Coating options

Chrome paint is made with different effects. Reflective compositions (white specular luster) resemble polished stainless steel, molten silver. Pigment dyes are not added to such a mixture, the base becomes transparent.

Reflective compositions (white specular luster) resemble polished stainless steel, molten silver.

Reflective compositions (white specular luster) resemble polished stainless steel, molten silver.

Yellowish, yellow-orange metallic shades are created through the use of ground copper alloys: brass, bronze. The effect is visible only after the base has dried. Coloring pigments are introduced into high-temperature coatings, achieving the required shade.

Yellowish, yellow-orange metallic shades are created through the use of ground copper alloys: brass, bronze.

Yellowish, yellow-orange metallic shades are created through the use of ground copper alloys: brass, bronze.

The matt paint creates a brushed metal effect that does not show minor scratches.

The matt paint creates a brushed metal effect that does not show minor scratches.

Classic version of painting with chrome

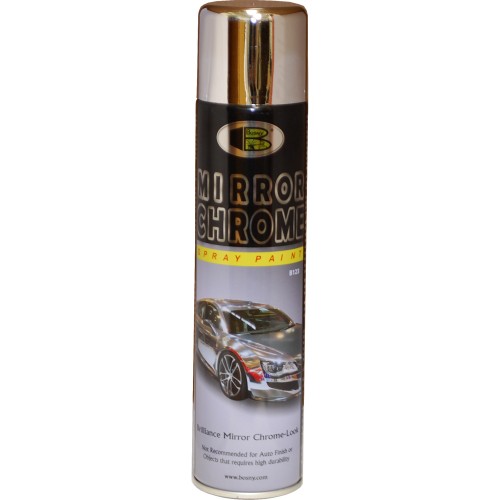

Mirror compositions are created for the restoration of chrome parts, they return them to their former shine and attractiveness. Spray cans are used to decorate photo frames, exotic bottles. Aerosols are produced with pigment dyes.

Powder can paint is used in auto repair shops to create a silver tint with a mirror finish. On a resinous or acrylic basis, finely dispersed aluminum powder is diluted, which, after the paint layer dries, refracts and reflects light rays.

Mirror compositions are created for the restoration of chrome parts, they return them to their former shine and attractiveness.

Mirror compositions are created for the restoration of chrome parts, they return them to their former shine and attractiveness.

Black chrome

There is a nitro paint in cans and cans, designed to paint objects black. This is an alternative to Kuzbasslak. The two-pack black chrome can paint produces a wear-resistant film. Nitro paint in spray cans has to be refurbished more often.

Aerosol black chrome dries the fastest.

Colored chrome plating

The introduction of a certain amount of pigment into the lacquer base does not affect the quality of the formed film, the gloss, the metallic effect is preserved. Manufacturers produce annual colored paints and varnishes and transparent, amenable to tinting. You can achieve the desired shade in car body repairs.

Pigments in liquid chromium should be translucent, refracting the light flux, and not absorbing light of a certain wavelength. There are dyes with a scattering effect, they are added to matte chrome used for household items, making souvenirs.

You can achieve the desired shade in car body repairs.

You can achieve the desired shade in car body repairs.

How to paint various surfaces and materials

There should be no dust in the painting room, it will stick to metal particles, mirroring cannot be achieved. Acrylic-based liquid formulations have their own peculiarity, the coatings fall on the primed surface.

The main stages of work:

- The surface is primed.

- A layer of background paint is applied, it will shine through the transparent chrome compounds.

- The substrate is polished after the background layer has dried.

- "Chrome" is sprayed from a can or applied from a spray gun.

- Before the next layer, the previous one must completely dry out.

For a top coat on glossy surfaces, varnish is recommended.

There should be no dust in the painting room, it will stick to metal particles, and mirroring cannot be achieved.

There should be no dust in the painting room, it will stick to metal particles, and mirroring cannot be achieved.

