Painting methods

Embossed wallpaper is usually painted with a spray gun or a regular roller with a long nap, and a narrow brush will help to paint over the corners.

These tools will ensure that the paint is evenly applied to the canvases.

It is better to start painting glass fiber wallpaper with a narrow brush from the upper and lower areas, as well as corners, after which you can apply a roller.

If the walls and ceiling are pasted over with fiberglass, then you should always start from the ceiling.

The painting is performed in two layers, allowing the first to dry for about 12 hours.

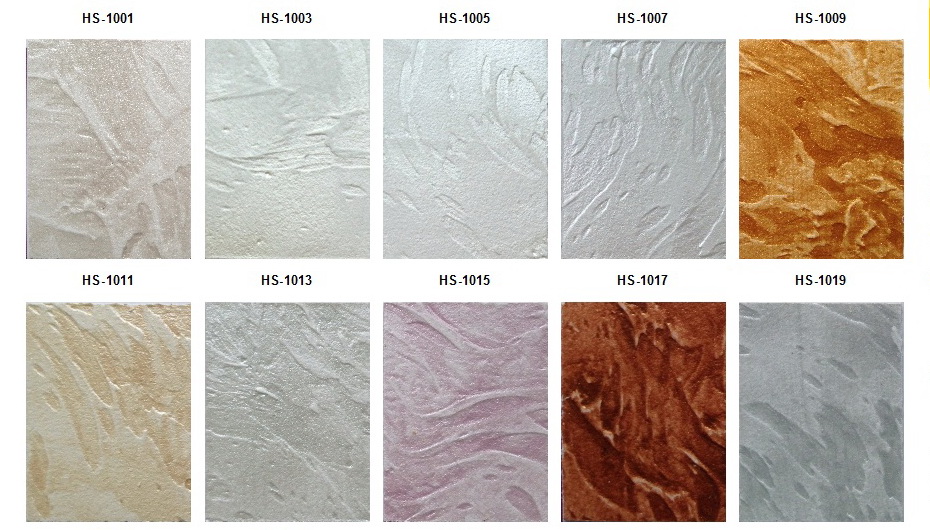

To make the final result more decorative, glass wallpaper can be painted using various techniques:

- using borders;

- using stencils;

- doctor blade staining;

- painting with azure.

Using curbs

Using borders, you can very easily improve the interior of any room. This is one of the most commonly used methods of painting glass cloth wallpaper.

With this method, two options are possible:

- choose fiberglass wallpaper with a pattern of one texture on top and bottom of the border;

- choose a canvas pattern of different textures in relation to the border.

Beforehand, markings are applied to the wall, the upper and lower parts are painted in two layers with an interval of 12 hours, and after 10 hours of drying, a border suitable for the relief is glued.

Stencil painting

By means of stencils on glass wallpaper, a geometric composition, ornament, pattern is created. It is necessary that the selected pattern matches the texture to the fiberglass.

After painting and drying the canvases, using masking tape, the desired pattern is applied to the surface.

The application of patterns should be done slowly and carefully; a piece of foam rubber or a sponge will do.

Be careful not to get paint under the masking tape

Take it off carefully in a day

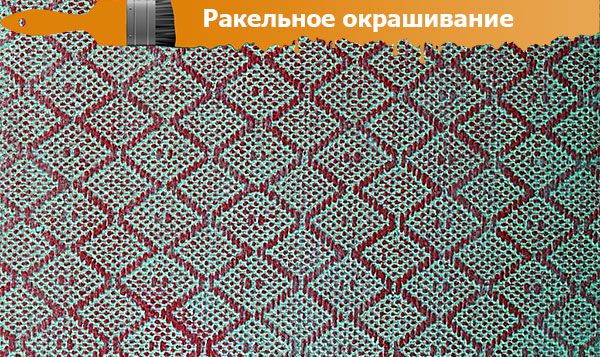

Squeegee painting

Squeegee painting impresses with its simplicity and efficiency. With this method, the first layer of paint should be deep and intense.

After drying, a water-based varnish or a composition with a metallic tint is applied.

