Types of paints and varnishes for concrete floors

They are resistant to moisture, to sudden changes in temperature. There is a wide selection of colors and shades. They can be glossy or matte. Acrylic is one of the most readily available materials, but its disadvantages include low strength.

Acrylic silicone enamels

Silicone resins make the compound more durable. The material itself is elastic and has good adhesion to concrete. Gives a light antibacterial effect. The disadvantage is the limited choice of colors, the complete absence of bright shades.

The enamel dries up in 2 hours, but emits fumes and is used only in non-residential premises. Withstands light loads, temperature changes and short-term exposure to moisture.

The main disadvantage is inelasticity, which can cause delamination. Not suitable for industrial facilities.

Epoxy paints

Two-component mixture (base + hardener). Possesses high wear resistance, withstands exposure to moisture, aggressive chemicals. Tinted in colors according to the Ral catalog.

The disadvantages include their inelasticity, however, it is much stronger than alkyd-urethane enamels and does not flake off.

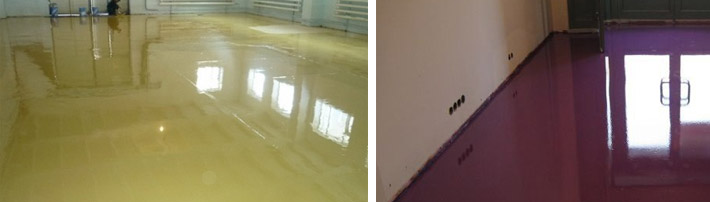

The base of a garage for heavy vehicles in Magadan was painted with Teping P1155 epoxy paint:

Rubber paints

The composition withstands medium loads, is used in industrial facilities, but is inferior to epoxy. withstands high temperature drops. Dries quickly.

The disadvantages include a large consumption of 0.4 per 1 sq. M. and therefore a high price.

Polyurethane enamels

Polyurethane is highly elastic. They withstand shock and vibration loads. They are resistant to temperature extremes - they can be used in freezers.

The disadvantages include a long drying time.

What is rubber paint

This tool is considered a versatile product, since it can be used on almost any type of surface.

General information

To begin with, it is advisable to understand the features of the composition.

The composition by its characteristics resembles a water-dispersion paint.

Dignity

Main Strengths of Rubber:

- Elasticity. After 2-3 coats, the coating becomes rubber-like. An excellent option for a playground, as it will protect children from injury.

- Good adhesive properties. With a well-carried out processing of the base, peeling and flaking are absent.

- No burnout. The color does not fade even after 10 years of use.

- Long period of use, immunity to weather changes. The average period of use is 8 to 10 years. Technical properties are more dependent on the product brand.

- Wear resistance. Thanks to this quality, the coating is used for concrete floors, sidewalks and parking spaces.

- Moisture resistance. The material does not allow liquid to pass through, which is why it is used to cover reservoirs, blind areas and plinths.

- Environmental friendliness. The product is odorless, water acts as a solvent. When used, no harmful substances are released, therefore, the product is applicable in schools, kindergartens and sports youth complexes. Works can be carried out even indoors.

- Fast drying speed. Often this figure is equal to several hours. After this time, you can start applying the next layer.

- Water vapor permeability. When painted indoors, it allows the walls to "breathe".

- Wide scope of application:

- brick;

- concrete;

- metal;

- wood;

- stone;

- tile, etc.

After painting, a strong film appears. It not only improves the appearance of the coating, but also protects it from destruction, preventing the appearance of microscopic cracks.

disadvantages

The disadvantages of rubber-based coating include high cost. The minimum price for 1 kg is from 200 to 300 rubles. Oil paint costs 2-4 times less. But this option is inferior in all characteristics.

The material is well tinted, so it is recommended to acquire white color and make the desired shade out of it. This method will save money on a large painting area. The larger the container volume, the cheaper the cost of 1 kg. The second disadvantage is poor covering ability.

To obtain an even color, the concrete paint has to be applied several times. There is no gloss after drying. The composition practically does not adhere to the uncleaned surface and begins to move away.

Properties

Rubber paint for concrete floors has found wide application due to its qualities:

- impact resistance;

- slip resistance;

- lack of organic solvents in the composition;

- lack of smell (during work and after drying).

This product is used to reduce the accumulation of dust on floors or other substrates. If the room is kept at a constant temperature (+ 20 ° C), it will take only 1 hour to dry.

Rubber is presented on sale in a variety of colors, which allows you to choose a shade for any interior. The treated surface prevents the appearance of defects as a result of mechanical damage or transport loads.