Features of surface preparation:

- The metal must be degreased using alcohol, other solvents, then the surface is washed, dried;

- Smooth plastic is treated with degreasing agents that do not destroy polymers, an ideally smooth surface after such processing becomes matte;

- The tree is pre-impregnated with a moisture-resistant stain, only then it is primed.

Subject to the rules for surface preparation, the paint will lie flat.

Subject to the rules for surface preparation, the paint will lie flat.

Subject to the rules for surface preparation, the paint will lie flat.

Advantages and disadvantages of sprays

Aerosol enamels are in great demand, because they have the following advantages:

- Do not require additional painting tools.

- Convenient and easy to use (even a beginner can handle the spray of a coloring spray).

- They give a beautiful even spray layer.

- Storage does not require special conditions. Even the remains of unused spray paint are protected from drying out and can be stored for a long time.

- Suitable for both decorative design and uniform coloring.

- They have a large palette of colors and allow you to simulate the structure of various materials (wood, metal).

- The bright color of the paint is not subject to fading and retains its novelty for a long time.

- Economical consumption. One can of paint is enough for a long time.

But like any product, plastic spray colorants have their drawbacks. These include:

- Lack of tinting options. But this drawback is conditional, because the color gamut of coloring sprays for plastic is very large, and you can easily choose the desired shade. If you need a complex color, then the tinters will create it, and refilling the spray can with paint - this service is available in most stores selling aerosol dyes.

- If the master is inexperienced, paint can form drips on smooth plastic. Beginners are advised to practice on an unnecessary piece of plastic that has a similar structure before dyeing a product.

- Wide spraying area. If you plan to paint only a small area, then it is necessary to cover the areas that cannot be painted with masking tape.

- The density of the enamel is not regulated, you have to work with the consistency of the solution that is filled into the can.

- The need to purchase a large number of cylinders at once when painting large areas.

- When working outdoors, you must wait for warm, calm weather.

Despite the small disadvantages of aerosol formulations, craftsmen very often use them to decorate plastic surfaces.

Characteristics of the chrome chameleon

Thermochromic paint deserves special attention, which changes its shade when exposed to temperature. Like other types of chrome paints, "chameleons" are heat-resistant.

Formulations are classified according to two criteria:

- By the type of color change, different tones are provided for heating and cooling, usually the room temperature is chosen as the zero point, dyes essentially act as a thermostat.

- Irreversibility or reversibility of thermal changes.

Reversible paint changes shades throughout the life of the surface layer. In irreversible compositions, structural changes occur when heated. Thermal paints "chameleon" are more expensive than the usual ones with the effect of chrome plating, they are more often used for making souvenirs - mugs with hot or cold drinks covered with such paint change color.

Reversible paint changes shades throughout the life of the surface layer.

Liquid chrome in spray cans

Most stores sell mirror effect paint in liquid form. This is the best option for those who want to quickly transform the look of individual parts at home: discs, headlights, inserts, as well as decor and interior items.

The base is acrylic resin. When using a quality product, you can get such a bright and strong reflection that it will seem like real chrome is used.If you purchase cans, then you do not need to mess around with diluting the mass.

Powdered product is inconvenient to use

Powdered product is inconvenient to use

The nuances of the selection of paint in spray cans

The first step is to know what type of plastic your parts are made of, since the further choice of the properties of the dye and the technology of its application depends on the material itself.

- ABS (Acrylonitrile Butadiene Styrene) - it is used to manufacture housings of household and computer equipment, mobile phones and much more.

- PVC (Polyvinylchloride) - window constructions, floor coverings, children's toys and goods, some types of household containers.

These two types of plastics differ in that when they are painted, a primer is a prerequisite. Its presence gives high-quality adhesion of paint to the surface, which excludes subsequent peeling and cracks. If you don't know what kind of plastic you are holding, there is a simple method to check.

Fill a container with water that will fit your plastic part (excluding large items). Dip the item into the water. If the plastic sinks, then no primer is required. You can apply paint directly to the surface. If your part remains welded, you will need to purchase a primer spray. Without it, the paint will not last long.