After 20 - 25 minutes, the applied last layer is carefully spread with a rubber spatula over the surface of the fiberglass. Clean off the top layer and excess with a moistened sponge, the paint remains only in the embossed recesses of the wallpaper

Clean off the top layer and excess with a moistened sponge, the paint remains only in the embossed recesses of the wallpaper.

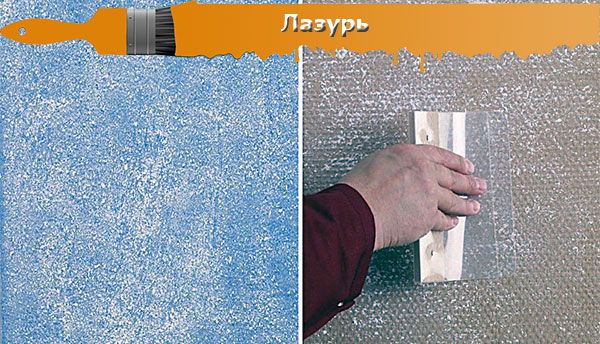

Azure

Using azure, you can achieve all sorts of color schemes. First, a layer of paint is applied using a roller or spray gun.

After the canvases have dried, the glaze is applied with a flat brush, transverse, small strokes. After 15 - 20 minutes with a rubber spatula, glaze is evenly distributed over the surface.

To achieve a more intense color scheme, cover the wallpaper with glaze 2 times.

Surface preparation for application

Before covering the wall with facade paint, it is necessary to prepare a base for it: this ensures the quality of painting, reliable adhesion of the coloring material, and the durability of the coating.

Surface preparation stages:

- cleaning (if any) from old paint. For this, special means are used to remove the stale layer, or cleaning is carried out by scraping;

- alignment of walls. It is produced by applying a putty. In addition, protrusions are removed and large gaps are closed.

Remains of dust, dirt should be removed, and the surface should be dry.

Types and characteristics

Interior paint is a general term that brings together almost all types of mixtures found on the market in this group.Depending on the structure and composition, these solutions can be divided into several large types.

Emulsion paints

The main component of such mixtures is water, which often acts as a solvent. Among the advantages of such products are environmental friendliness and fire safety (non-flammable paints). The solutions contain only natural ingredients that do not affect the environment and humans in any way. Another plus is the absence of an unpleasant odor that accompanies other types of mixtures.

Depending on the composition, emulsion paints are divided into several more groups:

water-based and water-dispersed mixtures. These solutions are almost identical in composition. They differ only in resistance to moisture. Water-based paints are much less resistant to humid environments, but they have a wide range of color shades. The color of many of them can be changed by adding color to the structure of the liquid;

acrylic. Paints of this type are based on acrylic resin, which is mixed with fine dust of natural or artificial origin. A feature of the mixtures is their high resistance to mechanical stress.

The film repels water well, but at the same time does not allow air to pass through, which is important for some materials. The only drawback of acrylic paint is its high price compared to similar products;

polyvinyl acetate

These products are the cheapest, as the paints are practically unable to withstand water and can be easily washed off with a damp cloth. The advantage of these mixtures can be considered their absolute environmental friendliness and safety. Many manufacturers add various components to the composition in order to improve technical performance;

Alkyd

These paints were made on the basis of alkyds, which, after drying, form a very durable film. The drying time for these solutions reached 2 days, which is not always practical in the modern world. Alkyd mixtures, when dried, emitted harmful volatile substances into the air. You can work with such paints only in protective clothing and respirators. But at the same time, indoors they are quite common, since after drying they become harmless and repel water well.

Enamel

The main component of such a solution is varnish of various kinds. Enamels are versatile, as they can be used both outside and inside the premises. The resulting layer dries quite quickly (it all depends on its thickness) and easily transfers ultraviolet radiation. The paints have an optimal balance of strength and water resistance.