Specifications

The main parameters of the paint and varnish material:

| Specifications | Options |

|---|---|

| Minimum and maximum temperature conditions, ° С | -55…+60 |

| Optimum temperature for painting, ° С | +5…+30 |

| Consumption, g / m2 | 180-230 |

| Density, kg / l | 1,4 |

| Dry residue,% | Not less than 45 |

| Drying time to touch, minutes | 30-60 |

| Final hardening time, hours | 12 |

| Film stretch,% | 400 |

Price

The cost of the most demanded coatings:

- Superdecor (1100 rubles per 6 kg).

- "Prosvet" (2500 rubles per 12 kg).

- Rezolux Universal (2800 rubles per 7 kg).

- Tikkurila Novasil (2000 rubles for 2.7 liters).

The first 3 products are produced domestically, and the last one is produced by a Finnish company. Rubber paint for concrete floor "EkoROSS", Moscow (255 rubles per 1 kg) is of good quality and fast drying speed (30 minutes at 20 ° C).

Coloring compositions

Paint option for concrete surfaces.

For painting concrete, special composites are used, made on the basis of substances of different chemical composition:

- oil and latex paints;

- enamels;

- varnishes;

- water-based acrylic and epoxy emulsions.

The difference between the compositions lies in their protective, operational and technical characteristics.

For example, one type of paint is intended only for internal coatings, the other is used for external and internal surfaces, it tolerates low temperatures and exposure to a humid environment well, does not lend itself to mechanical stress.

Therefore, when choosing a composition for processing concrete surfaces, you need to take into account the conditions of its operation:

- presence of aggressive media (acids, alkalis, etc.);

- ;

- the influence of sunlight;

- mechanical stress in wet or dry climates;

- a sharp change in temperatures.

Staining

the path in the summer cottages can be done with the help of an inexpensive material - wood stain. Water-based formulations are used with different types of active substances - acrylic and acid suspensions.

Due to this, materials treated with acrylic stains have the following properties:

- vapor permeability;

- durability;

- resistance to any precipitation.

After drying, the color becomes more saturated and resembles the shade of a wet stone.

Acid stain is made with the addition of a weak acid solution.This suspension, unlike classical impregnations, penetrates deeply into the concrete body through a branched system of capillaries, simultaneously entering into a chemical reaction with the components of the material.

The dye, interacting with calcium dioxide, creates solid, colored insoluble compounds in the structure of the cement stone. The decorative properties of the acid stain can mimic the texture of natural stone.

stained with wood stain.

Rubber paint

After drying of this substance, a strong elastic film is created on the concrete surface, which protects the base from the formation of cracks, fungi and mold. The coating has a matte hue, is non-toxic, washes well and has a long service life.

Advantages:

- versatility - suitable for all surfaces;

- high degree of adhesion - does not peel off, does not exfoliate;

- the paint is resistant to ultraviolet radiation, temperature extremes;

- waterproofness;

- well perceives shock mechanical loads.

Epoxy and acrylic paints

Epoxy paint is a mixture of mineral fillers and pigments in a liquid resin that gains strength under the action of special hardeners. It is used to create colored protective and decorative coatings on old or fresh concrete base.

Epoxy paint creates a glossy effect.

Performance properties:

- moisture resistance;

- the ability to apply paint layers on surfaces with a moisture content of up to 15%;

- high mechanical strength;

- abrasion resistance;

- high adhesion;

- does not contain organic solvents.

Paints based on acrylate synthetic resins are resistant to weathering, temperature extremes, low cost and long service life (up to 15 years). It is an environmentally friendly product that does not emit toxic substances. The material dries quickly and does not have a strong odor.

The aqueous emulsion can be applied to concrete surfaces without the use of sophisticated equipment - a brush or swab. 1-2 layers are applied at a temperature not lower than +5 ° C. Painted surfaces are highly wear-resistant, do not lend themselves to short-term exposure to alkalis, acids and chemically active detergents.

Polyurethane varnishes

Film-forming polyurethane compositions are made on the basis of polymers of the urethane group. High mechanical strength and wear resistance are the main features of these materials. They can be applied to concrete surfaces even at an ambient temperature of -30 ° C.

Two-component suspensions are combined with a catalyst before use and applied in a thick layer. The quality of the coating in this case is much higher than as a result of using one-component compounds. The disadvantages of this composition are the impossibility of processing products at low temperatures and the high setting rate of mixtures - the solution prepared at the construction site must be applied within 1 hour.

Indoor painting of concrete

Indoor painting of concrete is carried out with environmentally friendly CM. This is the main condition for the coloring composition. The assortment of shades and the availability of possibilities for decorative effects are also important. Depending on the purpose of the paint, the technical characteristics of the compositions also differ.

