ferrous metal surfaces. The paint creates a weather-resistant and water-repellent smooth finish even on rusty metal. Dries quickly on the surface to form an elastic coating.Heat resistance of glossy paint coating on metal

Smooth semi-matt paint for metal surfaces

Heat-resistant paint for metal semi-matt for protection against rust Heat-resistant paint for metal for indoor and outdoor use. Suitable for application on unpainted and previously painted rusty ferrous metal surfaces. Semi-matt paint is used for decorative finishing of metal surfaces. Thanks to the Dual Tech wax technology, Hammerite metal paint provides double protection of the metal surface

Hammerite Thinner & Cleaner

Thinner for Hammerite paints. Surface cleaner before painting It is used for thinning Hammerite paints and Rustbeater primer # 1. Hammerayt Thinner can be used as a surface cleaner before painting, as well as for cleaning painting tools and removing oil, grease and paint stains from contaminated surfaces. Hammerite Thinner and Cleaner is not suitable for use with waterborne paints.

Metal work

Two methods are also used to paint the car body. To use the first, you need to proceed as follows:

- clean the surface from dirt and dry;

- putty the flaws and wipe problem areas with fine-grained sandpaper, completely remove all dust;

- prime the surface and wait for the composition to dry;

- apply a layer of black paint;

- polish the surface;

- spray the chromium-plating material with a spray gun with a thin layer, dry it and repeat the action the required number of times;

- the last stage is varnishing.

The second method of painting in chrome with their own hands is popular among car owners. This is a good option if you need to paint the alloy wheels, give them a fresh look and mirror shine. For this, powder chrome paint is used. The material has high protective properties: excellent rust resistance, heat resistance, long service life.

The preparatory stage, as in the first method, begins with cleaning and ends with a primer. Next, using a spray gun, powder dye is applied, and the part is placed in an oven, where the material is polymerized.

Types and applications of acrylic paint

Depending on the scope and types of additives used, acrylic solutions also have their own classification. Each species has its own technical characteristics and features.

Each species has its own technical characteristics and features.

Facade paints

From the name it becomes clear that they were created to protect the facades of houses from the negative influence of the environment. In addition to facades, they are used for painting fences, gates, and backyard buildings.

The surfaces painted by them will be reliably protected from rain, snow, a sharp change in temperature indicators, and other harmful influences from the outside. Only the cheapest paints from the acrylic series require additional protective agents to be applied on top. The most durable and reliable are acrylic substances containing organic solvents.

Compositions for facade works, which are based on water, are considered to be faulty in terms of protective properties from natural factors, but when marble crumbs are added to them, these properties become more reliable.

Facade paints are created to protect the facades of houses from the negative influence of the environment.

When it is required to paint metal products, then it is necessary to choose compositions with elements designed to protect against rust formation on it.

It is necessary to choose formulations with elements designed to protect against rust formation on it.

Working with wood involves the addition of special components that resist fungal formations.Colorless acrylics can be used to preserve the natural grain of the wood. Acrylic paint is ideal for covering concrete, plaster, stone, brick surfaces.

Working with wood involves the addition of special components that resist fungal formations.

Interior paints

Acrylic formulations designed for indoor use differ from formulations for outdoor use in the absence of components to withstand environmental influences. But inside the building, they also show their durability, resistance (do not crumble or crack), and the ability to maintain the brightness of the color for a long period.

Since they are easy to apply, work does not require special skills, they are often chosen for painting walls and ceilings in a room, they are great for embodying the most daring design ideas. With them, you can create whole wall paintings in the room.

Interior applications are also possible for furniture, they are suitable for transforming windows and doors. The main difference in artistic use for interior design from oil products is that they do not have a pungent odor, so it is possible to work with them at any time of the year, because you do not need to open windows in the cold.

They are great for embodying the most daring design ideas.

Specialized paints

There are many variations of paints that are suitable for special applications, add components, and they are suitable for a specific application.

Their use for painting bathtubs can be noted, they can be used to refresh the enamel coating of an old bathroom.

To do this, first remove the old coating, and then cover the bath with a moisture-resistant acrylic compound, here it is important to create a thick layer of several millimeters, the surface of the bathroom painted in this way will serve for about 10 years

Their use for painting bathtubs can be noted, they can be used to refresh the enamel coating of an old bathroom.

Acrylic car blends are also popular, they create a beautiful decorative finish that also protects the car from corrosion.