Adhesive

Compositions of this kind are made from water-based organic polymers. The products are marketed as dry mixes. To obtain paint, it must be diluted with water in the proportion indicated by the manufacturer. Among the advantages are a wide range of colors. Materials of this type are of limited use, since the top layer is easily washed off with water, and is also destroyed by carbon dioxide.

Silicate

These are unique solutions, as they are composed of liquid glass. To bind it, alkaline mineral mixtures are added to the structure. After hardening, the top layer is air permeable and is able to withstand significant temperature fluctuations. The only drawback is the minimal moisture resistance. Mixtures are used for painting concrete surfaces in need of decoration.

Polymer cement

Materials of this type have appeared on the market relatively recently. In many ways, the products are similar to silicate mixtures. The main components of polymer-cement paints are white Portland cement, ground lime, lightfast pigments and aqueous dispersion.To bind all these components, synthetic latexes and polyvinyl acetate-based emulsions are added to the composition.

The compositions are used for painting concrete, brick or wood surfaces. Some varieties can also be used to cover reinforced concrete structures. Solutions can be used only at temperatures not lower than +2 degrees.

Polyester

Paints of this type are dry mixtures that are obtained in the process of homogenizing different substances. It is applied to the metal surface using the electrostatic method. They are rarely used for finishing interior domestic premises, since in some cases paint fusion can occur at very high temperatures.