The history of the appearance of chrome plating

Mirror emulsion, which is applied in compliance with a whole set of rules and conditions, creates a specific coating that completely imitates perfectly polished metal. This effect is created due to the fact that the composition of special paints includes the smallest particles of the metal itself, as well as a unique varnish. It is thanks to this composition that a thin layer is formed when it is applied, which forms a very smooth and shiny surface on almost any object. The range of application of this novelty is increasing every year, and the popularity of this invention is only increasing.

Chrome products have always attracted attention with their brilliance. Chrome plating technology developed rapidly in the middle of the twentieth century.

This type of coating is very widespread in plumbing. With proper care, this type of object always pleases the eye with its brilliance and irresistibility.

At one time, chrome plating was used extremely widely in the automotive industry. This was especially the case for North American automakers in the 50-60s of the last century.

If you look at the cars of those years, you will notice that they literally shone with an abundance of chrome. Bumpers, moldings, side-view mirrors, many overlays - all chrome plated

Looked great aesthetically, while providing a reasonably good anti-corrosion coating.

However, the achievement of such an effect was possible only when manufactured in the factory and with strict adherence to technology. Departure from the technological process threatened with the fact that the chrome peeled off from the metal. There was one more drawback at that time - chrome plating could only be applied to metal surfaces.

However, the achievement of such an effect was possible only when manufactured in the factory and with strict adherence to technology. Departure from the technological process threatened with the fact that the chrome peeled off from the metal. There was one more drawback at that time - chrome plating could only be applied to metal surfaces.

Progress does not stand still. Today it is possible to chrome plating on various surfaces. However, real chrome plating is still the lot of manufacturing enterprises. This is due to the fact that the deposition of metallic chromium is an electrical process.

An alternative to the technology of applying metallic chrome gives the paint chrome effect. Two options are possible here. This is the use of formulations using a traditional spray gun and liquid in cans. The first option can be subdivided into simple painting and heat treatment.

Review of popular manufacturers

Chrome paint has gained quite a lot of popularity. And this popularity is growing every day. Therefore, we will focus on the most popular spray cans:

- RUSH Power, a fairly inexpensive paint with a price of no more than three hundred rubles. It has a good spray and can give the desired effect from just one layer of paint. However, this type of paint is not suitable for use in a car, this spray is more suitable for graffiti.

- Bosny CHROME is also a budget option that can be used to paint small metal parts. For a more lasting effect, the use of a varnish is recommended.

- Chrome Effect is by far the most popular paint among car enthusiasts. Not the cheapest option. However, this manufacturer gives the most dignified appearance of the final product, which is most similar to a real chrome finish.

A wide range of currently existing types of chrome paint, as well as a huge range of colors allow even an ordinary person to apply chrome paint without special training.

Useful tricks

In order for the painting to be of high quality, professional masters recommend:

- Purchase cylinders with replaceable tips that make it possible to adjust the width of the jet of the dye.

- Apply a new layer only after the previous one is dry.

- If the product is to be used frequently, it is recommended to apply more layers.

Adherence to these little tricks and strict adherence to all the painting steps will guarantee an excellent result.

It is very convenient to use aerosols for painting plastic products. If you choose the type of coloring matter in accordance with the purpose of the thing and the type of plastic, then the decorated object will delight you with its beautiful appearance for a long time.

Recommendations for the use of paints

Each type of emulsion provides for a certain range of directions where it is recommended to use them. So it is with chrome dyes. There are a number of recommendations for using this type of emulsion:

- The best effect is given by formulations of well-known world manufacturers. Better to ditch cheap options from unknown brands;

- Applying the composition requires certain skills. Before painting the product, it is necessary to conduct training;

- Training is also necessary to prevent smudges, this greatly reduces the visual appeal of the final look;

- It is not recommended to use this type of colorant on flexible plastic;

- If further coating of the painted product with varnish is assumed, then you must first select the appropriate varnish. Otherwise, the paint coating may be damaged, which will lead to the need to repeat the painting process.

Compliance with these recommendations will reduce the time to work, as well as save money.