Applying dye to ceilings and walls

For the coating of concrete walls, a detergent resistant dye is selected. In living rooms, a matt surface is recommended. If you spend a long time in a room with walls with a reflective gloss, fatigue quickly sets in. The matt surface is easier to clean. Recommendations must be taken into account, since KM of the same model range is often chosen for the ceiling and walls.

The choice of CM for a dry room

The purpose of the room is taken into account when a paint is selected to cover a concrete surface.

Living room. In such a room, the main condition for CM is the safety of the material and its shade.

Acrylics and acrylates meet these requirements. The group of water-soluble compounds does not have a toxic odor either at the time of staining or during drying. The compositions have a wide range of shades.

Acrylate compounds are used to create a thin-layer composite material, which creates a glaze and glaze; for thick-layer CM, which is used for relief images. These compounds are used to create a coating on a concrete surface that mimics stone or wood. A set of decorative techniques and special materials are necessary to give the surface of such a design. So, to give the surface a shade of a stone, a relief pattern is used on a thick-layer CM. Later, a glazing treatment is done.

From alkyd compounds in the living room, the unpleasant odor will disappear only after the surface has completely dried.

CM of latex composition and acrylic (water dispersion base) are odorless. That is why they are applied to concrete in children's rooms.

For the ceiling, a water-based emulsion is recommended. It is an economical, harmless, easy-to-use material. Since it does not withstand moisture and mechanical stress, the room where the paint will be applied must be dry.

Public use room. In premises where there is a mass congestion of people, with their high traffic (shopping malls, parking lots), CMs are applied to concrete that are resistant to wear and tear, with "vandal-proof" properties. Such characteristics are possessed by alkyds, epoxies, polyurethanes.

In industrial premises, the concrete surface is most often decorated with a stone look. Mosaic paint is used for the walls, as an imitation of granite chips.

Video:

Exterior painting of concrete surfaces

If your concrete porch, figured piece such as a statue, or walkway is new and looks flat, apply acrylic latex paint with a roller without prior preparation. 5 liters of thick composition covers up to 12 square meters of surface.

Acrylic wear-resistant latex with low gloss is resistant to UV rays, abrasion, fading, cracking and flaking, making it an excellent choice for covering minor imperfections and providing a durable and effective finish.

Low gloss acrylic wear resistant latex resistant to UV rays, abrasion, fading, cracking and flaking.

Low gloss acrylic wear resistant latex resistant to UV rays, abrasion, fading, cracking and flaking.

If the concrete is old, cracked or highly porous, then it is advisable to apply the so-called concrete restorers. They are 10 times thicker than paints and fill cracks up to 6 mm thick. Also provides slip resistance and durability, with each new coating lasting up to 12 years. Together with the paint, the frost-resistant restorer will provide long-term protection of the concrete from moisture. A 5-liter can of the restorer is enough to renew up to 20 square meters of concrete.

These are siliconized (i.e. thickened with a fine sand filler) gray or white acrylics - with high performance resins that form a strong, durable and opaque film on properly prepared surfaces.

Sand out any splashes, lumps or uneven areas on the concrete with a hard scraper. Next, brush with water to remove any stubborn dirt. Allow the surface to dry completely, then seal all cracks and cavities with cement filler. More than one coat may be required. Let the sealant dry completely.

Using a brush (around the perimeter) and a roller (around the main surface), thoroughly saturate the surface with a concrete primer. Let it dry, it takes at least two hours for each layer. To obtain a good result, it is recommended to prime it twice. Repeat with the paint.

Sand down any splashes, lumps or uneven areas on the concrete with a hard scraper.

Sand down any splashes, lumps or uneven areas on the concrete with a hard scraper.

To summarize, we can say that decorative and at the same time protective painting of concrete is a simple and inexpensive task that most homeowners can solve on their own.

Varieties of paints

Concrete is used for cladding both inside the building and outside. Therefore, paints and varnishes are divided into two classes: for external and internal work. They differ in composition and protective characteristics. The main types of paint for concrete:

- Alkyd. It belongs to universal materials and can be used for painting any surfaces, including concrete. Weatherproof paint can withstand temperatures from -50 to + 60 ° C. It perfectly protects the surface from abrasion, retains a rich color for a long time, creates a protective film on the surface, therefore it is often used as a facade coating and for painting balconies. For concrete structures that are exposed to weathering, alkyd black enamel is sometimes used. Applied to a previously primed surface, it retains its properties for 6 years.

- Acrylic. Exterior concrete paint. Made from acrylic and polymer resin. Dries quickly, is abrasion resistant, protects the concrete surface from temperature extremes and moisture. Can be used for painting concrete floors and walls indoors (in garages and production sites). Heat-resistant acrylic paint VDS-30, resistant to alkalis and gasoline, is used as floor protection in car repair shops.