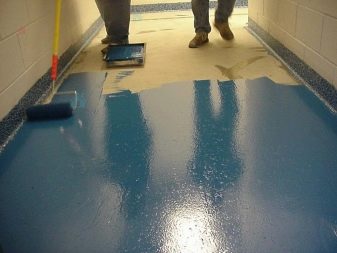

Painting technique for different types of surfaces

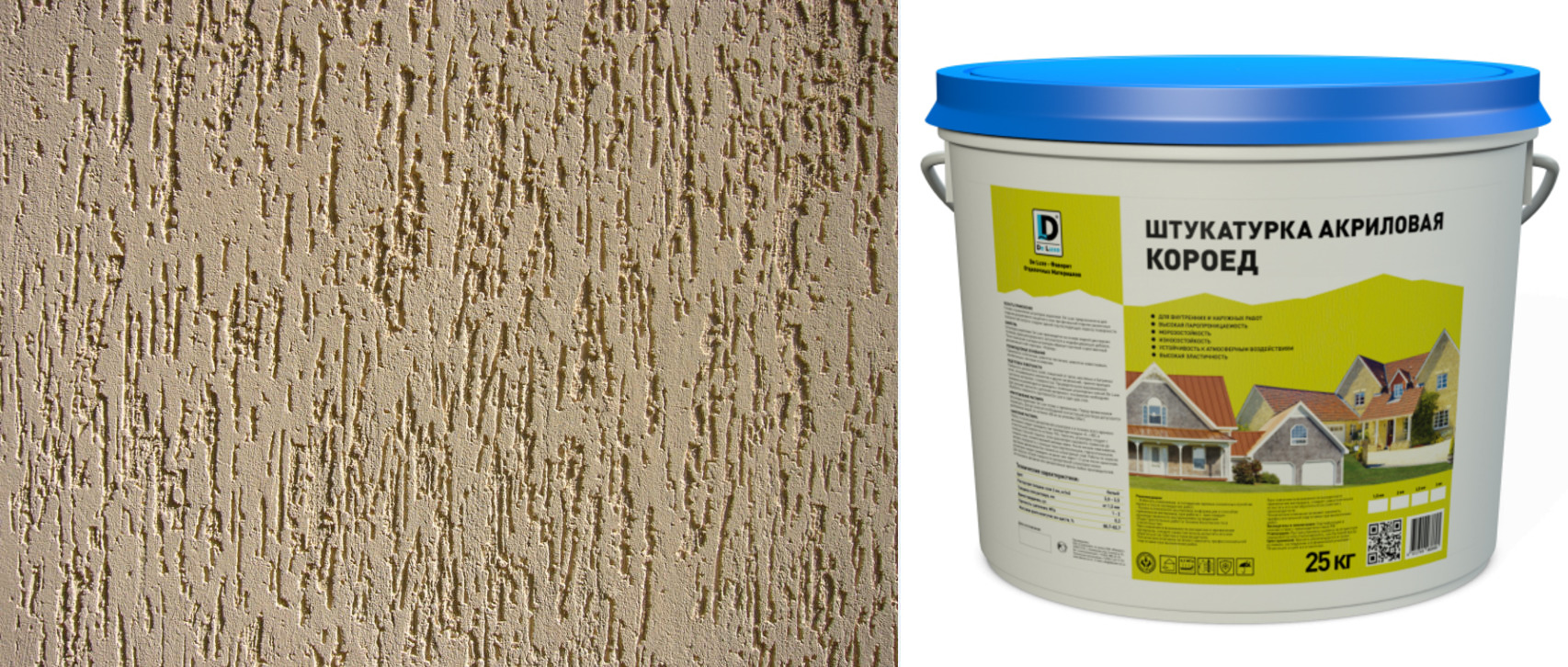

The most common types of products that are used to plaster walls are cement and plaster, they can be of a mixed type. To obtain the desired result after painting the surface, you should adhere to the following stages of work:

- They start with an assessment of the surface condition, if necessary, the surface is cleaned, existing defects are removed, putty can be applied. The cleanliness of the wall is important, because any unnecessary details will be visible through the painted coating;

- Dust is removed with a brush or roller, then the surface is primed, this stage will help to reduce the consumption of the coloring agent, and also increase the adhesion;

- Paint application tools can be brushes, rollers, or a spray gun. The choice should be made based on the experience of the master, his preferences and the type of paint, not all can be used with a spray gun. The data can be found in the manufacturer's instructions. Usually, hard-to-reach places and corners are treated with brushes, and they work with a roller along the rest of the wall;

- Based on the type of paint, it is being prepared for use. Some species are diluted with solvents to obtain the required density. If a basic white color is purchased, then a color scheme is added first, it must be introduced gradually, checking what color it turned out, you can test in an inconspicuous place to make sure that the desired shade is obtained. All breeding is carried out strictly according to the manufacturer's recommendations;

- When working with a roller, movements are done from top to bottom. Usually 2-3 coats are required, each of which must dry before applying the next. The spray gun should be at a certain distance from the wall, usually 20-30 centimeters. It is also recommended, in the absence of experience, to test its work on an inconspicuous section of the wall.

Usually 2-3 coats are required, each of which must dry before applying the next.

Usually 2-3 coats are required, each of which must dry before applying the next.

How to calculate consumption

The first step in calculating the area of a room, you need to multiply the measured lengths and heights of each wall, they add up. Then they recognize the area of windows and doors in the same way. This figure will need to be subtracted from the area of the room if they were taken into account in it.

The average consumption of each product may differ, so you need to know it, it is always written on the package. This figure is multiplied with the area of the room. As a result, a figure in kilograms is obtained, how much paint is needed for staining.

Also, when calculating, you need to take into account the number of layers, each new layer usually requires less paint.

The first step in calculating the area of a room, you need to multiply the measured lengths and heights of each wall, they add up.

Painting plaster can be a great option for wall decoration, it is bright and looks aesthetically pleasing.

There are many types of paints and varnishes for interior work, when choosing it is important to focus on the type of room that is going to be painted. The article described in detail the available types of products, this should help determine the appropriate option for finishing a particular room

The work itself is not difficult, it is important to properly prepare the surface, because the paint emphasizes any flaws.

Suitable paints

We can confidently say that it is not at all difficult to paint the walls covered with fiberglass, you don't even need to finish special courses for painters. However, it is advisable to choose a suitable wall paint so that it looks great and holds well.

I would like to say right away that the choice of ordinary water-based paint is not the best, since it is difficult to apply to such coatings, and its practical properties are not the best. Washing such walls will not work, and their surface will be rough, and in some cases a brand.

Another thing is if the paint for glass wallpaper is acrylic, latex. By and large, this is the same water-based emulsion, but it contains components of acrylic or styrene-butadiene (latex), which improve its quality. It is worth choosing a composition marked "washable", since this is the most practical type of paintwork.