How to paint a chrome part black

All existing chrome paint for cars is sold in two variations:

- funds in the bank;

- nitro paint pumped into a spray can.

It may seem that different packages contain the same material, respectively, the method of application should not differ significantly, but there is a difference. To get the desired result, first of all, you need to choose the right product.

The price for one can is always higher than for the same product in the bank

The price for one can is always higher than for the same product in the bank

The material from the can is more difficult to apply, but the aesthetic similarity with real chrome coatings is much higher. This method of application is used by professionals.

The material from the can is more difficult to apply, but the aesthetic similarity with real chrome coatings is much higher. This method of application is used by professionals.

To get a satisfactory result when working with a cylinder, you must study the instructions. When painting, make slow movements, evenly applying the composition to the surface

It is important that no joints form in one place, so you need to process the entire part as a whole, without waiting for one part to dry

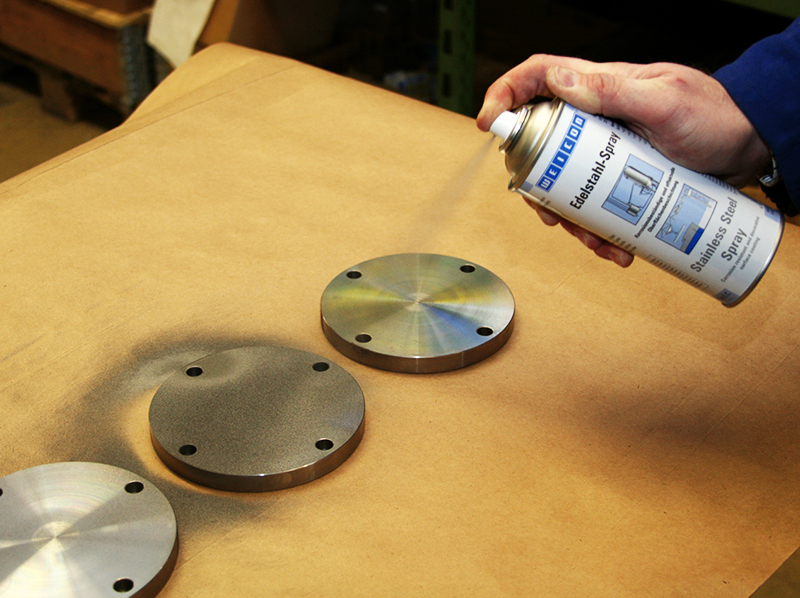

Spray paint for metal

When applying a black chrome coating, you need to remember one problem - the product dries up almost instantly.A situation is possible when, when spraying, paint hits the base, but does not have time to adhere to plastic or metal. In this case, after drying, the paint layer can be easily removed with a fingernail.

To prevent this from happening, it is necessary to study the application technology and act strictly according to the points:

- Prepare the surface for work, apply a base coat of primer.

- Cover the base with a special polymerization varnish, then let it dry for 2-3 days.

- Additionally, the surface should be polished.

- A chrome coating is applied to the resulting gloss. You need to act carefully and slowly, bring the can at a distance of no more than 10 cm, so that the coating has time to "catch" before it dries.

After the first layer has dried, it is recommended to apply another one, which will play a protective function.

Before starting painting, the metal surface is processed

Before starting painting, the metal surface is processed

The coating can be not only shiny, but also matte and black

The coating can be not only shiny, but also matte and black

Painting chrome parts

In order for the black chrome paint to lay evenly, it is necessary to choose the appropriate tools for its application. For work, you will need sandpaper, acetone or a special degreaser, transparent varnish and chrome powder paint.

It is not worth saving on the soil for processing parts, it is better to purchase a product in a spray can

It is not worth saving on the soil for processing parts, it is better to purchase a product in a spray can

Staining is carried out in several stages:

- using a special tool, the chrome part is removed from the car;

- the surface is rubbed with sandpaper until matt appears;

- a primer is applied. It is recommended to dry the part for 2-3 days;

- splashing paint.