- Water-based. Dry white powder to be diluted with water. A versatile material that can be applied to any surface. Its main advantages are environmental safety, non-flammability and low cost. Disadvantages - poor resistance to temperature extremes and mechanical stress. Now, water-based powder compositions, like oil paints, are used mainly for decorating utility rooms.

- Epoxy. Hardwearing concrete floor paint consists of two components that are mixed with a paint mixer just before painting. The most resistant and durable material that is used for painting industrial sites, parking lots, large open surfaces that constantly experience temperature changes. Long-lasting coating looks presentable even after several years of use. Water-repellent paint has waterproofing properties, is resistant to aggressive chemicals, retains high adhesion and bright color over a long period.

- Polyurethane. It also contains two components, which must first be thoroughly mixed and then combined. The unique qualities of this paint allow it to be used in the most adverse conditions. It serves for many years where any other coating will quickly deteriorate. Polyurethane has a huge margin of strength and durability. It goes well with any surface - concrete, metal, wood, stone; used to cover porous and even loose material. Polyurethane itself is harmless, but the solvent that it contains poses a health hazard. After complete drying, the paint becomes harmless.

- Rubber. It is mainly composed of acrylic, silicone additives and silicate glue. The rubber paint finish is hardwearing, impervious to moisture and chemicals. The concrete surface acquires a rich color and looks spectacular. The coating can be easily removed with a special solvent.

Varieties

Like all paintwork materials, concrete paints are divided into groups depending on the base:

1. Epoxy.

One of the first mixtures to appear for the protection of concrete surfaces.When applied in two layers, it is completely waterproof, which makes it suitable for outdoor use. Another feature is chemical resistance, and not only to aggressive media like sea water, but also to reagents. Ideal for concrete because it has good adhesion to it. And if you lay it on a floor that has not yet been frozen, then it is almost impossible to get rid of the coating later.

Wear-resistant epoxy floor paint allows you to significantly reduce the time of finishing work, if the object needs to be commissioned early. In addition, it is environmentally friendly, which means that it is safely used indoors.

The color fastness lasts for at least 10 years, but it will be difficult to radically change it at will. That's why when re-staining it is better to stick to about one tone. Moreover, the color palette is not very diverse. Wear-resistant epoxy paints can be found in Russian brands: Teping, Texil, ESP-Polymer.

2. Polyurethane.

Universal compound for outdoor and indoor use, which consists of one or two components, mixed immediately before starting. The technology is somewhat non-standard: the first layer is made very thin, it is a kind of light impregnation to improve the adhesion of the main coating to concrete. Only after the primer has dried can the polyurethane mixture be finally applied.

The curing time for the wear-resistant polyurethane compound is very long, as it acquires new properties over time:

- 2 days - superficial setting;

- 1 week - mechanical strength;

- 2 weeks - chemical resistance.

Otherwise, polyurethane concrete paint is as reliable as epoxy paint, but its consumption and cost are lower. It will save even more if, instead of impregnating with the paint itself, you use a suitable primer for concrete on the same binder.

Wear-resistant paint can be found in the assortment of Teknos, Biofa, Texil. Another type is made of polyurethane - a polyurethane-alkyd mixture. But taking all the disadvantages from the polymer base, she got her own. Within three weeks, when the concrete floor dries, the paint coat will continue to poison the indoor air with toxic fumes. And having gained full strength, it will not acquire resistance to chemical attack.

3. Acrylic.

Moderately wear-resistant paint is better suited for home use. Its water resistance is good, but only in the absence of other destructive factors. Therefore, you can paint the footpaths in the yard, or the concrete floor of the garage, but not the entrance to it. Allows single-layer application, but even professionals prefer to play it safe and make the layer thicker. Still, its durability is not the highest. Of the advantages, excellent anti-corrosion properties are noted, which will be relevant for concrete surfaces with protruding metal elements (ends of beams, corners, brackets).

Therefore, in pure form, acrylic compounds are not applied to concrete floors. To improve the characteristics of the protective coating and increase its service life, more complex mixtures are made by combining acrylic with the same polyurethane. For example, the wear-resistant acrylate-urethane paint Betolux from Tikkuril has very decent characteristics: in addition to increased strength, it is also resistant to oils and solvents.

4. Rubber.

A paint on a silicone, acrylic-silicone or acrylic-latex base with a long stretch can be called wear-resistant. Although it is considered weatherproof, it manifests itself much better on facades than on the floor.

Main pluses:

- elasticity of the coating;

- antistatic effect, facilitating floor care;

- obstacle to the development of mold in damp rooms;

- resistance to aggressive chemicals;

- non-toxic and environmental friendliness.