Painting glass wallpaper with acrylic or latex paint and varnish material will preserve the appearance and basic technical properties of the wall covering for a long time. For example, fiberglass painted with acrylic paint will also remain fireproof, environmentally friendly, moisture-resistant, and even more durable. Through this latex or acrylic paint, the texture of the wallpaper that you liked is excellent visible.

Acrylic Interior Wall Paint

At the same time, I would like to note the advantages of the paint:

- All water-based paints are acrylic and latex, odorless.

- It is very easy and simple to apply paint on glass wallpaper for painting with a roller, spray gun or brush.

- The speed of absorption and drying of the acrylic composition is quite fast, several times faster than other paints.

- During work, you should be careful to get dirty as little as possible, but there is nothing terrible in this, because water-based paints are easily washed off with water. In the case of acrylic, the water is relevant until the paint has dried, and then you will have to use solvents.

- The choice of paintwork is very large, in any hardware store you will find 3-4 worthy brands. Among foreign brands, everyone knows Tikkurila; among Russian brands, Teks, VGT, Dali can be distinguished.

- The cost of paint and color is low, acceptable for most people.

Once the paint has been applied to the walls and dried properly, it will look great. Caring for it will not be difficult, since such a coating can always be washed using a sponge, rag and soap solution.

Practical and durable glass wallpaper is used everywhere

Note that paint for glass wallpaper for painting is consumed to a large extent due to the technical features of the wallpaper, besides, the first painting is recommended to be performed in two layers. Therefore, it is necessary to budget for at least 500 ml of paint per 1 square meter. Yes, this is quite a lot, but most likely this is exactly how much paint and varnish material will be required for application to the walls.

Experts say that it is possible to reduce paint consumption if a liquid diluted glue is applied to the glass wallpaper in the first layer. This composition will allow the well-absorbing texture of the glass fiber to be thoroughly impregnated, after which the paint will adhere well and be consumed less.

Properties

Water-based paint is distinguished by a unique

application technology. From the point of view of the person applying the paint, the process

painting takes place the same, but at the molecular level serious

composition changes. Before application, the paint is water with many

additives mixed in it. These particles are not dissolved in water, but simply stirred.

in it, and being in this state, do not interact with each other.

When applied to a surface,

significant composition change:

- water evaporates, activating particles

paints; - binders converge,

turning into an even uniform layer; - hardeners give the coating

relative stiffness.

Considering that the solvent in similar types

paints are water, no harmful and toxic substances are emitted during evaporation.

The fire hazard of painting works is also minimized.

Another clear advantage is

durability and the ability to apply a new layer directly to the old paint. Front

applying a new layer does not require any special treatment or removal

old paint (provided that the old coating was not oily).

Negative property of water-based emulsion

paint is the effect of corrosion when pure metal comes into contact with water. But

a number of manufacturers, using modern additives, have established the production of paint,

minimizing such consequences.

Composition

The exact composition will vary depending on

paint manufacturer and its purpose, and, as a rule, is kept by the company in

secret. But, without going into the smallest details, it can be argued that any

water-based paint consists of the following components:

- 40-60% water and dissolved in it

film former; - 30-40% fillers and coloring pigments;

- 5-10% plasticizers;

- 5-10% other additives.

To create facade paints, always use

antifreeze designed to withstand freezing temperatures, and acrylic

resins to give elasticity to the finished paint layer. Also apply

ultraviolet and infrared filters to prevent damage,

caused by solar activity. Waterproof

paint is obtained by adding synthetic rubber to the composition or

analogs.

Shelf life

The shelf life directly depends on the storage conditions.

Manufacturers guarantee the complete safety of the product for at least 6

months, the same period is fixed by the current GOST. The paint should be stored in

sealed original packaging without exposure to sunlight.

The storage temperature is strictly positive, from +5 to + 30 ° С. Allowed

transposition at low temperatures, but not more than 1 month.