The most important task is to clean the part well before applying paint. Before you paint the chrome, you need to make sure that there are no traces or old layers left.

Chrome paint in spray cans: pros and cons

In order for the surface of the car to acquire the desired color, it is necessary not only to choose the right coating, but also to take into account all the advantages and disadvantages of this method of changing the look of the iron horse.

Pros of chrome paint:

- guaranteed result: silver color and mirror shine;

- lays on all types of surfaces: plastic, wood, iron;

- fast drying;

- paint in cylinders can be used by anyone.

Minuses:

- complex application process, the paint, after drying, can easily come off the surface;

- the best option is powder paint, but it is suitable for application in special conditions.

In order not to be mistaken, you should set aside a few days to transform the large part, and gradually clean one side, immediately applying the coating.

Small parts will take no more than

Small parts will take no more than

Stages of work

When enamel is sprayed from a cylinder, a suspension of tiny paint particles is formed in the air, which can get on the skin and into the respiratory tract

Therefore, it is important to put on glasses, work gloves and a respirator (if possible) before starting work.

Surface preparation process

Before proceeding directly to staining, the plastic must be prepared in a certain way.

- First, the product must be cleaned with a stiff brush and detergent, then rinsed with water and allowed to dry completely.

- After that, the product is sanded with a "sandpaper", smoothing out all the irregularities. If the defects are too deep, you can use a special plastic primer and level the surface.

- Then the plastic must be treated with a degreaser, and then you can proceed with the primer, if it is necessary for this type of material.

- If there are doubts about the type of material, then it is better to put a primer in any case. It will not be superfluous, but it will provide a more reliable adhesion of the paint and the surface of the plastic.

For information on how to properly prepare plastic for painting, see the next video.

Painting

Spray painting takes place in several stages:

- First, it is necessary to cover all areas not intended for painting with cardboard, film or an unnecessary piece of cloth. Very small areas can be sealed with tape (use masking tape, as ordinary tape can damage the old coating when it is removed). If the product is small, it is advisable to lay it horizontally on some surface over which paint will be sprayed.

- Shake the can of paint for 30-40 seconds to mix the dye evenly.

- Remove the spray cap from the top of the can. Apply paint to the plastic with constant smooth movements, without holding your hand in one place to avoid drips.

- The hand with the spray must be kept at a distance of at least, but not more than 20-30 cm from the surface to be painted.

- After applying the first layer, let the paint dry for 30-40 minutes. Then you can apply a second layer and let it dry in the same way. If necessary, it is permissible to apply additional layers according to the same algorithm.

- Despite the fact that the paint itself dries quickly enough, it is not recommended to use the painted product for one day. During this time, the dyes are finally polymerized, so the surface will be reliably protected from various damages.

Getting a mirror finish

To achieve the effect of a metal polished to a shine of silver or gold color, the plastic is covered with a special paint, and the process itself is called chrome plating.

The price for this service is quite high, so working independently with such a dye is a great opportunity to save money.

In general, the process of working with chrome paint is carried out in the same way as with any mixture for plastic in a cylinder, only a spray is applied to the surface already pre-painted with black paint. Without preparatory staining in black, creating a mirror effect at home simply will not work.

There are several more subtleties of staining for chrome:

- It is better not to pursue cheapness and purchase proven formulations from foreign manufacturers.

- It is more difficult to apply such an aerosol than regular paint, so it is worth pre-practicing on various surfaces and areas.

- If the product will be varnished, it is necessary to first check the compatibility of the purchased paint and varnish. Some types of varnish mixtures can destroy even a correctly applied chromium layer.

It is necessary to be prepared for the fact that paint from a balloon and chrome plating with your own hands does not always give the effect of salon coloring, but the prospects for development in this direction are quite high.

Possible problems

Some difficulties arise when working with compositions containing metal powder. The film turns out to be uneven, the color has to be repeated. Typical situations:

- Too thick coating layer, after drying, "orange peel" forms, porosity, smudges;

- Poor penetration of the powder and base into the structure of the painted surface is associated with poor preparation of the parts;

- The reflector will be damaged if it is coated with thermal paint, which becomes matte.