They create a beautiful decorative coating that also protects the car from corrosion.

Acrylic varnishes, which are often used for manicure and pedicure in beauty salons, are widely known. They are easy to apply, you can create a beautiful nail design, such a nail coating lasts for a long time.

They are easy to apply, you can create a beautiful nail design, such a nail coating lasts for a long time.

There are special paints for painting. They are available in tubes, cans, and other types of containers.

They are available in tubes, cans, and other types of containers.

It is not for nothing that acrylic paints are so popular, they have a number of advantages, and can be used to implement many design ideas, and simply as a protective coating for surfaces. Their main plus is environmental friendliness and safety against the background of good practical properties. A wide variety of species makes it possible to choose the best composition suitable for a specific purpose.

Variety of colors

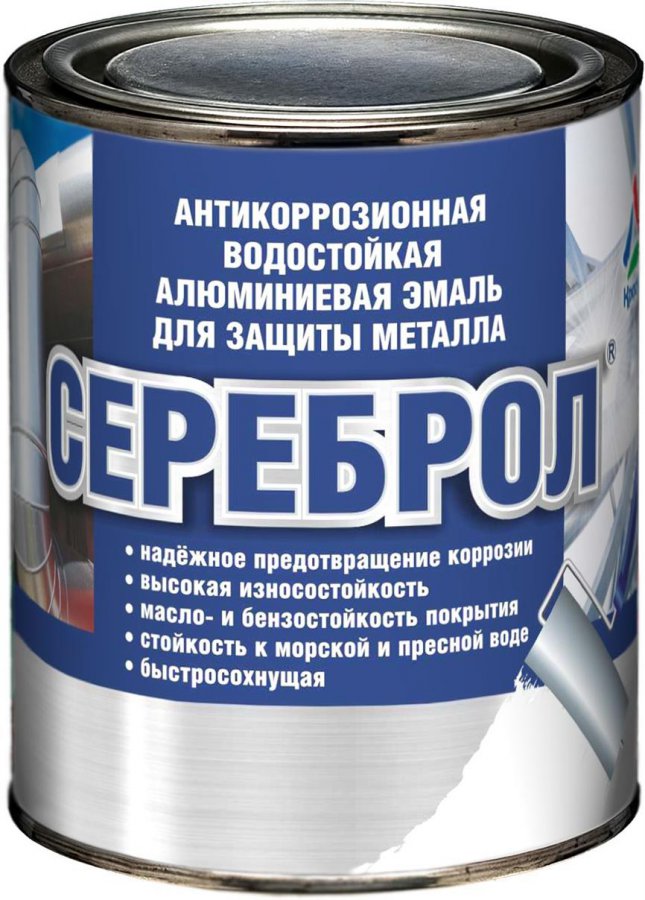

Mineral chrome paint is the most common coloring composition, one of the components of which is aluminum powder. The coating usually has a classic silver tint, but there are other color options:

- The gilding effect is achieved by adding yellow metal particles to the coloring agent. The dried surface acquires an appropriate shade and a mirror-like shine.

- If the aluminum powder is diluted with a translucent black pigment, the result is a very elegant finish. Black chrome surfaces look stylish and unusual.

- To enrich the usual metallic with some other shade, they resort to tinting the varnish, which is applied over the dried paint layer at the final stage of the work.

Acrylic paints

Acrylic paints are generally odorless. Acrylic-based compounds can be used not only for painting the floor, but also for other types of substrates. This paint is often produced only in white, so it can be tinted to give it the desired color.

When purchasing paints with the addition of acrylic, you need to look at the product labeling. Typically, products for rooms with high humidity have a special label.

Such a material can withstand moisture, but here we are not talking about constant exposure to water. Such a coating can sometimes be wiped with wet cleaning, but it will not withstand streams of water (especially hot).

Odorless acrylic-based coloring products are used when painting even an already painted floor surface made of wood or concrete. Very often, such paints are used for decoration in kindergartens, hospital buildings, residential apartments.

Before applying the paint, the base of the surface must be primed. The characteristics of the primer will depend on the accompanying properties of the surface substrate. For example, wood absorbs the primer quite strongly, therefore, for high-quality adhesion, it is imperative to reapply the primer.

When choosing acrylic paints for painting windows and doors, you need to give preference to facade options, since the painted surface will be in direct contact with the external environment.

Specialized components are added to such products, allowing the paints to retain their basic properties for a long time.