In fact, the paint is stored at least twice

longer, and some manufacturers still indicate on the packaging a period of 12

months. After this period, the paint will begin to lose its properties, but for local

works, many also use 2-year-old remnants of already open paint. Requirements

it is better to observe the temperature regime, because a significant part of the paint is water,

which can turn into ice.

Viscosity in DIN

According to the current GOST, the viscosity

water-based paints is at least 30din. Overwhelming

most manufacturers supply paint with a viscosity of 50-60 and more, for

subsequent dilution with a solvent. Measurements must be carried out at

paint and ambient temperature within 18-22 ° С, otherwise indicators

will not be true.

Depending on the method of applying the paint,

the optimal viscosity of the composition will also change:

- 20-25 when using

spray gun; - 30-40 for roller

- 40-50 for a brush.

When diluted with water-based paint with water

it is recommended to use only distilled water. Plain water from

under the tap or the nearest body of water is not suitable because of the contained in its composition

various impurities. When applying paint with similar water to the surface, after

evaporation of water will leave white marks and streaks.

Basic rules for working with silicate paints

The application of this type of paints and varnishes to the surface to be treated is practically no different from working with other types of paints. You can paint with a brush or roller, as well as a spray gun.But in order for the coating to be of high quality, certain conditions must be observed:

- The surface to be painted must first be thoroughly cleaned of dust and dirt, remnants of the old coating (especially if it is an organic paint and varnish material).

- All irregularities and cracks must be repaired with mineral plaster or putty. A silicate dye composition will not be able to hide even the smallest crack.

- A water-based primer should be applied to the prepared surface and allowed to dry.

- It is allowed to work with these coloring materials at temperatures not lower than 5 degrees Celsius.

- It is undesirable to get moisture and direct sunlight on a freshly applied coating. Otherwise, the structure of the material may become spongy and brittle.

Work with paintwork materials should be using personal protective equipment, and avoid contact with the dye on exposed skin and eyes. If this does happen, you should urgently rinse the affected areas with plenty of water.

You may also be interested in reading what is acrylic paint for facades and the features of its application.

Varieties of paints for plastering, advantages and disadvantages

Plaster paints for interior work on the construction market are presented in large quantities. But you should not buy the first one that comes across; when choosing, you need to take into account the characteristics of the apartment, the wishes of the tenants for the external design. Below is a description of those types of paints and varnishes that can be used for painting indoors.

Plaster paints for interior work on the construction market are presented in large quantities.

Plaster paints for interior work on the construction market are presented in large quantities.

Water based paint

Water-based formulations are popular, they are environmentally friendly, so they can be applied indoors safely. They create a matte finish, but the color palette is not rich, the use of color schemes corrects this defect, with them you can get any shade.

Can be applied on all types of substrates, easy to apply. However, it does not withstand the effects of moisture, therefore it is suitable only for dry rooms. To get the best adhesion, a priming stage of the walls is preliminarily carried out.

Can be applied on all types of substrates, easy to apply.

Can be applied on all types of substrates, easy to apply.

Acrylic washable paint

Washable acrylic paint for interior work on plaster is suitable for rooms with high humidity. The following characteristics characteristic of the composition are distinguished:

- Withstands the effects of moisture, which creates the possibility of washing the surface with damp rags, the brightness of the color will not decrease from this process;

- It is possible to add color schemes to get the desired shade. That allows you to implement any design solutions;

- Creates a matte finish;

- The strength properties are high;

- Ease of work;

- Long-lasting result;

- High rates of elasticity.

Washable acrylic paint for interior work on plaster is suitable for rooms with high humidity.

Washable acrylic paint for interior work on plaster is suitable for rooms with high humidity.

Silicate paint

Silicate plaster paint is created using water glass, pigments and fillers. If the painting was carried out according to the rules of work, then such a coating will last 10-15 years. It has a vapor-permeable property, it stands out for its good degree of resistance to ultraviolet radiation. Mold and mildew will not form on the wall.

However, there are also disadvantages to the tool. One of them is a low elasticity index, which can lead to cracks on the surface. Does not fit any base, does not combine with organic elements. High temperatures can deform the layer.