When choosing spray cans, you should carefully read the manufacturer's recommendations, adhere to the paint application technology.

Poor penetration of the powder and base into the structure of the painted surface is associated with poor preparation of the parts.

Poor penetration of the powder and base into the structure of the painted surface is associated with poor preparation of the parts.

For painting decorative elements with chrome, a lot of compositions with amazing shades and properties are produced. When restoring details, it is better to give preference to professional canned paints. The glossy shine of chrome-plated parts can be restored flawlessly.

Preparation for painting

For beginners, the process of working with an aerosol spray may seem complicated, but strict adherence to all the steps will help to achieve success. Before you start painting, you need to prepare the surface of the product.To do this, do the following:

- Cleaning the product. For the final result to please with beauty and durability, it is necessary to thoroughly rinse the surface with water with the addition of detergent, deep dirt can be washed off with a stiff brush. Do not be afraid to scratch the surface of the plastic: further grinding and applying enamel will make the surface even. But if the dirt is not completely removed, then the paint will lie unevenly and soon begin to bubble or crack. After the item has been washed, it must be rinsed with clean water to remove the remaining detergent and dry well.

- Grinding. All small irregularities are smoothed out with a fine-grained "skin". If the product has large cracks or dents, it is recommended to smooth them out using a plastic putty before sanding.

- Degreasing. Various grease stains impair the adhesion of the enamel to the base, therefore, they must be removed using degreasing agents. It is not necessary to rinse off alcohol-containing degreasers, but other solvents must be removed by rinsing the product with clean water and dried.

- Padding. This step is not required for all types of plastic. How to determine the need for priming? Put the plastic item in a large container of water: if it drowned, then the process of applying the primer can be skipped. In the event that there are doubts about the need for a primer, it is better to apply the primer. Additional priming will promote stronger adhesion of the enamel to the base.

After the primer has dried, you can start applying paint.

Pros and cons of aerosol enamel

Spray paints are easy to use. You don't need special skills, training or additional expensive equipment. It is enough to adhere to the simple recommendations from the manufacturer.

The advantages of enamel also include:

- Smooth smooth surface. Modern spray heads are made in such a way as to simulate the torch of a paint spray gun. This allows you to achieve a uniform spray of enamel, due to which an even, smooth surface layer is obtained.

- Drying speed. Spray paint dries very quickly, which is an undoubted convenience, since you do not have to spend a lot of time on work and speed up drying with additional methods.

- Economical consumption. Balloon enamel is consumed slowly and one cartridge is enough for a large surface.

- Convenience of storage. There is no need to create special conditions for storing unused leftovers, pouring and carefully closing, as is the case with cans. The enamel in the cylinder is stored for a very long time and reliably.

- Large palette of colors and textures. This allows you to achieve great artistic expression and imitate many surfaces, for example, metal.

However, the spray surface is small. It is impossible to mix paints to obtain the desired shade. As a rule, there is a certain set of colors on sale, so it is not always possible to accurately match the tone of the wallpaper or window details.

Cons of spray paint:

- If the aerosol is brought too close to the surface to be painted, smudges may form on smooth plastic. To work with spray cans requires the acquisition of skills and dexterity.

- Large spray area. Elements for painting will have to either be dismantled or protected from splashes using film and special paper tape adjacent surfaces.

- Limited ink density. You will not be able to adjust the hiding power or transparency of the paint; you will have to work with the enamel thickness specified by the manufacturer.

- Temperature conditions of work. Painting of external elements must be carried out in warm, calm, sunny weather. In case of wind or precipitation, the result is unpredictable.

- Some paints may contain acetone and acetone derivatives. Be sure to study the composition and consult the seller on this issue. Acetone enamels can seriously damage plastic.

Photo of the best spray paint in spray cans

We also recommend viewing:

- Which parquet varnish is better to choose

- Which solvent is better to choose

- Quick-drying, odorless paint for interior use

- Best water based paint

- How to choose a facade paint for outdoor use

- Which oil paint is best

- Best interior wall paint

- What paint for wallpaper for painting is better

- DIY paint tinting

- How to choose an epoxy paint

- How to choose the best wood wax

- Best Heat Resistant Varnish

- Which decorative paint is best

- The best enamel paints

- Which drying oil is better to choose

- Best Waterproof Bathroom Paint

- How and how to remove or remove old paint

- How to choose an impregnation for wood

- Instructions on how to paint the walls with your own hands

- Which varnish for wood is better to choose

- How to choose a bituminous varnish

- How to calculate paint consumption per 1 m2

- What is alkyd paint and how to use it

- Types of liquid glass

- Water-based dispersion paint

- Best Fire Retardant Paint

- How to choose a color for paint

- Fire retardant composition for wood

- Powder painting at home

- Glue-based paint

- Best wall paint

- Painting tools and accessories

- How to choose the best paint roller

- Tips for choosing floor paint

- What is the advantage of Tikkurila paint

- The best textured wall paints with effects

- Types and applications of spray paint

- How to choose white paint

- The best varnishes for metal

- Step by step instructions on how to paint the ceiling

- TOP of the best yacht varnishes

- Best acrylic primer

- Types of the best paints for metal

- The best paint for wood

- How to choose the best ceiling paint

- Varieties of wood stains

- Review of the best rust converters

- What is the best wood preservative

- How to choose a paintbrush

- The best water-based paint for walls and ceilings

Types of colorful aerosols

Paint and varnish cans are not the same, they are of several types. There are only three main groups of paints: alkyd, acrylic, nitro enamels. It is advisable to choose the type based on the task.

Spray acrylic paint is used for interior and exterior decoration of various structures. They are highly demanded. The following advantages of this type can be distinguished:

- Dry quickly;

- High degree of adhesion;

- Variety of colors;

- Ease of use;

- The coating lasts a long time, withstand exposure to ultraviolet radiation;

- Low level of toxicity.

Spray acrylic paint is used for interior and exterior decoration of various structures.

Alkyd paints help to achieve similar characteristics to acrylic-based paints. However, their constituents are more toxic, which requires compliance with safety measures. In addition, the service life is shorter, the degree of adhesion is less. However, they also cost less, which makes them popular as well.

Their constituent elements are more toxic, which requires compliance with safety measures.

Nitro enamels are distinguished by a high level of toxicity, therefore they are chosen less often. Their price is lower, and if used correctly, the coating will serve for a long time, it dries quickly.

When used correctly, the coating will serve for a long time, dries quickly.

Aerosol enamels for metal

They can be used for work inside and outside the building. Eco-enamels have a vanilla aroma. Can be used to coat steel and cast iron metals. Regular enamel serves to change the color, there are enamels that can be applied together with the primer mixture. They also produce products with an anti-corrosion effect.

Can be used to coat steel and cast iron metals.

Construction and heat-resistant enamels

They produce special enamels in cans that can withstand high-temperature exposure. They can safely paint stoves, radiators, fireplaces. In construction, they are used to cover concrete substrates, indoor walls, and ceramic surfaces. For surfaces that are constantly exposed to moisture (swimming pools, saunas).

They produce special enamels in cans that can withstand high-temperature exposure.

Compositions for painting plastic and wood

To correct defects that appear on a plastic surface, it is often aerosol paints that are chosen.

They are distinguished by a high level of adhesion, which is important when working with plastics. May have additional properties in the form of resistance to abrasive substances, a structural effect that allows the plastic coating to be leveled

Most often chosen to update the appearance of old items. It is important for the tree to create additional protection against moisture.

Spray paints are often chosen to correct defects on plastic surfaces.

Decorative compositions

Manufacturers have come up with a separate type of coating, denoted by the abbreviation RAL. They are designed to cover glass objects with ease. Work in a domestic environment and apply stencils to various materials. The water-based composition is safe and can be used for dyeing textiles.

They are designed to cover glass objects with ease.