It has a vapor-permeable property, it stands out for its good degree of resistance to ultraviolet radiation.

It has a vapor-permeable property, it stands out for its good degree of resistance to ultraviolet radiation.

Silicone paint

Silicone paint is based on silicone resins.They help to obtain a porous texture on the surface, unlike other types that create a film. This allows you to obtain a vapor-permeable effect, protecting against biological formations.

Despite the vapor permeability, a moisture resistant coating is created that can be washed if necessary. The surface does not attract dust, which is definitely a plus. Plaster coloring makes it possible to close existing defects up to 2 millimeters. It stands out for its high level of adhesion. However, the product price is high.

The surface does not attract dust, which is definitely a plus.

The surface does not attract dust, which is definitely a plus.

Alkyd and oil paints

These types create a durable and wear-resistant coating that is resistant to mechanical stress. They can be washed, the colors are bright, but the color palette is not large. They serve for a long time, can be used in rooms with high humidity. Get a glossy effect on the walls. However, they have an unpleasant odor when applied, material consumption is high, and it is easy to ignite.

These types create a durable and wear-resistant coating that is resistant to mechanical stress.

These types create a durable and wear-resistant coating that is resistant to mechanical stress.

Advantages and disadvantages of PVA compounds

The advantages of polyvinyl acetate paints include the following:

- applicability even to highly porous materials (some types of wood, plaster, cardboard);

- high drying speed;

- simple preparation of the composition and simple application to the surface;

- high explosion safety and fire safety;

- lack of unpleasant odors, since there are no solvents in the composition of PVA;

- non-toxicity of paint and varnish material;

- the existence of additives, despite the limited color palette, due to which it is possible to obtain a matte or glossy surface;

- competitive prices for products;

- an excellent option for painting drywall and other smooth surfaces (due to its high adhesive ability);

- the ability to use for re-painting after surface treatment with oil paints;

- water solubility;

- UV resistance;

- the ability to resist mold and mildew;

- elasticity of the formed coating.

The PVA composition also has a number of disadvantages:

- Minor color palette.

- The instability of PVA to low temperatures during painting, since, according to the recommendations of the manufacturers, the minimum air temperature should be 6 degrees above zero (the paint freezes at temperatures below zero).

- For interior finishing work, not any paint is suitable, but only containing acrylate and verstat components.

- There is a tendency for the cost of PVA paints to rise, as manufacturers often add all new components to the formulations.

- Painting with polyvinyl acetate water-based emulsion compositions is carried out only after preparation of the rough layer, since PVA gives high surface tension (objects need to be cleaned several times and then sanded).

- The paint and varnish material is unstable to high humidity, therefore it is rarely used for painting the external parts of buildings (the problem is partially solved by adding an acrylic component to the composition).

- PVA cannot be applied to chalky whitewash, alumina, alum and vitriol primers.

Choice of paint

The versatile composition of polyvinyl acetate paint, characterized by elasticity, practicality and durability, has found new life as a result of the use of acrylic as a bonding agent. Thanks to the acrylic base, the already excellent performance characteristics of the paint are significantly increased.

When choosing between local and imported manufacturers, the difference can only be in price, that is, foreign parties will cost an order of magnitude more.

It should also be remembered that European companies are trying to optimize their products for their climatic conditions, therefore, the characteristics declared by them may not be suitable for a specific region, especially with rather harsh or, conversely, tropical climatic conditions. Consequently, there is still a plus here for local manufacturers.

For facade work, it is recommended to give preference to moisture- and light-resistant compounds with an antistatic effect. For the interior, you can buy paint with an average value, unless, of course, we are talking about a bathroom or kitchen.

You need to know the exact consumption of the emulsion in order to purchase the required displacement. Consumption directly depends on the degree of hiding power of the slurry, which according to the modern DIN EN 13300 standard is expressed in classes.

Their numerical number indicates the number of layers required for a high-quality coating of the base. Density is also considered to be the determining factor in consumption - the denser the PVA-emulsion, the correspondingly more of it is needed to cover the surface.